Before using the machine please read this manual carefully.

Please note that non-compliance to the manual releases the manufacturer from any responsibility.

The machine must not be used for purposes other than the ones shown in this manual. Any improper use of

the machine will nullify warranty conditions. The slush machine should not be placed close to explosive or

fire hazards and should be installed in accordance with local fire and electrical codes. This manual provides

basic infomation about the slush machine. The illustrations and specifications are not binding in the tile.

We reserve the right to make changes to the slush machine without notice, and without incurring any

obligation to modify or provide new parts for slush machine built prior to date of change. Do not attempt to

service or operate the slush machine until instructions and safety precautions in this manual are read

completely and are thoroughly understood. If problems develop or questions arise in connection with

installation, operation or servicing of the slush machine, contat your distributor.

The slush machine has been assembled, operated and inspected at the factory. Upon arrival at the final

destination, the complete slush machine must be checked for any damage which may have occurred during

transit.

With the method of packaging used, the slush machine should arrive in excellent condition. The carrier is

responsible for all damage in transit, whether visible or concealed.

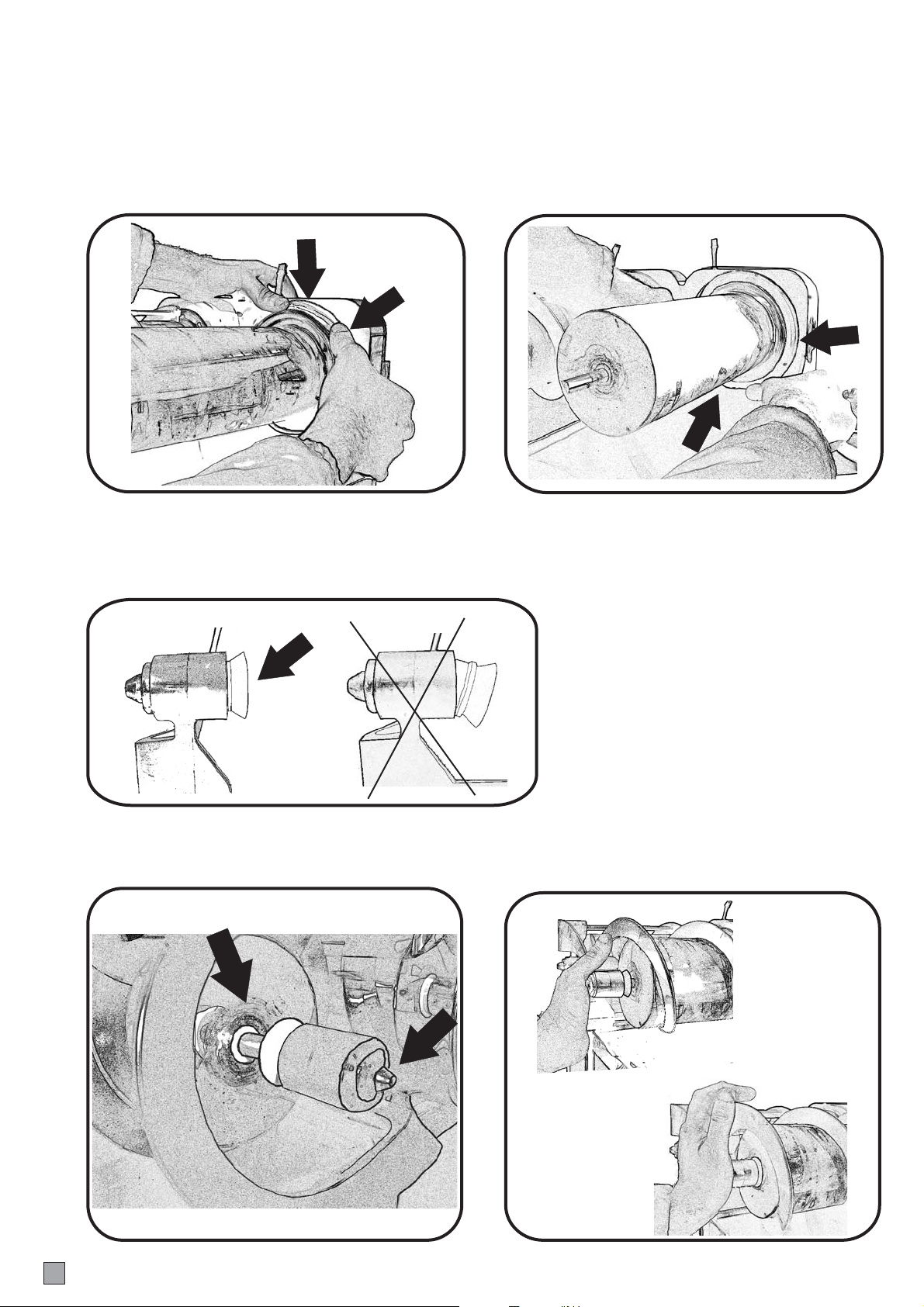

Installation of the slush machine involves moving the slush machine close to its permanent location;

removing all crating, setting in place, assembling parts and cleaning.

SHIPMENT and TRANSIT

INSTRUCTION MANUAL

MODEL 1 MODEL 2 MODEL 3

ELECRTICAL

POWER ABSORBED

BOWL

Dimensions

WIDTH

DEPTH

HEIGHT

NET WEIGHT

GAS

1 phase,

115Vac

60 Hz

1 phase,

115Vac

60 Hz

1 phase,

115Vac

60 Hz

530 W 850 W 1100 W

2.75 gallon 2.75 gallon 2.75 gallon

7.87 “ 15.75 “ 23.62 “

18.90 “ 18.90 “ 18.90 “

33.08 “ 33.08 “ 33.08 “

66 lbs

R404a

5.3 oz

114.40 lbs

R404a

10.94 oz

154 lbs

R404a

13.75 oz

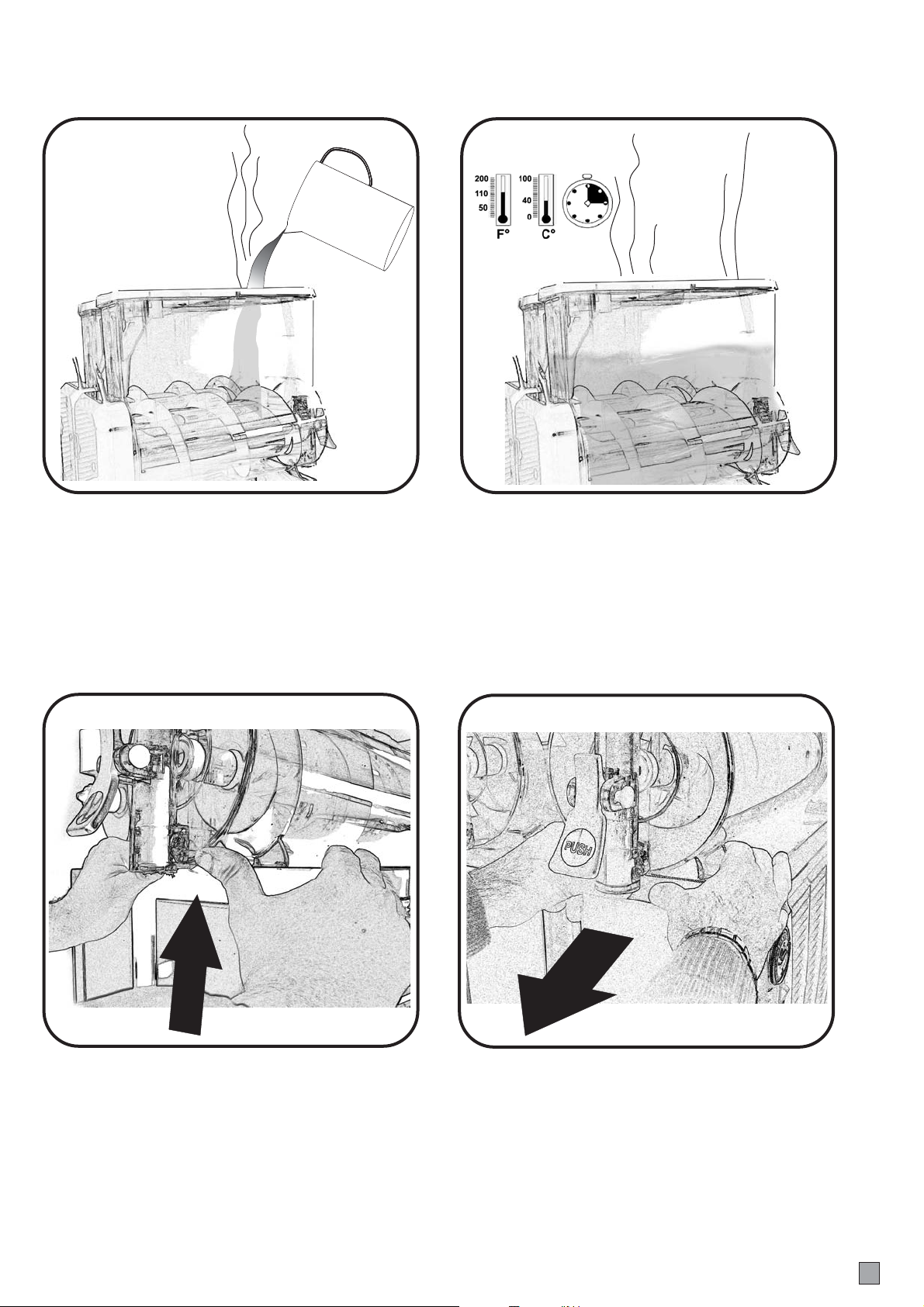

Pic. 3

Height

Pic. 1

Pic. 2

Widht

Depht