Starting Out

5

QPAC User's ManualGetting Started, Chapter 1

Starting Out

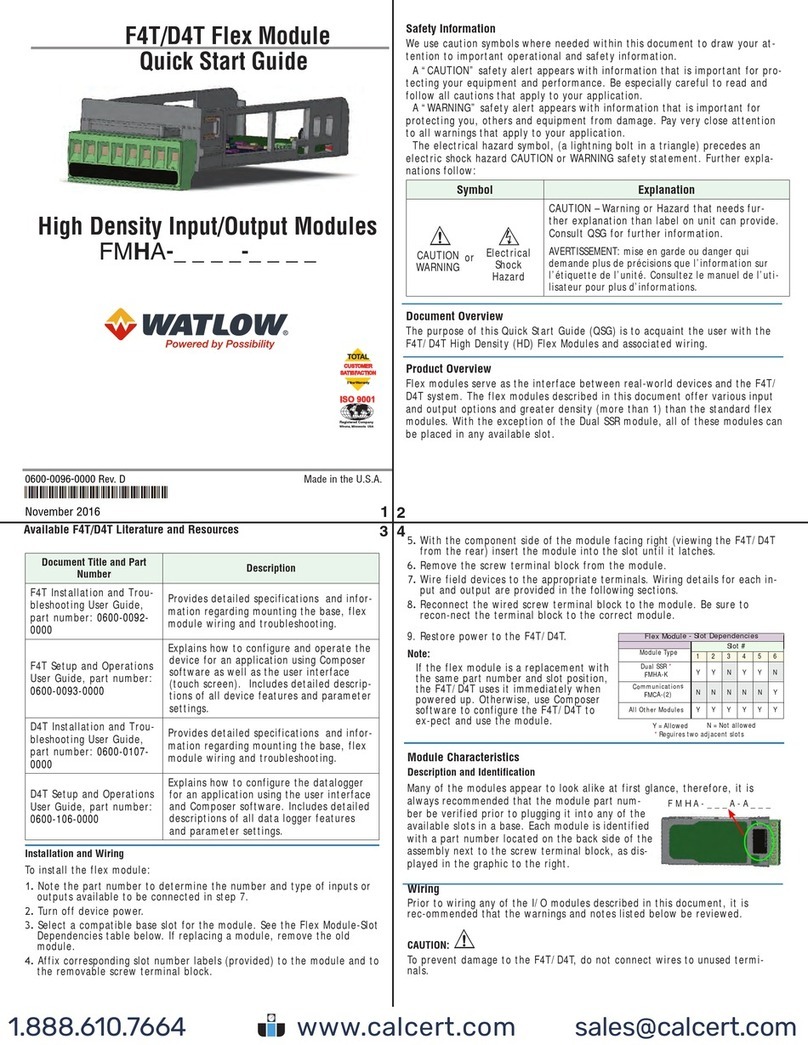

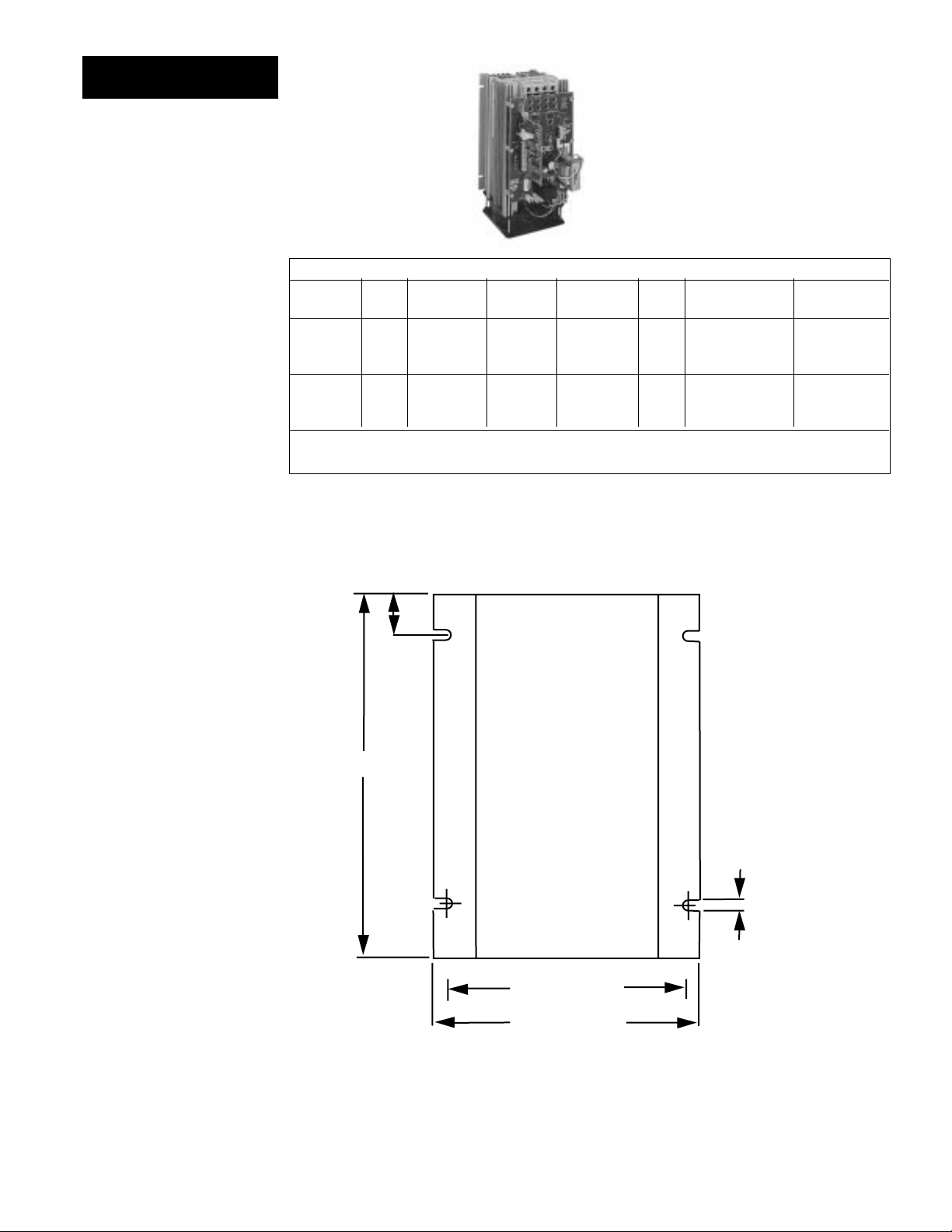

Card. See Figure 2. Power Bases are avaliable in 30 to 300A ratings with

UL508 and C-UL listing and 400-1,000 amps non-agency approved in single

phase, three phase-two leg and three phase-three wire configurations. A

Transformer plugged into the Power Base allows the QPAC to operate on any

voltage from 120 to 480Vac fan. 575Vac consult factory. The plug-in Control

Card sets the QPAC’s firing mode. Control Cards are available in solid state

contactor, burst firing (zero cross), or phase angle firing with a wide variety of

options. This modular approach, using a standard Power Base with plug-in

Transformers and Control Cards, allows power control users, distributors and

OEMs to maintain minimum inventories while still providing rapid service.

The different QPACs provide the types of power control needed for different

power sources and loads. The QPAC-01 is designed for all single phase

power sources and loads. The QPAC-32 is for three phase zero cross applica-

tions such as resistance heating elements, balanced or unbalanced. The

QPAC-33 is best suited for balanced three phase, phase angle applications

requiring soft start or current limiting, or with inductive loads.

Steps To Put Your Power Control To Work

To put your QPAC to work, we suggest the following steps:

•Read the User's Manual.

•Plan your installation and wiring.

•Mount the QPAC.

•Wire your QPAC to the system.

•Start the system and, if applicable, adjust the bias and gain on the QPAC.

•That's all there is to it!

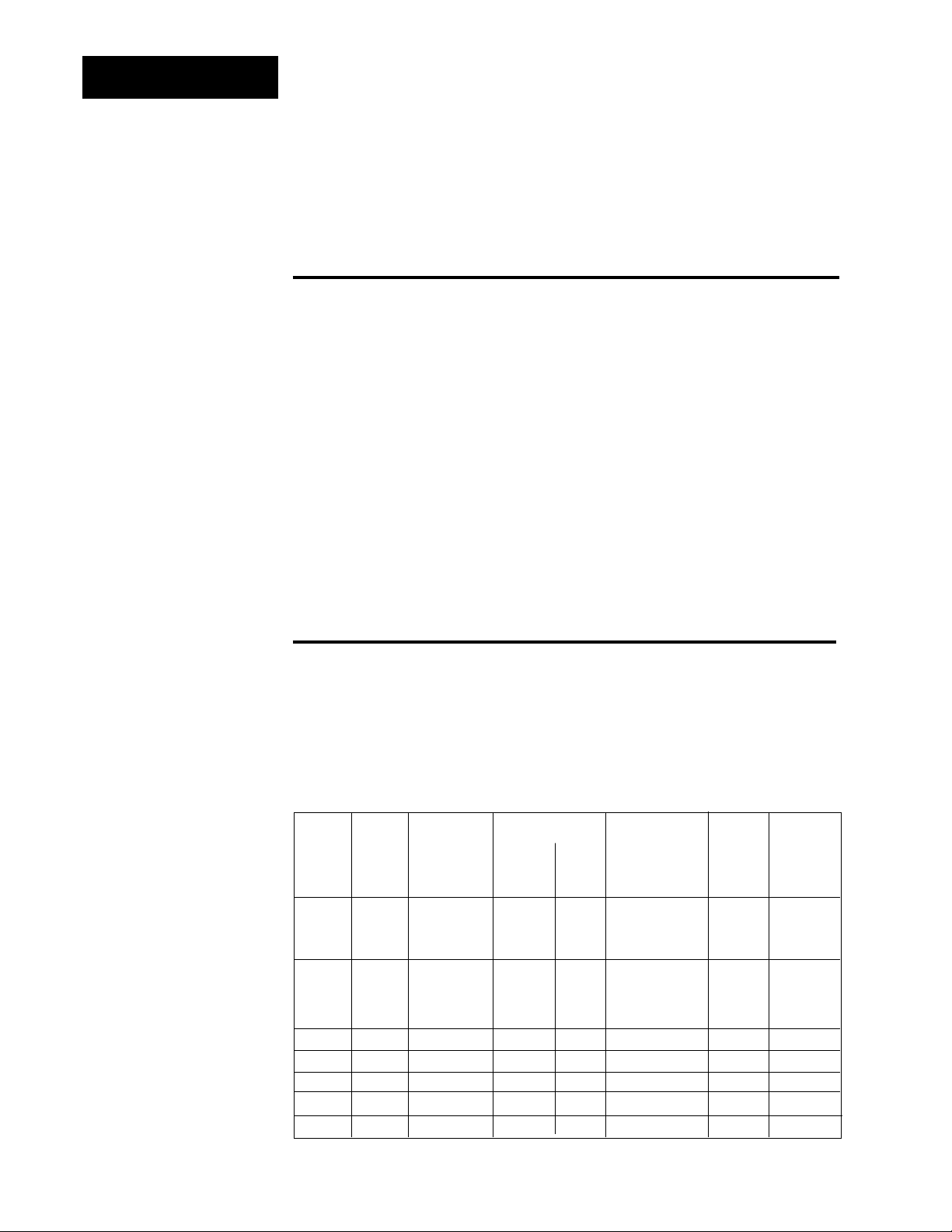

Figure 2 -

QPAC Modularity

Overview

QBF 08-5289

U1

U2

TB1

Control Cards

•Solid state contactor, AC input, CA

•Solid state contactor, DC input, CD

•Burst firing (zero cross) fixed time base, BF

•Burst firing (zero cross) variable time base, BV

•Phase angle control, AF *

•Phase angle control with current limiting, AL *

*Note: For 1Ø and 3Ø, 3 wire controls

only; not for 3Ø, 2 leg controls.

Power Bases With Motherboards

• QPAC-01: 1Ø, 30 - 300A

•QPAC-32: 3Ø, 2 leg, 30 - 300A

•QPAC-33: 3Ø, 3 wire, 30 - 300A

Plug-in transformers (50/60 Hz.)

•120Vac

•208/240Vac

•380Vac

•415Vac

•480Vac

•575Vac, consult factory