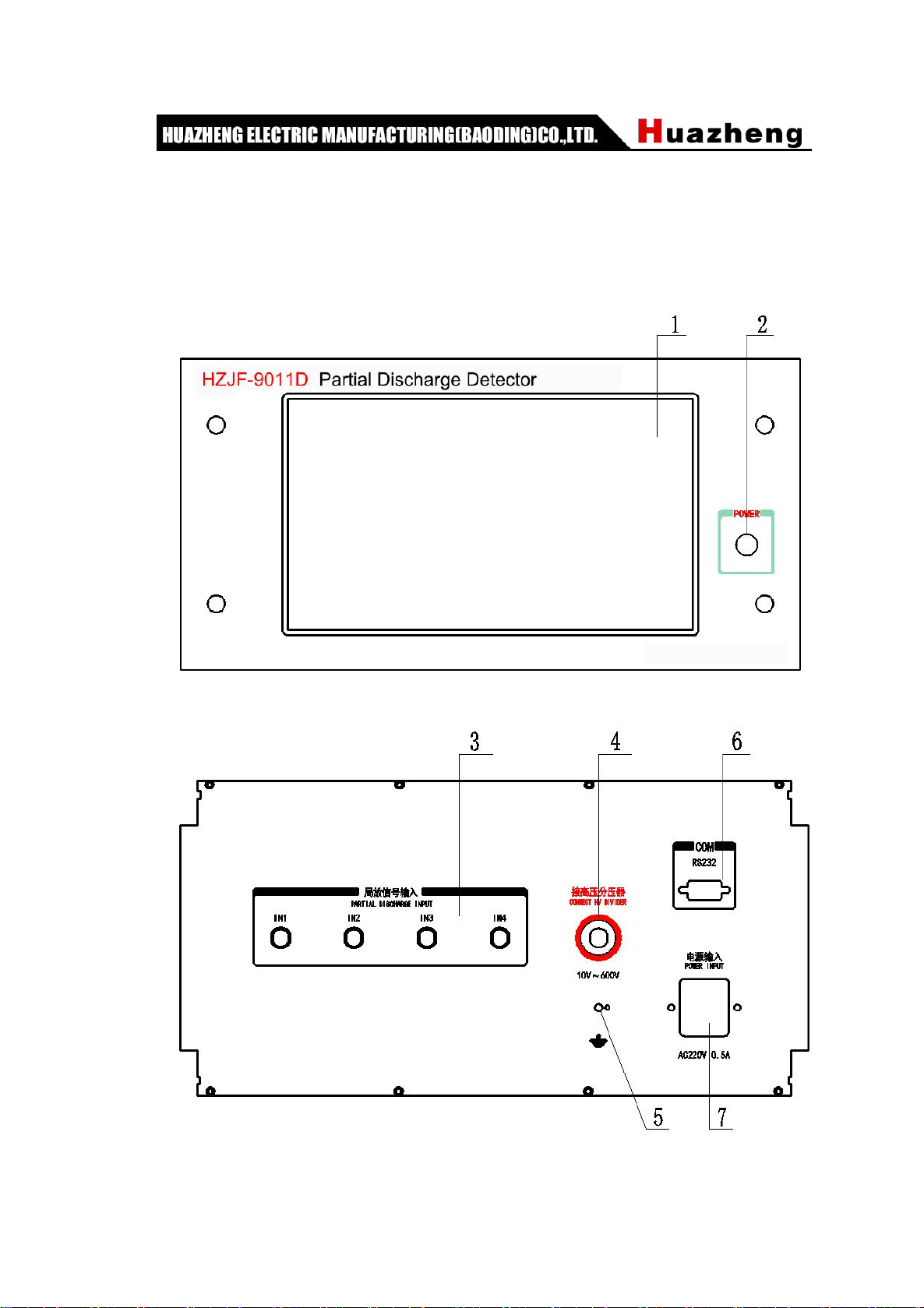

V.HZJF-9011D Description Of Front Panel And Rear

Panel Components

1. Touch screen: display the measured PD waveform, PD, test voltage, test frequency

and other parameters;

2. Power switch button: press once to turn on; press again to turn off;

3. Partial discharge input: partial discharge measurement signal input, HZJF-9011D

single channel, signal can be connected from any channel;

4. High voltage voltage divider, voltage range: 150V;

5. Grounding bolt: reliable grounding is required during test;

6. RS232 port: through this serial port, the parameters of partial discharge instrument can

be uploaded to other equipment;

7. External power supply input;

VI.Operating Instructions

(1)Preparation test

1. Check the grounding condition of the test site. Connect the grounding bolt 5 at the back

of the instrument with the grounding wire of the test site with thick copper wire (preferably

braided copper tape). The grounding short circuit piece of the input unit should also be

properly grounded.

2. According to the size of the test capacitor CX coupling capacitance CK, select the

suitable serial number input unit. In Table 1, the tuning capacitance refers to the

equivalent capacitance seen at the two ends of the primary winding of the input unit

(which can be roughly estimated by the series value of CX and CK).

The input unit should be as close as possible to the tested object. The Q9 socket of the

input unit is connected to the amplifier input socket 3 (channel 1) on the back panel of the

instrument through an 8-meter long cable.

3.There are several methods to connect the sample to the input unit (see Figure 3).