WATERS CORPORATION 2432 Operating manual

2432 Conductivity

(Cond) Detector

Overview and Maintenance Guide

715004730 / Revision A

Copyright © Waters Corporation 2015

All rights reserved

General information

Copyright notice

© 2015 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF AMERICA

AND IN IRELAND. ALL RIGHTS RESERVED. THIS DOCUMENT OR PARTS THEREOF

MAY NOT BE REPRODUCED IN ANY FORM WITHOUT THE WRITTEN PERMISSION OF

THE PUBLISHER.

Trademarks

ACQUITY® is a registered trademark of Waters Corporation.

ACQUITY ArcTM is a trademark of Waters Corporation.

ACQUITY UPLC® is a registered trademark of Waters Corporation.

Alliance® is a registered trademark of Waters Corporation.

Empower® is a registered trademark of Waters Corporation.

THE SCIENCE OF WHAT'S POSSIBLE® is a registered trademark of Waters

Corporation.

Waters® is a registered trademark of Waters Corporation.

LAC/ETM is a trademark of Waters Corporation.

All other trademarks or registered trademarks are the sole property of their

respective owners.

Customer comments

Waters’ Technical Communications organization invites you to report any errors that

you encounter in this document or to suggest ideas for otherwise improving it. Help

us better understand what you expect from our documentation so that we can

continuously improve its accuracy and usability.

We seriously consider every customer comment we receive. You can reach us at

December 7, 2015, 715004730 Rev. A

Page ii

Contacting Waters

Contact Waters with enhancement requests or technical questions regarding the use,

transportation, removal, or disposal of any Waters product. You can reach us via the

Internet, telephone, or conventional mail.

Waters contact information

Contacting

medium

Information

Internet The Waters Web site includes contact information for Waters

locations worldwide.

Visit www.waters.com

Telephone and fax From the USA or Canada, phone 800-252-4752, or fax

508-872-1990.

For other locations worldwide, phone and fax numbers appear

in the Waters Web site.

Conventional mail Waters Corporation

Global Support Services

34 Maple Street

Milford, MA 01757

USA

Safety considerations

Some reagents and samples used with Waters instruments and devices can pose

chemical, biological, or radiological hazards (or any combination thereof). You must

know the potentially hazardous effects of all substances you work with. Always follow

Good Laboratory Practice (GLP), and consult your organization’s standard operating

procedures as well as your local requirements for safety.

Safety hazard symbol notice

Documentation needs to be consulted in all cases where the symbol is used to

find out the nature of the potential hazard and any actions which have to be taken.

December 7, 2015, 715004730 Rev. A

Page iii

Considerations specific to the Waters 2432 Conductivity

Detector

Warning: To avoid electric shock, do not remove protective panels from

system modules. The components within are not user-serviceable.

Warning: To avoid injury from electrical shock or fire, and damage to the

equipment, do not place vessels containing liquid atop the workstation or ancillary

equipment or otherwise expose those units to dripping or splashing liquids.

Prohibited: To avoid equipment damage caused by spilled solvent, do not

place reservoir bottles directly atop an instrument or device or on its front

ledge. Instead, place the bottles in the bottle tray, which serves as

secondary containment in the event of spills.

FCC radiation emissions notice

Changes or modifications not expressly approved by the party responsible for

compliance, could void the user's authority to operate the equipment. This device

complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause

undesired operation.

Electrical power safety notice

Do not position the instrument so that it is difficult to disconnect the power cord.

Equipment misuse notice

If equipment is used in a manner not specified by its manufacturer, protections

against personal injury inherent in the equipment’s design can be rendered

ineffective.

Safety advisories

Consult the "Safety advisories" appendix in this publication for a comprehensive list

of warning advisories and notices.

December 7, 2015, 715004730 Rev. A

Page iv

Operating this device

When operating this device, follow standard quality-control (QC) procedures and the

guidelines presented in this section.

Applicable symbols

Symbol Definition

Manufacturer

Date of manufacture

Authorized representative of the European Community

Confirms that a manufactured product complies with all

applicable European Community directives

or

Australia EMC compliant

Confirms that a manufactured product complies with all

applicable United States and Canadian safety requirements

Consult instructions for use

Alternating current

Electrical and electronic equipment with this symbol may contain

hazardous substances and should not be disposed of as general

waste.

For compliance with the Waste Electrical and Electronic

Equipment Directive (WEEE) 2012/19/EU, contact Waters

Corporation for the correct disposal and recycling instructions.

Serial number

REF

Part number catalog number

December 7, 2015, 715004730 Rev. A

Page v

Audience and purpose

This guide is intended for personnel who install, operate, and maintain the Waters

2432 Conductivity Detector.

Intended use of the detector

The Waters 2432 Conductivity Detector is intended to measure the ionic strength of

a solution with a pair of inert electrodes. The resulting chromatograms measure

concentrations of anions and cations. Typical applications are in water chemistry,

sugar and salt content in food, and water analysis for pollution. The Waters 2432

Conductivity Detector is not intended for clinical applications, but rather for use as a

general laboratory module.

Calibrating

To calibrate LC systems, follow acceptable calibration methods using at least five

standards to generate a standard curve. The concentration range for standards must

include the entire range of QC samples, typical specimens, and atypical specimens.

Quality control

Routinely run three QC samples that represent subnormal, normal, and above-

normal levels of a compound. If sample trays are the same or very similar, vary the

location of the QC samples in the trays. Ensure that QC sample results fall within an

acceptable range, and evaluate precision from day to day and run to run. Data

collected when QC samples are out of range might not be valid. Do not report these

data until you are certain that the instrument performs satisfactorily.

EMC considerations

Canada spectrum management emissions notice

This class A digital product apparatus complies with Canadian ICES-001.

Cet appareil numérique de la classe A est conforme à la norme NMB-001.

December 7, 2015, 715004730 Rev. A

Page vi

ISM classification: ISM group 1 class B

This classification has been assigned in accordance with IEC CISPR 11 Industrial

Scientific and Medical (ISM) instrument requirements.

Group 1 products apply to intentionally generated and/or used conductively coupled

radio-frequency energy that is necessary for the internal functioning of the

equipment.

Class B products are suitable for use in both commercial and residential locations and

can be directly connected to a low voltage, power-supply network.

EC authorized representative

Address Waters Corporation

Stamford Avenue

Altrincham Road

Wilmslow SK9 4AX UK

Telephone +44-161-946-2400

Fax +44-161-946-2480

Contact Quality manager

December 7, 2015, 715004730 Rev. A

Page vii

Table of contents

General information ......................................................................ii

Copyright notice........................................................................................... ii

Trademarks ................................................................................................. ii

Customer comments..................................................................................... ii

Contacting Waters ....................................................................................... iii

Safety considerations................................................................................... iii

Safety hazard symbol notice ...............................................................iii

Considerations specific to the Waters 2432 Conductivity Detector ............iv

FCC radiation emissions notice ............................................................iv

Electrical power safety notice ..............................................................iv

Equipment misuse notice....................................................................iv

Safety advisories...............................................................................iv

Operating this device ....................................................................................v

Applicable symbols ............................................................................ v

Audience and purpose........................................................................vi

Intended use of the detector...............................................................vi

Calibrating........................................................................................vi

Quality control ..................................................................................vi

EMC considerations...................................................................................... vi

Canada spectrum management emissions notice ...................................vi

ISM classification: ISM group 1 class B ................................................vii

EC authorized representative ....................................................................... vii

1 2432 Conductivity Detector .........................................................11

1.1 Location of the detector within the system ..................................................... 11

1.2 Major components ...................................................................................... 14

1.3 Theory of operation .................................................................................... 16

1.3.1 Flow cell design............................................................................... 16

1.3.2 Conductance................................................................................... 16

1.3.3 Temperature................................................................................... 16

1.3.4 Autozero ........................................................................................ 17

December 7, 2015, 715004730 Rev. A

Page viii

2 Preparing and operating the detector..........................................18

2.1 Stacking system modules ............................................................................ 18

2.2 Connecting the tubing ................................................................................. 19

2.3 Installing the multi-detector drip tray............................................................ 21

2.4 Making the USB connection.......................................................................... 21

2.5 Connecting signal cables ............................................................................. 21

2.6 Input/output signal connectors..................................................................... 23

2.7 Connecting to the electricity source............................................................... 23

2.8 Adding the detector to the system ................................................................ 24

2.9 Measuring the cell constant.......................................................................... 26

2.10 Installation recommendations for fittings ....................................................... 26

2.10.1 One-piece PEEK fitting ..................................................................... 26

3 Maintenance procedures .............................................................27

3.1 Maintenance schedule ................................................................................. 27

3.2 Spare parts ............................................................................................... 27

3.3 Taking care of the flow cell .......................................................................... 27

3.4 Safety and handling.................................................................................... 28

3.5 Replacing the module's fuses ....................................................................... 28

3.6 Cleaning the exterior of the equipment.......................................................... 30

A Safety advisories.........................................................................32

A.1 Warning symbols........................................................................................ 32

A.1.1 Specific warnings............................................................................. 33

A.2 Notices ..................................................................................................... 34

A.3 Bottles Prohibited symbol ............................................................................ 35

A.4 Required protection .................................................................................... 35

December 7, 2015, 715004730 Rev. A

Page ix

A.5 Warnings that apply to all Waters instruments and devices .............................. 35

A.6 Warnings that address the replacing of fuses.................................................. 39

A.7 Electrical symbols....................................................................................... 41

A.8 Handling symbols ....................................................................................... 42

B Specifications ..............................................................................43

B.1 Physical specifications ................................................................................. 43

B.2 Environmental specifications ........................................................................ 43

B.3 Electrical specifications................................................................................ 44

B.4 Operational specifications ............................................................................ 44

B.5 Flow cell specifications ................................................................................ 45

B.6 Input specifications..................................................................................... 45

B.7 Wetted materials of construction .................................................................. 46

December 7, 2015, 715004730 Rev. A

Page x

12432 Conductivity Detector

The 2432 Conductivity Detector detects and measures anions and cations present in

column eluent.

1.1 Location of the detector within the system

The detector is configured as part of the following systems:

• ACQUITY Arc system

• ACQUITY UPLC H-Class or ACQUITY UPLC Bio H-Class system

• Alliance HPLC system

• Modular liquid chromatography system

See also: For detailed configuration information, contact your sales representative.

December 7, 2015, 715004730 Rev. A

Page 11

Figure 1–1: Location of a detector in an example ACQUITY Arc system

1

2

3

4

5

2432 Conductivity Detector

30-cm Column heater

Quaternary solvent manager-R

Sample manager - Flow through needle-R

Bottle tray

December 7, 2015, 715004730 Rev. A

Page 12

Figure 1–2: Location of a detector in an example ACQUITY UPLC H-Class

system

1

2

3

4

5

6

2432 Conductivity Detector

30-cm Column heater

Quaternary solvent manager

Sample manager - Flow through needle

Column heater

Bottle tray

December 7, 2015, 715004730 Rev. A

Page 13

Figure 1–3: Location of a detector in an example Alliance HPLC system

1

2

3

4

2432 Conductivity Detector

30-cm Column heater

e2695 separations module

Solvent bottle tray

1.2 Major components

When you open the detector's door, the only visible components are two fittings

where tubing is attached and routed in and out of the detector. The rear of the

detector has a USB port, an I/O signal connector, and an inlet for ac power.

December 7, 2015, 715004730 Rev. A

Page 14

Figure 1–4: Detector with door open

OUT

IN

1

2

Eluent flow out

Eluent flow in

Figure 1–5: Detector rear

1

2

3

December 7, 2015, 715004730 Rev. A

Page 15

Signal cable

USB port

Power inlet

1.3 Theory of operation

1.3.1 Flow cell design

The flow cell has an internal volume of 0.8 µL, and the microprocessor controls

conductivity measurement.

The cell constant is typically 16/cm, and you can adjust it from 13/cm through

21/cm.

Column effluent flows through an internal heater and directly through the flow cell.

1.3.2 Conductance

The specific conductance, κ, of a solution of known concentration is calculated using

the following equation. The detector measures conductivity in µS*cm-1.

κ = θL = θ/Rcell

Where:

θ = cell constant

L = measured conductance of the solution

Rcell = measured resistance

1.3.3 Temperature

The flow cell heater minimizes the effect of ambient temperature fluctuations on

measurement accuracy. Generally, a solution’s conductivity rises about 2% for every

degree Celsius of temperature increase.

You can set the temperature to between 20 °C and 50 °C, in 5-degree increments.

The detector controls only those temperatures above ambient temperature.

Recommendation: Operate the detector at 5 °C over ambient temperature.

See: For instructions on setting cell temperature and the temperature coefficient,

see the online Help.

December 7, 2015, 715004730 Rev. A

Page 16

1.3.4 Autozero

You can eliminate the eluent’s contribution to conductivity using the Autozero

function. When you select Autozero, the detector measures the eluent conductivity

and assigns it a value of zero. Thus, any sample ions appear as positive or negative

measurements, relative to a zero baseline.

Figure 1–6: Absolute and relative (autozeroed) conductivity traces

December 7, 2015, 715004730 Rev. A

Page 17

2Preparing and operating the

detector

Install the detector as described in this section.

2.1 Stacking system modules

This procedure applies to system modules equipped with interlocking features.

Important: For the order in which to stack modules, contact your field service

engineer.

Notice: To avoid overheating the module, do not block the air vent. Ensure

that a minimum gap of 6 inches exists behind the system, for ventilation and

rear-panel connections.

Warning: To avoid spinal and muscular injury, do not attempt to lift a

system module without assistance.

Warning: To avoid crushing your fingers beneath or between modules, use

extreme care when installing a module in the system stack.

December 7, 2015, 715004730 Rev. A

Page 18

To stack the modules:

1. Place the rear feet of the module that you are adding atop the previously added

module in the system stack, and slide it backward until its rear alignment pin

rests in the rear alignment slot on the previously added module.

Figure 2–1: Aligning pins with slots

Alignment pin (2)

Alignment slot (2)

2. Lower the front of the module that you are adding so that its front alignment

pin rests in the front alignment slot on the previously added module.

3. Repeats steps 1 and 2 for the remaining system modules.

2.2 Connecting the tubing

To connect the tubing to the detector:

1. Connect the tubing from the column manager to the fixture labeled "IN".

Requirement: There are two lengths of tubing in the kit. Connect the shorter

tubing with the smaller ID to "IN".

December 7, 2015, 715004730 Rev. A

Page 19

OUT

IN

1

Tubing from the column manager

2. Direct the tubing from the fixture labeled "OUT" to a waste container.

Requirement: Connect the longer tube with the larger ID to "OUT".

Requirement: Ensure that the waste container is placed lower than, or at the

same level as, the detector.

OUT

IN

1

Tubing directed to waste

December 7, 2015, 715004730 Rev. A

Page 20

Table of contents

Other WATERS CORPORATION Security Sensor manuals

Popular Security Sensor manuals by other brands

Berker

Berker Radio Detector 180 operating instructions

Respirex

Respirex Simplair Instructions for use

Eelectron

Eelectron PD00D01KNX Product handbook

Samsung

Samsung S-1 URX-P01 user manual

Atim Cloud Wireless

Atim Cloud Wireless LoRaWAN ACW/LW8-THX user guide

Tempo Fitness

Tempo Fitness 200FP instruction manual

Agilent Technologies

Agilent Technologies G6600-90006 Operation and maintenance manual

Honeywell

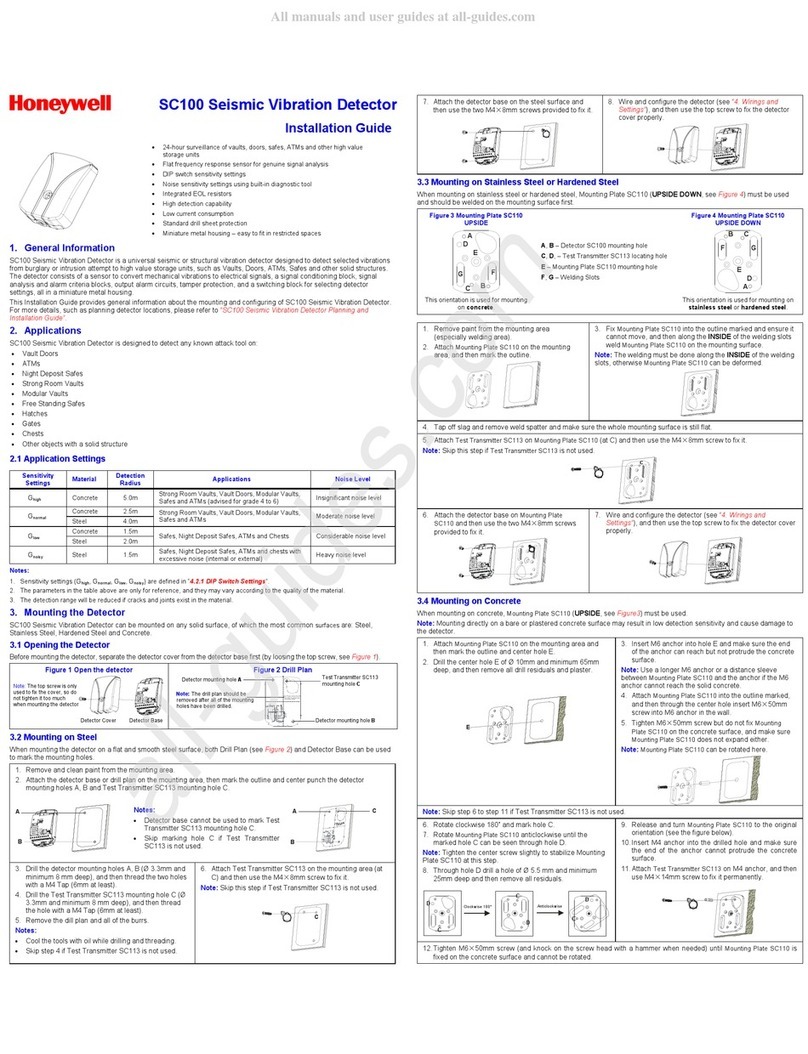

Honeywell SC100 installation guide

Skyhawk

Skyhawk Kiwi IR Installation & user manual

Vega

Vega VEGASON 62 operating instructions

Busch-Wachter

Busch-Wachter 6847 220 MasterLINE operating instructions

ORORO

ORORO TWIN-CITIES HEATED GLOVES manual