8Warner Electric • 800-234-3369 P-239-24-WE

DÉCLARATION DE CONFORMITÉ

Nous: WARNER ELECTRIC

449 Gardner Street

South Beloit, IL 61080

déclarons sous notre seule responsabilité que les produits de la famille

CBC 500-90 &CBC 500-24

CBC 550-90 & CBC 550-24

sont uniquement destinés à l’intégration dans une machine. La mise en serv-

ice de ces produits est subséquente à l’homologation de l’ensemble de

l’équipmement, conformément à la directive 89/392/CEE.

La conformité des produits spécifiés ci-dessus avec les exigences de la direc-

tive 72/23/CEE est supportée par le respect des normes EN 61010-1.

Si les instructions de montage et de câblage du manuel sont respectées, ce

produit est conforme aux normes EN50081-1 et EN50082-1 directive

89/336/CEE relative à la CEM.

South Beloit, IL 61080

VP and General Manager: S. O.

Afin d’éviter des blessures,

s’assurer que toute puissance

soit coupée avant installation ou intervention sur ces

équipements.

NE PAS TOUCHER LE CIRCUIT ÉLECTRONIQUE, SI LA PUISSANCE

EST APPLIQUÉE.

INSTRUCTIONS D’INSTALLATION

ET DE CABLAGE

relatives à la CEM, directive 89/336/CEE

DES CONTROLES POUR EMBRAYAGES ET FREINS

1. L’ appareil doit être monté dans une armoire métallique close.

2. Liasion de puissance entre contrôle et embrayage/frein par cãble blindé.

3. Raccordements de consigne, entrées et sorties par cãbles blindés.

4. Les blindages sont reliés à la terre aux deux extrémités du cãble.

5. Les cãbles de commande et les cãbles de puissance ne seront pas placés

dans le mëme caniveau.

DECLARACION DE CONFORMIDAD

Nosotros: WARNER ELECTRIC

449 Gardner Street

South Beloit, IL 61080

declaramos bajo nuestra propia responsabilidad que los productos de la famil-

ia

CBC 500-90 &CBC 500-24

CBC 550-90 & CBC 550-24

son diseñados exclusivamente para incorporarse en otra maquina. El fun-

cionamiento de este producto esta sujeto al cumplimiento de todo el equipo

usado en la maquina, con los lineamientos de la norma 89/392/EEC.

El cumplimiento de los lineamientos de la norma 72/23/EEC con los productos

mencionados anteriormente, se basa y respeta los estandares EN 61010-1.

Si las instrucciones de montaje e instalación electrica del instructivo son

respetadas, este producto cumplirá con los estandares EN50081-1 y

EN50082-1 que se relacionan con la norma 89/336/EEC.

South Beloit, IL 61080

VP and General Manager: S. O.

Para evitar cualquier daño

personal, antes de intentar

instalar o reparar este control, siempre asegurese que

todas las fuentes de poder esten apagadas.

NO TOQUE EL CIRCUITO ELECTRICO SI LA FUENTE DE PODER

ESTA ENCEDIDA.

INSTRUCCIONES DE MONTAJE Y

CONEXIONES ELECTRICAS

en relación a la norma de EMC 89/336/EEC

PARA CONTROLES DE CLUTCHES Y FRENOS

1. El control debe de instalarse adentro de una caja metalica.

2. Las conexiones electricas entre el control y el cluch/freno DEBEN hacerse

con cable blindado.

3. Las conexiones de bajo voltaje en el control deben utilizar cables blinda-

dos.

4. El blindaje de los cables debe de aterrizarse en ambos lados.

5. Las conexiones entre la fuente de poder, y las conexiones de bajo voltaje

deben de hacerse en diferentes cables.

KONFORMITÄTSERKLÄRUNG

Wir: WARNER ELECTRIC

449 Gardner Street

South Beloit, IL 61080

erkälren in alleiniger Verantwortung, daß die Prdukte der Familie

CBC 500-90 &CBC 500-24

CBC 550-90 & CBC 550-24

ausschließlich zum Einbau in eine andere Maschine bestimmt sind. Die

Inbetriebnahme ist solange untersagt, bis die Konformität des Endproduktes

mit der Richtlinie 89/392/EWG gegeben ist.

Die Übereinstimmung des bezeichneten Produktes mit den Vorschriften der

Richtlinie 72/23/EWG wird nachgewiesen durch die Einhaltung der Normen EN

61010-1.

Sofern die Montage-Anweisungen der Bedienungsanleitung eingehalten wur-

den, ist dieses Podukt knoform zu EN50081-1 und EN50082-1 und die EMV

somit gewährleistet - Richtlinie 89/3366/EWG.

South Beloit, IL 61080

VP and General Manager: S. O.

Vor Einbau oder Wartung des

Gerätes unbedingt die

Stromversorgung unterbrechen um Verletzungen zu ver-

meiden.

KARTE BEI EINGESCHALTETER STROMVERSORGUNG NICHT

BERÜHREN.

MONTAGE UND KABELVERBINDUNGEN

ANWEISUNGEN

bezogen zu den EMW Richtlinic 89/336/EWG

FÜR STEURGERÃTE KUPPLUNGEN UND BREMSEN

1. Das Gerãt muß in einem gesclossenen metallschrank eingebaut werden.

2. Leistungsverbindungen Steuergerãte/Kupplungen - Bremsen mit

abgeschim Kabel durchfubren.

3. Steuerdeitungen, Ein-und Ausgãnge mittels abgeschimten Kabeln durch-

führen.

4. Abschirmung an beiden Enden des Kabels erden.

5. Leistungs-und Steuerverbindungen in separate Kabelkanãle durchziehen.

DECLARATION OF CONFORMITY

WE: WARNER ELECTRIC

449 Gardner Street

South Beloit, IL 61080

declare under our sole responsibility that the products of the family

CBC 500-90 &CBC 500-24

CBC 550-90 & CBC 550-24

are exclusively designed for incorporation in another machine. The operation of

the product is submitted to the conformity of the complete equipment, follow-

ing the provisions of the directive 89/392/EEC.

The conformity of the above specified products with the provisions of the

Directive 72/23/EEC is supported by the full respect of the standards EN

61010-1.

If the mounting and connecting instructions of the installation’s manual have

been respected, this product will be conform to the standards EN50081-1 and

EN50082-1 relating to the EMC directive 89/336/EEC.

South Beloit, IL 61080

VP and General Manager: S. O.

To avoid injury, always make certain all

power is off before attempting to install

or repair this control.

DO NOT TOUCH THE BOARD IF POWER IS APPLIED.

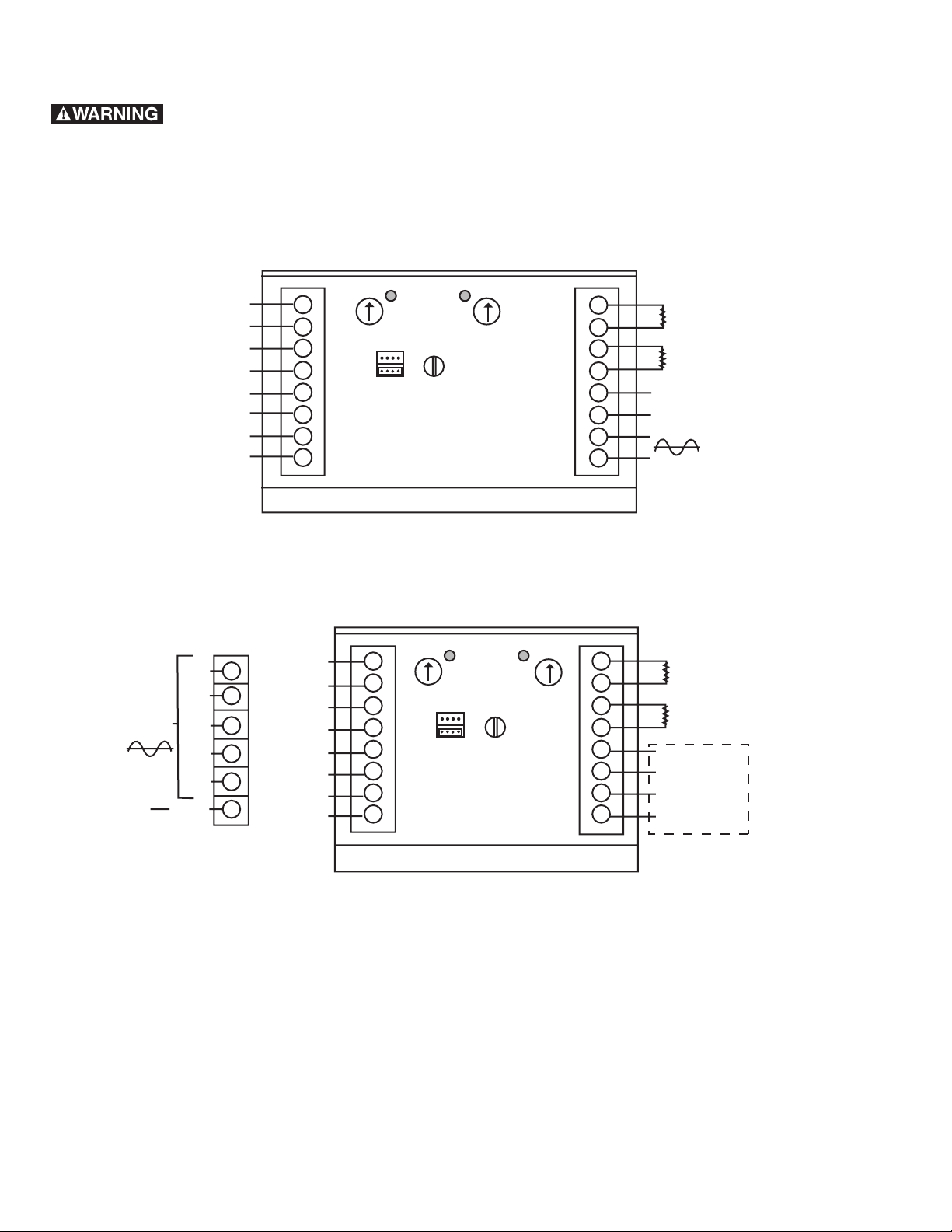

Mounting and Connecting Instructions

related to the EMC-directive 89/336/EEC

For Clutch and Brake Control

1. The control must be mounted in a closed metal cabinet.

2. The power connection between control and clutch/brake must be MADE

using shield cable.

3. The control connection must utilize shielded cables.

4. The shield of the cables must be grounded at both ends.

5. Power connections and control connection must be placed in separate

canals.

WARUNG:

ADVERTENCIA:

ADVERTISSEMENT: