© WASP S.r.l.

3

Summary

0 Premises ............................................................................ 5

0.1. How the read the manual of instructions...................... 6

0.2. Storage of the manual of instructions ........................... 6

0.3. Updating the manual of instructions .............................. 6

1 General information ...................................................... 7

1.1. Manufacturer identification data...................................... 7

1.2. Indentification label................................................................ 7

1.2.1. Position of the label on the machine..................................8

1.3. Testing.......................................................................................... 9

1.4. Warranty...................................................................................... 9

1.5. General safety warnings.................................................... 10

1.5.1. Personal protective equipment........................................11

1.5.2. Operators for whom the manual is intended ..............11

1.5.3. Residual risks ............................................................................11

1.5.4. Safety stickers..........................................................................12

1.6. Glossary and pictograms.................................................. 13

1.6.1. Identification of operating personnel ............................13

1.6.2. Editorial pictograms............................................................... 14

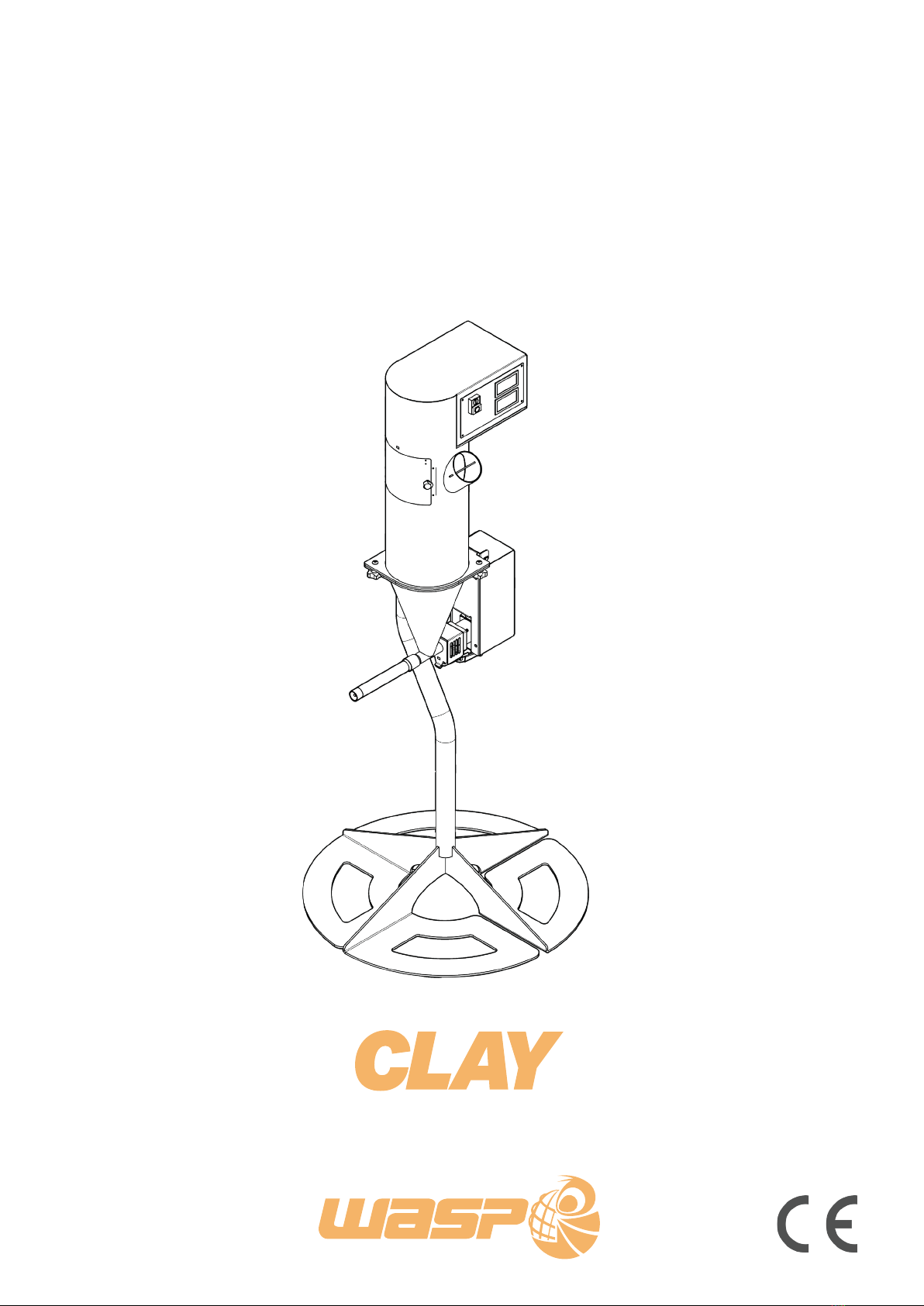

2 Description of the continuous feeding ................15

2.1. Main view.................................................................................. 16

2.2. Rear view .................................................................................. 17

2.3. Technical data........................................................................ 18

2.4. Noisiness.................................................................................. 19

2.5. Intended use of the continuous feeding.................... 19

2.6. Improper use of the feeder.............................................. 19

3 Transport and handling ..............................................20

3.1. General warnings.................................................................. 20

3.1.1. Delivery of the machine........................................................20

3.2. Unpackaging........................................................................... 21

3.3. Content ..................................................................................... 22

3.4. Lifting and handling of the printer................................. 22

4 Installation.......................................................................22

4.1. General warnings.................................................................. 22

4.1.1. Placement...................................................................................22

4.2. Electrical connection.......................................................... 23

5 Preparing to use the continuous feeding ...........24

5.1. General warnings.................................................................. 24

5.2. User interface......................................................................... 25

5.2.1. Main board..................................................................................25

6 First use of the machine .............................................27

6.1. General warnings.................................................................. 27

6.2. Joints and alignments checks........................................ 28

6.3.

Connecting the Continuous Feeding to the 3D printer

... 30

6.4. Loading of material.............................................................. 32

6.5. First extrusion ........................................................................ 34

6.6. Synchronized use with 3D printer................................. 36

7 Ordinary and extraordinary maintenance .........37

7.1. General warnings.................................................................. 37

7.2. Cleaning.................................................................................... 38

7.2.1. Machine cleaning..................................................................... 38

7.2.2. Extruder and 3D printer cleaning..................................... 43

7.3. Ordinary maintenance........................................................ 44

7.3.1. Extrusion screw .............................................................................45

7.3.2. Mixer ......................................................................................................45

7.3.3. Fan filter ...............................................................................................45

7.3.4. Mixer bearing...................................................................................45

7.3.5. Mixer shaft .........................................................................................45

7.3.6. Support bearing.............................................................................45

8 Additional Informations .............................................47

8.1. General warnings.................................................................. 47

8.2. Decommissioning and dismantling.............................. 47

8.3. Instructions for emergency situations ....................... 48