4

Engine

The engine MUST be filled with the correct amount of engine oil supplied with the

delivery before its first commissioning. The bottle with engine oil may contain larger

amount than required for the particular engine type. For specifics refer to the

Technical data section.

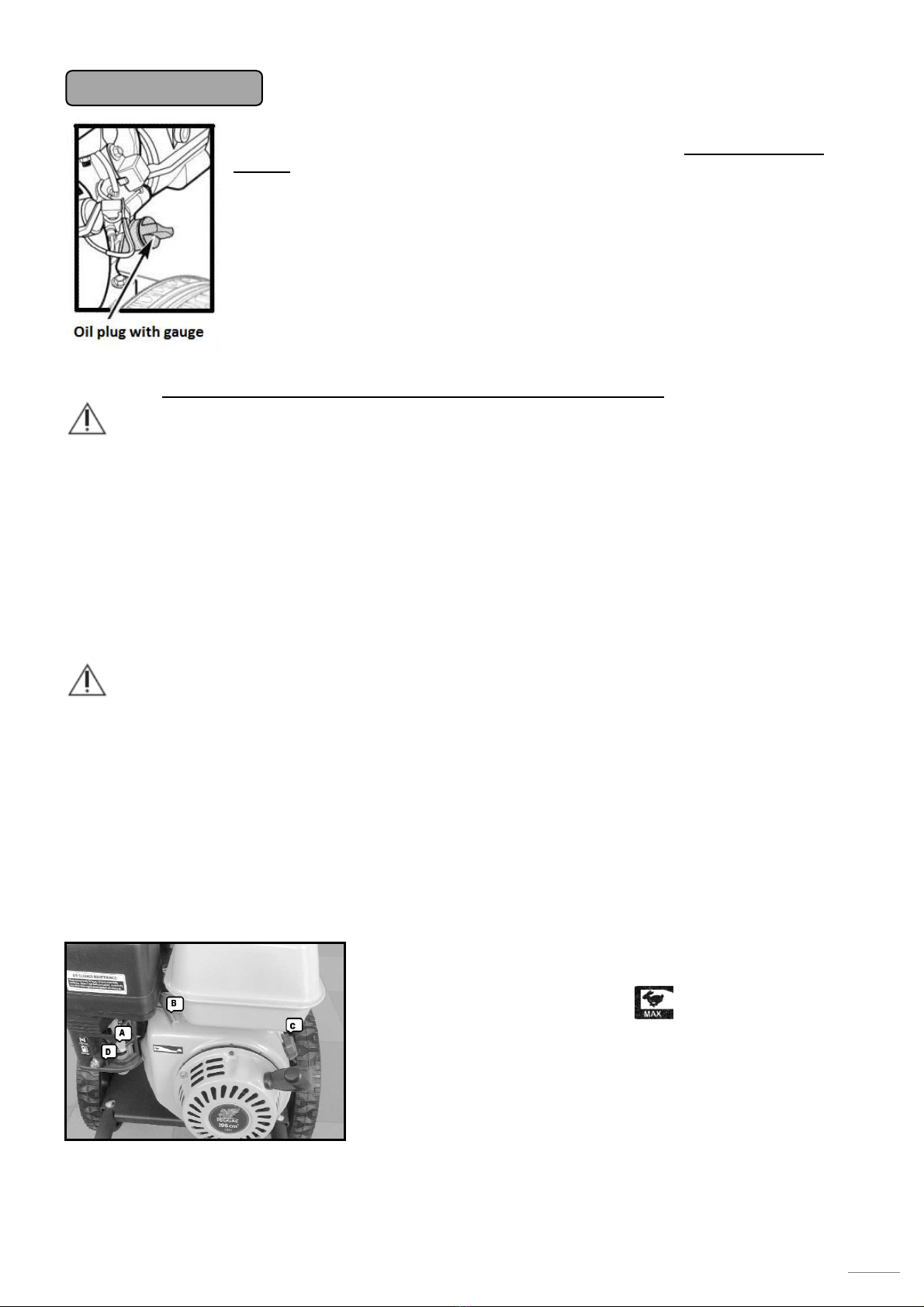

Set the pump on a horizontal surface. Open the oil sump plug, also fitted with the oil

gauge. Fill the engine with appro imately ¾ of the oil amount required. Screw the

plug back into the oil sump. With the C switch se to the OFF position (see the figure

below), cycle the engine by pulling the starter cord. Remove the plug, wipe the gauge

dry and check the engine oil level.

CAUTION: To get the correct reading, the gauge must be fully screwed in place.

Top up the oil to achieve the final level between the MIN and MAX marks.

Remove the plug and fill the tank with petrol carefully. To ensure full performance of

the engine, use fresh petrol with the octane rating of 91 or higher. The physical

properties of old and vapid petrol are different and it may cause an uneven run of the engine or reduced pump

performance. Use clean and oil-free petrol only - your engine is a four-stroke type.

DANGER

When in operation, the engine produces carbon monoxide, which is a colourless and

odourless poisonous gas. Inhalation of carbon monoxide may cause nausea, headaches,

dizziness, vomiting or even death!

The device may be used outdoors only, with proper ventilation ensured. It is also necessary

to prevent ingress of exhaust gases into enclosed rooms via unsealed openings.

When working with the engine on, turn the device in such direction, where the exhaust does

not remain pointed at persons standing in the vicinity or any opening in nearby structures

(garages, galleries, cellars, etc.).

When in operation, the engine produces waste heat, resulting in heat-up of various engine

components (exhaust, engine cylinder), which may cause serious burns. These components

may cause fire, when in contact with flammable materials.

DANGER

Petrol fumes are extremely flammable and explosive substances that max cause

burns, fire or even explosion, when handled improperly.

Let the engine cool down for 5 minutes before adding petrol into the tank. Then

proceed with careful removal of the tank lid and start pouring the petrol in with

caution. NEVER fill the fuel up to the rim, since petrol warms up during engine

operation and swells, which may result in leakage through the lid and subsequent

explosion of fire. NEVER tip the high-pressure device into such position, where

petrol may leak from the tank.

NEVER attempt to start the engine with damaged components in the fuel supply,

ignition or safety features.

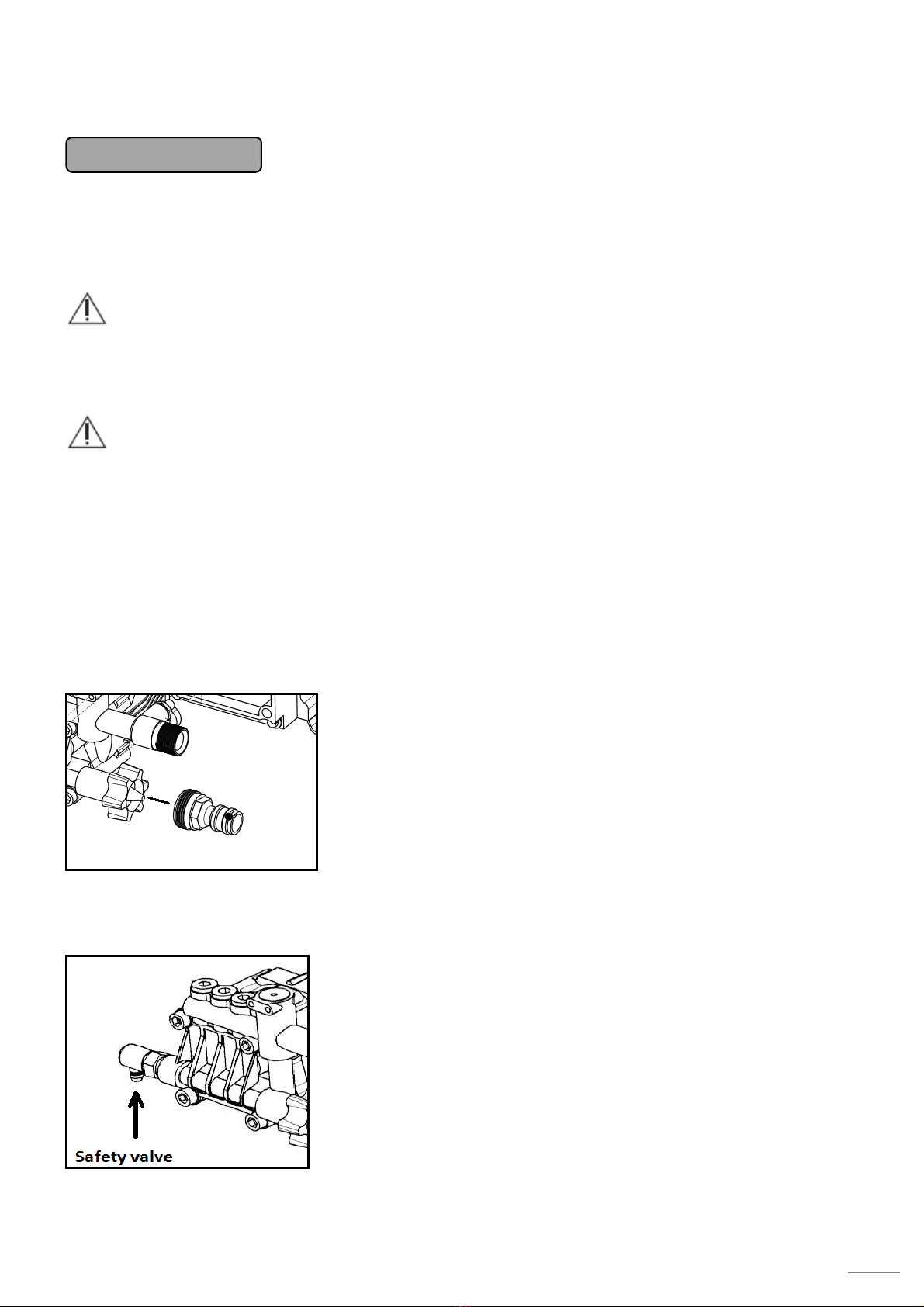

The turn the engine switch C and the fuel switch D into the ON

(I) position.

Shift the speed control lever B into the position.

Shift the choke control lever A into the CHOKE position.

Grasp the pump grip with one hand firmly and use the other hand

to hold the starter cord grip.

Pull the starter cord to the point, where you feel resistance from the

engine. Then pull the grip sharply to prevent recoil. If the engine

fails to start on the first attempt, depress the gun and relieve the

water pressure in a safe direction. Then repeat the starting process

by pull the starter grip again.