INSTRUCTIONS AND SECURITY

DESCRIPTION

These electric actuators have been designed to perform the control of a valve with 90° rotation. Please consult us

for any different application. We cannot be held responsible if the mentioned actuators are used in contradiction to

this advice.

TRANSPORT AND STORAGE

x The forwarding agents being held as responsible for damages and delays of the delivered goods, the consign-

ees are obliged to express if applicable their reserves, prior to accept the goods. The goods delivered directly

ex works are subject to the same conditions.

x The transport to the place of destination is carried out by using rigid packing material.

x The products must be stored in clean, dry, and ventilated places, preferably on appropriate palettes or shelves.

MAINTENANCE

x Maintenance is ensured by our factory. If the supplied unit does not work, please check the wiring according to

the electric diagram as well as the power supply of the concerned electric actuator.

x For any question, please contact our after-sales service.

x To clean the outside of the actuator, use a lint and soapy water. DO NOT USE CLEANING PRODUCT WITH SOL-

VENT OR ALCOHOL.

WARRANTY

x 100% of the actuators are fully tested and set in our factory.

x These products have a 3-year warranty from the delivery date or 50,000 operating cycles against all types of

manufacturing and material faults (operating time and model class according to standard CEI34).

x This warranty will only be valid if the unit has not been disassembled or self-repaired during its service life. The

warranty neither applies for wear or damages caused by chocks or faulty operations nor by the use of the unit

following conditions not in accordance or with its nominal characteristics. The warranty is strictly limited to the

replacement of original parts found defective when checked by our member staff. The cost of shipping to our

premises, the return of devices to the customer as well as the repair cost will be chargeable. We will not assume

the responsibility for any direct or indirect accidents/risks originated by a failure of our products. The warranty

does not cover the consequences of breakdown and excludes any payments for indemnities. The accessories

and adaptations are excluded from the guarantee. In the event that a customer has not proceeded to payments

within the agreed period, our warranty will be suspended until the delayed payments have been received and

with the consequences that this suspension will not prolong the warranty period in any case.

RETURN OF GOODS

x The customer is obliged to check the conformity of the goods with regard to their definition at the time of deliv-

ery.

x The acceptance of the goods by the purchaser disclaims the supplier of all responsibility if the purchaser dis-

covers any non-conformity after the date of acceptance. In such case, the repair cost will be borne by the pur-

chaser who will also exclusively bear all financial consequences of any resulting damage. Returned goods will

only be accepted if our prior agreement has been given to this procedure : the goods must be sent free of all

cost and being shipped solely and in their original packing. The returned goods will be credited to the purchaser

with a reduction of 20% on the unit’s price charged in accordance with the original invoice of the returned goods.

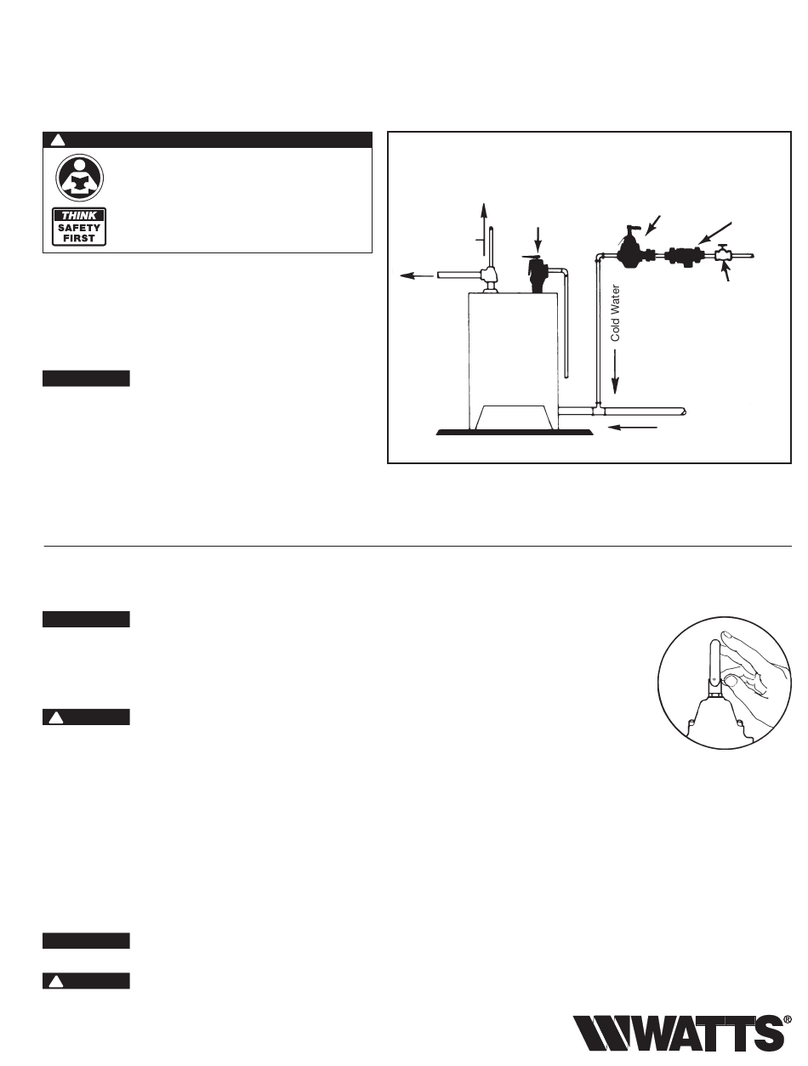

SAFETY INSTRUCTIONS (To be read prior to the installation of the product)

x The electric power supply must be switched-off before any intervention on the electric actuator (i.e. prior de-

mounting its cover or manipulating the manual override knob).

x Any intervention must only be carried out by a qualified electrician or persons instructed in accordance with the

regulations of electric engineering, safety, and all other applicable directives.

x Strictly observe the wiring and set-up instructions as described in the manual: otherwise, the proper working of

the actuator can not be guaranteed anymore. Verify that the indications given on the identification label of the

actuator fully correspond to the characteristics of the electric supply.

x Any other use than that described by the manufacturer jeopardizes the protection provided by this apparatus.

MOUNTING INSTRUCTIONS (To be read prior to the installation of the product)

x Do not mount the actuator less than 30 cm from an electromagnetic disturbance source.

x Do not position the equipment so that it is difficult to operate the disconnecting device.

x Respect all safety rules during fitting, dismantling and porting of this apparatus.