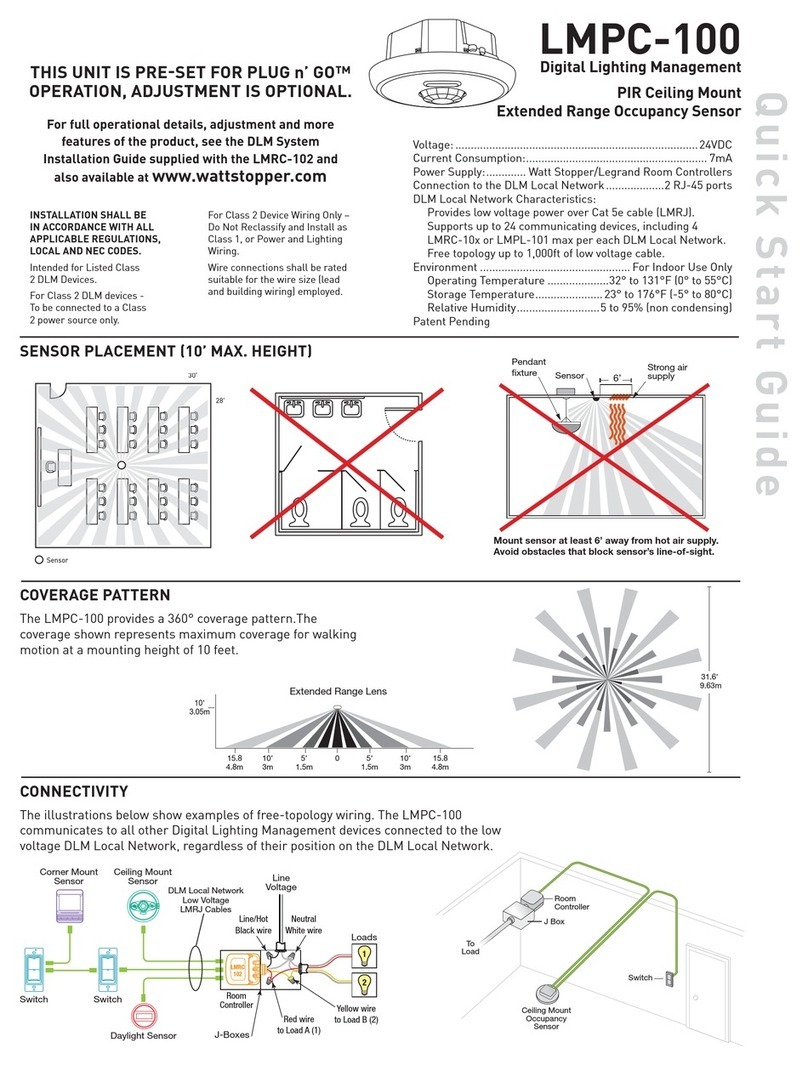

SENSOR ADJUSTMENT

The sensor comes factory preset and ready

for operation.

If testing of operation is desired:

• Remove the sensor’s cover (twist).

• Refer to the DIP switch settings chart

below for switch configurations.

• Make sure that office furniture and fixtures

are in place.

1. Restore power to the lighting

circuits and turn the lights on.

• There is a one minute

warm-up when power is

initially restored to the sensor

before the sensor works

properly.

2. For testing, set the Time Delay

to minimum (15 secs.).

3. Set Sensitivity to maximum.

4. Turn Light Level Adjustment

trimpot to maximum.

5. Replace the sensor’s cover then

move away from sensor and be

still. The lights should go off

after 15 seconds.

If lights remain on, see

Unwanted Sensor Activations

under Troubleshooting.

With movement in the area, the

lights should turn back on.

6. If using the light level feature

(otherwise skip to step 7),

turn the adjustment trimpot to

minimum, and repeat step 5.

Unless it is very dark, when the

lights turn off, the lights controlled by light level should not turn

back on even with movement in the area.

Until ready to make the final adjustment, leave the setting at maximum.

The controlled lights will then not be affected by ambient light levels.

To make the light level adjustment: (The final light level setting

for normal operation should be made at a time when... with the

lights off, the ambient light level is at the point where it is desired

for the lights to turn on.)

Set the Time Delay and the Light Level to minimum, then be still

until the lights turn off (about 15 seconds). Slowly turn the light

level adjustment toward maximum until the lights turn on—then

turn it back slightly. At this setting the lights will not turn on if

ambient light levels are above the current level.

7. Set the desired Time Delay for operation (DIP switches #1 – 6).

Factory preset Time Delay is 18 minutes; other suggestions are:

Offices and conference rooms (10 minutes), Classrooms (10 minutes),

Warehouses (6 minutes), Hallways (4 minutes).

TROUBLESHOOTING

≠CAUTION≠

USE PROPER SAFETY PRECAUTIONS WHEN

WORKING WITH OR NEAR HIGH VOLTAGE

Lights will not turn on:

1. Verify the lens is not masked in the direction being tested (see Masking).

2. Adjust Sensitivity settings up if needed (DIP switches #7 & 8).

3. Verify power pack and sensor connections are correct and secure.

4. Check for +24VDC at RED wire from the power pack to sensor.

• If present, the problem may be with the sensor. Try another

sensor (if available).

• If there is no voltage, see Power Pack High Voltage Checklist, below.

Lights will not turn off:

1. Check that Time Delay settings are correct (DIP switches #1 – 6).

2. Decrease Sensitivity settings if needed (DIP switches #7 & 8).

3. Verify power pack and sensor connections are correct and secure.

4. Disconnect BLUE wire on power pack from sensor.

• If the lights turn off, the problem may be in the sensor. Turn

Sensitivity and Time Delay to minimum and allow the sensor

to time-out.

- If the lights turn off, the sensor is working correctly. See

Unwanted Sensor Activations, next page. And go through the

Sensor Adjustment process again.

• If the lights stay on, the problem may be in the power pack.

See Power Pack High Voltage Checklist, below.

Isolated relay not functioning properly:

CAUTION: Use proper high voltage precautions, if applicable.

1. Check that Time Delay settings are correct (DIP switches #1 – 6).

2. Check Sensitivity setting. Also see, Unwanted Sensor Activations,

next page.

3. Verify all wire connections from sensor are correct and secure.

4. Check that there is voltage to the Isolated Relay.

5. Check for +24VDC at RED wire from the power pack to sensor.

6. Use an ohmmeter to check the function of the Isolated Relay:

• Turn off the power connected to Isolated Relay wires (if applicable).

- With motion in front of the sensor’s lens, check that the

connection between the BROWN and RED wires is open.

- With motion in front of the sensor’s lens, check that the

connection between the ORANGE and RED wires is closed.

• Turn Sensitivity and Time Delay to minimum, cover the sensor’s

lens with a cloth (not your hand), be still and allow the sensor to

time-out.

- Check that the connection between the BROWN and RED

wires is closed.

- Check that the connection between the ORANGE and RED

wires is open.

Power Pack High Voltage Checklist:

CAUTION: Use proper high voltage precautions.

1. Check that power pack high voltage wire connections are correct

and secure.

2. Check that the power pack is rated at the correct voltage.

3. Check that there is high voltage going into the power pack.

4. Try another power pack (if available).

SPECIFICATIONS

Voltage Supply . . . . . . . . . . 20–30VDC (24VDC Typical)

Current Consumption . . . . . . . @24VDC, 24mA Maximum

Isolated Relay Rating . . . . . . . . . . 1A @24VDC or 24VAC

Time Adjustment . . . . . . . . . . . . 15 seconds–30 minutes

Sensitivity Adjustment. . . . . . . . . . . . minimum-maximum

Light Level Adjustment . . . . . . . . . . . . . . . . . . . 1–190FC

Installation Instructions

Unwanted sensor activations (LED flashes):

Possible causes

1. People moving or walking outside of the desired coverage area,

but in view of the sensor and within it’s range (see Coverage

Patterns and Placement).

2. HVAC vents with heavy air flow.

Possible solutions

1. Masking (see Masking).

2. Setting the Sensitivity lower.

3. Relocating the sensor.

Sensor Override:

If the sensor fails, set DIP switch #6 to OFF. This overrides the sensor

and sets the circuits to “on”.

Santa Clara, CA 95050 USA

1(800)879-8585 1(972)578-1699

WARRANTY INFORMATION

The Watt Stopper®, Inc. warranties its products to be free of defects in

materials and workmanship for a period of five years. There are no

obligations or liabilities on the part of The Watt Stopper, Inc. for

consequential damages arising out of or in connection with the use or

performance of this product or other indirect damages with respect to

loss of property, revenue, or profit, or cost of removal, installation or

reinstallation.

U.S. Patents:

4,757,204

4,787,722

Des360,842

Putting a Stop to Energy Waste®

Santa Clara CA 95050 USA ☎1(800) 879-8585 1(972)578-1699

86-0474-00r3 9/99

✆Call 1(800)879-8585 For Technical Support✆

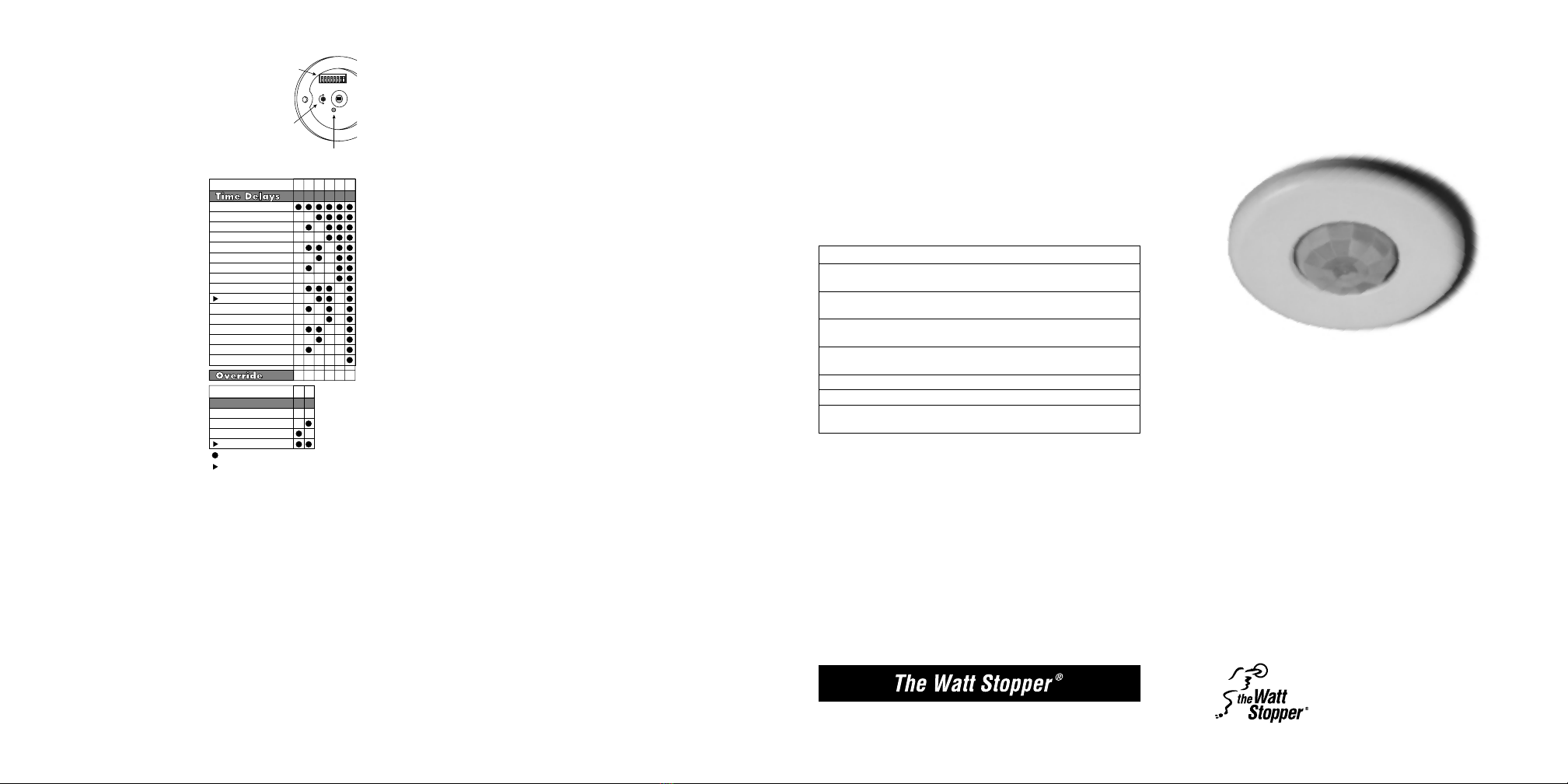

ORDERING INFORMATION

Catalog# Description

CI-200 20–30VDC Occupancy Sensor

with Extended Range Lens (Standard)

CI-200-1 20–30VDC Occupancy Sensor

with High Density /Reduced Range Lens

B120E-P Power Pack: 120VAC, 60Hz, 150mA

20A ballast/13A incandescent

B230E-P Power Pack: 230VAC, 50/60Hz, 150mA

20A ballast/13A incandescent

B277E-P Power Pack: 277VAC, 60Hz, 150mA, 20A ballast

B347D-P Power Pack: 347VAC, 60Hz, 150mA, 15A ballast

S120/277/347E-P Slave Pack: 120/277VAC, 60Hz, 20A ballast

347VAC. 60Hz, 15A ballast

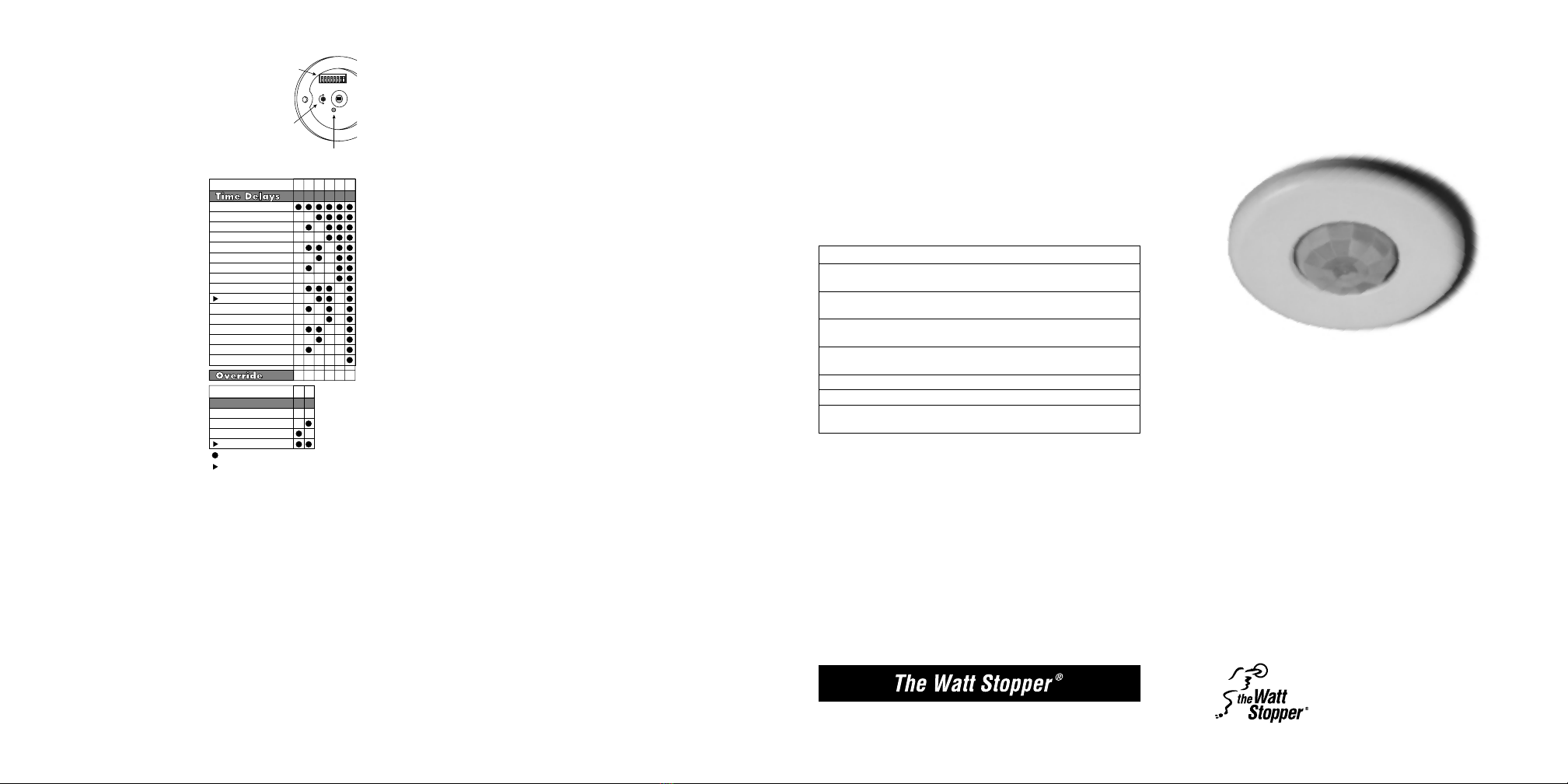

LED

Light Level

Adjustment

DIP Switch Control

for Time Delay and

Sensitivity

MAX

MIN

DIP Switch #

15 seconds

4 minutes

6 minutes

8 minutes

10 minutes

12 minutes

14 minutes

16 minutes

18 minutes

20 minutes

22 minutes

24 minutes

26 minutes

28 minutes

2 minutes

1234

DIP Switch #

56

30 minutes

––

––

–––

––

–– –

–––

––––

––

–– –

–––

––– –

–––

–– ––

––––

–––––

–

Minimum

Medium Low

Medium High

Maximum

78

Sensitivity

= ON –= OFF

= Factory Presets

–

–

–

–

DIP Switch Settings:

CI-200

version 2

360° PIR Occupancy Sensor

Check Our Web Site For FAQs: www.wattstopper.com