Watts bar switchcontrol SC-M2 Installation instructions

switchcontrol ®

bar-gmbh.de

Operating, mounting and adjusting instruction

Original operating manual

2

Safety Regulations:

Read these instructions before commis-

sioning the equipment!

The bar switchcontrol is designed for ope-

ration as an optical display for intermediary

and end positions from position indicators,

on industrial fittings. Just before reaching

the end position, an electrical signal is ge-

nerated, e.g. for feedback to the process

control point.

All of these units are to be installed only

by suitably qualified skilled personnel. The

hereby quoted regulations are to be strictly

adhered to.

Incorrect handling or non-adherence to the

designated usage can lead to the loss of

function of the unit described in this docu-

ment!

• Work on the bar switchcontrol must be

always s carried out without connection

to the voltage supply and under accep-

tance and adherence to the current na-

tional and international Safety Regulati-

ons. Also disconnect the compressed air

supply to the actuator!

• Before installing, i.e. commissioning the

unit described in this document, check

the technical parameters, especially the

electrical connection values of the ap-

plied sensors.

• Take note of the diagram on the inside

of the housing.

• A change in the actuator pivoting angle

requires renewed adjustment of the unit

described in this documentation.

• Do not mount the unit described in this

document with the cable glands pointing

upwards.

• The unit may only be operated when it is

correctly closed according to this docu-

mentation.

• In Ex-areas, adjustment work on the ope-

ned unities only to be carried out under

the following conditions:

•You fulfil the authorised regulations

(informing the fire brigade etc.)

•You follow exactly the local necessa-

ry protective measures! (Continuous

measurement of combustible at-

mosphere etc.)

•You avoid electrostatic charges,

even the metallic housing on the

sensors.

• When laying cables in Ex-areas, make

sure you adhere to DIN EN 60079-14.

• In explosion-protected areas, it may be

necessary to provide direct sunlight

protection, to shield the surface of the

3

Safety Regulations: Table of Contents:

unit from the overheating effects of too

much direct sunlight. In explosion- pro-

tected areas, only intrinsically safe so-

lenoid valves may be connected in the

bar-switchcontrol.

• Do not use thinners or abrasive medi-

ums to clean the unit, the plastic win-

dow may lose its clarity.

• The bar-switchcontrol is not designed

to be used for the transport, leverage

in any way of actuators or automatic

valves. It is also not a step or climbing

help for fitters. The fixings can break

under these loads.

bar GmbH

Auf der Hohl 1

D - 53547 Dattenberg / Germany

Tel.: +49 (0)2644-9607-0

Fax: +49 (0)2644-960735

E-Mail: bar-info@wattswater.com

Safety Regulations 2

Technical Data – general 4

Technical Data –

bar-switchcontrol types 5

Declaration of Conformity 6

ATEX-Declaration of Conformity 7

Mounting

• mounting feet 8

• actuator 9

Connecting

• Electrical connection 10

• Connection of round initiator 10

• Connection of micro switch 11

• Connection of slot initiator 11

Setting

• switching cams 13

• round initiators 14

• position indicator 14

• micro-switches 15

• slot initiators 15

Accessories and spare parts 16

Accessories and spare parts

(Mounting instructions) 17

4

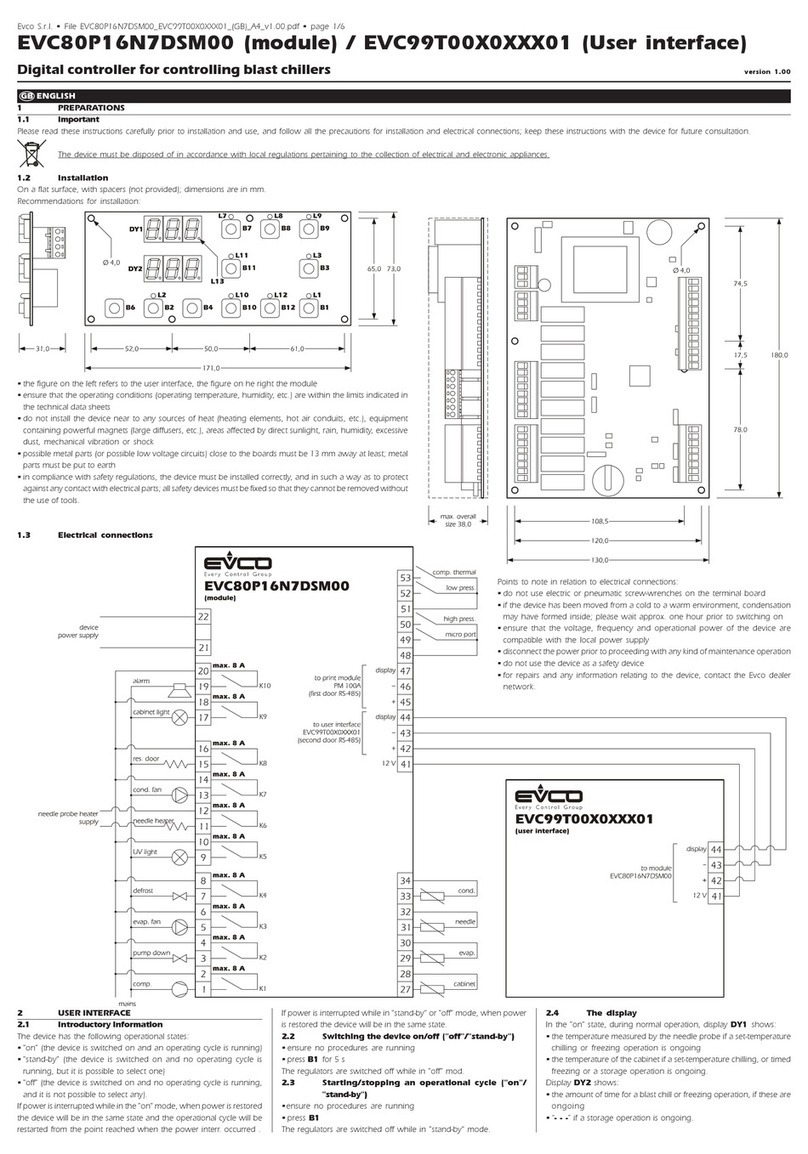

Technical Data – General Data:

Fixing dimensions: acc. to VDI/VDE 3845 for flange plates 30 x 80 mm

and 30 x 130 mm

Materials:

Housing:

Viewing glass:

Screws:

Blanking plugs and

cable glands:

Plate:

Aluminium, resin-coated

Polycarbonat (PC), with ATEX model anti-static coated

stainless steel A2

Polyamid (PA)

ABS+PC, ATEX model excl. plate

Protection type: IP 67

Temperature range: -20°C to + 70°C;

low temperature: -40°C to +70°C on request

Cable glands: M20x1,5; clamping range 7–13 mm

Cable: Ø7–13 mm, max. 2,5 mm2,

screw terminal with protection

Weight: 0,8 kg

Display and

switching range: 0 to 180° pivoting angle

5

Technical Data – bar-switchcontrol types:

Micro-switch: Type SC-M2

Voltage range:

Constant current:

Switching function:

to 250 VAC

5A

changer, contacts precious metal-coated

Inductive round sensor: Type SC-D2 (Signal „OPEN + CLOSED“); Type SC-DA (Signal

„OPEN“); Type SC-DZ (Signal „CLOSED“)

Voltage range:

Operating current IL:

Idling current Io:

Switching function:

10–30 VDC

0–100 mA

< 15 mA

PNP closer, with yellow switch position display (LED)

Inductive round

sensor NAMUR:

Type SC-N2 (Signal „OPEN + CLOSED“)

Type SC-NA (Signal „OPEN“)

Type SC-NZ (Signal „CLOSED“)

Rated voltage Uo:

Current input:

Switching function:

Switch type:

ATEX-Identification:

8 VDC

damped < 1 mA; undamped > 3 mA

NAMUR opener, yellow switch position display (LED)

Pepperl + Fuchs NCN4-12GM35-N0

EC-type examination certificate PTB 00 ATEX 2048 X and

ZELM 03 ATEX 0128 X (You find the ATEX certificate also on

the Internet: www.pepperl-fuchs.com)

II 2GD EEx ia IIB T6 EEx iaD 21

Inductive slot sensor NAMUR: Type SC-NS2 (Signal „OPEN + CLOSED“); Type SC-NSA

(Signal „OPEN“); Type SC-NSZ (Signal „CLOSED“)

Display and switching range: 0 to 180° pivoting angle

Rated voltage Uo:

Current input:

Switching function:

Switch type:

ATEX-Identification:

8 VDC

damped < 1 mA; undamped > 3 mA

NAMUR opener, yellow switch position display (LED)

Pepperl + Fuchs SC3,5-N0-yellow

EC-type examination certificate PTB 00 ATEX 2219 X and

ZELM 03 ATEX 0128 X (You find the ATEX certificate also on

the Internet: www.pepperl-fuchs.com)

II 2GD EEx ia IIB T6 EEx iaD 21

6

Declaration of Conformity:

Name and address of the manufacturer: bar pneumatische Steuerungssysteme GmbH

Auf der Hohl 1, 53547 Dattenberg/Germany

Herewith we declare, that product described below

Product denomination: Limit switch box for pneumatic

double piston actuator

Model/type: bar-switchcontrol type SC-M2 and SC-D2

was manufactured according to the following standards:

Where appropriate Harmonised Standards used:

Low-voltage switchgear and controlgear EN 60947-5-2

Part 5-2: Control circuit devices and switching elements

Low-voltage switchgear and controlgear EN 60947-5-6

Part 5-6: Control circuit devices and switching elements, DC interface for proximity sensors

The products according to the following directives:

2006/95/EC Low voltage directive

2004/108/EC EMC directive

2006/95/EC CE marking directive

Please take care about the technical data and the relevant warning and safety notices.

The person authorised to compile the technical documentation

(must be established within EU):

Dattenberg, 08.04.2010 Scholl, Klaus, Manager R&D

Place, Date Surname, first name and function of signatory Signature

7

ATEX-Declaration of Conformity:

Name and address of the manufacturer: bar pneumatische Steuerungssysteme GmbH

Auf der Hohl 1, 53547 Dattenberg/Germany

Herewith we declare, that product described below

Product denomination: Limit switch box for pneumatic double piston actuator

Model/type: bar-switchcontrol type SC-N2, SC-NS2, SCE-N2

in association with used switches: SC 3,5-N0; SJ 3,5-SN; NCN 4-12GK35-N0;

NCN 4-12GM35-N0; NJ 2-12GK-N; NJ 4-12GK-SN;

NS 5002

was manufactured according to the following standards:

Where appropriate Harmonised Standards used:

Low-voltage switchgear and controlgear EN 60947-5-2;

Part 5-2: Control circuit devices and switching elements

Low-voltage switchgear and controlgear EN 60947-5-6;

Part 5-6: Control circuit devices and switching elements

Explosive atmospheres EN 60079-0; Part 0: Equipment – General requirements

Electrical apparatus for explosive gas atmospheres EN 60079-25;

Part 25: Intrinsically safe systems

The products according to the following directives:

94/9/EC ATEX-directive

2006/95/EC Low voltage directive

2004/108/EC EMC directive

2006/95/EC CE-marking directive

Designation: II 2 G Ex ia IIB T6

II 2 D Ex ia D21 T 120 °C

Please take care about the technical data and the relevant warning and safety notices.

The person authorised to compile the technical documentation

(must be established within EU):

Dattenberg, 04.10.2010 Scholl, Klaus, Manager R&D

Place, Date Surname, first name and function of signator y Signature

8

Mounting the bar-switchcontrol:

Adjusting the mounting feet

The unit described in this documentation

is equipped with mounting feet, which can

be mounted onto all actuators fitted with

an interface acc. to VDI/VDE 3845.

The dimensional width is achieved by ha-

ving the feet mounted either inwards or

outwards (Fig. 1 and 2), and the height

is adjusted by sliding the mounting feet

along the guides on the side of the housing

(Fig. 3).

Fig. 1: Feet mounted inwards:

Fixing dimensions 80 x 30 mm

Fig. 3: Height adjustment for different

pinion lengths 20, 30, 40 and 50 mm

Fig. 2: Feet mounted outwards:

Fixing dimensions 130 x 30 mm

9

Mounting on the actuator:

When mounting the limit switch box onto the actuator interface, it is impe-

rative to take note of the rotational direction of the actuator pinion, becau-

se incorrect mounting of round initiators can lead to damage to the initiator

and drive. Take care for stress-free mounting of the bar-switchcontrol with

the actuator!

Attention!

1a. For the mounting on actuators which

correspond with the provided adjusted

mounting measures unscrew the back-

sided screws, set the bar-switchcon-

trol onto the actuator and tighten the

screws again.

1b. For mounting onto actuators, whose

connection dimensions differ from tho-

se of the mounting feet dimensions

provided, then follow the instructions

below:

• Loosen and remove the two fixing

screws.

• Slide the mounting feet along the

guide to reach the desired height.

• If distance between the mounting

feet is not correct, then change over

to reach the desired width.

• Take fixing screws and washers and

fix in position.

2. Place the bar-switchcontrol onto the

actuator interface and fix in position

using the fixing screw set provided.

10

The supply cable must be fixed in positi-

on and protected against rotation! Cable

and supply lines must comply with DIN EN

60079-14 in Ex-areas! The circuit diagram

on the inside of the housing gives the con-

nection system. Take care to observe the

connection data for the switch and/or in-

itiator.

Connecting:

Electrical connection for the bar-switchcontrol

Connecting round initiators (Type SC-D and SC-N)

Connection diagram for round initiators (Type SC-N and SC-D)

onto terminal 3 and 4 (Type SC-

N), and/or 4,5 and 6 (Type SC-D)

onto terminal 1 and 2 (Type SC-

N), and/or 1,2 and 3 (Type SC-D)

inductive switch, NAMUR round initiator:

(Type SC-N)

inductive switch, 3-core:

(Type SC-D)

11

Connecting:

Connecting micro-switches

(Type SC-M)

• The upper operating cam/actuating

element actuates the higher ranking

switch on the bar-switchcontrol (termi-

nal 4-6), which is preferentially alloca-

ted the „Open-Position“ of the valve.

• The lower operating cam/actuating ele-

ment actuates the lower-ranking switch

on the bar bar-switchcontrol (terminal

1-3), which is preferentially allocated

the „Closed-Position“ of the valve.

• The micro-switches are changers. The

exact terminal connection plan is de-

pendant on the wiring system of the

whole plant.

Connection diagram

micro-switch (Type SC-M)

12

All types of bar-switchcon-

trol ordered with internal

connection of solenoid valves

(S1-connection) have an 8-fold

terminal block. Connection of terminals 7

and 8 is as per connection diagram.

Solenoid valve con-

nection equal for all

types.

Connection of slot initiators (type SC-NS) – Attention!

Connecting:

Connecting slot initiators (Type SC-NS)

Connection diagram slot initiator

(Type SC-NS)

onto terminal 3 and 4

onto terminal 1 and 2

Inductive switch, NAMUR slot

initiator: (Typ SC-NS)

13

Adjusting the switching cam:

• Before setting the switching

cams in actuators with ad-

justable pivoting angle-valve

and actuator must be adju-

sted beforehand.

• A suitable electrical testing device is

required for setting, e.g. Pepperl and

Fuchs ST03 (not for use in Ex-areas).

• Before working on the bar-switchcon-

trol, make sure the voltage supply is

isolated!

• In the setting instructions, it is assumed

that the valve (looking from above the

axis) closes in a clockwise direction.

• During the setting, it is best to remove

the white position indicator from the

camshaft.

• Inside every bar-switchcontrol there is

an adjusting tool (E) for the cam set-

ting – this can be found in the actuating

shaft.

• After the position setting, the adjusting

tool (E) must not be rotated. Additionally,

it must be then pulled out and inserted

into the deeper recess of the camshaft,

so that the „Flag“ lies over the other re-

cess (Fig. C), otherwise it is not possible

to replace the position indicator.

• After successfully comple-

ting the setting, the position

indicator is inserted onto

the cam-shaft, whereby the

cam is finally snapped in

place.

• Screw the cover back in po-

sition before restarting to re-

place the position indicator.

General Instructions – Attention!

Fig. A: The lower switching

cam can be set, when the

adjusting tool is pressed

down as far as marking

1 as delivered!

Fig. B: To set the upper

switching cam, adjusting

tool is pressed into the

opposite-lying recess as

far as marking 2.

Fig. C:

14

Setting the round initiators and Position Indicator:

Setting the round initiators

• According to the General Instructions,

the appropriate actuating device for the

Open- i.e. Closed-Position in the basic

position of the automatic valve is to be

set, so that it generates a signal a few

degrees before reaching the end positi-

on.

• Then set the other actuating device

slightly less than 90° to the first actua-

ting device (see picture this page).

• Take the valve to the other end position,

and set the actuating device, so it also

generates a signal a few degrees before

reaching the end position.

• The red marking is there to indicate the

open way for the valve. Simply bend

and tear of f the unused segment from

the red T-formed display clip.

15

Setting the micro-switches and slot initiators:

Carry out the setting according to Matrix. Attention! In the setting instructions, it is

assumed that the valve (looking from above the axis) closes in a clockwise direction!

Kennzeichnung bar-switch-

control

1 = Article number

2 = Protection class

3 = Type designation bar-

switchcontrol

4 = Type designation switch

5 = Number of operating

instructions (only for

Ex-protected units)

6 = Ex-Identification

7 = Delivery date

Carry out the setting according to Matrix. Attention!

In the setting instructions, it is assumed that the valve

(looking from above the axis) closes in a clockwise direction!

Identification bar-switchcontrol

1 = Article number

2 = Protection class

3 = Type designation switchcontrol

4 = Type designation switch

5 = Number of operating instructions

(only for Ex-protected units)

6 = Ex-Identification

7 = Delivery date

Setting the micro-switches and slot initiators

15

1 2

3

4

5

6

7

1

2

3

4

5

6

7

Micro switches Operated switching

Slot initiators Damped switching

Valve

„OPEN“ „CLOSED“

2-fold

Micro switches Not operated switching

Slot initiators Undamped switching

Valve

„OPEN“ „CLOSED“

2-fold

Identification

bar-switchcontrol

I II III IV V VI

X XI XIIVII VIII IX

1. Open the valve.

2. Insert the adjusting tool according to fig. B/page 12.

3a. The switch is already operated/damped: (I)

Turn the adjusting tool anticlockwise until the switch

is no longer actuated/damped. (II)

Keep on turning until switching point is reached. (III)

3b. The switch is not operated/damped: (II)

Turn the adjusting tool anticlockwise until switching

point is reached. (III)

1. Open the valve.

2. Insert the adjusting tool according

to fig. B/page 12

3a. The switch is not operated/damped: (VII)

Turn the adjusting tool anticlockwise until the switch

is no longer actuated/damped. (XIII)

Keep on turning until switching point is reached. (IX)

3b. The switch is already operated/damped: (VIII)

Turn the adjusting tool anticlockwise until swit-

ching point is reached. (IX)

1. Close the valve.

2. Insert the adjusting tool according to fig. A/page 12.

3a. The switch is already operated/damped: (IV)

Turn the adjusting tool clockwise until the switch

is no longer operated/damped. (V) Keep on

turning until switching point is reached. (VI)

3b. The switch is not operated/damped: (V)

Turn the adjusting tool clockwise until switching

point is reached. (VI)

1. Close the valve.

2. Insert the adjusting tool according

to fig. A/page 12.

3a. The switch is not operated/damped: (X)

Turn the adjusting tool clockwise until the switch

is operated/damped. (XI) Keep on turning until

switching point is reached. (XII)

3b. The switch is already operated/damped: (XI)

Turn the adjusting tool clockwise until switching

point is reached. (XII)

16

Name: Consisting of:

Spare part set No. 1

Housing feet

2 pieces

2 pieces

4 pieces

8 pieces

12 pieces

Left feet

Right feet

Screw M5 short

Screw M5 long

Washer

Spare part set No. 2

Display window

3 pieces

3 pieces

3 pieces

3 pieces

3 pieces

3 pieces

Display glass

O-Ring for display glass

O-Ring for cover

Position indicator

Clip

Cap

Spare part set No. 3

Actuating shaft Micro-switch

3 pieces

3 pieces

3 pieces

6 pieces

Actuating shaft

O-Ring

Adjusting tool

Switching cam

Spare part set No. 4

Actuating shaft Round Initiator

3 pieces

3 pieces

3 pieces

6 pieces

Actuating shaft

O-Ring

Adjusting tool

Switching cam; Actuating device Round initiator

Spare part set No. 5

Actuating shaft Slot Initiator

3 pieces

3 pieces

3 pieces

6 pieces

Actuating shaft

O-Ring

Adjusting tool

Switching cam; Actuating device Slot initiator

Spare part set No. 6

Pressure compensating element

3 pieces

3 pieces

3 pieces

Pressure compensating element

Counter-nut

Reducer

Spare part set No. 7

Solenoid valve switching

3 pieces

3 pieces

6 pieces

6 pieces

Terminal block 8x

Flathead screw

Locking washer; Cable gland

Counter-nut

Spare part set No. 8

Micro-switch

2 pieces

2 pieces

2 pieces

Micro-switch with connecting cable

Nut M3

Screw M3

Round Initiator NBN 4-12GM40-E2 1 piece Round initiator

Round Initiator NCN 4-12GM35-NO 1 piece Intrinsically Round initiator for Ex-Areas

Slot Initiator SC 3,5-N0 Gelb 1 piece Intrinsically Slot initiator for Ex-Areas

Accessories and spare parts:

17

Mounting instructions for accessories and spare parts:

Before working on the bar-switchcontrol,

isolate the unit from the voltage supply!

Spare part set 2: Display window

The display window can be pressed out

using the thumbs. Pull the O-ring over the

new display window before replacing the

spare part in position.

Spare part set 3:

Actuating shaft micro-switch

• Disconnect bar-switchcontrol and remo-

ve from the actuator.

• Press together the snap lock on the

actuating shaft and pull out the shaft.

Press snap lock together here. Equip

the spare actuating shaft with the sup-

plied parts and insert in the housing.

• Mount the bar-switchcontrol, set the cams,

and remake the electrical connection.

Type: SC-M2

Connect to lower switch

at 1, 2, 3. Connect to upper

switch at 4, 5, 6.

1 bue

2 black

3 brown

4 brown

5 black

6 blue

The assignment of end positions to

the switches is depending from the

adjustment of the switching cams.

The assignment of end positions to

the switches is depending from the

adjustment of the switching cams.

1 blue

2 brown

3 blue

4 brown

Type: SC-NS2

Connect the switch at 1, 2.

Connect the switch at 3, 4.

4 blue

5 black

6 brown

Left end

position

1 brown

2 black

3 blue

Right end

position

Type: SC-D2

Connect to switch at 4, 5, 6.

Connect to switch at 1, 2, 3.

18

Mounting instructions for accessories and spare parts:

Before working on the bar-switchcontrol,

isolate the unit from the voltage supply!

Spare part set 4:

Actuating shaft round initiator

• Disconnect the bar-switchcontrol and re-

move from the actuator.

• Press together the snap lock on the ac-

tuating shaft and pull out the shaft.

• Place spare actuating shaft in housing.

• Equip the spare cam with the actuating

devices, and push onto the spare actu-

ating shaft. Take care to observe, that

the actuating devices and their sides

are next to one another.

• Mount the bar-switchcontrol, set the ac-

tuating device, and remake the electrical

connection.

Spare part set 5:

Actuating shaft slot initiator

• Disconnect the bar-switchcontrol and re-

move from the actuator.

• Turn the actuating device with the ad-

justing tool, so that the actuating shaft

can be pulled out upwards, without colli-

ding with the initiator.

• Press together the snap lock on the ac-

tuating shaft and pull out the shaft.

• Place spare actuating shaft in housing.

• Equip the spare cam with the actuating

device, and push onto the spare actu-

ating shaft. Take care to observe, that

the actuating devices with their sides

are next to one another.

• Mount the bar-switchcontrol, set the ac-

tuating device, and remake the electrical

connection.

Spare part set 6:

Pressure compensating element

Replace blind plugs in the housing with a

reducer and screw the pressure compen-

sating element into the reducer.

Spare part set 7:

Solenoid valve switching

• Disconnect the bar-switchcontrol and re-

move from the actuator.

• Turn the actuating device with the ad-

justing tool, so that the actuating shaft

can be pulled out upwards, without colli-

ding with the initiator.

• Press together the snap lock on the actu-

ating shaft and pull out the shaft.

• Remove the black mounting plate.

• Disconnect the switch/initiator from the

terminal block.

• Loosen the terminal block from the

mounting plate, whereby the mounting

on the underside is pushed temporarily

to one side.

• Push and click the 8x terminal block into

the mounting plate.

• Reconnect the switch/initiator according

to the circuit diagram in the inner side of

the housing.

• Connect the descending cable to the

solenoid valve to the free terminal block

next to the switch/initiator cables.

19

Montagehinweise für Zubehör und Ersatzteile:

• Replace mounting plate into the housing,

remove cams from the actuating shaft.

• Insert the actuating shaft into the

housing.

• Equip the spare cam with the actuating

device, and push onto the spare actu-

ating shaft. Take care to observe, that

the actuating devices with their sides

are next to one another.

• Fit the bar-switchcontrol onto the ac-

tuator, make the setting and electrical

connection.

Spare part set 8: Micro-switch

• Disconnect the bar-switchcontrol and

pull the cam from the actuating shaft.

Remove the black mounting plate and

disconnect the switch from the terminal

block.

• Exchange micro-switches and reconnect

according to the circuit diagram on the

inner side of the housing.

• Replace mounting plate into the hou-

sing.

• Push the cam onto the actuating shaft,

whereby the exact positioning is to be

secured (see also Fig. C in the chapter

„Adjusting the switching cams“).

• Fit the bar-switchcontrol onto the ac-

tuator, make the setting and electrical

connection.

Spare part:

Round initiator / Slot initiator

• Disconnect the bar-switchcontrol and re-

move from the actuator.

• Press together the snap lock on the ac-

tuating shaft and pull out the shaft.

• Remove mounting plate and exchange

initiator.

• Screw mounting plate back in positi-

on and place actuating shaft in the

housing.

• Remount the bar-switchcontrol, reset

the actuating device, and remake the

electrical connection.

SC-IM-DE-b-DE-02-19-Rev.0

bar pneumatische Steuerungssysteme GmbH

Auf der Hohl 1 • 53547 Dattenberg • Germany

Tel. +49 (0)2644 96070 • Fax +49 (0)2644 960735

bar-info@wattswater.com • www.bar-gmbh.de

© 2018 Watts

The descriptions and images contained in this product data sheet are for informational purposes only and are not

guaranteed. Watts Industries reserves the right to make technical and constructive changes

to its products without prior notice.

Warranty: All purchases and sales contracts expressly require the Purchaser to accept the General Terms and

Conditions of Sale and Delivery which can be found on www.wattswater.com/agb. Watts hereby objects to any

deviating or additional condition to the General Terms and Conditions of Sale and Delivery which has been com-

municated to the Purchaser in any form without the written consent of a Watts representative.

Warranty

The bar products are comprehensively tested. The company bar therefore only guarantees the replacement or - at

its sole discretion - the free repair of those components of the delivered products which, in the opinion of bar, have

demonstrable manufacturing defects. Warranty claims due to defects or defects of title can be asserted within

one (1) year from delivery/transfer of risk. Excluded from the warranty are damages due to normal product use or

friction as well as damages due to changes or unauthorized repairs to the products for which bar rejects any claim

for damages (direct or indirect). (Please refer to our website for detailed information.) All deliveries are subject to

the General Conditions of Sale which can be found at www.bar-gmbh.de.

Other Watts Control System manuals