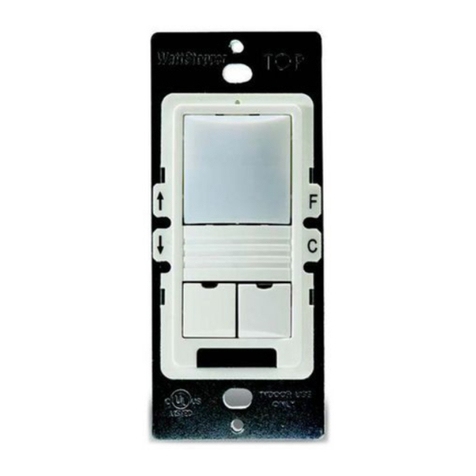

SSENSOR ADJUSTMENT

THE SENSORS ARE FACTORY PRESET*TO ALLOW FOR QUICK INSTALLATION IN

MOST APPLICATIONS. However, verification of proper wiring or coverage, or customizing

of the sensor’s settings can be done through the following steps.

Before starting, make sure the office furniture is installed, lighting circuits are turned on,

and the HVAC systems are in the overridden/on position. VAV systems should be set to

their highest airflow.

There is a warm-up period when power is first

applied to the sensor of up to one and a half

minutes.

1. For testing, set the Time Delay to minimum, 15 seconds.

See chart below for DIP switch configurations.

2. Ensure that the Sensitivity and Light Level trimpots

are set to maximum, fully clockwise.

3. Remain still. The lights should turn off after

approximately 15 seconds (If not, see Troubleshooting).

4. Set the desired Time Delay.

5. Readjust the angle of the sensor if necessary.

Time Delay:

• The Time Delay is set with DIP Switches 1 thru 4.

Light Level feature:

• The Light Level feature holds lights off upon initial

entry into the space if adequate ambient light exists.

It will not turn the lights off if they are on.

• Adjust the Light Level during daylight hours when

ambient light in the area is adequate.

• Avoid mounting the sensor too close to lighting fixtures.

1. Set the Time Delay to minimum, 15 seconds.

2. Set the Light Level trimpot to minimum,

fully counterclockwise.

3. Be still and allow the lights to turn off.

4. Move a hand in front of sensor every 10 seconds (to

keep sensor activated), and without blocking any light

from reaching the sensor, in small increments, turn

Light Level adjustment toward maximum, waiting at

least 5 seconds between increments, until the lights

turn on. Then turn it back slightly. At this setting the

lights will not turn on with occupancy if the ambient

light is above the current level.

5. Set the desired Time Delay.

6. Readjust the angle of the sensor if necessary.

*Time Delay=18 minutes / Sensitivity & Light Level settings=Maximum.

Light Level

Adjustment

LED

Sensitivity

Adjustment

Time-Delay

DIP Switch

on

25431

✆Call (800) 879-8585 For Technical Support ✆

STROUBLESHOOTING

Lights do not turn on with occupancy, and the following condition exists:

• LED does NOT flash:

When power is initially applied to the sensor, there is a warm-up period of up to

60 seconds before the LED is active.

1. Check that the circuit breaker has been turned back on.

2. Check the Sensitivity settings. Increase (clockwise) as needed.

3. Check all sensor and power pack wire connections.

4. Check for 24VDC at sensor (violet and green or gray wires).

- If 24VDC is present, replace the sensor.

- If 24VDC is not present, check that high voltage is present to power pack.

If it is, replace power pack.

• LED does flash:

1. The Light Level setting or the Sensitivity may be set too low.

2. If the sensor’s Light Level feature has been utilized, the lights connected to the Light

Level Output might be held off because of the level of ambient light in the

controlled area.

- To test whether the Light Level adjustment is the problem, cover the PIR lens

with your hand for 5 seconds to see if the lights turn on, or turn the Light Level

adjustment toward maximum (clockwise). If the lights turn on, the Light Level

setting was keeping the lights off.

• Increase the Light Level setting slightly or follow the procedures under

“Sensor Adjustment” to adjust the Light Level setting.

- The Sensitivity adjustment should be set to maximum, unless a decrease is made

due to an “Unwanted Sensor Activations” adjustment.

3. Check all sensor and power pack wire connections.

4. Check for 24VDC at the power pack’s blue wire connection to sensor while

someone moves in front of sensor to activate the LED. If there is no voltage,

replace the sensor. If there is voltage, replace the power pack.

≠CAUTION≠

TURN POWER OFF AT THE CIRCUIT BREAKER

BEFORE WORKING WITH OR NEAR HIGH VOLTAGE.

Check Our Web Site For FAQs: www.wattstopper.com

Lights do not turn off automatically:

1. The sensor may be experiencing activations from outside the controlled area or

from some type of interference (see “Unwanted Sensor Activations” next page).

2. Check all sensor and power pack wire connections.

3. Disconnect power pack’s blue wire:

If the lights do not turn off, replace power pack. Reconnect blue wire.

If the lights turn off, the problem may be in the sensor—to check:

- Reconnect the blue wire.

- Turn sensitivity and time delay to minimum and allow the sensor to time out.

If the lights turn off, the sensor is working properly (see number 1., above, and

“Sensor Adjustment” for readjustment of sensor).

Unwanted Sensor Activations (LED flashes):

• Possible causes

1. Improper sensor location or angle adjustment causing detection outside of desired

coverage area.

2. Sensitivity set too high.

3. Sensor located too close to HVAC or VAV vents with heavy air flow.

• Possible solutions

1. Mask the lens to reduce PIR coverage (see “Masking the lens”, under “Coverage

Patterns”).

2. Reduce the sensitivity (counterclockwise) as needed (see “Sensor Adjustment”).

3. Adjust the sensor angle (see “Sensor Adjustment”).

4. Relocate the sensor.

Override:

To override all sensor functions, set DIP switch #5 to on.

This bypasses the occupancy and light level control functions of the sensor, but still allows

the lights to be manually controlled with a light switch.

SORDERING INFORMATION

A277E-P

A347D-P

CX-100-3 Occupancy Sensor, Two-Sided Aisleway Lens

MB-1 Industrial Mount Bracket

Power Pack: 277VAC, 60Hz, 20A ballast, 100mA

Power Pack: 347VAC, 60Hz, 15A ballast, 100mA

CX-100

CX-100-1

Occupancy Sensor, Dense Wide Angle Lens (Std)

Occupancy Sensor, Long Range Lens

CX-100-4 Occupancy Sensor, One-Sided Aisleway Lens

A120E-P Power Pack: 120VAC, 60Hz, 100mA

20A ballast/13A incandescent

B230E-P Power Pack: 230VAC, 50/60Hz, 150mA

20A ballast/13A incandescent

B120E-P Power Pack: 120VAC, 60Hz, 150mA

20A ballast/13A incandescent

B347D-P

S120/277/347E-P

Power Pack: 347VAC, 60Hz, 15A ballast, 150mA

B277E-P Power Pack: 277VAC, 60Hz, 20A ballast, 150mA

Slave Pack: 120/277VAC, 60Hz, 20A ballast

347VAC, 60Hz, 15A ballast

Putting a Stop to Energy Waste®

Santa Clara CA 95050 1(800)879-8585 1(972)578-1699

70-0004-00 4/98

SWARRANTY INFORMATION

The Watt Stopper, Inc. warranties its products to be free of defects in materials and

workmanship for a period of five years. There are no obligations or liabilities on the part of

The Watt Stopper, Inc. for consequential damages arising out of or in connection with the

use or performance of this product or other indirect damages with respect to loss of

property, revenue, or profit, or cost of removal, installation or reinstallation.

Installation Instructions

CX-100

PIR Occupancy Sensor

Santa Clara, CA 95050

1(800) 879-8585 1(972)578-1699

www.wattstopper.com

U.S.Patent:

4,787,722

SSPECIFICATIONS

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24VDC

Current Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19mA*

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . Watt Stopper Power Pack

B series power packs supply power for up to 6 CX-100 sensors

A series power packs supply power for up to 3 CX-100 sensors

Isolated Relay Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1A@24VDC

Time Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 15 seconds–30 minutes

Sensitivity Adjustment . . . . . . . . . . . . . . . . . . . . . . . . Minimum–Maximum

Light Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–200FC

*Current consumption can be slightly higher when only one sensor per power pack is used.

✆Call (800) 879-8585 For Technical Support ✆

All sensors are white.

15 seconds

4 minutes

6 minutes

8 minutes

10 minutes

12 minutes

14 minutes

2 minutes

16 minutes

20 minutes

22 minutes

24 minutes

26 minutes

28 minutes

30 minutes

Override

18 minutes

12345

DIP Switch #

Time Delays