4

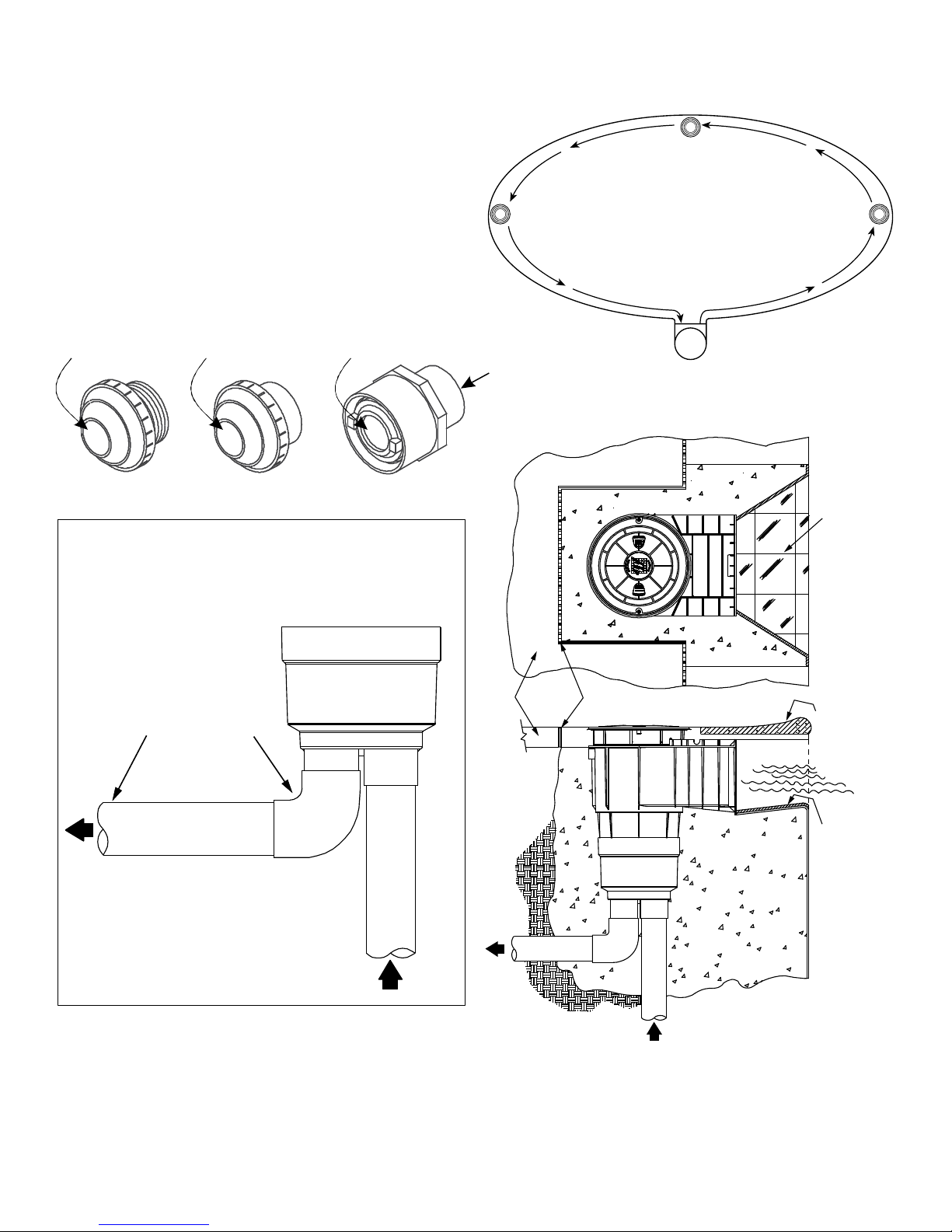

SKIMMER WITH DIVERTER PLATE

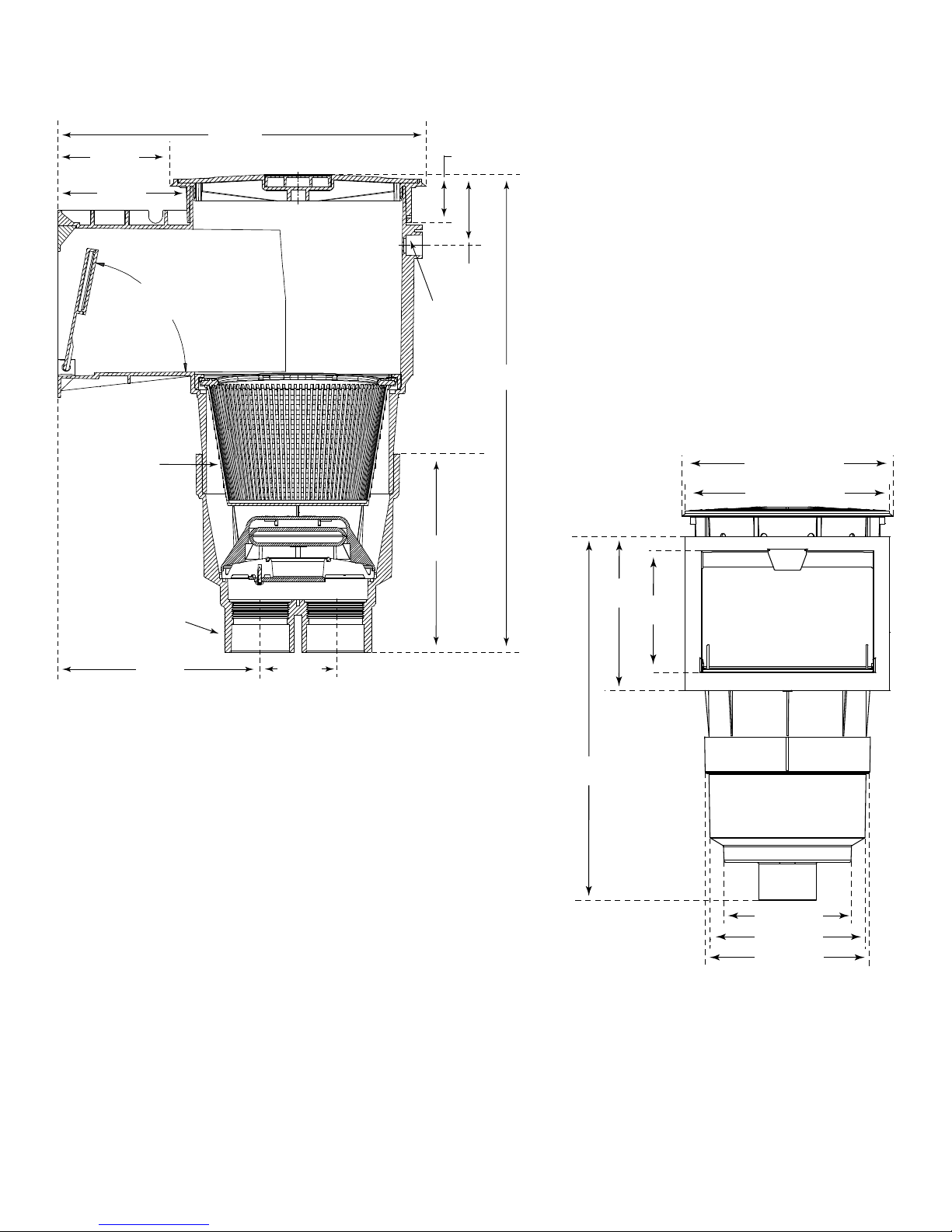

SKIMMER WITH FLOAT VALVE (OPTIONAL)

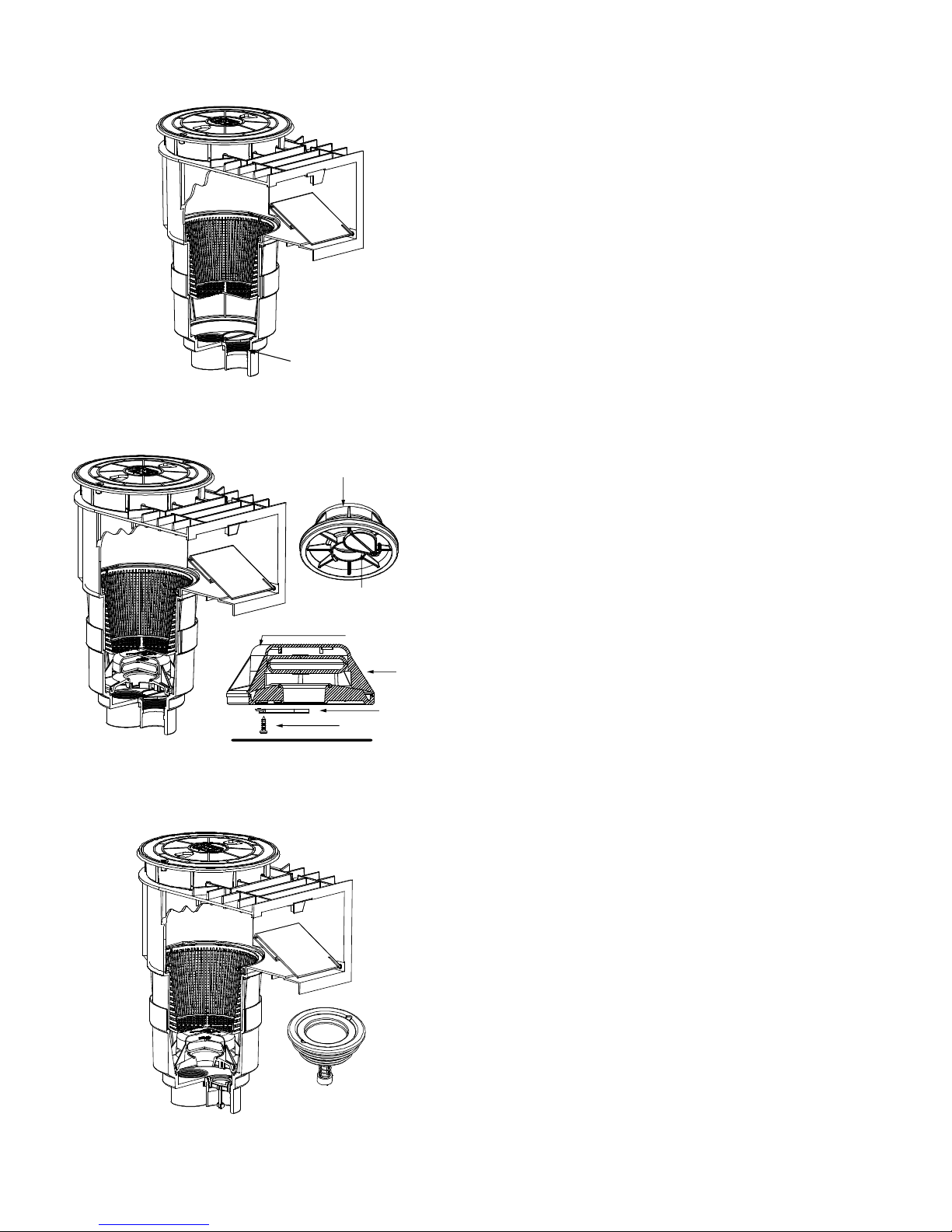

SKIMMER WITH FLOAT VALVE & EQUALIZER VALVE (REQUIRED FOR COMMERCIAL USE)

FLOW ADJUSTMENT

For full follow, slide the diverter plate until it is fully open.To adjust flow, slide diverter

plate to desired position over pump outlet.

TO VACUUM

Remove the cover and the basket. Screw the hose adapter into the pump outlet. Fill

the vacuum hose with water and insert over the hose adapter.

When using the Float Valve Assembly, water is drawn by the suction of the pump from

the surface of the pool and the main drain line.The flow is balanced by the diverter

plate located under the FloatValve Assembly. If obstruction or evaporation occurs,

causing a significant reduction of flow over the weir, the float will automatically snap

shut.This diverts all flow to the pump from the main drain line ad prevents possible air

lock. When the pump is shut off or water level condition has been remedied, the float

will rise back to the top of the assembly, allowing for normal operation of the flow.

TO SWEEP/BRUSH

To divert all suction of the main drain, simply hold the wire above the normal

operation level and allow the float to snap shut. Or lift the Float Valve Assembly out,

close the diverter plate and replace. To reset float after sweeping, turn off pump for

about 10-15 seconds and allows the float to rise back up.

TO VACUUM

Remove the cover, basket, and the Float Valve Assembly. Screw the hose adapter into

the pump outlet. Fill the vacuum hose with water and insert over the hose adapter.

Equalizer Check Valve Assembly screws into the main drain port and is used in

conjunction with the FloatValve Assembly. If the water level drops below the skimmer

opening, or the skimmer flow is obstructed, the float will automatically snap shut and

the equalizer valve will open. This diverts all flow to the pump from the equalizer line

and prevents airlock in the pump. When the pump is off, and the water level condition

is corrected, the float valve will rise and the equalizer valve will open, allowing normal

skimming operation when the pump is restarted.

TO VACUUM

Select one convenient skimmer and remove the cover and FloatValve Assembly. Place

the vacuum plate on the basket. Fill the vacuum hose with water and insert over the

hose adapter. Throttle down the flow from the other skimmer(s) until desired suction

is obtained through vacuum.

Diverter Plate

Float Valve

Float Valve O-Ring

Screw Diverter Plate

Float Valve

Side View

Valve Housing

Diverter Plate

Snaps in 3 Positions

Equalizer Valve

(optional 2" only)

810-0054.0618

©2018 Waterway Plastics