New

PM3

Needed

New

PM3

Needed

New

PM3 text

Needed

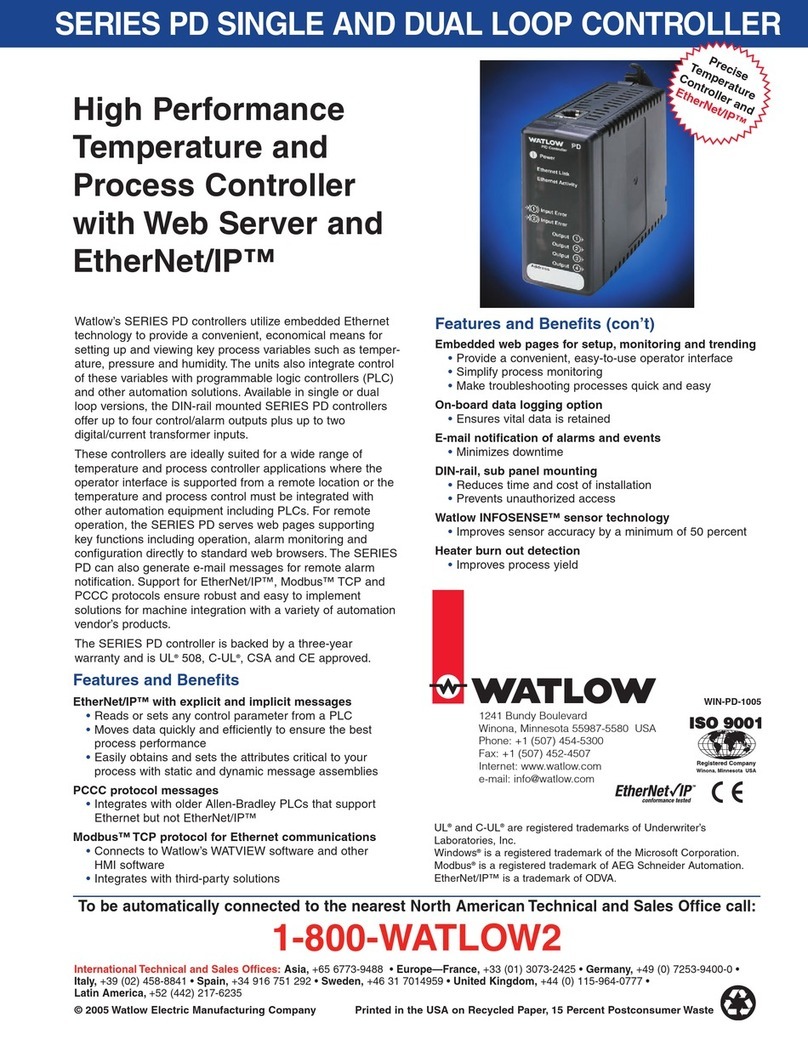

PM3 LEGACY™

PID CONTROLLER

QUICK START

GUIDE

For Configurations:

PM3_ _ [A,C,E,F,K] [A,C,J,K] -_ AAAN _ _

For assistance contact Watlow: www.watlow.com

1-800-WATLOW2 (1-800-928-5692)

wintechsupport@watlow.com

Document #10-43056, Part #2152-6956 December, 2020

1 - MOUNT TO PANEL NOTE: Mounting requires access to

the back of the panel. 2 - CONNECT THE SENSOR INPUT

Connect your sensor as

indicated in the diagram for

your sensor input. Figure

4 is an example illustrating

the connection shown for a

Thermocouple.

Thermocouple

S1 Figure 4: Thermocouple Wiring Example

Platinum 100Ω or 1000Ω RTD

20Ω max. round trip lead resistance

Process Voltage or Current

Voltage: 0 to 50 mV or 0 to 10V@ 20kΩ

Current: 0 to 20 mA @ 100Ω

3 - WIRE OUTPUT 1 Refer to the wiring diagram for your configuration

code and connect to the slots indicated.

PM3_ _ [E] _ _AAAN_ _:

Mechanical Relay 5A Form C Relay

PM3_ _ [C] _ _AAAN_ _: Switched DC or Open Collector

Figure 5: Switched DC Output Wiring

PM3_ _ _ [C ] _ AAAN_ _: Switched DC

4 - WIRE OUTPUT 2

PM3_ _ _ [J] _ AAAN_ _:

Mechanical Relay 5A Form A Relay

PM3_ _ [F] _ _ AAAN_ _: Universal Process

6 - CE DECLARATION OF CONFORMITY

5 - CONNECT POWER

–

+S1

R1

T1

–

+

S1

volts

R1

T1

–

+

S1

amperes

R1

S3

2-wire

S1

T1

S1

R1

T1

S1

S3

S1

S2

3-wire

R1

X1

Y1

Internal Circuit

Common

Switched DC

Open Collector

W

1

Power Supply

Load

Load

–

–

–

+

+

+

–

+

24V(dc)

F1

G1

H1

+

Internal Circuit

Voltage Load Current Loador

Load

Load

–

4 to 20mA

0 to 10 V

L1

K1

J1

Internal Circuit

Common

Normally

Open

Normally

Closed

AC

Load

Load

Internal Circuit Common

Normally Open

L2

K2

AC

Load

Configuration Code:

PM3 _ [1,2,3,4] _ _ _AAAN _ _

1 or 2: 120-240 V (ac)

3 or 4: 24 V (ac or dc)

CAUTION

Do not connect high voltage to a controller

that requires low voltage.

Declaration of Conformity - Series EZ-ZONE

®

PM

WATLOW Electric Manufacturing Company

1241 Bundy Blvd. Winona, MN 55987 USA

Declares that the following product meets the essential requirements of the following European Union Directives by using

the relevant standards show below to indicate compliance.

Designation: Series EZ-ZONE

®

PM (Panel Mount)

roretteLynA()4ro9,8,6,3(MP:srebmuNledoM number)(1, 2, 3 or 4)(A, C, E, F or K) (A, C,

H, J or K) – (Any letter or number)(Any letter or number)(A, C, E, F or K)(A, C,

H, J or K

etaCnoitallatsnI,lortnocerutarepmeT:noitacifissalC

15 to 36 V dc/ 24 V~ac 50/60 Hz

Rated Power Consumption: 10 VA maximum PM3, PM6 Models.

14 VA maximum PM8, PM9, PM4 Models

2014/30/EU Electromagnetic Compatibility Directive

EN 61326-1:2013 Electrical equipment for measurement, control and laboratory use – EMC

requirements

.

IEC 61000-4-2:2008 Electrostatic dischar

IEC 61000-4-3:2007 +A1/2008,

2/2010

Radiated, radio-frequency electromagnetic field immunity 10V/M 80–1000 MHz, 3 V/M

1.4

2.7 GHz

IEC 61000-4-4:2012 Electrical fas

-transient / burst immunit

IEC 61000-4-5:2014 +A1/2017 Sur

IEC 61000-4-6:2013 +

Corri

endum 2015

Immunity to conducted disturbances induced by radio-frequency fields

IEC 61000-4-11:2004 +

e dips, short interruptions and volta

EN 61000-3-2:2014 Limits for harmonic current emissions for equipment 16 Amps per phase

EN 61000-3-3

1

:2013 + A1/2017 Volta

e fluctuations and flicker 16 Amps per phase

SEMI F47-0812 Specification for semiconductor sa

ure R1-1

1

For mechanical relay loads, cycle time may need to be extended up to 160 seconds to meet flicker requirements

depending on load switched and source impedance.

2014/35/EU Low-Voltage Directive

EN 61010-1:2010

2

Safety Requirements of electrical equipment for measurement, control and

laborator

use. Part 1: General requirements

2

Compliance with 3rd Edition requirements with use of external surge suppressor installed on 230 Vac~ power line units.

Recommend mi nimum 1000 V peak to maximum 2000 V peak, 70 joules or better part be used.

Compliant with 2011/65/EU RoHS2 Directive Per 2012/19/EU W.E.E.E Directive

Please Recycle Properly. Models PM(4, 8 or 9)E contain a type BR1225 coin cell battery which shall be

recycled at end of life per 2006/66/EC Battery Directive as amended by 2013/56/EU Directive.

Models PM6XXXX – (B, E, F, G, H, J, K)XXXXXX where (X = any letter or number allowed above)

Include Bluetooth

®

wireless technology and have been reviewed to the following additional requirements.

2014/53/EU Radio Equipment DireĐƟǀĞ (RED)

EN 61010-1:2010

Safety Requirements of electrical equipment for measurement, control and laboratory use.

Part 1: General requirements

Coverin

the essential requirements of article 3.1

or Directive 2014/53/EU

EN 61326-1:2013 Electrical equipment for measurement, control and laboratory use – EMC requirements

(Industrial Immunity, Class A Emissions).

CAUTION: This equipment not intended for use in residential environments and may not provide

adequate protection to radio reception in such environments.

EN 301 489-1 V2.1.1 ElectroMagnetic Compatibility (EMC) standard for radio equipment and services; Part 1: Common

technical requirements; Harmonized Standard covering the essential requirements of article

3.1

of Directive 2014/53/EU and the essential requirements of article 6 of Directive 2014/30/EU

EN 301 489-17 V3.1.1 ElectroMagnetic Compatibility (EMC)

standard for radio equipment and services; Part 17:

Specific conditions for Broadband Data Transmission Systems; Harmonized Standard covering

the essential requirements of article 3.1

of Directive 2014/53/EU

EN 300 328 V1.9.1 Electromagnetic compatibility and Radio spectrum Matters (ERM); Wideband transmission

systems; Data transmission equipment operating in the 2,4 GHz ISM band and using wide band

modulation techniques; Harmonized EN covering the essential requirements of article 3.2 of the

R&TTE Directive

NVLAP Test Report 10928545H-

EN 300 328 V2.1.1 Additional Receiver blocking test for to cover requirements for 2014/53/EU.

NVLAP Test Report 11649468H-E

Contains Module FCC ID: VPYLBZY Part 15C 2.

Contains Module IC: 772C-LBZY RSS 210

Output Power: Frequency Range 2402.0 - 2480.0

Output Power 0.001 Watts Antenna gain: -0.6 dBi PCB antenna

Dou

SU,atosenniM,anoniWathcuK

Name of Authorized Representative Place of Issue

Director of Operations Ma

2018

Signature of Authorized Representative

Internal Circuit

Common

W

2

Y2

Load

–

+

24V(dc)

PM3_ _ _ [C] _ AAAN_ _: Switched DC

Internal Circuit Common

Normally Open

L2

K2

AC

Load

PM3_ _ _ [K] _ AAAN_ _:

Solid State Relay 0.5A, Form A

Figure 3

Figure 1

are on the sides (see figure 2), then slide the base over

the back of the controller.

5. Slide the mounting bracket over the controller with the

screws aligned to the collar base. Push the bracket gently

but firmly until the hooks snap into the slots in the case.

6. Tighten the two #6-19 x 1.5 in. screws with a phillips

screwdriver until the device is flush to the panel

(3 to 4 in-lbs torque).

7. Reinstall the terminal connectors to their original locations.

(Or first connect field wiring as indicated in this guide and

then reinstall the connectors).

1. Make the panel cutout using

the measurements in figure 1.

2. Remove the green terminal

connectors and the mounting

collar assembly.

3. Insert the controller into the

panel cutout from the front.

4. Orient the collar base so the flat side

faces front and the screw openings

Figure 2

Collar Base

Terminal

Connectors

Mounting

Bracket

Internal Circuit Common

Normally Open

L1

K1

AC

Load

PM3_ _ [K] _ _ AAAN_ _:

Solid State Relay 0.5A, Form A

45.2 mm

(1.78 in.)

22.4 mm

(0.88 in.)

New

PM3

Needed

New

PM3

Needed

New

PM3 text

Needed

PM3 LEGACY™

PID CONTROLLER

QUICK START

GUIDE

For Configurations:

PM3_ _ [A,C,E,F,K] [A,C,J,K] -_ AAAN _ _

For assistance contact Watlow: www.watlow.com

1-800-WATLOW2 (1-800-928-5692)

wintechsupport@watlow.com

Document #10-43056, Part #2152-6956 December, 2020

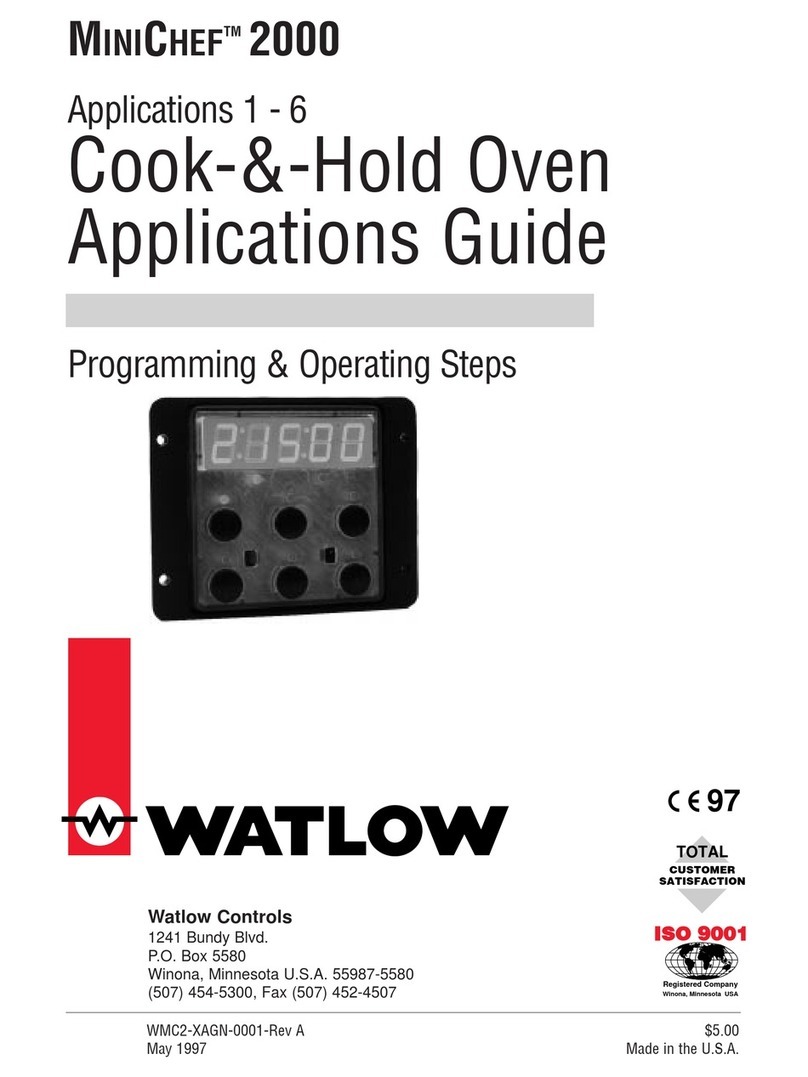

1 - MOUNT TO PANEL NOTE: Mounting requires access to

the back of the panel. 2 - CONNECT THE SENSOR INPUT

Connect your sensor as

indicated in the diagram for

your sensor input. Figure

4 is an example illustrating

the connection shown for a

Thermocouple.

Thermocouple

S1 Figure 4: Thermocouple Wiring Example

Platinum 100Ω or 1000Ω RTD

20Ω max. round trip lead resistance

Process Voltage or Current

Voltage: 0 to 50 mV or 0 to 10V@ 20kΩ

Current: 0 to 20 mA @ 100Ω

3 - WIRE OUTPUT 1 Refer to the wiring diagram for your configuration

code and connect to the slots indicated.

PM3_ _ [E] _ _AAAN_ _:

Mechanical Relay 5A Form C Relay

PM3_ _ [C] _ _AAAN_ _: Switched DC or Open Collector

Figure 5: Switched DC Output Wiring

PM3_ _ _ [C ] _ AAAN_ _: Switched DC

4 - WIRE OUTPUT 2

PM3_ _ _ [J] _ AAAN_ _:

Mechanical Relay 5A Form A Relay

PM3_ _ [F] _ _ AAAN_ _: Universal Process

6 - CE DECLARATION OF CONFORMITY

5 - CONNECT POWER

–

+S1

R1

T1

–

+

S1

volts

R1

T1

–

+

S1

amperes

R1

S3

2-wire

S1

T1

S1

R1

T1

S1

S3

S1

S2

3-wire

R1

X1

Y1

Internal Circuit

Common

Switched DC

Open Collector

W

1

Power Supply

Load

Load

–

–

–

+

+

+

–

+

24V(dc)

F1

G1

H1

+

Internal Circuit

Voltage Load Current Loador

Load

Load

–

4 to 20mA

0 to 10 V

L1

K1

J1

Internal Circuit

Common

Normally

Open

Normally

Closed

AC

Load

Load

Internal Circuit Common

Normally Open

L2

K2

AC

Load

Configuration Code:

PM3 _ [1,2,3,4] _ _ _AAAN _ _

1 or 2: 120-240 V (ac)

3 or 4: 24 V (ac or dc)

CAUTION

Do not connect high voltage to a controller

that requires low voltage.

Declaration of Conformity - Series EZ-ZONE

®

PM

WATLOW Electric Manufacturing Company

1241 Bundy Blvd. Winona, MN 55987 USA

Declares that the following product meets the essential requirements of the following European Union Directives by using

the relevant standards show below to indicate compliance.

Designation: Series EZ-ZONE

®

PM (Panel Mount)

roretteLynA()4ro9,8,6,3(MP:srebmuNledoM number)(1, 2, 3 or 4)(A, C, E, F or K) (A, C,

H, J or K) – (Any letter or number)(Any letter or number)(A, C, E, F or K)(A, C,

H, J or K

etaCnoitallatsnI,lortnocerutarepmeT:noitacifissalC

15 to 36 V dc/ 24 V~ac 50/60 Hz

Rated Power Consumption: 10 VA maximum PM3, PM6 Models.

14 VA maximum PM8, PM9, PM4 Models

2014/30/EU Electromagnetic Compatibility Directive

EN 61326-1:2013 Electrical equipment for measurement, control and laboratory use – EMC

requirements

.

IEC 61000-4-2:2008 Electrostatic dischar

IEC 61000-4-3:2007 +A1/2008,

2/2010

Radiated, radio-frequency electromagnetic field immunity 10V/M 80–1000 MHz, 3 V/M

1.4

2.7 GHz

IEC 61000-4-4:2012 Electrical fas

-transient / burst immunit

IEC 61000-4-5:2014 +A1/2017 Sur

IEC 61000-4-6:2013 +

Corri

endum 2015

Immunity to conducted disturbances induced by radio-frequency fields

IEC 61000-4-11:2004 +

e dips, short interruptions and volta

EN 61000-3-2:2014 Limits for harmonic current emissions for equipment 16 Amps per phase

EN 61000-3-3

1

:2013 + A1/2017 Volta

e fluctuations and flicker 16 Amps per phase

SEMI F47-0812 Specification for semiconductor sa

ure R1-1

1

For mechanical relay loads, cycle time may need to be extended up to 160 seconds to meet flicker requirements

depending on load switched and source impedance.

2014/35/EU Low-Voltage Directive

EN 61010-1:2010

2

Safety Requirements of electrical equipment for measurement, control and

laborator

use. Part 1: General requirements

2

Compliance with 3rd Edition requirements with use of external surge suppressor installed on 230 Vac~ power line units.

Recommend minimum 1000 V peak to maximum 2000 V peak, 70 joules or better part be used.

Compliant with 2011/65/EU RoHS2 Directive Per 2012/19/EU W.E.E.E Directive

Please Recycle Properly. Models PM(4, 8 or 9)E contain a type BR1225 coin cell battery which shall be

recycled at end of life per 2006/66/EC Battery Directive as amended by 2013/56/EU Directive.

Models PM6XXXX – (B, E, F, G, H, J, K)XXXXXX where (X = any letter or number allowed above)

Include Bluetooth

®

wireless technology and have been reviewed to the following additional requirements.

2014/53/EU Radio Equipment DireĐƟǀĞ (RED)

EN 61010-1:2010

Safety Requirements of electrical equipment for measurement, control and laboratory use.

Part 1: General requirements

Coverin

the essential requirements of article 3.1

or Directive 2014/53/EU

EN 61326-1:2013 Electrical equipment for measurement, control and laboratory use – EMC requirements

(Industrial Immunity, Class A Emissions).

CAUTION: This equipment not intended for use in residential environments and may not provide

adequate protection to radio reception in such environments.

EN 301 489-1 V2.1.1 ElectroMagnetic Compatibility (EMC) standard for radio equipment and services; Part 1: Common

technical requirements; Harmonized Standard covering the essential requirements of article

3.1

of Directive 2014/53/EU and the essential requirements of article 6 of Directive 2014/30/EU

EN 301 489-17 V3.1.1 ElectroMagnetic Compatibility (EMC)

standard for radio equipment and services; Part 17:

Specific conditions for Broadband Data Transmission Systems; Harmonized Standard covering

the essential requirements of article 3.1

of Directive 2014/53/EU

EN 300 328 V1.9.1 Electromagnetic compatibility and Radio spectrum Matters (ERM); Wideband transmission

systems; Data transmission equipment operating in the 2,4 GHz ISM band and using wide band

modulation techniques; Harmonized EN covering the essential requirements of article 3.2 of the

R&TTE Directive

NVLAP Test Report 10928545H-

EN 300 328 V2.1.1 Additional Receiver blocking test for to cover requirements for 2014/53/EU.

NVLAP Test Report 11649468H-E

Contains Module FCC ID: VPYLBZY Part 15C 2.

Contains Module IC: 772C-LBZY RSS 210

Output Power: Frequency Range 2402.0 - 2480.0

Output Power 0.001 Watts Antenna gain: -0.6 dBi PCB antenna

Dou

SU,atosenniM,anoniWathcuK

Name of Authorized Representative Place of Issue

Director of Operations Ma

2018

Signature of Authorized Representative

Internal Circuit

Common

W

2

Y2

Load

–

+

24V(dc)

PM3_ _ _ [C] _ AAAN_ _: Switched DC

Internal Circuit Common

Normally Open

L2

K2

AC

Load

PM3_ _ _ [K] _ AAAN_ _:

Solid State Relay 0.5A, Form A

Figure 3

Figure 1

are on the sides (see figure 2), then slide the base over

the back of the controller.

5. Slide the mounting bracket over the controller with the

screws aligned to the collar base. Push the bracket gently

but firmly until the hooks snap into the slots in the case.

6. Tighten the two #6-19 x 1.5 in. screws with a phillips

screwdriver until the device is flush to the panel

(3 to 4 in-lbs torque).

7. Reinstall the terminal connectors to their original locations.

(Or first connect field wiring as indicated in this guide and

then reinstall the connectors).

1. Make the panel cutout using

the measurements in figure 1.

2. Remove the green terminal

connectors and the mounting

collar assembly.

3. Insert the controller into the

panel cutout from the front.

4. Orient the collar base so the flat side

faces front and the screw openings

Figure 2

Collar Base

Terminal

Connectors

Mounting

Bracket

Internal Circuit Common

Normally Open

L1

K1

AC

Load

PM3_ _ [K] _ _ AAAN_ _:

Solid State Relay 0.5A, Form A

45.2 mm

(1.78 in.)

22.4 mm

(0.88 in.)

New

PM3

Needed

New

PM3

Needed

New

PM3 text

Needed

PM3 LEGACY™

PID CONTROLLER

QUICK START

GUIDE

For Configurations:

PM3_ _ [A,C,E,F,K] [A,C,J,K] -_ AAAN _ _

For assistance contact Watlow: www.watlow.com

1-800-WATLOW2 (1-800-928-5692)

wintechsupport@watlow.com

Document #10-43056, Part #2152-6956 December, 2020

1 - MOUNT TO PANEL NOTE: Mounting requires access to

the back of the panel. 2 - CONNECT THE SENSOR INPUT

Connect your sensor as

indicated in the diagram for

your sensor input. Figure

4 is an example illustrating

the connection shown for a

Thermocouple.

Thermocouple

S1 Figure 4: Thermocouple Wiring Example

Platinum 100Ω or 1000Ω RTD

20Ω max. round trip lead resistance

Process Voltage or Current

Voltage: 0 to 50 mV or 0 to 10V@ 20kΩ

Current: 0 to 20 mA @ 100Ω

3 - WIRE OUTPUT 1 Refer to the wiring diagram for your configuration

code and connect to the slots indicated.

PM3_ _ [E] _ _AAAN_ _:

Mechanical Relay 5A Form C Relay

PM3_ _ [C] _ _AAAN_ _: Switched DC or Open Collector

Figure 5: Switched DC Output Wiring

PM3_ _ _ [C ] _ AAAN_ _: Switched DC

4 - WIRE OUTPUT 2

PM3_ _ _ [J] _ AAAN_ _:

Mechanical Relay 5A Form A Relay

PM3_ _ [F] _ _ AAAN_ _: Universal Process

6 - CE DECLARATION OF CONFORMITY

5 - CONNECT POWER

–

+S1

R1

T1

–

+

S1

volts

R1

T1

–

+

S1

amperes

R1

S3

2-wire

S1

T1

S1

R1

T1

S1

S3

S1

S2

3-wire

R1

X1

Y1

Internal Circuit

Common

Switched DC

Open Collector

W

1

Power Supply

Load

Load

–

–

–

+

+

+

–

+

24V(dc)

F1

G1

H1

+

Internal Circuit

Voltage Load Current Loador

Load

Load

–

4 to 20mA

0 to 10 V

L1

K1

J1

Internal Circuit

Common

Normally

Open

Normally

Closed

AC

Load

Load

Internal Circuit Common

Normally Open

L2

K2

AC

Load

Configuration Code:

PM3 _ [1,2,3,4] _ _ _AAAN _ _

1 or 2: 120-240 V (ac)

3 or 4: 24 V (ac or dc)

CAUTION

Do not connect high voltage to a controller

that requires low voltage.

Declaration of Conformity - Series EZ-ZONE

®

PM

WATLOW Electric Manufacturing Company

1241 Bundy Blvd. Winona, MN 55987 USA

Declares that the following product meets the essential requirements of the following European Union Directives by using

the relevant standards show below to indicate compliance.

Designation: Series EZ-ZONE

®

PM (Panel Mount)

roretteLynA()4ro9,8,6,3(MP:srebmuNledoM number)(1, 2, 3 or 4)(A, C, E, F or K) (A, C,

H, J or K) – (Any letter or number)(Any letter or number)(A, C, E, F or K)(A, C,

H, J or K

etaCnoitallatsnI,lortnocerutarepmeT:noitacifissalC

15 to 36 V dc/ 24 V~ac 50/60 Hz

Rated Power Consumption: 10 VA maximum PM3, PM6 Models.

14 VA maximum PM8, PM9, PM4 Models

2014/30/EU Electromagnetic Compatibility Directive

EN 61326-1:2013 Electrical equipment for measurement, control and laboratory use – EMC

requirements

.

IEC 61000-4-2:2008 Electrostatic dischar

IEC 61000-4-3:2007 +A1/2008,

2/2010

Radiated, radio-frequency electromagnetic field immunity 10V/M 80–1000 MHz, 3 V/M

1.4

2.7 GHz

IEC 61000-4-4:2012 Electrical fas

-transient / burst immunit

IEC 61000-4-5:2014 +A1/2017 Sur

IEC 61000-4-6:2013 +

Corri

endum 2015

Immunity to conducted disturbances induced by radio-frequency fields

IEC 61000-4-11:2004 +

e dips, short interruptions and volta

EN 61000-3-2:2014 Limits for harmonic current emissions for equipment 16 Amps per phase

EN 61000-3-3

1

:2013 + A1/2017 Volta

e fluctuations and flicker 16 Amps per phase

SEMI F47-0812 Specification for semiconductor sa

ure R1-1

1

For mechanical relay loads, cycle time may need to be extended up to 160 seconds to meet flicker requirements

depending on load switched and source impedance.

2014/35/EU Low-Voltage Directive

EN 61010-1:2010

2

Safety Requirements of electrical equipment for measurement, control and

laborator

use. Part 1: General requirements

2

Compliance with 3rd Edition requirements with use of external surge suppressor installed on 230 Vac~ power line units.

Recommend minimum 1000 V peak to maximum 2000 V peak, 70 joules or better part be used.

Compliant with 2011/65/EU RoHS2 Directive Per 2012/19/EU W.E.E.E Directive

Please Recycle Properly. Models PM(4, 8 or 9)E contain a type BR1225 coin cell battery which shall be

recycled at end of life per 2006/66/EC Battery Directive as amended by 2013/56/EU Directive.

Models PM6XXXX – (B, E, F, G, H, J, K)XXXXXX where (X = any letter or number allowed above)

Include Bluetooth

®

wireless technology and have been reviewed to the following additional requirements.

2014/53/EU Radio Equipment DireĐƟǀĞ (RED)

EN 61010-1:2010

Safety Requirements of electrical equipment for measurement, control and laboratory use.

Part 1: General requirements

Coverin

the essential requirements of article 3.1

or Directive 2014/53/EU

EN 61326-1:2013 Electrical equipment for measurement, control and laboratory use – EMC requirements

(Industrial Immunity, Class A Emissions).

CAUTION: This equipment not intended for use in residential environments and may not provide

adequate protection to radio reception in such environments.

EN 301 489-1 V2.1.1 ElectroMagnetic Compatibility (EMC) standard for radio equipment and services; Part 1: Common

technical requirements; Harmonized Standard covering the essential requirements of article

3.1

of Directive 2014/53/EU and the essential requirements of article 6 of Directive 2014/30/EU

EN 301 489-17 V3.1.1 ElectroMagnetic Compatibility (EMC)

standard for radio equipment and services; Part 17:

Specific conditions for Broadband Data Transmission Systems; Harmonized Standard covering

the essential requirements of article 3.1

of Directive 2014/53/EU

EN 300 328 V1.9.1 Electromagnetic compatibility and Radio spectrum Matters (ERM); Wideband transmission

systems; Data transmission equipment operating in the 2,4 GHz ISM band and using wide band

modulation techniques; Harmonized EN covering the essential requirements of article 3.2 of the

R&TTE Directive

NVLAP Test Report 10928545H-

EN 300 328 V2.1.1 Additional Receiver blocking test for to cover requirements for 2014/53/EU.

NVLAP Test Report 11649468H-E

Contains Module FCC ID: VPYLBZY Part 15C 2.

Contains Module IC: 772C-LBZY RSS 210

Output Power: Frequency Range 2402.0 - 2480.0

Output Power 0.001 Watts Antenna gain: -0.6 dBi PCB antenna

Dou

SU,atosenniM,anoniWathcuK

Name of Authorized Representative Place of Issue

Director of Operations Ma

2018

Signature of Authorized Representative

Internal Circuit

Common

W

2

Y2

Load

–

+

24V(dc)

PM3_ _ _ [C] _ AAAN_ _: Switched DC

Internal Circuit Common

Normally Open

L2

K2

AC

Load

PM3_ _ _ [K] _ AAAN_ _:

Solid State Relay 0.5A, Form A

Figure 3

Figure 1

are on the sides (see figure 2), then slide the base over

the back of the controller.

5. Slide the mounting bracket over the controller with the

screws aligned to the collar base. Push the bracket gently

but firmly until the hooks snap into the slots in the case.

6. Tighten the two #6-19 x 1.5 in. screws with a phillips

screwdriver until the device is flush to the panel

(3 to 4 in-lbs torque).

7. Reinstall the terminal connectors to their original locations.

(Or first connect field wiring as indicated in this guide and

then reinstall the connectors).

1. Make the panel cutout using

the measurements in figure 1.

2. Remove the green terminal

connectors and the mounting

collar assembly.

3. Insert the controller into the

panel cutout from the front.

4. Orient the collar base so the flat side

faces front and the screw openings

Figure 2

Collar Base

Terminal

Connectors

Mounting

Bracket

Internal Circuit Common

Normally Open

L1

K1

AC

Load

PM3_ _ [K] _ _ AAAN_ _:

Solid State Relay 0.5A, Form A

45.2 mm

(1.78 in.)

22.4 mm

(0.88 in.)