8

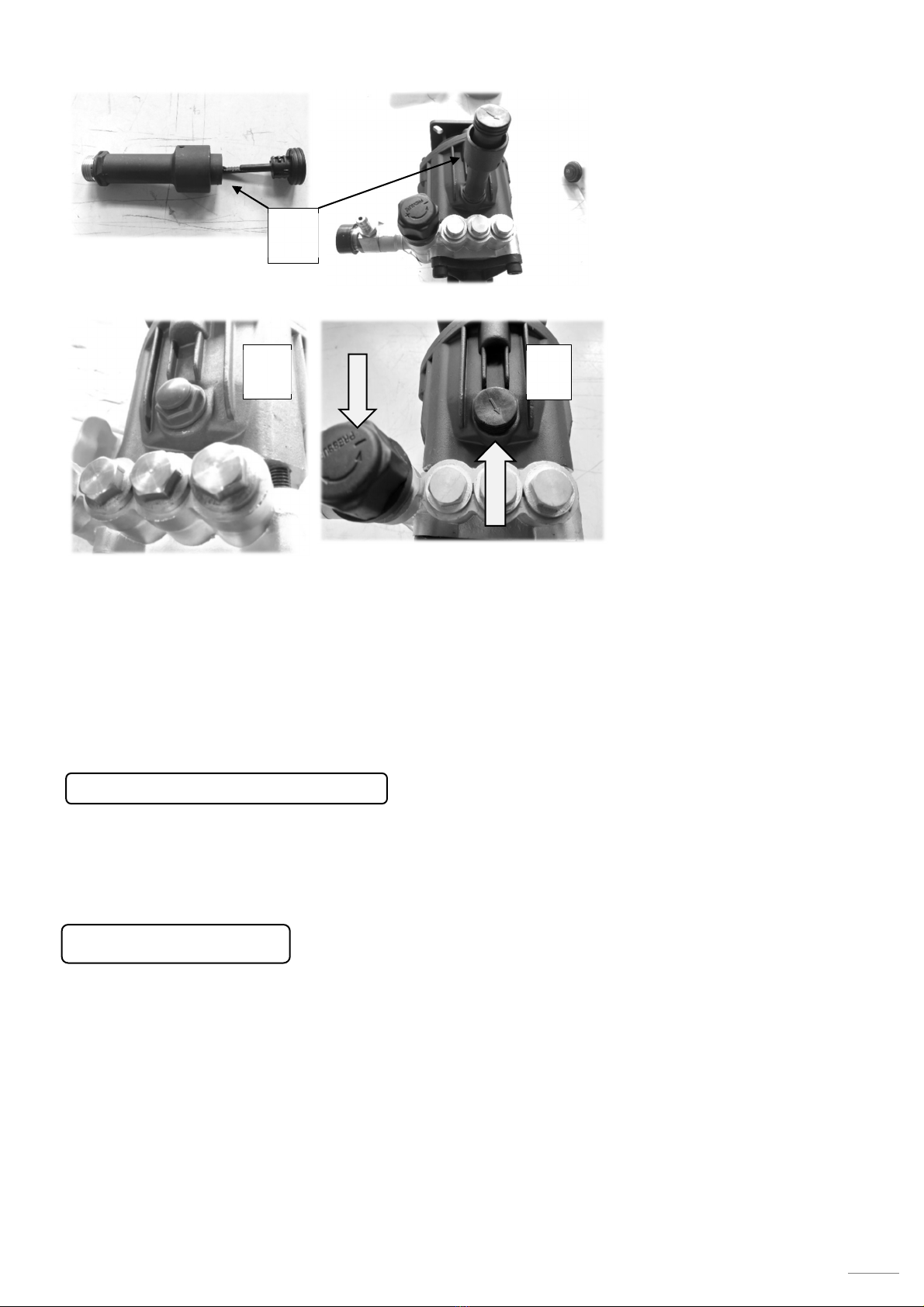

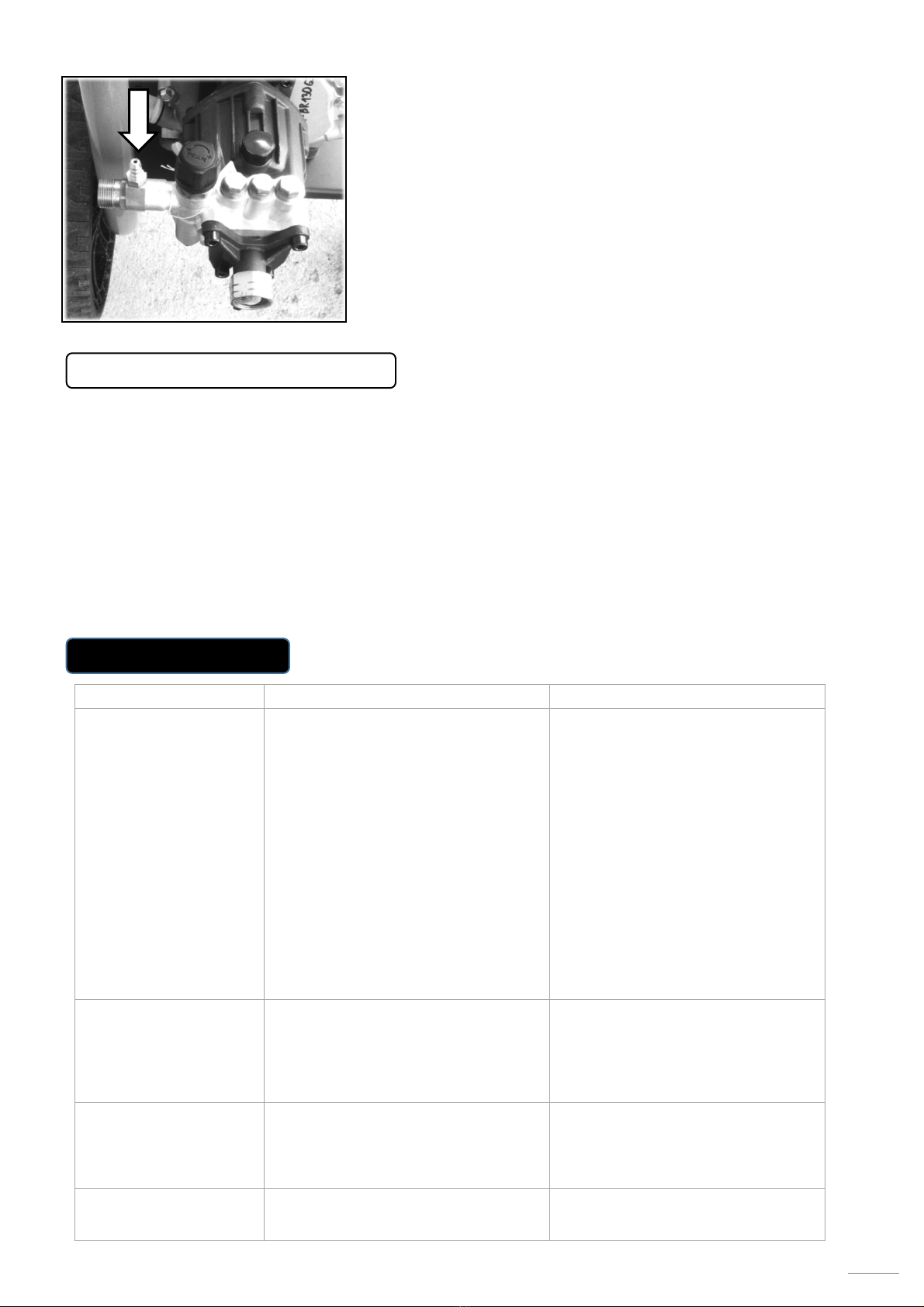

Use of self-priming detergent

The pump has the ability to automatically inject the detergent with

pressure from the container. A black nozzle for the application of

detergent is required to run this function (cat. number: ASBS0-

N0065). Only with the use of the nozzle, the pump starts to inject the

detergent itself through the hole indicated by the arrow. Connect the

supplied detergent tube to the place mark with an arrow (near the

pump high-pressure end) and immerse the other end with the

suction sieve into the diluted detergent container. Apply the

detergent by pressing the gun trigger.

This configuration

doesn’t serve to create active foam.

In order to create

active foam, it’s necessary to buy an aerator (cat. number:

S 000-

FL002).

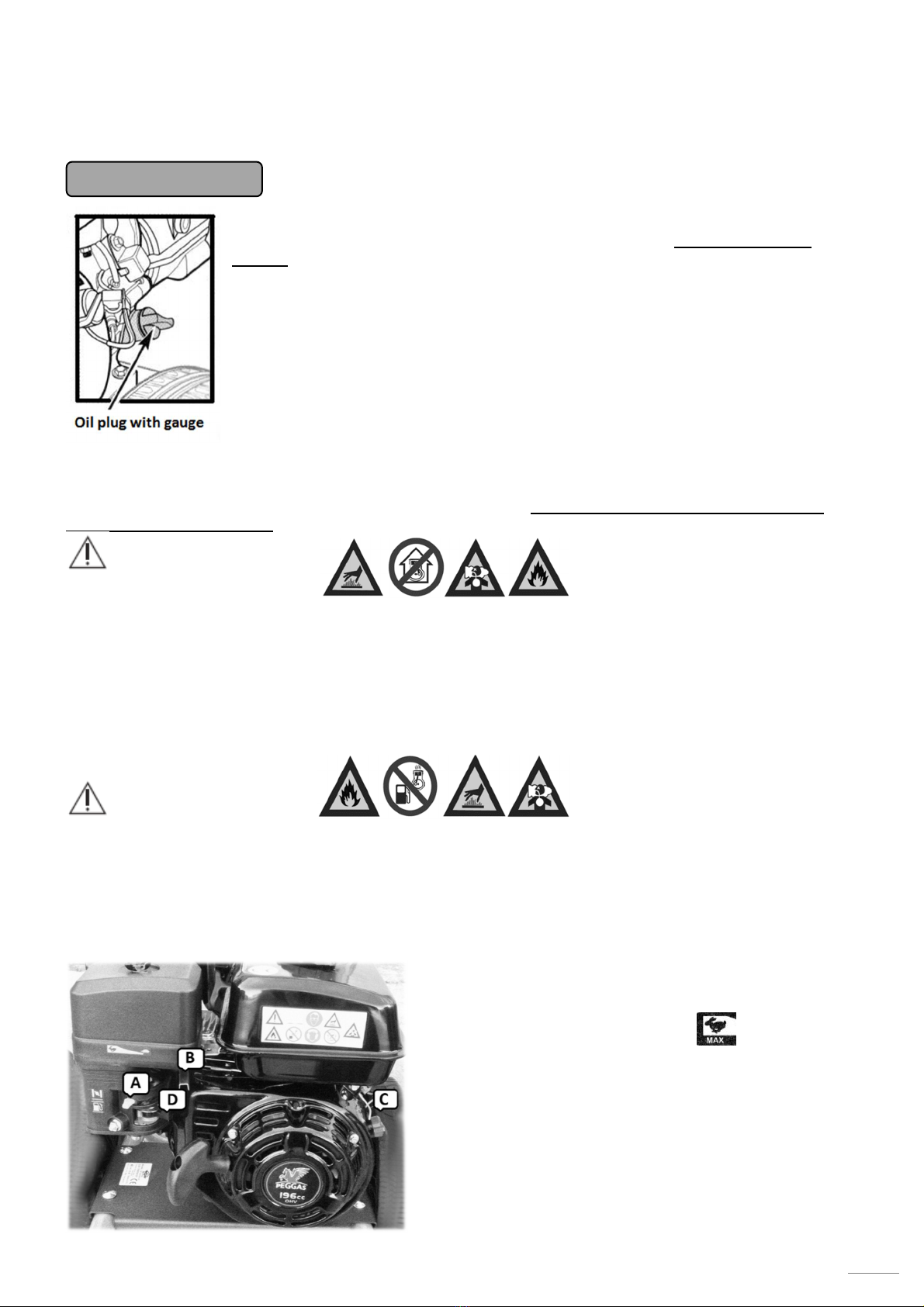

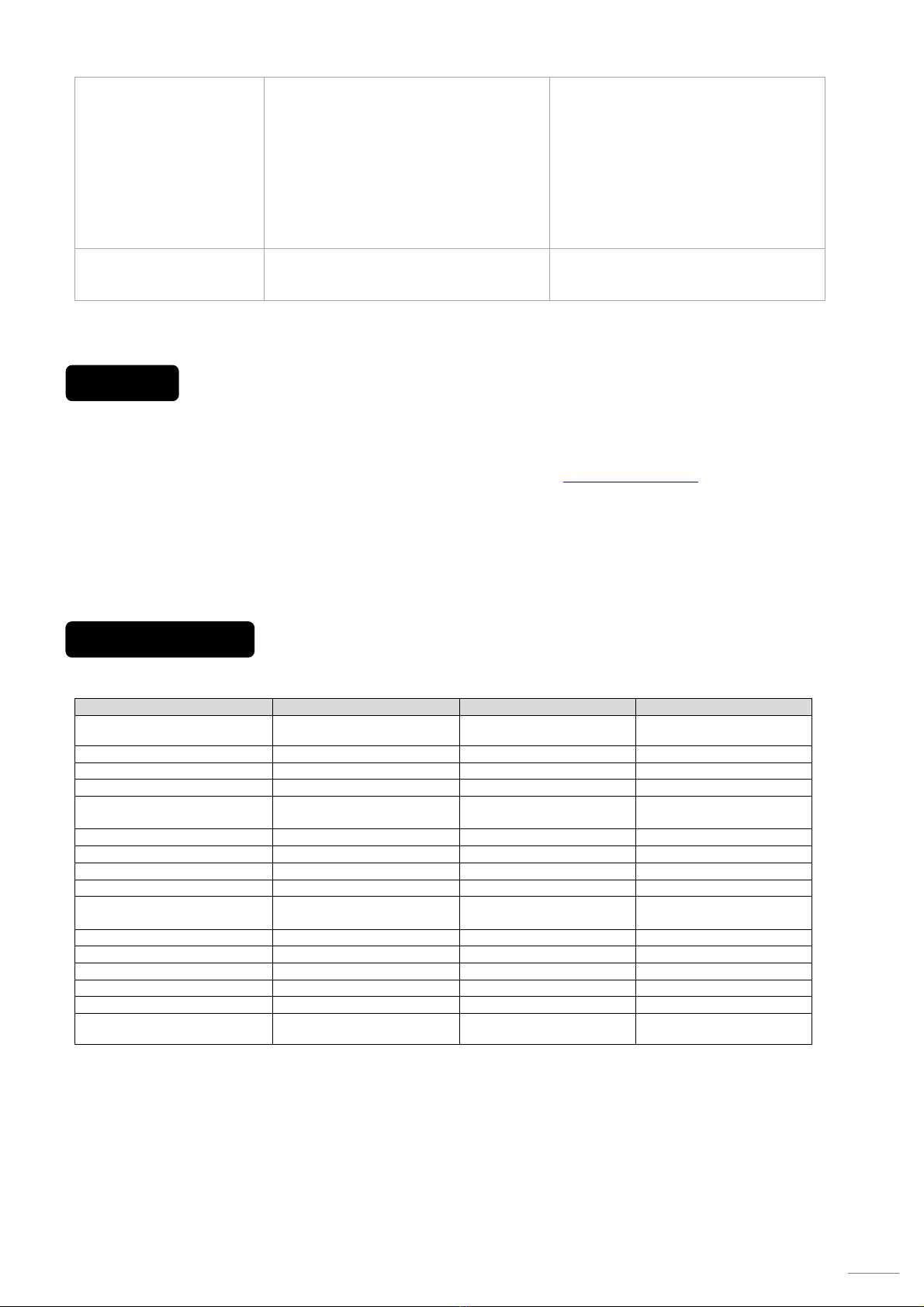

Pump storage for winter season

Storing the pump in areas with the ambient temperature below the freezing point may

result in irreversible damage to internal components, if not drained properly!

Excess water draining procedure:

Make sure the engine switch (p. 3 pos. C) is in the

OFF (0) position.

Disconnect the supply hoses from the pump. Grasp the starter cord grip and pull the cord

5 times,

as if you

were starting the engine. This action will help the water drain out of the pump through the high-pressure opening.

It is not recommended to store the pump in areas with the ambient temperature dropping below the freezing

point, since a significant change of outside temperature may result in condensation of water vapour even in

areas regularly not affected by water ingress. That may result in internal corrosion and a more significant

reduction of the service life of pump and engine.

Troubleshooting

The pump fails to generate

sufficient water pressure,

the water jet is intermittent

and the water flow is low

1.Nozzle with a large opening used

2.Blocked water supply

3.Low volume of water supply

4.Clogged screen on water supply line

5.Clogged or leaking high-pressure hose

6.Supply water temperature too high

7.Water pressure leakage from the gun

8.Clogged nozzle

9.Damaged pump

10. Improper priming of pump during the

self-priming mode

1.Replace it with a nozzle of the correct size

2.Check free water flow

3.Use a higher water pressure or a hose of

larger diameter

4.Clean the screen or replace it with a new

one

5.Remove contaminants, turn the hose

around, flush it or replace it with a new hose

6. rocure a supply of colder water

7.Check the connections for tightness, replace

the gun

8.Clean the nozzle with a steel wire and flush

it with flowing water

9.Contact a servicing centre

10. Check all the connections on the inlet side

for tightness, prime the pump as instructed

(page 4)

The pump fails to draw the

cleaning agent

1.Wrong nozzle used

2.The priming hose is not dipped in the cleaning

agent or it is clogged

3.Clogged hose or strainer

1.Replace the high-pressure nozzle with a

low-pressure (black) one

2.Check the volume of cleaning agent and

adjust the position of hose

3.Clean the washer with flowing water,

replace the priming hose

The engine runs smoothly

when not loaded, jerky under

load

1.Low engine speed

2.

Water pressure too high

1. Adjust the position of speed control lever,

check the position of locking screw for engine

speed control

2. Reduce the water outlet pressure by the

pump controller as described on page 8.

The engine stopped during

operation

1.The engine has run out of fuel

2.The spark plug terminal has fallen out

3. Low oil level in the engine

1.Add fuel into the tank

2.Check the spark plug terminal

3. Check the engine oil level