of service, allowing membrane to “break

in”.

(g) Check for production as follows:

Using a measuring cup, or measuring device

marked in fluid ounces, measure the RO water

production for 1 minute. This will give you the

production in ounces for one minute.

(Ounces per minute X 1440 ÷ 128=gallons per 24 hours)

Water temperature and water pressure will vary

the production. See production conversion charts

on Specification Sheet.

(h) Close the ball valve feeding into the

membranes and reconnect the ¼” blue line.

(i) Open ball valve feeding into membrane and

allow unit to fill storage tank. Depending on

water temperature, water pressure and size

storage tank, the time will vary to fill the

storage tank completely. Allow 12 to 24

hours to fill tank the first time. Check for

leaks.

System Disinfecting

If System is used to supply RO drinking water

for human consumption disinfection is

recommended. System should be disinfected

at least once every 12 months.

(a) Storage tank should be completely filled

before disinfecting.

(b) Drain RO water from all post treatment

equipment at the furthest point down stream

from the storage tank. This will flush any

particles from the final filters and lines.

(c) Shut off the incoming water supply to RO

unit and close faucet down stream of RO.

(d) Remove all filter cartridges from post

treatment housings down stream of WM.

(e) Add 1 teaspoon of hydrogen peroxide to all

filter housings down stream of RO unit.

Reconnect to filter housings without the

cartridge.

(f) Add 1 teaspoon of hydrogen peroxide to

storage tank, by removing tank tee from the

storage tank or by adding hydrogen peroxide

to the line feeding into the storage tank.

(g) Turn on water supply to RO unit and allow

WM to produce water for 2 hours.

(h) If you have ball valve after the storage tank

or before the post filter housing you may

shut the RO water supply off at that point.

(i) Open faucet at the furthest point from

storage tank to depressurize Ro water lines.

Add post filter cartridge back to its filter

housings.

(j) Close faucet and open any valve that may

have been closed. Any hydrogen peroxide

still in the storage tank or lines will be

removed by the final polishing filter or will

break down to oxygen and water.

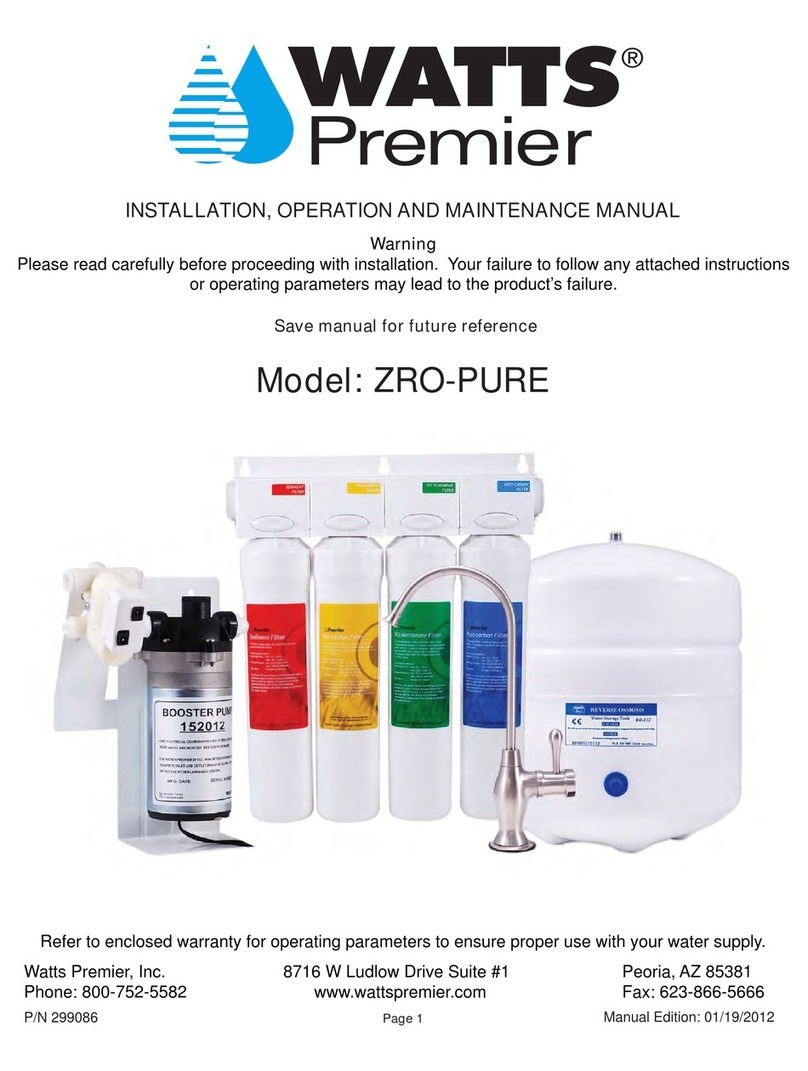

MAINTENANCE Schedule

Replacement Pre-filter for WM-120:

1st Stage: Part #WP 304003 Sed-20”-5-micron

2nd Stage: Part #WP201011 Carbonblock-20”-

5m

3rd Stage: Part #WP 201011 Carbonblock-20”-

5m

WM-120 pre-filters should be changed once

every 6 months or sooner depending on

incoming feed water conditions or when the

outlet pressure gauge form pre-filter drop

below a reading of 40 psi.

WM-120 replacement membranes:

Part #WP 110012 MEM-TFM-75 gpd

WM-120 membranes depending on water

conditions should be replaced once every 12 to

24 months.

Changing Pre-filters

1. Close the ball valve on the inlet side of

WM-120.

2. Close ball valve feeding into the RO

membranes.

3. Open flush ball valve and drain water into a

pail or drain.

4. Unscrew the blue 20” filter housing by

turning counter clockwise. Note: A filter-

housing wrench may be need.

5. Drain and remove filter cartridges from

housing. Discard used filter cartridges. DO

NOT discard filter-housing o-ring.

6. Clean filter housing with warm soapy water.

Rinse with clean water.

7. Clean and lubricate filter-housing o-ring

with K-Y Jelly or silicone. Do not use a

petroleum-based lubricant.

8. Insert new filter cartridges into the

appropriate housing.

9. Follow normal start up procedures.

Watts Pure Water