Specifications

Controller

• Microprocessor-based, user selectable control modes

• Heat and cool auto-tune for control outputs

• Universal input 1, auxiliary input 2, 4 outputs

• Control outputs user selectable as on-off, P, PI, PID

• Input sample period; Single input 10Hz (100 ms), dual

input 5Hz (200 ms) adjustable digital filter

• Display update; 2Hz (500 ms), adjustable digital filter

• Output update; burst, 0.1 to 999.9 seconds

• Input/Output/Communication isolation

• Displayed in °C, °F, or process units

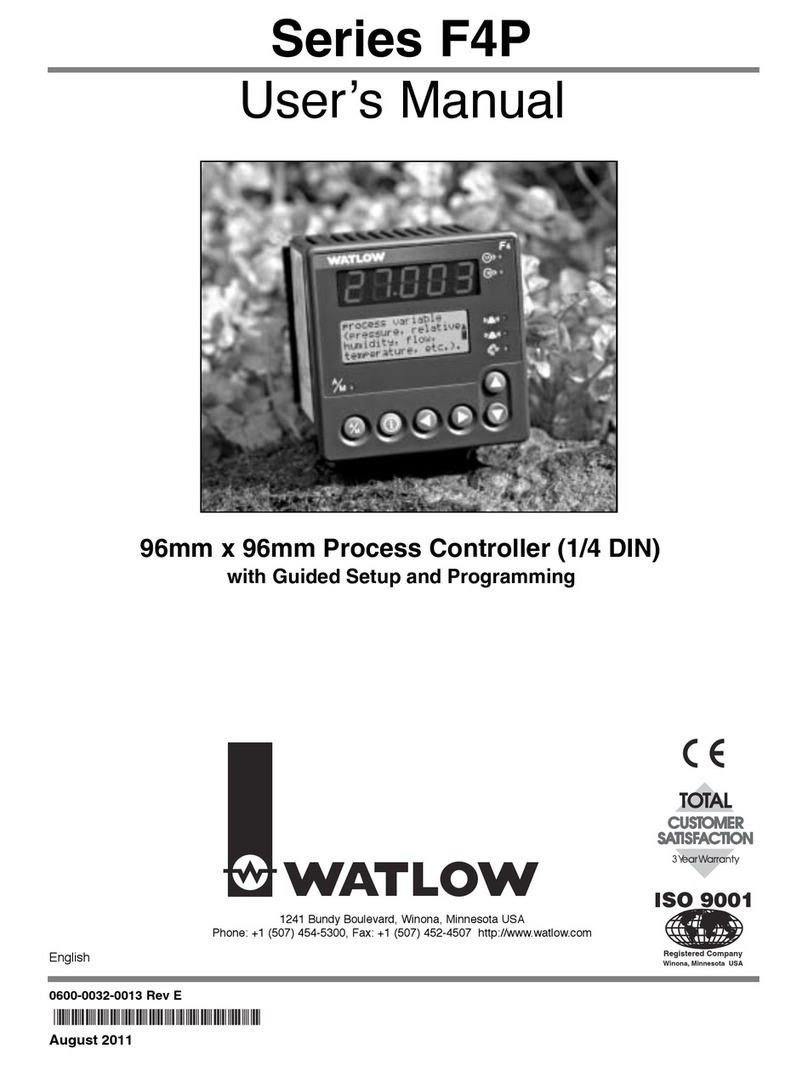

Operator Interface

• Dual 4-digit LED displays: upper 10.2 mm (0.4 in.),

lower 6.2 mm (0.244 in.)

• Advance, Up Arrow, Down Arrow, Infinity tactile keys

Standard Conditions For Specifications

• Ambient temperature 25°C/77°F ±3°C, rated line

voltage, 50 to 60Hz, 0 to 90 percent RH

non-condensing, 15 minute warm-up

Universal Input 1

Thermocouple

• Type J, K, T, N, C (W5), E, Pt 2, D (W3), B, R, S

thermocouple types

• >20MΩinput impedance

• Maximum 20Ωsource resistance

•30µAopen detection bias

RTD

• 2- or 3-wire platinum, 100Ω

• JIS and DIN curves

• Whole or tenth degree indication

• 150µA nominal RTD excitation current

Process

• Range selectable: 0-10VÎ(dc), 0-5VÎ(dc),

1-5VÎ(dc), 0-20mA, 4-20mA,

• Voltage input impedance 20kΩ

• Current input impedance 100Ω

• Minimum current source resistance 1MΩ

• Input resolution 50,000 bits (approx.) at full scale

• mV input impedance 20MΩ

Input 2

Event Input

• Contact or voltage

• 20KΩinput impedance

• Voltage input: event high state 3 to 36VÎ(dc),

event low state 0 to 2VÎ(dc)

•Resistance/contact input: event high state > 23kΩ,

event low state 0 to 2kΩ

Remote Set Point Input: mA or VDC RangeSelectable

• Voltage input impedance 20kΩ

•Current input impedance 100Ω

Output Types

Open Collector/Switched DC

• Open collector configuration:

Maximum voltage 42VÎ(dc)

Maximum current 200mA

Maximum “on” resistance 1.1Ω

Maximum offstate leakage current 100µA

• Switched dc configuration:

Switched dc supply voltage 22 to 28VÎ(dc)

dc supply current limited to 30mA

Solid State Relay

• Optically isolated

• Zero cross switched

• Without contact suppression

• Minimum load current 0.5mA rms

• Maximum current 0.5A rms at 20 to 280VÅ(ac)

• Maximum offstate leakage current 10µA rms

• For resistive loads only, must use RC suppression for

inductive loads

Electromechanical Relay

• Form C contact configuration

•Minimum load current 10mA @ 5VÎ(dc)

•Rated resistiveand inductiveloads: 2A @ 250VÅ(ac)

or 30VÎ(dc) maximum

• Electrical life 100,000 cycles at rated current

• For resistive loads only, must use RC suppression for

inductiveloads

Process

• Range selectable: 0-20mA, 4-20mA, 0-5VÎ(dc),

1-5VÎ(dc), 0-10VÎ(dc)

• Reverse or direct acting

• 0 to 10VÎ(dc) voltage output into 1000Ωminimum load

resistance

•0to 20mA current output into 800Ωmaximum load

resistance

• Resolution:

dc ranges = 2.5mV nominal

mA ranges = 5µA nominal

• Calibration accuracy:

dc ranges = ±15mV

mA ranges = ±30µA

• Temperature stability 100ppm/°C

Retransmit

• Range selectable: 0-20mA, 4-20mA, 0-5VÎ(dc),

1-5VÎ(dc), 0-10VÎ(dc)

• 0 to 10VÎ(dc) voltage output into a 1,000Ωminimum

load resistance

•0to 20mA current output into an 800Ωmaximum load

resistance

• Resolution:

dc ranges = 2.5mV nominal

mA ranges = 5µA nominal

• Calibration accuracy:

dc ranges = ±15mV

mA ranges = ±30µA

• Temperature stability 100ppm/°C