Page 3For technical questions, please call 1-888-866-5797.Item 56434

SAFETYOPERATIONMAINTENANCE SETUP

5. Children, pregnant or potentially pregnant

women, and nursing mothers should not

be present in the work area until the work

is done and all clean up is complete.

6. Wear a dust respirator mask or a dual filter

(dust and fume) respirator mask which has been

approved by the Occupational Safety and Health

Administration (OSHA), the National Institute

of Safety and Health (NIOSH), or the United

States Bureau of Mines. These masks and

replaceable filters are readily available at major

hardware stores. Make sure the mask fits. Beards

and facial hair may keep masks from sealing

properly. Change filters often. DISPOSABLE

PAPER MASKS ARE NOT ADEQUATE.

7. Use caution when operating the Heat Gun.

Keep the Heat Gun moving as excessive

heat will generate fumes which can

be inhaled by the operator.

8. Keep food and drink out of the work area.

Wash hands, arms and face and

rinse mouth before eating or drinking.

Do not smoke or chew tobacco in the work area.

9. Clean up all removed paint and

dust by wet mopping the floors.

Use a wet cloth to clean all walls, sills and any

other surface where paint or dust is clinging.

DO NOT SWEEP, DRY DUST OR VACUUM.

Use a high phosphate detergent or trisodium

phosphate (TSP) to wash and mop areas.

10. At the end of each work session put the paint

chips and debris in a double plastic bag, close it

with tape or twist ties and dispose of properly.

11. Remove protective clothing and work shoes in

the work area to avoid carrying dust into the rest

of the dwelling. Wash work clothes separately.

Wipe shoes off with a wet rag that is then

washed with the work clothes. Wash hair

and body thoroughly with soap and water.

12. Hidden areas behind walls, ceilings, floors, soffit

boards, and other panels may contain flammable

materials that could be ignited by the heat gun

when working in these locations. The ignition

of these materials may not be readily apparent

and could result in property damage and injury

to persons. When working in these locations,

keep the heat gun moving in a back-and-forth

motion. Lingering or pausing in one spot could

ignite the panel or the material behind it.

13. CAUTION – To reduce the risk of

electric shock, keep extension cord

connection dry and off the ground.

14. When working with plastics, varnish, or

similar materials, gases develop that are

easily flammable and can lead to explosions.

Be prepared for flames to develop and keep

suitable fire extinguishing means at hand.

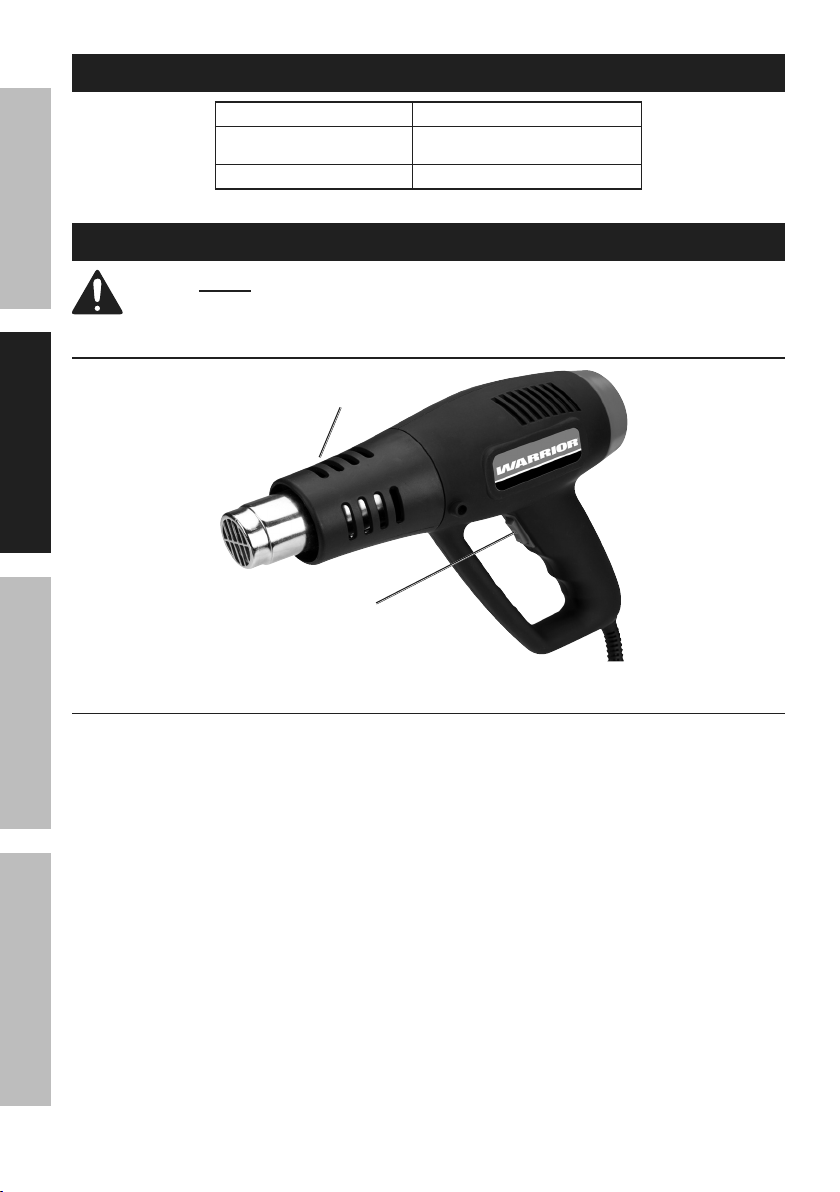

15. The Nozzle becomes very hot. Do not lay the

Heat Gun on flammable surfaces when operating

the Gun or immediately after turning the Gun off.

Always set the Heat Gun on a flat, level surface

so that the Nozzle tip is directed upwards

and away from the supporting surface.

16. Do not use the Heat Gun near flammable materials.

17. Do not point the Heat Gun at people or

animals. The intense heat can injure them.

18. Do not touch the tube of the heating

element or the Nozzle when they are hot.

They will be hot enough to cause burns

during use and for some time afterwards.

19. Do not use the Heat Gun on glass.

20. Do not use the Heat Gun as a hair dryer.

21. Do not heat up materials that can be

damaged by high temperatures.

Personal safety

1. Only use safety equipment that has been approved

by an appropriate standards agency. Unapproved

safety equipment may not provide adequate

protection. Eye protection must be ANSI-approved

and breathing protection must be NIOSH-approved

for the specific hazards in the work area.

2. Avoid unintentional starting.

Prepare to begin work before turning on the tool.

3. Do not leave the tool unattended when it is plugged

into an electrical outlet. Turn off the tool, and

unplug it from its electrical outlet before leaving.

4. This product is not a toy.

Keep it out of reach of children.

5. People with pacemakers should consult their

physician(s) before use. Electromagnetic fields in

close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure.

In addition, people with pacemakers should:

• Avoid operating alone.

• Do not use with Power Switch locked on.

• Properly maintain and inspect to avoid

electrical shock.

• Properly ground power cord.

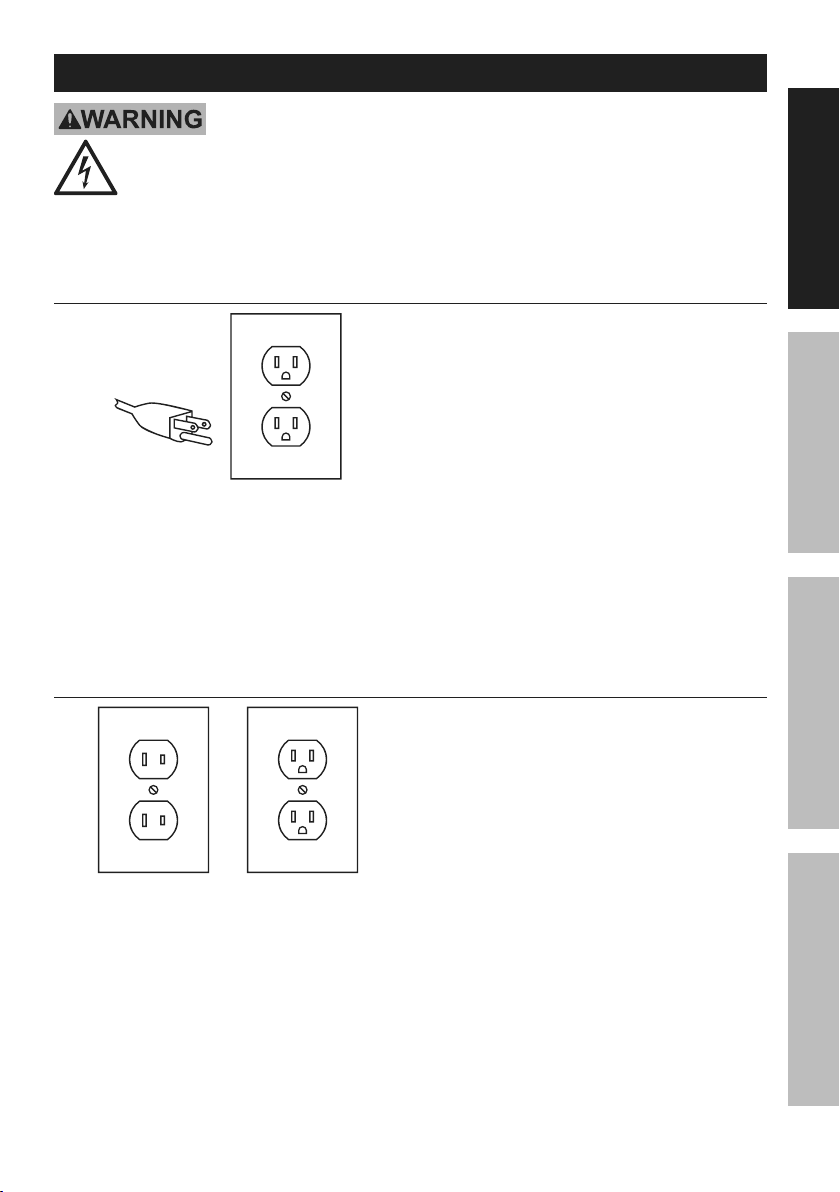

Ground Fault Circuit Interrupter (GFCI)

should also be implemented – it prevents

sustained electrical shock.