Contents

1 Features....................................................................................................................................... 4

2 Sa ety Symbols used in this Manual.............................................................................................4

3 Sa ety Guidelines.........................................................................................................................5

4 Responsibility or Operation or Damage.......................................................................................5

5 Application....................................................................................................................................6

6 Be ore Starting............................................................................................................................. 6

6.1 Transport............................................................................................................................................... 6

6.2 Storage.................................................................................................................................................. 6

6.3 Installation............................................................................................................................................. 7

7 Installation/ Start-up.....................................................................................................................7

8 Operation..................................................................................................................................... 8

8.1 General Operating Instructions.............................................................................................................. 8

8.2 Filling with Abrasive............................................................................................................................... 8

8.3 Abrading................................................................................................................................................ 9

8.4 Regulating the Abrasive........................................................................................................................ 9

8.5 Cleaning Nozzles................................................................................................................................... 9

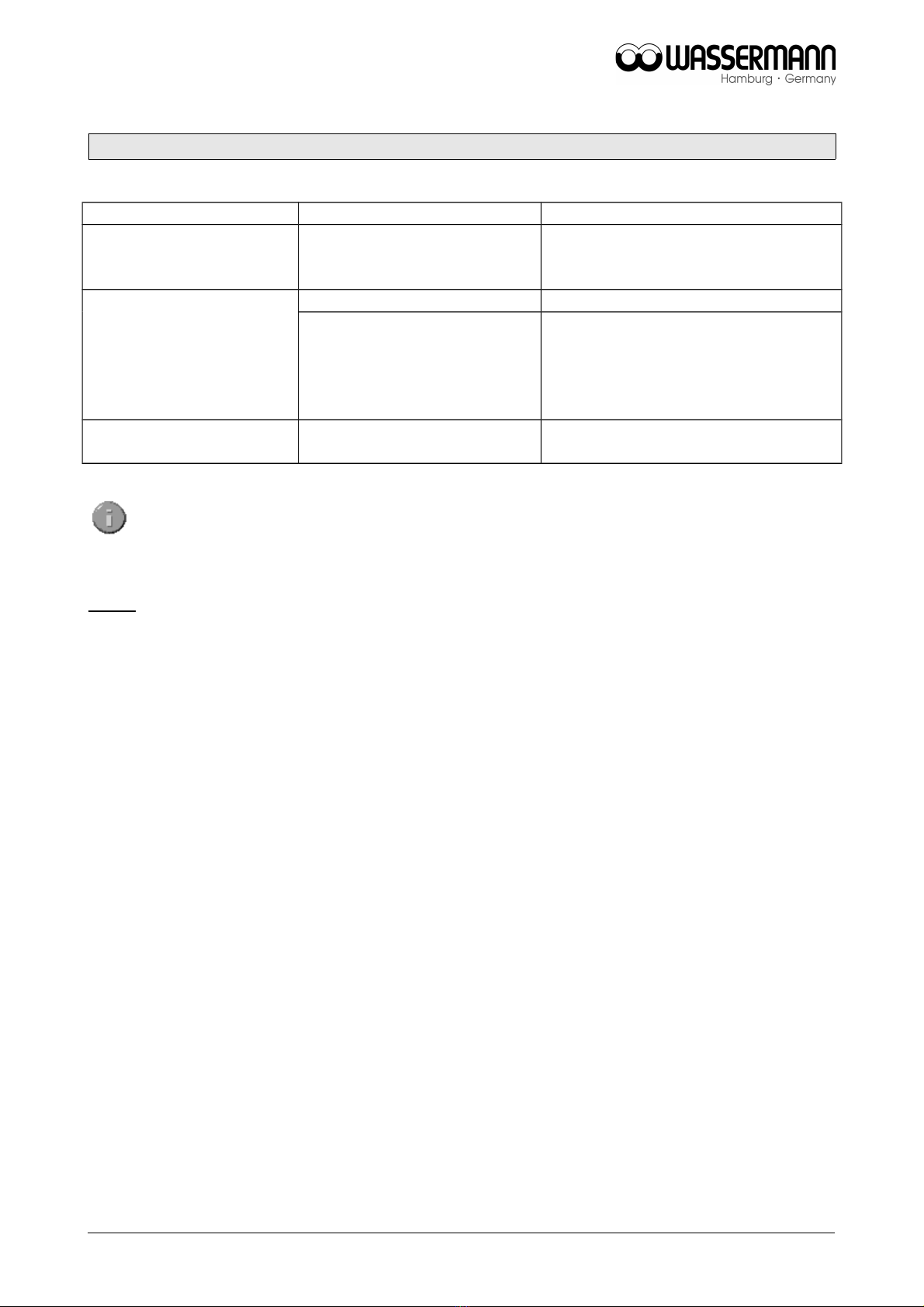

9 Troubleshooting.......................................................................................................................... 10

10 Care and Maintenance.............................................................................................................11

10.1 Cleaning............................................................................................................................................ 11

10.2 Maintenance/ Replacing worn Components......................................................................................12

10.2.1 Sleeves...................................................................................................................................... 12

10.2.2 Specially Coated Protection Shield............................................................................................12

10.2.3 Hoses......................................................................................................................................... 12

10.2.4 Pencils........................................................................................................................................ 13

10.2.5 Lamp.......................................................................................................................................... 13

10.2.6 Nozzles...................................................................................................................................... 14

10.2.7 Pressure Regulator.................................................................................................................... 14

10.3 Warranty............................................................................................................................................ 14

10.4 Spare Parts........................................................................................................................................ 15

10.5 Service Hotline 0049 (0)40 730 926 -20/ -24..................................................................................... 15

10.6 Scope o Delivery/ Accessories......................................................................................................... 15

10.7 Repairs.............................................................................................................................................. 15

11 Technical Data.........................................................................................................................16

12 Disposing o the Unit................................................................................................................16

12.1 In ormation on Disposal or Countries within the EU.........................................................................16

13 EU Declaration o Con ormity...................................................................................................17