810-1800.0522

©2022 Waterway Plastics

Failure to remove pressure test plugs and/or plugs used in winterization of the pool/spa from the suction

outlets can result in an increased potential for suction entrapment as described on the previous page.

The 8”/ 640-1800 V tting is rated at 120 GPM for oor and 80 GPM for wall. If the tting is missing or broken,

replace with a tting of equivalent rating or higher. Use of a lower rated suction tting could result in

entrapment of the body which could result in serious injury including drowning.

Do not use or operate pool, spa, or hot tub if this suction tting is missing, broken or not secured per

instructions. The suction tting is intended to prevent entrapment of the body. Use of the spa hot tub with a

missing, broken or improperly secured suction grate may result in serious personal injury including drowning.

When the pool, spa or hot tub is in operation, suction is created at this tting. Users of the spa or hot tub must

be instructed not to come in contact with this tting in such a way as to block its orice. If a user of the spa or

hot tub blocks this tting with his/her body, serious personal injury or drowning may occur.

Failure to keep suction outlet components clear of debris, such as leaves, dirt, hair, paper and other material,

can result in an increased potential for suction entrapment as described on the previous page.

Suction outlet components have a nite life. The cover/grate should be inspected frequently and replaced at

least every seven years, or if found to be damaged, broken, cracked, missing, or not securely attached.

WARNING

Do not exceed the safe ow rate. Do not increase ow through system by increasing pump size or horsepower.

Do not allow children to sit, play or interact with main drains or suction outlet.

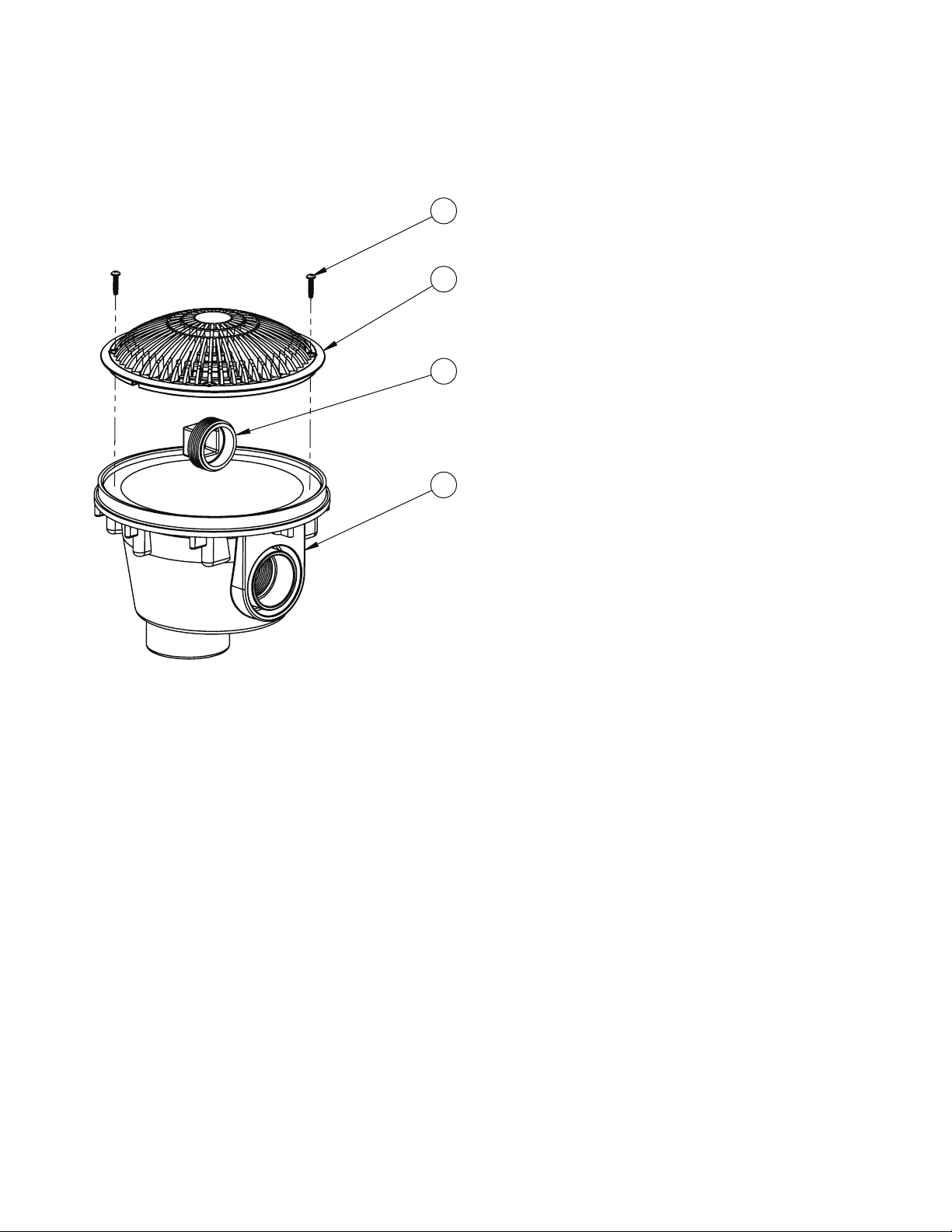

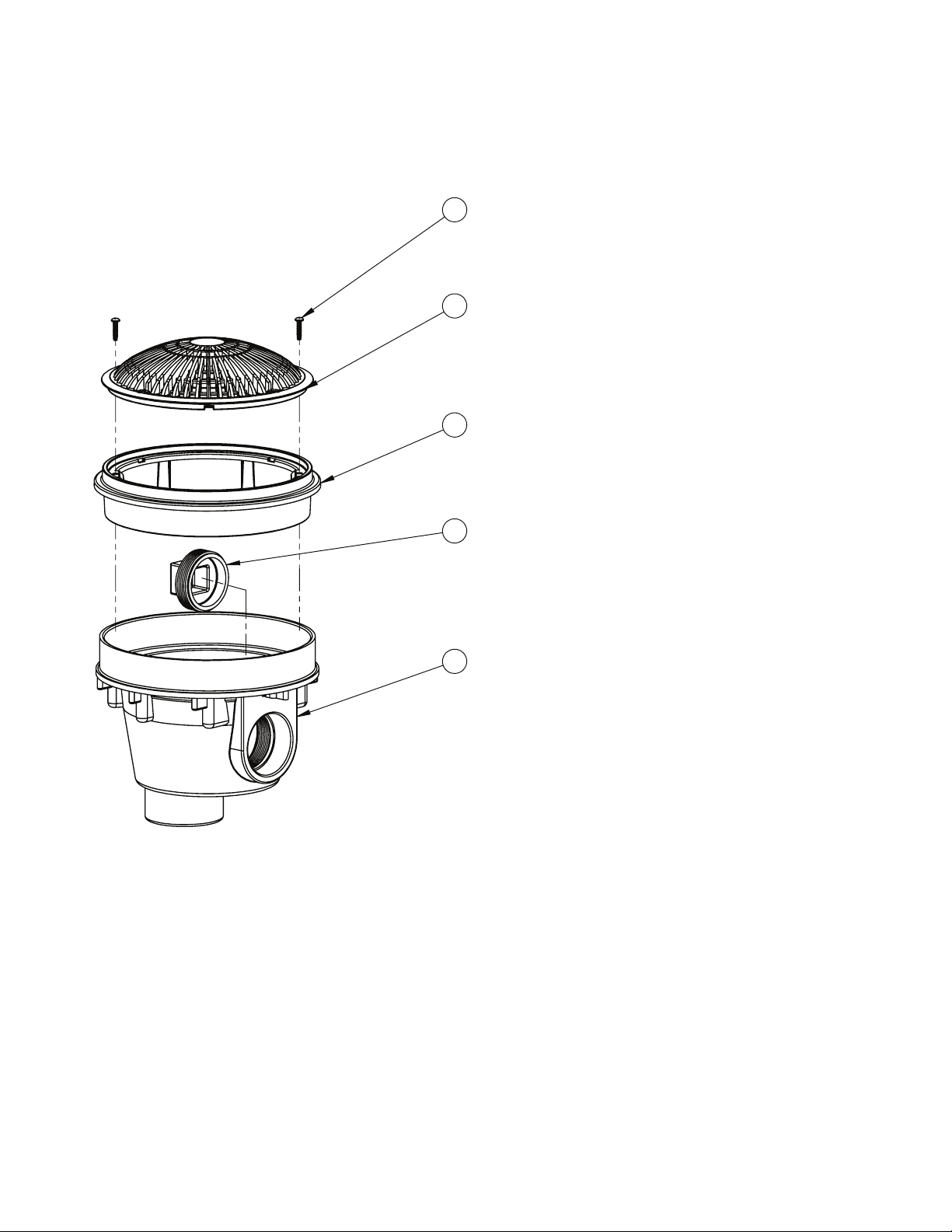

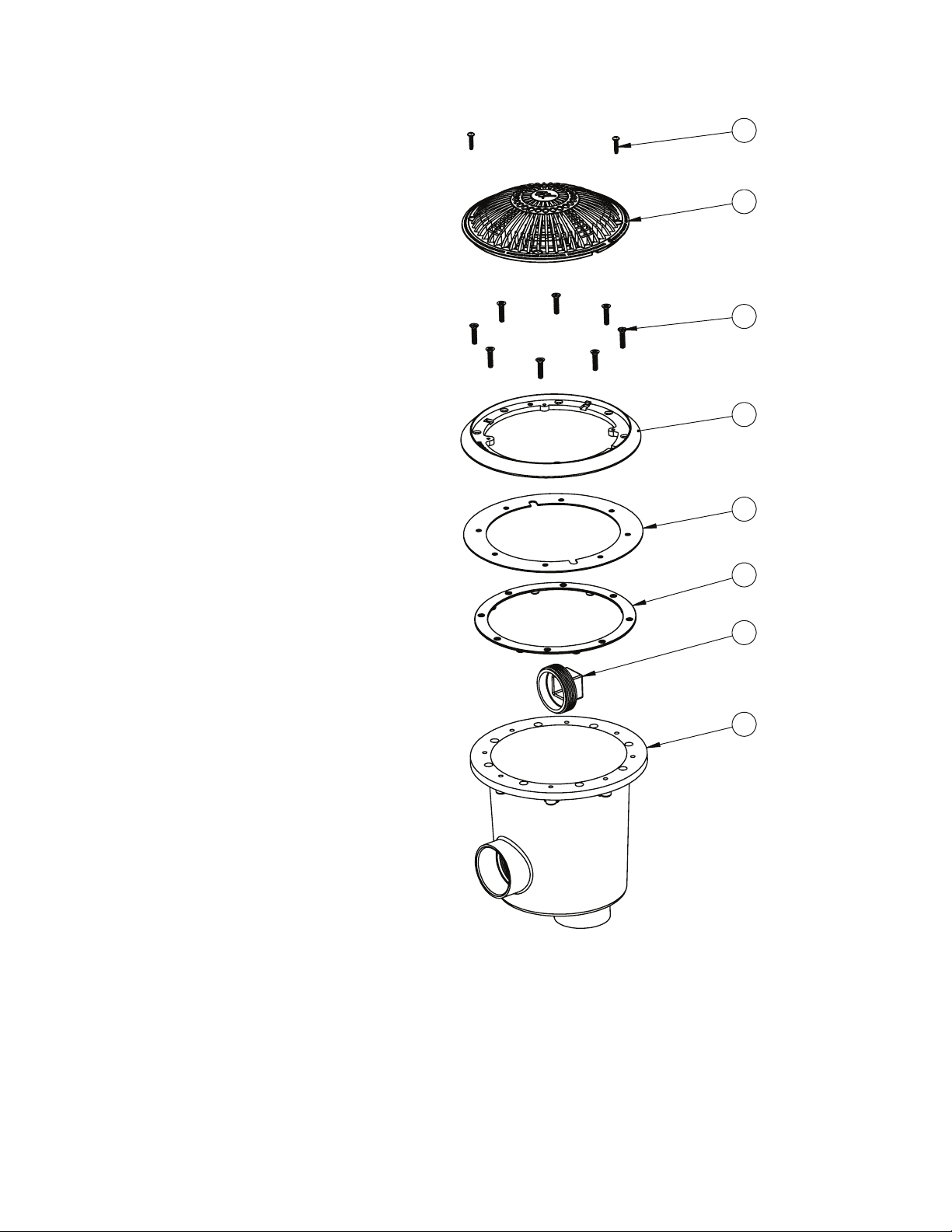

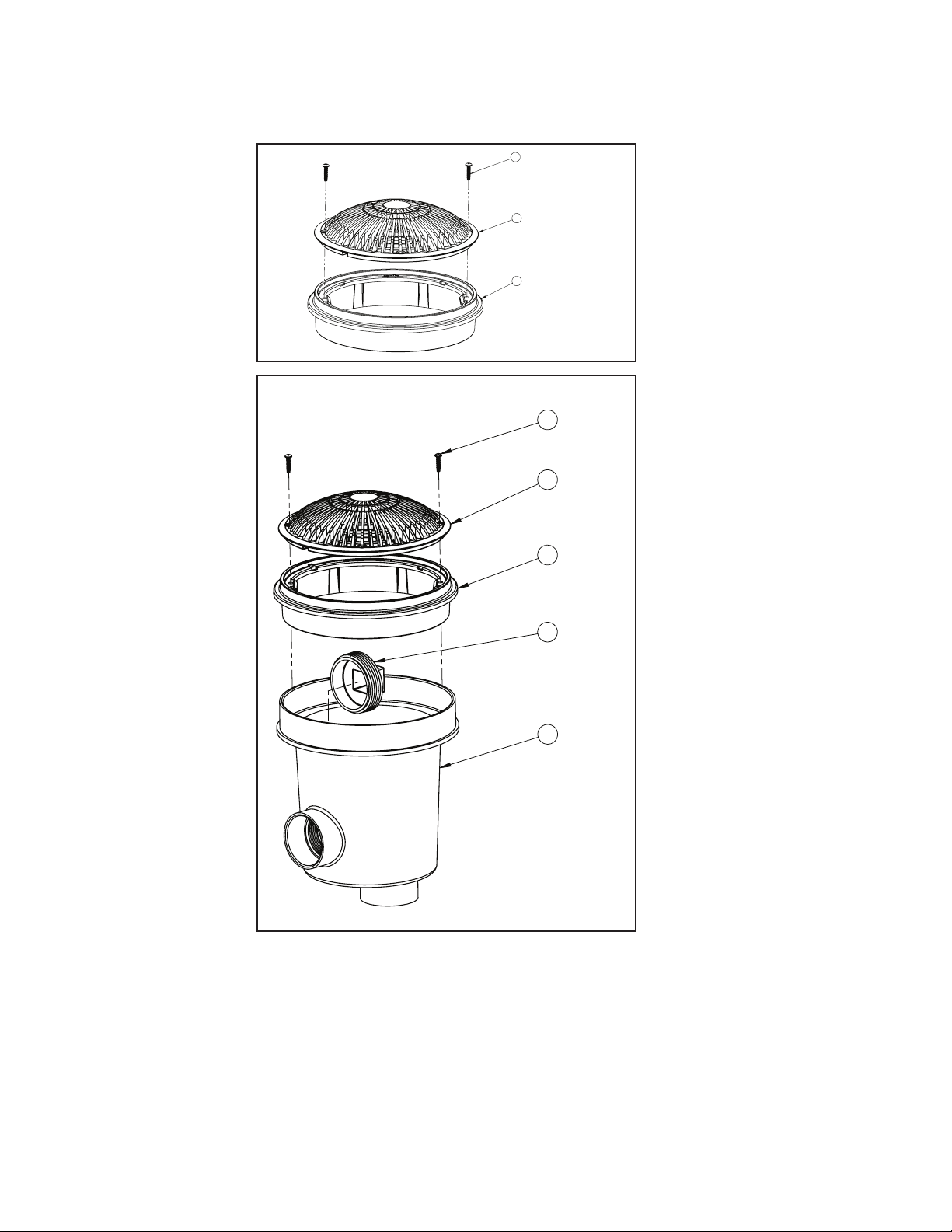

In order to remove the suction cover (for service or winterization), using a Phillips-head screw driver remove

the screws. Inspect both the suction cover and suction tting for any cracks or damages.

Any and all broken or missing parts must be replaced prior to starting spa or pool pump. Never operate spa or

pool without drain cover in place and properly axed, death or serious injury can result.

It is imperative to securely attach the suction cover to the wall ttings (use only the original supplied screws

or obtain original replacements). Do not over tighten the screws. Inspection of fasteners and observation for

damaged/tampered with suction ttings is required.

• A minimum of two functioning suction

outlets per pump must be installed.

Suction outlets in the same plane

(i.e. oor or wall) must be installed a

minimum of three feet (3') / 1 meter

apart, as measured from suction pipe center to suction pipe center.

• Dual suction ttings shall be placed in such locations and distances

to avoid “dual blockage”by a user.

• Dual suction ttings shall not be located on seating areas or on the

backrest for such seating areas.

• The maximum system ow rate shall not exceed the ow rating of

any listed (per ANSI/APSP/ICC-16-2017)

suction outlet cover installed. In the event of one suction outlet being

completely blocked, the remaining suction outlets serving the

system shall have a ow rating capable of the full ow of the

pump(s).

• Never use a pool or spa if any suction outlet component is damaged,

broken, cracked, missing, or not securely attached.

• Replace damaged, broken, cracked, missing, or not securely attached

suction outlet components immediately.

• Two or more suction outlets per pump should be installed in

accordance with latest APSP Standards and CPSC guidelines, and

follow all National, State, and Local codes applicable.

• Replace the suction within 7 years from the installation date.

• Installation of a vacuum release system, which relieves entrapping

suction, is recommended.

TO REDUCE THE RISK OF ENTRAPMENT HAZARDS: