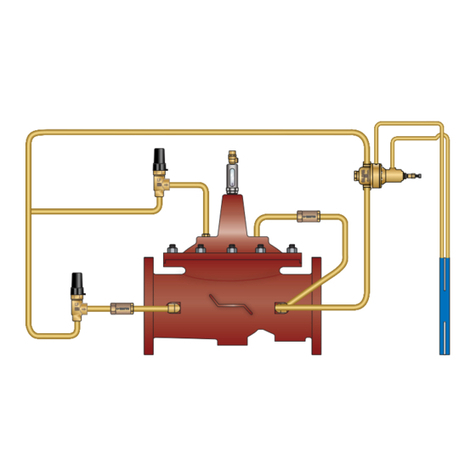

Figure 3

Temperature Adjustment

Factory Preset:

1170-M2, LF1170-M2: 120°F (49°C)

L1170-M2, LFL1170-M2: 90°F (31°C)

Under following conditions:

Cold Inlet: 60-70°F (16-21°C)

Hot Inlet: 140-145°F (60-63°C)

Supply Pressure: 45psi (3.15 bar)

1. Let water flow for at least two minutes to allow supply tem-

perature to stabilize.

2. Calibrate the mixed water outlet temperature by placing a

thermometer in the mixed water stream.

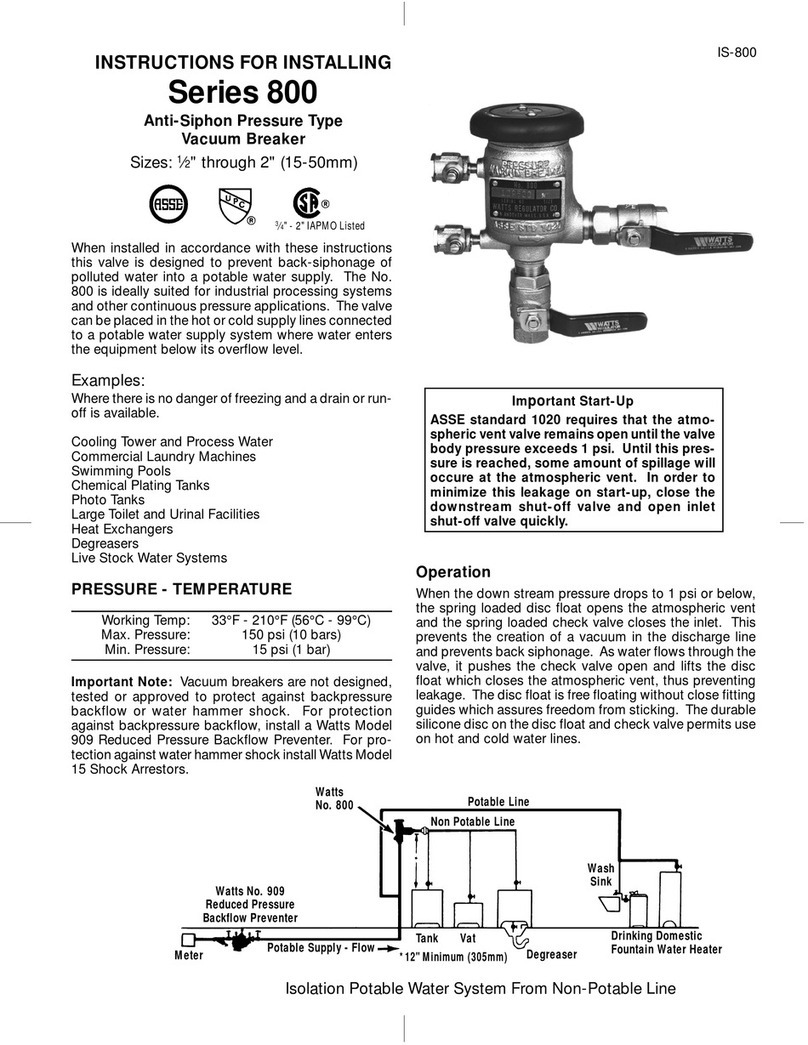

3. To adjust the setting of the valve, loosen locking cap screw

with hex wrench, see Figure 3. Cap must be lifted 1/4" to

adjust temperature. To increase the temperature, turn coun-

terclockwise. To decrease temperature turn clockwise.

4. Lower handle and tighten screw.

5. Check outlet temperature.

Period Inspection/Maintenance

This valve requires periodic inspection and verification of the out-

let temperature by a licensed contractor. Corrosive water condi-

tions, hot inlet water temperature over 200°F (93°C), unauthor-

ized adjustments or repairs could render the valve ineffective for

its intended service. Regular cleaning and checking of thermo-

stat assembly helps to maximize valve life and mixing function.

Frequency of cleaning depends on local water conditions.

Pressure — Temperature

Minimum Supply Pressure (Static): 30psi (207 kPa)

Inlet Temperatures: hot inlet, 120°F – 200°F (49°C – 93°C),

cold inlet, 40°F – 85°F (4°C – 29°C)

Hot Water Inlet to Outlet Differential Temperature: 5°F (3°C)

1170-M2, LF1170-M2 Temperature Out:

Field range: 90°F – 160°F (32°C – 71°C), adjustable.

Accurate within ±3°F (1.7°C)

L1170-M2 and LFL1170-M2 Temperature Out:

Field range: 60°F – 120°F (16°C – 49°C), adjustable.

Accurate within ±3°F (1.7°C)

Maximum Temperature: 200°F (93°C)

Maximum Pressure: 150psi (10.3 bar)

Maximum Pressure Differential Between Hot and Cold

Water Supplies: 25%.

Approval: CSA B125 certified

Listing: ASSE 1017 and IAPMO UPC

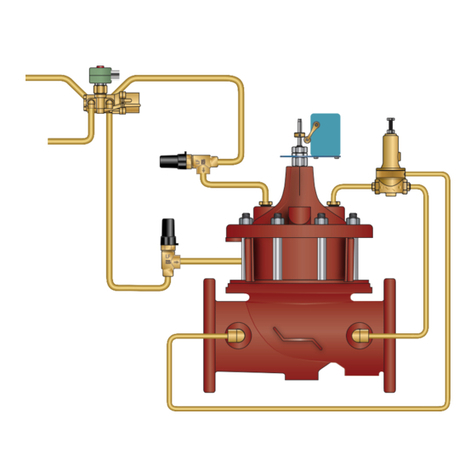

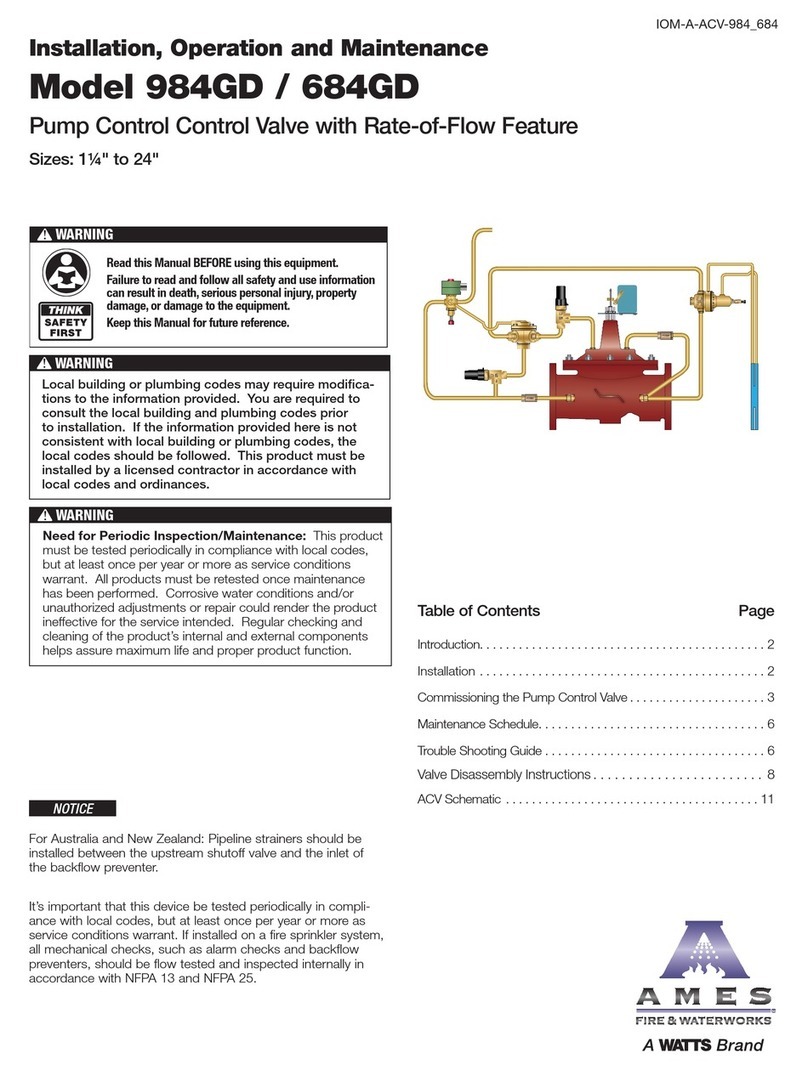

Figure 2

Radiant Heat Application

from Boiler

Cold

Radiant Return

Mixed

to Radiant

to Boiler

Watts Flow

Check Watts

Ball Valve

TP

Test Plug

Watts

Ball Valve

RPV

CV, CVS

Check Valve

Circulator

1170-M2,

L1170-M2

Hotter

3/32" Hex Wrench

Turn

Colder

Unscrew, lift

cap to adjust

Watts Hot Water Temperature Control Valves cannot be used for tempering

water temperature at fixtures. Severe bodily injury (i.e. scalding or chilling)

and/or death may result depending upon system water pressure changes.

ASSE Standard 1016, ASSE 1070 listed devices such as Watts Model L111,

LFL111 Series USG, LFUSG, MMV or LFMMV should be used at fixtures

to prevent possible injury. The Watts Hot Water Temperature Control Valves

are designed to be installed at or near the boiler or water heater. They are not

designed to compensate for system pressure fluctuations and should not be

used where ASSE 1016 devices are required. These WATTS valves should never

be used to provide “anti-scald” or “anti-chill” service.

When installing the Series 1170-M2 valves in a radiant heat application, the

components of the radiant heat system must be of materials with a construction

capable of withstanding the high limit output temperatures of the heating boiler.

If you are uncertain as to the product’s adaptability for your application, please

consult an authorized representative before installing or using the product.

WARNING

!