WATERS CORPORATION ACQUITY UPLC Operating manual

i

ACQUITY UPLC

TUV Detector

Operator’s Overview and Maintenance Guide

Revision A

Copyright © Waters Corporation 2010

All rights reserved

ii

Copyright notice

© 2010 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF

AMERICA AND IN IRELAND. ALL RIGHTS RESERVED. THIS

DOCUMENT OR PARTS THEREOF MAY NOT BE REPRODUCED IN ANY

FORM WITHOUT THE WRITTEN PERMISSION OF THE PUBLISHER.

The information in this document is subject to change without notice and

should not be construed as a commitment by Waters Corporation. Waters

Corporation assumes no responsibility for any errors that may appear in this

document. This document is believed to be complete and accurate at the time

of publication. In no event shall Waters Corporation be liable for incidental or

consequential damages in connection with, or arising from, its use.

Trademarks

ACQUITY, ACQUITY UPLC, UPLC, Waters PIC, and Waters are registered

trademarks, and Empower, MassLynx, and “THE SCIENCE OF WHAT’S

POSSIBLE.” are trademarks of Waters Corporation.

PEEK is a trademark of Victrex Corporation.

Teflon is a registered trademark of E. I. du Pont de Nemours and Company.

TRITON is a trademark of Union Carbide Corporation.

Other registered trademarks or trademarks are the sole property of their

owners.

iii

Customer comments

Waters’ Technical Communications department invites you to tell us of any

errors you encounter in this document or to suggest ideas for otherwise

improving it. Please help us better understand what you expect from our

documentation so that we can continuously improve its accuracy and

usability.

We seriously consider every customer comment we receive. You can reach us

iv

Contacting Waters

Contact Waters®with enhancement requests or technical questions regarding

the use, transportation, removal, or disposal of any Waters product. You can

reach us via the Internet, telephone, or conventional mail.

Safety considerations

Some reagents and samples used with Waters instruments and devices can

pose chemical, biological, and radiological hazards. You must know the

potentially hazardous effects of all substances you work with. Always follow

Good Laboratory Practice, and consult your organization’s safety

representative for guidance.

When you develop methods, follow the “Protocol for the Adoption of Analytical

Methods in the Clinical Chemistry Laboratory,” American Journal of Medical

Technology, 44, 1, pages 30–37 (1978). This protocol addresses good operating

procedures and the techniques necessary to validate system and method

performance.

Waters contact information

Contacting medium Information

Internet The Waters Web site includes contact

information for Waters locations worldwide.

Visit www.waters.com.

Telephone and fax From the USA or Canada, phone 800

252-HPLC, or fax 508 872 1990.

For other locations worldwide, phone and fax

numbers appear in the Waters Web site.

Conventional mail Waters Corporation

34 Maple Street

Milford, MA 01757

USA

v

Considerations specific to the ACQUITY TUV detector

High voltage hazard

Safety advisories

Consult the Safety Advisories section on page 62 for a comprehensive list of

warning and caution advisories.

Warning: To avoid electric shock, do not remove the TUV detector’s

protective panels. The components within are not user-serviceable.

vi

Operating the ACQUITY TUV detector

When operating this instrument, follow standard quality-control (QC)

procedures and the guidelines presented in this section.

Applicable symbols

Audience and purpose

This guide is intended for personnel who install, operate, and maintain

ACQUITY TUV detectors. It gives an overview of the instrument’s technology

and operation.

Intended use of the ACQUITY TUV detector

The Waters ACQUITY TUV detector is for research use only.

Symbol Definition

Authorized representative of the European

Community

Confirms that a manufactured product complies

with all applicable European Community

directives

Australia C-Tick EMC Compliant

Confirms that a manufactured product complies

with all applicable United States and Canadian

safety requirements

This product has been tested to the requirements

of CAN/CSA-C22.2 No. 61010-1, second edition,

including Amendment 1, or a later version of the

same standard incorporating the same level of

testing requirements

Consult instructions for use

vii

Calibrating

To calibrate LC systems, follow acceptable calibration methods using at least

five standards to generate a standard curve. The concentration range for

standards must include the entire range of QC samples, typical specimens,

and atypical specimens.

When calibrating mass spectrometers, consult the calibration section of the

operator’s guide for the instrument you are calibrating. In cases where an

overview and maintenance guide, not operator’s guide, accompanies the

instrument, consult the instrument’s online Help system for calibration

instructions.

Quality-control

Routinely run three QC samples that represent subnormal, normal, and

above-normal levels of a compound. Ensure that QC sample results fall within

an acceptable range, and evaluate precision from day to day and run to run.

Data collected when QC samples are out of range might not be valid. Do not

report these data until you are certain that the instrument performs

satisfactorily.

When analyzing samples from a complex matrix such as soil, tissue,

serum/plasma, whole blood, and other sources, note that the matrix

components can adversely affect LC/MS results, enhancing or suppressing

ionization. To minimize these matrix effects, Waters recommends you adopt

the following measures:

• Prior to the instrumental analysis, use appropriate sample

pretreatment such as protein precipitation, liquid/liquid extraction

(LLE), or solid phase extraction (SPE) to remove matrix interferences.

• Whenever possible, verify method accuracy and precision using

matrix-matched calibrators and QC samples.

• Use one or more internal standard compounds, preferably isotopically

labeled analytes.

viii

Authorized representative information

Authorized representative

ISM classification

ISM Classification: ISM Group 1 Class B

This classification has been assigned in accordance with CISPR 11 Industrial

Scientific and Medical (ISM) instruments requirements. Group 1 products

apply to intentionally generated and/or used conductively coupled

radio-frequency energy that is necessary for the internal functioning of the

equipment. Class B products are suitable for use in both commercial and

residential locations and can be directly connected to a low voltage,

power-supply network.

Waters Corporation (Micromass UK Limited) is

registered in the United Kingdom with the Medicines

and Healthcare Products Regulatory Agency (MHRA)

at Market Towers, 1 Nine Elms Lane, London,

SW8 5NQ.

Waters Corporation (Micromass UK Ltd.)

Floats Road

Wythenshawe

Manchester M23 9LZ

United Kingdom

Telephone: +44-161-946-2400

Fax: +44-161-946-2480

Contact: Quality manager

Table of Contents ix

Copyright notice ................................................................................................... ii

Trademarks ............................................................................................................ ii

Customer comments ............................................................................................ iii

Contacting Waters ............................................................................................... iv

Safety considerations .......................................................................................... iv

Considerations specific to the ACQUITY TUV detector.................................... v

Safety advisories.................................................................................................. v

Operating the ACQUITY TUV detector ........................................................... vi

Applicable symbols ............................................................................................. vi

Audience and purpose......................................................................................... vi

Intended use of the ACQUITY TUV detector.................................................... vi

Calibrating ........................................................................................................ vii

Quality-control .................................................................................................. vii

Authorized representative information ...................................................... viii

Authorized representative............................................................................... viii

ISM classification .............................................................................................. viii

ISM Classification: ISM Group 1 Class B ...................................................... viii

Overview ................................................................................................................ 1

Principles of operation ....................................................................................... 2

Detector optics...................................................................................................... 2

Wavelength verification and test........................................................................ 8

Operational modes............................................................................................... 9

Before you begin ................................................................................................ 12

Installing the detector ...................................................................................... 13

Plumbing the detector ...................................................................................... 15

Installing the multi-detector drip tray ............................................................. 19

Table of Contents

x Table of Contents

Making Ethernet connections ......................................................................... 20

I/O signal connector ........................................................................................... 21

Connecting to the electricity source ............................................................. 21

Starting the detector ......................................................................................... 22

Monitoring detector LEDs................................................................................. 24

About the detector control panel....................................................................... 25

Shutting down the detector ............................................................................. 27

Shutting down for less than 24 hours............................................................... 27

Shutting down for more than 24 hours............................................................. 28

Maintaining the Detector ................................................................................. 29

Contacting Waters technical service................................................................. 29

Maintenance considerations.............................................................................. 30

Proper operating procedures ............................................................................. 30

Maintaining the leak sensor ............................................................................. 32

Replacing the detector’s leak sensor................................................................. 36

Maintaining the flow cell................................................................................... 38

Replacing the lamp ............................................................................................ 49

Replacing the fuses ............................................................................................ 52

Cleaning the instrument’s exterior................................................................... 53

Error Messages ................................................................................................... 54

Startup error messages ..................................................................................... 54

Error messages preventing operation............................................................... 58

Safety Advisories ................................................................................................ 62

Warning symbols ............................................................................................... 62

Caution symbol .................................................................................................. 65

Warnings that apply to all Waters instruments .............................................. 66

Electrical and handling symbols....................................................................... 72

Specifications ...................................................................................................... 74

Solvent Considerations .................................................................................... 77

Introduction........................................................................................................ 77

Solvent miscibility ............................................................................................. 78

Wavelength selection......................................................................................... 81

Overview 1

Overview

The Waters ACQUITY UPLC tunable ultraviolet (TUV) optical detector is a

two-channel, ultraviolet/visible (tunable UV/Vis) absorbance detector

designed for use in ACQUITY UPLC or ACQUITY UPLC H-Class systems.

The detector, controlled by Empower, MassLynx, or third-party software for

both LC/MS and LC applications, operates as an integral part of the system.

The detector offers two basic, primary flow cell options: the analytical flow

cell, with a volume of 500 nanoliters and a path length of 10 mm, and the high

sensitivity flow cell, with a volume of 2.4 microliters and a path length of

25 mm. The design of both flow cells reflects the Waters’ patented,

light-guiding, flow cell technology. This guide focuses on the light-guiding,

flow cell operating principles and maintenance procedures.

The Waters ACQUITY TUV detector operates at wavelengths ranging from

190 to 700 nm. The detector can sample up to 80 data points per second.

The detector has the following capabilities:

• Single or dual-wavelength – Monitors absorbance at one or two discrete

wavelengths.

• Wavelength verification reference filter – Ensures wavelength accuracy.

• Automatic, second-order filter – Automatically engaged for wavelengths

of 370 nm and greater and removed for wavelengths 369 nm or less.

• Spectrum scan and storage – Supports spectrum scan, display,

subtraction, storage, and playback, in addition to standard absorbance

and UV/Vis functionality.

• Full diagnostic capability – Supports built-in diagnostic tools, to

optimize functionality and performance.

• One contact closure output – The detector has one configurable switch,

which can accommodate a maximum of +30 VDC, 1.2-A current carrying

capacity, and 0.5-A current switching. The switch can trigger fraction

collectors and other external devices, as well as activate according to

time, absorbance threshold, or ratio criteria.

2

• Thermal wander management – To mitigate thermal instability caused

by ambient temperature changes, the detector’s insulation ensures air

flow across the optics bench, and its variable speed fan runs at higher or

lower speeds, as needed. The fan normally changes speeds in response to

the thermal changes. This feature can be optimized for two average

temperature zones, or disabled for maximum cooling of the optics and

flow cell.

• Median Baseline Filter (MBF) – A variation of the data mode, the MBF

decreases the effects of gradient separations on the chromatographic

baseline. It enhances the UV detector's baseline stability by decreasing

its curvature, making the development of integration methods easier.

Principles of operation

To use the detector effectively, become familiar with its optical and electronic

design and the theory and principles of its operation.

This section describes the detector’s optics and the wavelength verification

process and test.

Detector optics

The Waters ACQUITY TUV detector optics include these components:

• High brightness deuterium (D2) lamp

• Two mirrors: one, off-axis, ellipsoidal mirror and one spherical mirror

•Filterwheel

• Shutter, wavelength calibration filter, and second-order filter

• Entrance slit

• Blazed, plane-holographic, diffraction grating

•Beamsplitter

• Sample and reference photodiodes

• Waters light-guiding flow cell

Principles of operation 3

Waters ACQUITY TUV detector optics assembly

Optics assembly light path

The detector provides an extremely efficient design for exceptionally high

light throughput. It operates as follows:

1. The ellipsoidal mirror collects light from the lamp and focuses it through

the filter wheel onto the entrance slit. The spherical mirror directs light

toward the grating. A different portion of the spherical mirror focuses

dispersed light of a particular wavelength band, determined by the

grating angle, onto the entrance of the flow cell. Light exiting the flow

cell passes to the sample photodiode.

2. The beamsplitter, located just ahead of the flow cell, diverts a portion of

the light to a reference photodiode.

4

3. When you specify a new wavelength via Empower, MassLynx, or

third-party software, the detector rotates the grating to the appropriate

position.

4. The preamplifier board integrates and digitizes the currents from the

photodiodes for processing by the signal processing electronics and

output to a computer, chart recorder, or integrator.

Light-guiding flow cell operating principles

Small-bore, high-capacity columns like those used in UPLC produce

small-volume peaks. To avoid bandspreading and maintain concentration, the

flow cell volume must be correspondingly small. A rule of thumb is to hold cell

volume to 1/10th or less than the peak volume. To achieve the required volume

reduction with conventional absorbance detector flow cells, the path length

must be reduced to avoid a drastic cut in light throughput. Reduced path

length results in less analytical sensitivity as predicted by Beer’s law, but

high light levels are necessary to preserve a high signal-to-noise ratio.

Fortunately, a small-volume light-guiding flow cell can be designed with

optimum path length and high light throughput. Such a flow cell is analogous

to an optical fiber, where the core is the fluid sample and the cladding is

Teflon®AF, a unique, chemically inert, amorphous fluoropolymer made by

DuPont. The refractive index of Teflon AF is lower than that of water or other

HPLC mobile phases. Light rays entering the liquid core, within the cone

half-angle, α, are totally internally reflected when they meet the Teflon AF

boundary. These rays are transmitted through the flow cell, theoretically

without loss, except for absorption by the sample.

Light transmission through a light-guiding flow cell

Rays of light

Cladding (Teflon AF)Core (sample fluid)

α

Principles of operation 5

This information complements the foregoing illustration:

• The core of the light guide is the fluid sample, with refractive index n1.

• The cladding is a Teflon AF tube, with refractive index n2.Index n2< n1.

• The cross-sectional area of the tube is A and the length d. Cell volume =

Ad.

In the figure “Light transmission through a light-guiding flow cell” on page 4,

two rays of light are shown reflecting from the core-cladding interface. In a

flow cell, the number of “bounces” depends on the length of the Teflon AF tube,

its inside diameter (lumen), and the ray angle, “α”. The light beam (which

represents the energy transmitted through the cell) is comprised of many such

rays, up to a maximum whose angle is theoretically set by the refractive index

of the core and cladding. In the ACQUITY UPLC TUV detector, this angle is

mechanically controlled by components external to the flow cell so that the

variation in refractive index arising from different mobile phases does not

materially influence the efficiency of the transmitted energy.

The following schematic diagram of the flow cell shows the light-guiding

portion of the cell inside the cell assembly.

Light-guiding portion of flow cell

The sample fluid is introduced and removed from the flow cell via PEEK™

tubing. Probe radiation from the lamp housing is focused onto the input face of

the optical fiber that forms one end of the flow cell. Light travels down this

optical fiber until it encounters the fluid channel defined by the internal

diameter of the Teflon AF tube. The light then exits the optical fiber and

enters the fluid-filled Teflon AF tube. As the light passes through this tube, it

interacts with the sample stream. Any absorption by the fluid reduces the

Window

Tef l on A F

Fluid out

Light in

Fluid in

Light out

6

light intensity. The reduction is subsequently converted to absorbance. The

light exits the flow cell through a fused silica window, where it projects onto

the sample photodiode.

Unlike other flow cell designs, where the light beam is designed to avoid

striking the internal walls of the cell, light-guiding relies on internal

reflections from the walls of the Teflon AF tubing. Consequently, it is

important to maintain flow cell cleanliness by following the recommended

procedures described in “Maintaining the Detector” on page 29. With such

care, the instrument and flow cell should provide you continuous sensitive

detection.

Filtering noise

The detector provides a Hamming filter to minimize noise. The Hamming

filter is a digital finite-impulse-response filter, which creates peak height

degradation and enhances the filtering of high frequency noise.

The behavior of the filter depends on the filter time-constant you select. You

can program a filter time to be Fast, Slow, Normal, or Other. If you select

Fast, Slow, or Normal, you do not need to enter a value. The filter constant is

determined by the data rate. If you select Other, you can enter a value.

However, the value you enter is rounded up or down to a value based on the

data rate.

The filter time-constant adjusts the filter response time to achieve an optimal

signal-to-noise ratio. Selecting Other and entering a value of 0.0 disables all

filtering.

Lower time-constant settings produce these effects:

• Narrow peaks with minimal peak distortion and time delay

• Very small peaks become harder to discriminate from baseline noise

• Less baseline noise is removed

Caution: To ensure the detector cell is properly aligned and calibrated,

the flow cell must be filled with flowing solvent before you power-on the

detector. An empty flow cell causes a calibration error. Refer to the

recommended procedures described in “Maintaining the Detector” on

page 29 for more information.

Principles of operation 7

Higher time-constant settings produce these effects:

• Greatly decrease baseline noise

• Shorten and broaden peaks

The software includes fast or normal filtering constants at each data rate that

are appropriate for high speed or high sensitivity applications, respectively.

The following figure shows the relationship between increased filter

time-constant and absorbance.

Filter time-constant comparison

Tip: Although the peak shape shows some distortion and the signal output is

delayed with different time-constants, the peak area remains the same.

0 sec

1 sec

2 sec

Time (minutes)

Absorbance

8

Wavelength verification and test

The detector’s deuterium arc lamp and integral erbium filter exhibit peaks in

the transmission spectrum at known wavelengths. Upon startup, the detector

verifies calibration by comparing the locations of these peaks with expected

wavelengths based on calibration data stored in the detector’s memory. If the

results of this verification differ from the stored calibration by more than

1.0 nm, the detector displays a Wavelength Verification Failure message. The

detector verifies, rather than recalibrates, on startup to avoid errors arising

from residual materials left in the flow cell.

Requirement: Always ensure that the front door is secured during startup

verification.

You can initiate a manual wavelength calibration at any time. A manual

calibration replaces the previous calibration data with new data.

The verification and calibration algorithms are virtually identical. However,

the verification algorithm can issue an error message indicating that actual

data do not match stored data where the calibration algorithm replaces the

stored data with the new.

The detector wavelength verification procedures establish an approximate

home position using a grating homing sensor. Once Home is established, the

detector locates and references the 656.1-nm peak in the deuterium lamp

emission spectrum.

The integral erbium filter moves into the common light path ahead of the flow

cell entrance slit, enabling the detector to locate three additional spectral

features at these wavelengths:

• 256.7 nm (UV)

• 379.0 nm

• 521.5 nm

The verification tests for the detector require five minutes of lamp warmup

time.

Recommendation: If you run the detector continuously, perform wavelength

verification weekly by turning off the detector, and then turning it on again.

Principles of operation 9

Operational modes

The detector operates in single or dual-wavelength mode, allows spectrum

scanning using a flow cell, and provides RatioPlot, difference plot, and

MaxPlot functions.

Single-wavelength mode

Single-wavelength is the detector’s default mode of operation that supports

monitoring a single-wavelength, from 190 nm to 700 nm, settable in 1-nm

increments on channel A.

In single-wavelength mode, the detector automatically engages the

second-order filter for wavelengths 370 nm and above and removes it for

wavelengths under of 370 nm. The second-order filter is an optical filter that

blocks unwanted ultraviolet (UV) light from striking the diffraction grating

and interfering with absorbance detection above 370 nm.

You can configure several additional parameters when using the detector in

single-wavelength mode.

Primary parameters

The following are the values of major parameters that apply to

single-wavelength mode:

• Wavelength, in nanometers – Specifies a wavelength for channel A, from

190 nm to 700 nm, settable in 1-nm increments.

• Sensitivity in AUFS – Specifies the scaling factor for the analog output

channel and corresponds to the absorbance unit (AU) value where the

analog outputs saturate at full-scale values. Absorbance units full-scale

(AUFS) vary from 0.0001 to 4.000 AU.

Tip: Changing the sensitivity (AUFS) setting affects the 2-V output.

• Chart polarity (+ or –) – Reverses the polarity of the charted

chromatogram. Select + for a normal chromatogram, or – for an inverted

chromatogram. This function changes the direction of the plot on the 2-V

output, similar to reversing the leads to an external chart recorder.

• Filter time-constant – Programs a filter time, in seconds. Options are

Fast, Slow, Normal, or Other. If you select Fast, Slow, or Normal, you

need not enter a value. The filter constant is determined by the data

rate. If you select Other, you can enter a value, but the value you enter is

10

rounded up or down to a value based on the data rate. Selecting Other

and entering a value of 0.0 disables all filtering.

• Analog rate – Specifies a value as high as 80 Hz.

Dual-wavelength mode

In dual-wavelength mode, the detector can monitor two wavelengths, one on

channel A and one on channel B. The sampling frequency is reduced to 1 or

2 Hz, limiting use of this mode to more standard chromatography, where

peaks span at least 20 seconds, to enable full characterization of a peak. You

can use dual-wavelength mode to obtain additional information about an

analyte by running in the ratio plotting (RatioPlot) or

maximum-absorbance-volume plotting (MaxPlot) mode.

You select any two wavelengths from 190 nm to 700 nm.

In dual-wavelength mode, the following conditions apply:

• If both selected wavelengths are greater than 370 nm, the detector

applies the second-order filter to block unwanted UV light.

• If both selected wavelengths are less than or equal to 370 nm, the

detector removes the second-order filter.

• If the selected wavelengths bracket the 370 nm threshold, the detector

does not apply the second-order filter and issues a warning message that

any data collected for the wavelength above 370 nm can contain

inaccuracies because of possible UV light interference (second-order

effects).

Chart-out selection modes

When operating in dual-wavelength mode, the detector offers more choices for

analog output than the selections offered in single-wavelength mode. The

default selection for dual-wavelength mode is Absorbance.

• Absorbance (A and B) – The standard LC mode where the current

absorption is scaled and sent directly out the analog output. The scaling

depends on the AUFS setting and the absorbance offset. The absorbance

value is scaled for the 2-V analog output. If a setting of 1 AU/V is

desired, you can set an AUFS of 2.0000 in single-wavelength mode or in

dual-wavelength mode.

• MaxPlot – This mode results in the output of the larger of the two

absorbance values scaled to the selected AUFS setting. Use this mode

Table of contents

Other WATERS CORPORATION Security Sensor manuals

Popular Security Sensor manuals by other brands

ITALIANA SENSORI

ITALIANA SENSORI 8032-ISR023 Installation, operation and maintenance manual

ring

ring Motion Detector 2nd Generation Z-Wave Technical manual

EINHELL

EINHELL TC-MD 50 operating instructions

Inovonics

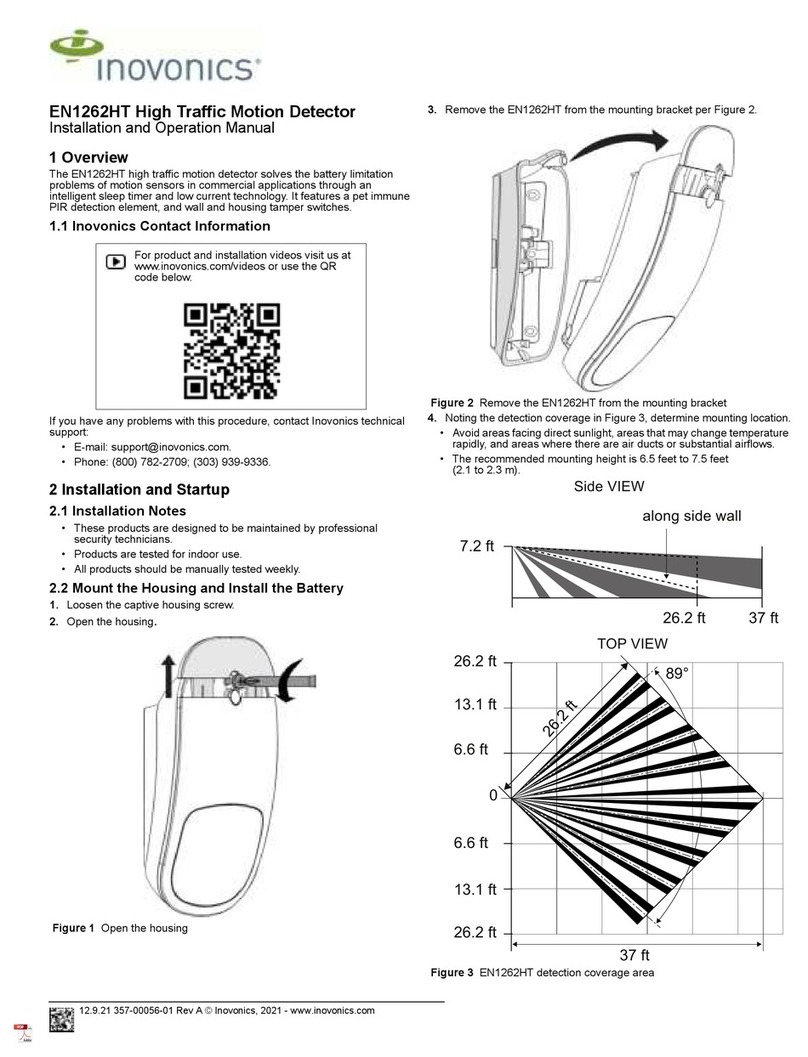

Inovonics EN1262HT Installation and operation manual

FootfallCam

FootfallCam SpaceSense installation guide

Aritech

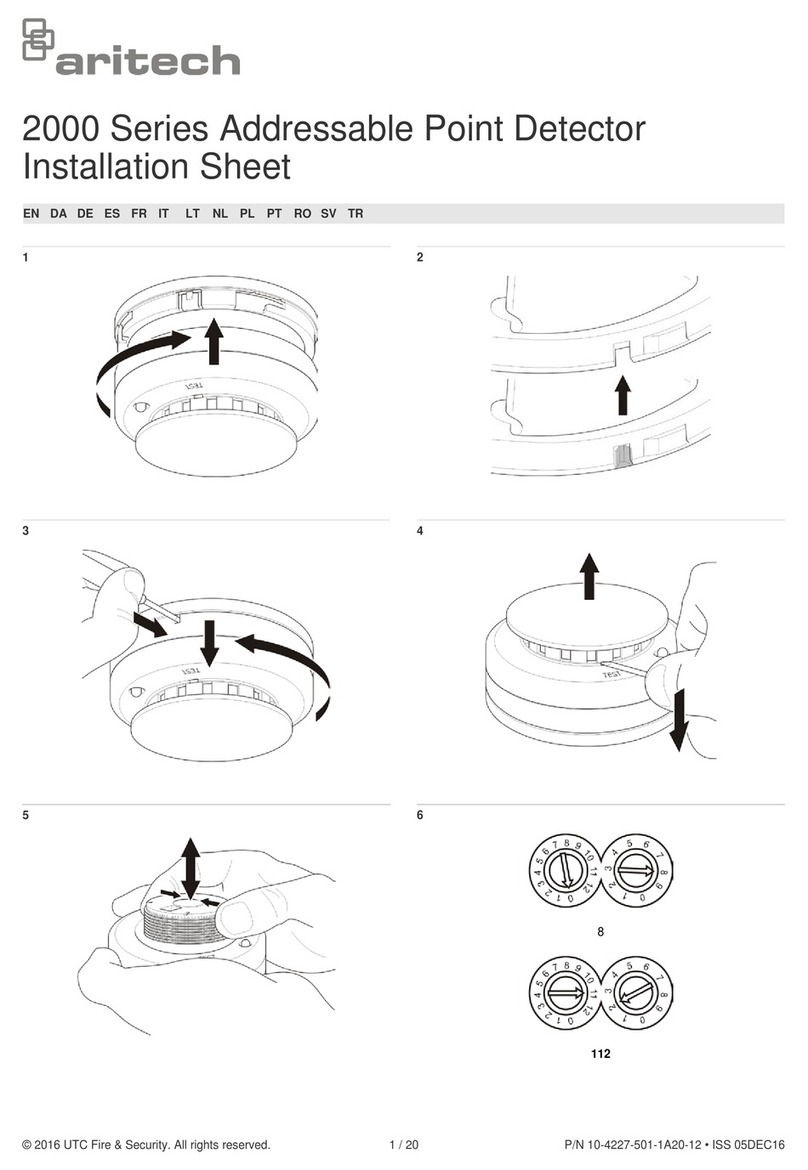

Aritech 2000 Series Installation sheet

Orbis

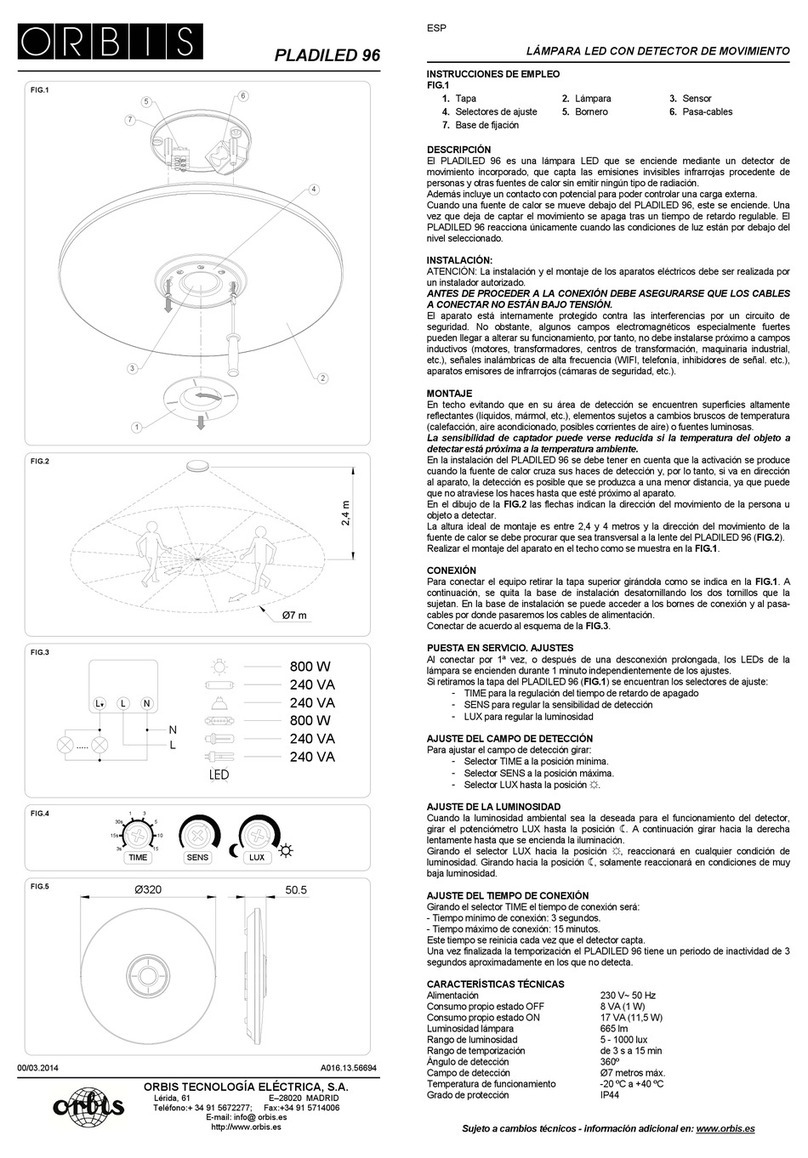

Orbis PLADILED 96 operating instructions

Risco

Risco BWare BUS QUAD AM G3 quick guide

Honeywell

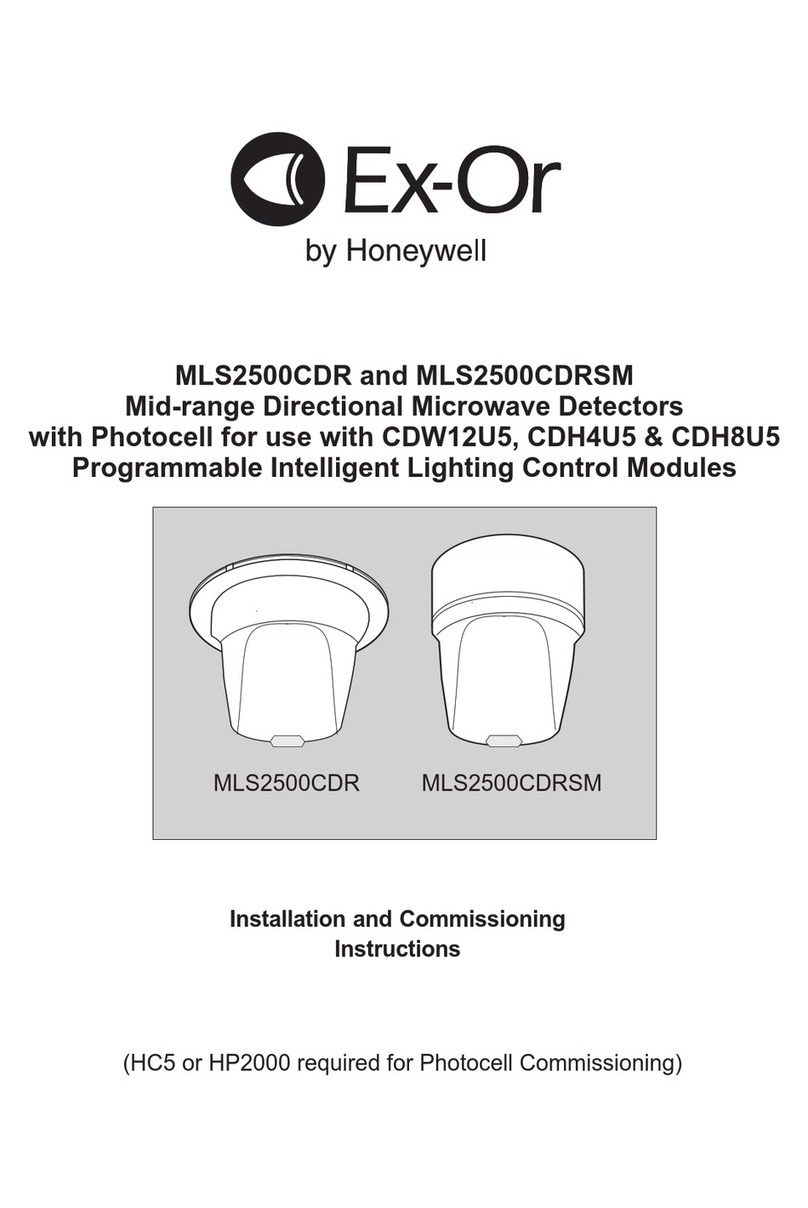

Honeywell Ex-Or MLS2500CDR Installation and commissioning instructions

Huazheng

Huazheng HZJF-9011D user manual

Honeywell

Honeywell IS216 Features & specifications

Ecolink

Ecolink Firefighter CS-600 Installation manual & users guide