TROUBLESHOOTING

Error Codes

NOTE:

Error

codes

appear

on

the

In

-Service

display.

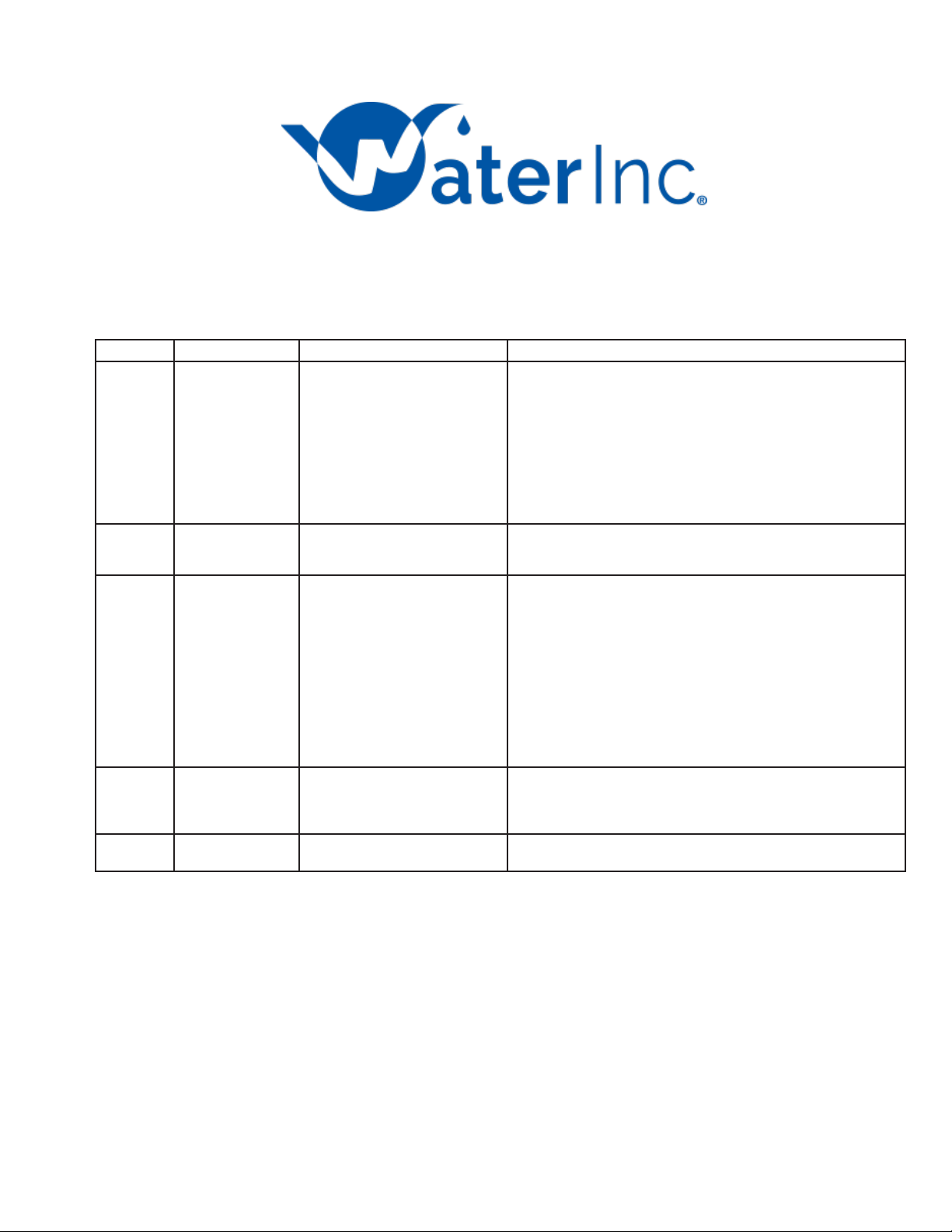

Error Code Error Type Cause

Reset

and

Recovery

---0

Motor Stall /Cam

Sense Error

No state changes in the optical

sensor are detected for six

seconds.

Unplug the unit and plug back in. Allow the control to attempt to find

position again.

Verify the optical sensor is in place with the wires connected to the

circuit board. Verify the motor and drive train components are in good

condition and assembled properly. Check the valve and verify that the

piston travels freely. Replace/reassemble the various components as

necessary.

Plug the unit back in and observe its behavior. If the error reoccurs,

unplug the unit, put it into bypass and contact technical support.

---1

Motor Run-On Error

/Cycle

Sense

Error

An undesired optical sensor state

change occurred.

Non-critical error. Extra optical sensor pulse detected. Press any

button to clear the error. Press extra cycle button to advance motor to

clear error.

---2

Regen

Failure The system has not regenerated

for more than 99 days (or 7 days if

the Control Type has been set to

Day-of-Week).

Perform a Manual Regeneration to reset the error code.

If the system is metered, verify that it is measuring flow by running

service water and watching for the flow indicator on the display. If the

unit does not measure flow, verify that the meter cable is connected

properly and that the meter is functioning properly.

Enter Master Programming Mode and verify that the unit is configured

properly, For the valve configuration. Check that the correct system

capacity has been selected, that the day override is set properly, and

that meter is identified correctly. If the unit is configured as a Day-of-

Week system, verify that at least one day is set ON. Correct the setting

as necessary.

---3

Memory

Error

Control board memory failure.

Perform a Master Reset and reconfigure the system via Master

Programming Mode. After reconfiguring the system, step the valve

through a manual regeneration. If error continues, call technical

support.

---4

Fail

Safe

Error

Valve has failed to find position in

one minute.

Unplug the unit and plug it back in. If error continues, call technical

support.

Thank You for Your Purchase!

Questions ? Please contact Water, Inc. Service Department 1-800-322-9283

F:HousePure/ HP02 5800 Installation 11-02-2022