Safe Circulation

Heater Ideal for

Contamination-Free

Gas and Liquid

Heating

The new CAST-X 500 from Watlow®is a small, lightweight

circulation heater ideal for heating gas or liquids in

demanding applications. Even in its compact size, the

CAST-X 500 is extremely powerful with operating

temperatures up to 350°F (177°C) and working fluid

pressure up to 3000psi. The CAST-X 500 heater is

available in a variety of wattages and can be shipped in

just a few days.

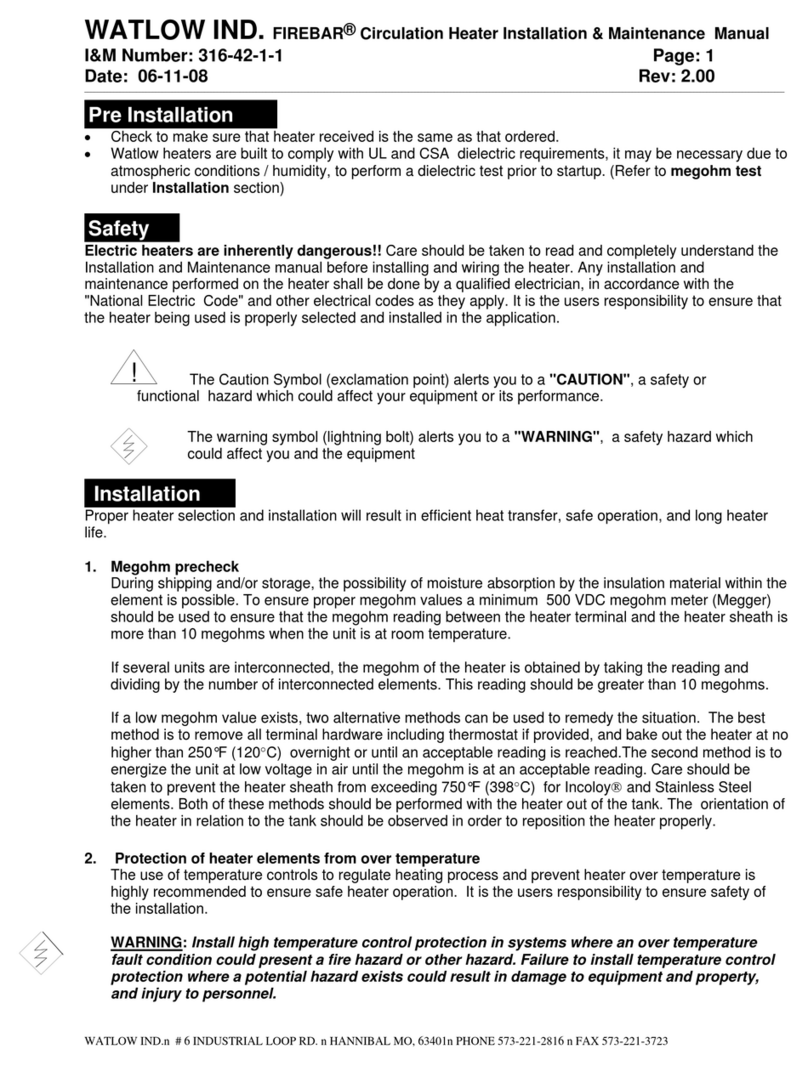

The CAST-X 500 heater is constructed of a helical coiled

tube cast into an aluminum body with a replaceable cartridge

heater installed in the center. The cartridge heater can be

replaced with various wattages to suit your equipment’s

changing requirements.

The aluminum body serves as the heat transfer media

between the cartridge heater and the coiled tube where

the fluid is being heated. The aluminum mass acts as a

“thermal flywheel” and ensures accurate temperature control

of the fluid to prevent degradation.

The unique, non-weld construction of the CAST-X 500 allows

it to be used where thermally sensitive materials are being

heated such as paints, resins and flammable materials.

The heater is suited for applications where fluid cleanliness

is critical, because the material being heated never comes in

contact with the heater. This is a performance requirement in

foodservice, semiconductor and analytical industries.

CAST-X 500 CIRCULATION HEATERS

BAT-CX500-0807

Features and Benefits

Fluid path constructed independent from heater sheath

•Assures an intrinsically safe thermal solution

•Prevents fluid contamination upon heater failure

•Heats sensitive materials safely because the material

heated does not come in contact with heating elements

Robust cast-in aluminum construction

•Assures longer heater life

•Offers accurate temperature control

Non-welded construction

•Minimizes potential leakage

•Offers an economical priced package

•Provides high pressure operation to 3000 psi

•Self draining when mounted vertically

Standard stainless steel fluid path

•

Assures material compatibility with many different materials

Replaceable cartridge heater

•Offers low cost of ownership due to ability to replace

heater in field

•Assures faster delivery and customization from factory

Compact size

•Assures quick response due to low mass (2.375 lbs)

•Saves real estate in equipment because of small footprint

© 2007 Watlow Electric anufacturing Company

Applications

•Solvent heating

•Air, CO2and nitrogen heating

•DI water heating

•Packaging sterilization

•Hydrogen peroxide vaporization

•Analytical instrumentation

•Sample heating

•Foodservice

•Steam generation

•Glycol heating for CIP systems

•Pasteurization

•Printing ink heating

•Diesel and fuel heating

To be automatically connected to the nearest North American Technical Sales Office:

1-800-WATLOW2 • www.watlow.com • info@watlow.com

International Technical Sales Offices: Australia, +61-3-9335-6449 • China, +86-21-6106-1425 • France, +33 1 3073-2425 •

Germany, +49 (0) 7253-9400-0 • Italy, +39 (0) 2 458-8841 • Japan, +81-3-3518-6630 • Korea, +82-2-2628-5770 • alaysia, +60-3-8074-8741 •

exico, +52 (442) 217-6235 • Shanghai, +86-21-6106-1425 • Singapore, +65-6773-9488 • Spain, +34 91 675 1292 • Sweden, +46 35-27-1166 •

Taiwan, +886-7-288-5168 • United Kingdom, +44 (0) 115-964-0777

Watlow®is a registered trademark of Watlow Electric Manufacturing Company.