wattstopper LP Series Service manual

LP8 & LP24

Lighting Control Panel

LP8 LP24

SPECIFICATIONS

Supply Voltages..............................................per selected power supply

P115/277 Power Supply...............................................115 or 277VAC

P240 Power Supply................................................................. 240VAC

P115/347 Power Supply...............................................115 or 347VAC

Load Ratings

@120VAC, 50/60Hz ....................................... 20A Tungsten or Ballast

@277/347VAC, 50/60Hz .....................................................20A Ballast

@250VAC .......................................................................................1HP

Accessory Power Ouput..................................800mA @24VDC/VAC/ACR

Environmental

Maximum Ambient Temperature ................................................60°C

Maximum Humidity ........................ 5% to 90% RH, non-condensing

UL & cUL Listed for receptacle rated circuit control

Installation & Wiring Reference

LIST OF FIGURES

Figure 1: LP8 components...................................................................3

Figure 2: System Wiring Overview ............................................................4

Figure 3: LP8 Enclosure.....................................................................6

Figure 4: LP24 Enclosure....................................................................6

Figure 5: P115/277 wiring ...................................................................7

Figure 6: P115/347 wiring ...................................................................7

Figure 7: P240 wiring .......................................................................7

Figure 8: Relay Control Buttons & Status LEDs .................................................7

Figure 9: Low voltage switch and device wiring..................................................8

Figure 10: Installing the EM-24A2 Exterior Photocell with the LP8 ..................................9

Figure11: Group Switching ...................................................................9

Figure 12: Smartwire Setup steps..............................................................9

CONTENTS

SPECIFICATIONS..................................................................... 1

INTRODUCTION ...................................................................... 3

Welcome to the LP Series Lighting Control Panels...........................................3

System Wiring Overview.................................................................4

INSTALLATION....................................................................... 5

Mount the Enclosure ...................................................................5

Install Interior .........................................................................6

CONNECT THE LP8 POWER SUPPLY .................................................... 7

Power Up and Test Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Confirm Nominal Operation..............................................................7

LOW VOLTAGE WIRING................................................................ 8

Hardwire Low Voltage Switches (Optional)..................................................8

Install and Wire Exterior Photocell (Optional) ...............................................9

Using Low Voltage Sensors with LP Panels.................................................9

Group Switching (GS Card) and Smartwire Procedure (Optional)................................9

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

ORDERING INFORMATION – STANDARD CONFIGURATIONS ............................... 12

WARRANTY INFORMATION ........................................................... 12

2Visit our web site for FAQs: www.wattstopper.com

Call 888.852.2778 for Technical Support

INTRODUCTION

Welcome to the LP Series Lighting Control Panels

The LP panels contain up to 8 relays controlling lighting through automatic scenarios, time schedules,

photocells and occupant controlled switches. Scheduling capability is included through a built-in clock with a

keypad and display window on the interior. The interior provides isolation between the line- and low-voltage

sections of the panel, as well as the mounting frame for relays, the power supply and the circuit board

assemblies.

LP panels are shipped with all their components installed in a locking enclosure. The LP8’s enclosure is

compact, measuring only 16.5” x 15.1”. The LP24’s enclosure is equipped with din rails to accomodate up

to 12 contactors. A secure outer cover protects the user from the high voltage area. A separate interior

enclosure protects the low voltage wiring and components while allowing easy user access to the time clock

scheduling controls.

Most functions are the same for the LP24 as for the LP8. References to LP8 features, functions,

programming and wiring also apply to the LP24, unless specified otherwise. If you have any questions, call

technical support at: 888.852.2778.

Use the plastic sleeve affixed inside the enclosure cover door to keep these instructions

and the completed system documentation forms for future reference.

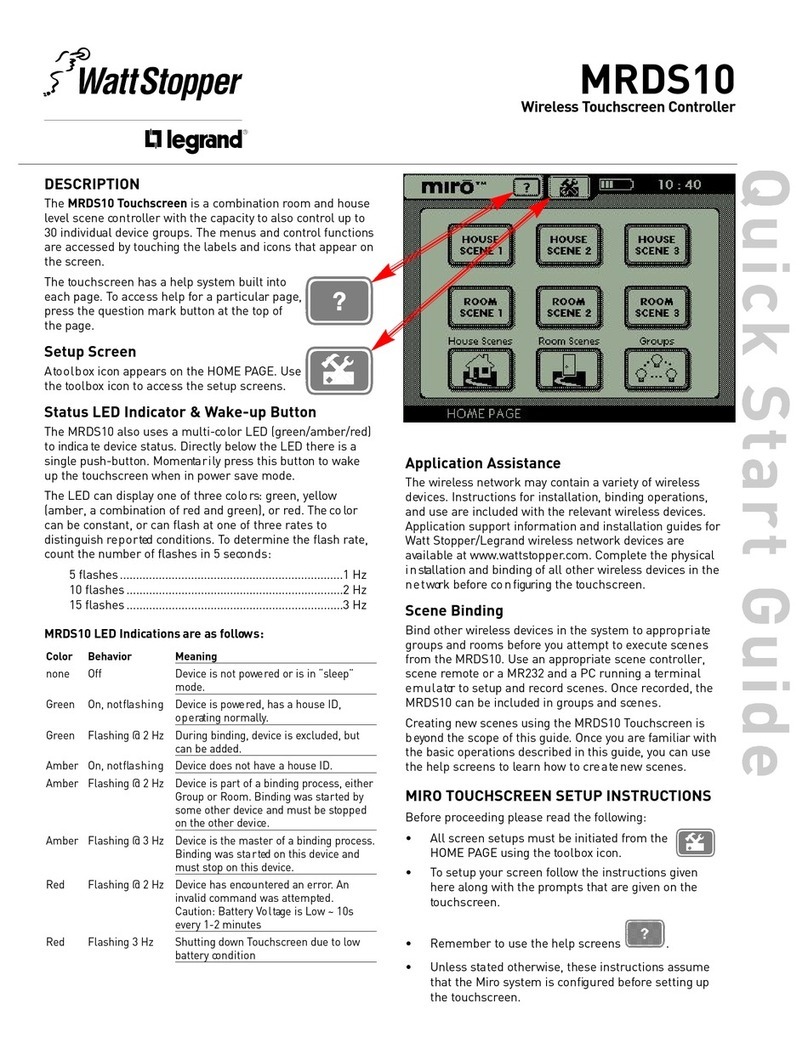

Figure 1: LP8 components (enclosure cover removed and interior keypad and display door open)

EM-24A2 Photocell Connections

Relay Control

Push-buttons

Accessory Power Connections

Power Supply Connections

Relay Switch and Pilot Connections

Relay Line and

Load Connections Keypad and Display Door (open)

Optional Gr

oup Switching

(GS) Card

3

Visit our web site for FAQs: www.wattstopper.com

W

B

Y

R

W

B

Y

R

W

B

Y

R

W

B

Y

R

W

B

Y

R

W

B

Y

R

W

B

Y

R

W

B

Y

R

277V

115V

NEUT

GND

1

2

3

4

5

6

7

8

AS-100

* For LP24

models only

Two wire

momentary

switch (typical)

Three wire

momentary

switch (typical)

Ceiling mount

Watt Stopper sensor (typical)

4 pole

contactor*

Din Rail*

For standard use 3/#18

For pilot use 4/#18

Use 4/#20

Clock Screen

Only required if one of the

channel scenarios is

“Photocell On/Off”, or

“Photocell and Schedule On/Off”.

Optional exterior

photocell EM-24A2

Group switch

card (“GS” Option)

Inner cover latch (1 of 2). Pull to release, press to latch.

Ground

Neutral ◊

Line ◊

Relay status LED

ABCD EFGH

Power

supply

ACC. POWER

24VDC

24VR

24VAC

WHITE

YELCOM

24VR

24VAC

WHITE

RELAY PILOT

Manual override

switch for relays

Factory installed jumper provides 24V rectied power to pilot contacts.

A different voltage (5-24V) can be connected to the YELCOM terminal

from other equipment looking to monitor relay state pilot contacts.

For standard

use 3/#18

Line ◊

Neutral ◊

To relay

as rquired

For standard use 2/#18

For pilot use 3/#18

Light xture

Light xture

Light xture

Notes:

The exterior enclosure cover has

a hinged door allowing easy

access to the low voltage section

of the panel. The line voltage

section is accessible only by

removing the enclosure cover.

Inside the panel, all low voltage

terminals are below a hinged

metal inner cover barrier on

which the clock screen display

and programming keypad

are mounted.

HELP

Line ◊

Neutral ◊

Line ◊

Neutral ◊

Line ◊

Neutral ◊

◊

Observe correct voltage as marked on power supply.

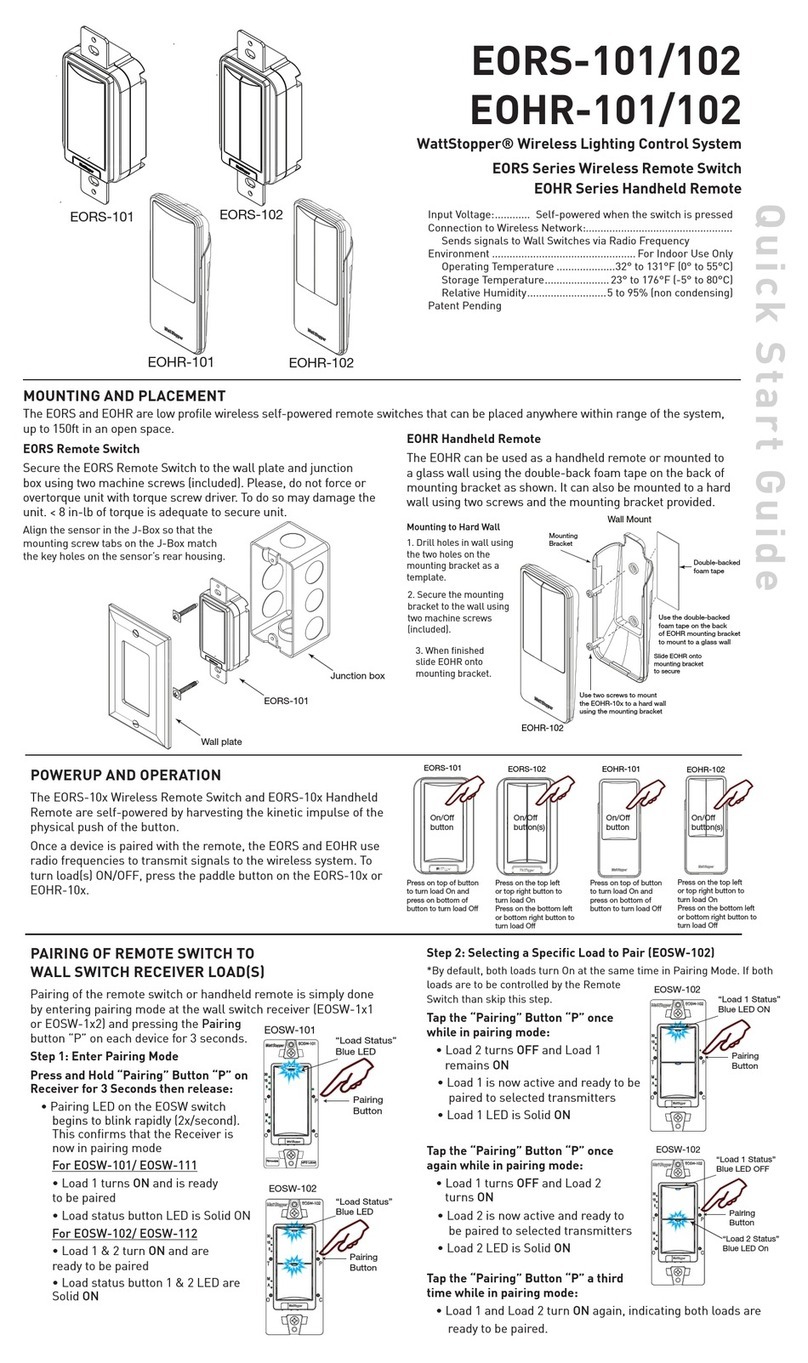

System Wiring Overview

4

Figure 2: System Wiring Overview

INSTALLATION

Some of the procedures in this manual may have been previously completed using the “LP8 Quick Start

Installation Guide.” The instructions that follow contain additional details about the installation that may

be useful in particular applications. These instructions also provide information about installing optional

equipment.

CAUTION

RISK OF ELECTRIC SHOCK

General Installation Information

• All power must be turned off prior to wiring, installation or service.

• More than one disconnect may be required to de-energize power to the LP8.

• External circuit protection to the LP8 is required (e.g., circuit breaker).

• Installation shall be in accordance with all applicable regulations, wiring practices, and codes.

• Care should be taken to separate high voltage power from low voltage (Class 2) control wiring.

• Do not energize wiring until the unit is fully assembled and connected circuits have been tested and

found to be free of electrical shorts.

WARNING

IMPROPER INSTALLATION OR CONNECTION OF THE LP8 MAY RESULT IN SERIOUS

PERSONAL INJURY AND/OR DAMAGE TO THE LP8 AND OTHER DEVICES.

Mount the Enclosure

1. Place the LP on a sturdy, flat, horizontal surface.

2. Remove the outer cover by removing the cover screws. Set it aside.

3. Open the interior door containing the clock keypad and display window by pulling up the two black

plastic self-retained pop-fasteners on the left side.

4. Remove the panel interior assembly.

a. Remove the washer and nut that attaches the transformer mounting assembly to the back of the

enclosure.

b. Remove the four sets of nuts and washers that attach the interior assembly to the back of the

enclosure.

c. Close the interior door and press down on the two black plastic self-retained pop-fasteners on the

left side to lock the door closed.

d. Lift the entire interior assembly out of the enclosure and set it aside.

Keep the hardware in a safe place until all rough-in conduit and wiring is completed.

5. Attach the enclosure to the wall. The enclosure should be level, plumb and rigidly installed with hard-

ware sufficient to hold 100 pounds (46kg) minimum.

6. Determine the appropriate wire entry locations. Make sure that all line and low voltage wiring entry

locations are confined to the appropriate compartments as shown in Figure 2 or 2a as appropriate.

Do not run low voltage wiring with line voltage or power wiring.

7. Drill or knock out openings to bring wiring conduit into the enclosure.

Call 888.852.2778 for Technical Support 5

Visit our web site for FAQs: www.wattstopper.com

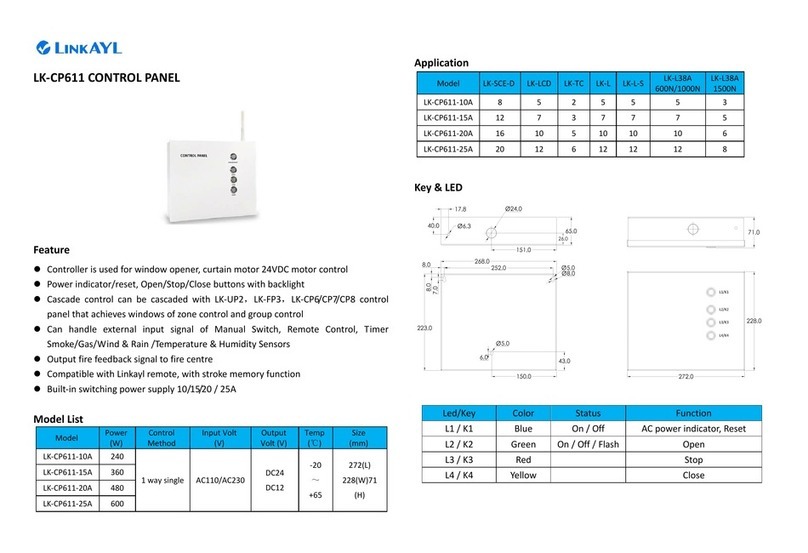

14.5"

(368.3 mm)

12.53"

(318.3 mm)

Slotted

Mounting

Holes

16.5"

(419.1 mm)

15.08"

(383.0 mm)

Line Voltage Compartment

(High Voltage)

6"

(152.4 mm)

Low Voltage Compartment

(Class 2)

Figure 3: LP8 Enclosure dimensions, mounting holes, location of line and low voltage wiring compartments

/RZ9ROWDJH&RPSDUWPHQW

&ODVV

PP

PP

PP

/LQH9ROWDJH&RPSDUWPHQW

+LJK9ROWDJH

PP

PP

PP

/RZ9ROWDJH

%DUULHU+HUH

Figure 4: LP24 Enclosure dimensions, mounting holes, location of line and low voltage wiring compartments

Install Interior

Do not reinstall the interior until after the exterior enclosure has been securely mounted to the wall and the

conduit/wiring holes have been drilled or knocked out.

1. Place the interior in the enclosure.

2. Align the interior with the studs provided in the enclosure.

3. Hold the interior in place while you pull up on the black self-retaining pop-fasteners to open the door.

4. Replace the washers and tighten down the nuts removed in 4b of the mounting process.

5. Attach the transformer mounting assembly to the back of the enclosure using the washer and nut

removed in 4a of the mounting process.

6. Close the interior door and push in the pop-fasteners.

6

Call 888.852.2778 for Technical Support

CONNECT THE LP8 POWER SUPPLY

The LP8 has several power supply options that allow it to operate with 115VAC, 240VAC, 277VAC or 347VAC

line voltage. These power supplies function with either 50 or 60 Hz. They have internal overcurrent protection.

The transformer automatically turns off when overloaded and resets when the fault is removed. The power

supply contains MOVs to protect all downstream electronics from powerline voltage spikes.

1. Read and remove the CAUTION label covering the terminals.

2. Note that there are different terminals for supply voltage input. Wire to only one of these terminals.

Match your input voltage to the correct terminal.

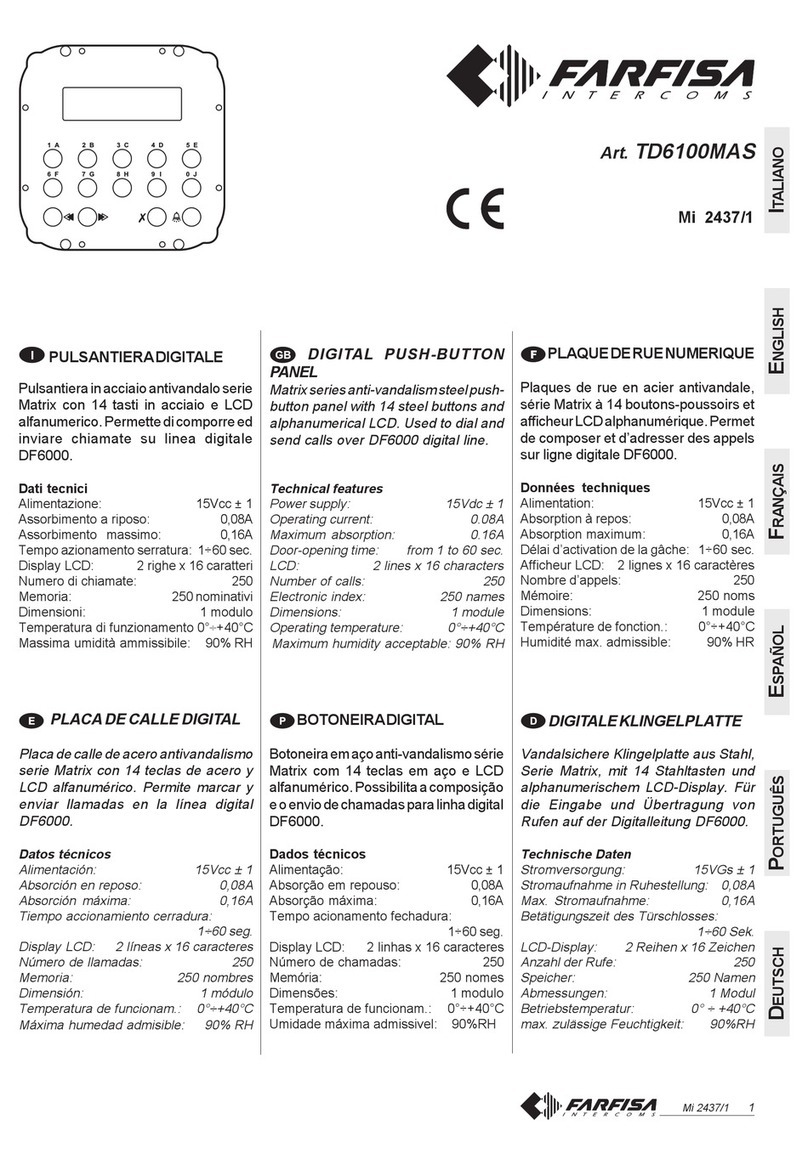

Figure 5: P115/277 wiring Figure 6: P115/347 wiring Figure 7: P240 wiring

CONNECT LINE VOLTAGE

Before making any connections to the relays, make sure that none of the load circuits are shorted. Wire from

the circuit breaker through each relay’s SPST output terminals, and from there to the loads. Confirm that

each circuit is wired to the relay specified in the electrical construction drawings.

Power Up and Test Relays

1. Apply power to the LP8 power supply ONLY.

Do NOT apply power to the controlled circuit loads.

2. As shown in the illustration,

press the Relay Control Button

next to each relay’s yellow

plug-in terminal to toggle it on/

off. The relay should “click” and

it’s LED indicator should change

state.

3. Confirm the operation by measuring the continuity at the

line voltage terminations of each relay.

4. Apply power to the relays.

5. Being careful not to touch any line voltage wiring, toggle

each relay on/off again and confirm that each relay con-

trols the appropriate load.

Confirm Nominal Operation

With power applied to the LP8 panel, there should be two (2)

green LED indicators glowing on the power supply card in the

lower left corner of the panel. And, there should be six (6) green

LED indicators glowing at the top of the panel below the EM24A2

photocell connector. A single (1) blue LED in this group blinks

approximately once per second indicating normal operation.

Each relay driver card (2 cards for 8 relays) has a blue LED that should flash randomly. The group switching

card (optional) also has two (2) blue LEDs that flash randomly during normal operation.

If you are having problems with your LP8, please note the condition of

all the LEDs before calling Watt Stopper technical support.

240

NEU

GND

240VAC Supply

347

115

NEU

GND

115VAC Supply

347

115

NEU

GND

347VAC Supply

277

115

NEU

GND

115VAC Supply

277

115

NEU

GND

277VAC Supply

CAUTION

Verify whether your supply line voltage is 115VAC, 240VAC, 277VAC, or 347VAC and that the

power supply in the LP8 matches that line voltage. Wiring to the incorrect voltage terminal may

result in damage to the Power Supply and/or the panel, and will void the product warranty.

Figure 8: Relay Control Buttons

& Status LEDs

Status LEDs (7)

Solid Green (4)

Power LEDs (2)

Solid Green

Solid Green (2)

Blinking Blue (1)

Relay Driver (RD)

boards (2)

Flashing Blue

(at DS6)

Power Supply

(PS) board

C8 (motherboard)

Blinking Amber on RD board

(at DS7) = trouble condition

RELAY

CONTROL

BUTTON

TO RELAY

LED

R B Y W

7

8

LOW VOLTAGE WIRING

Open the interior door to access the connectors in the low voltage section. All input/output wiring in this

section must be low voltage, Class 2 wiring. Do not use the low voltage wiring compartment as a raceway or

junction box. Refer to local codes regarding Class 2 wiring practices.

Hardwire Low Voltage Switches (Optional)

LP panels include a switch input for each relay. These accept any of the dry-contact configurations shown

below. Operation of the switch will turn on/off the corresponding relay.

To control multiple relays from a single input device, we recommend

using the optional Group Switching Card. See page 9.

Figure 9: Low voltage switch and sensor wiring

R B Y W

2-WIRE MAINTAINED

CONTACT

R -to- B JUMPER

B -to- W JUMPER

2-WIRE MOMENTARY

PUSH BUTTON

STANDARD 3-WIRE

MOMENTARY

STANDARD 3-WIRE

MAINTAINED

R B Y W

RED

WHITE

RED

WHITE

BLACK

WHITE

RED

BLACK

WHITE

RED

R B Y W

R B Y W

R B Y W

OCCUPANCY SENSOR or

INDOOR PHOTOCELL

BLACK

BLUE

RED Blue

Black

Red

White

24VDC

24VR

24VAC

COMMON

CONTROL

24VDC

R B Y W

COMBINATION OF

2-WIRE MOMENTARY PUSHBUTTON

WITH OCCUPANCY SENSOR or

INDOOR PHOTOCELL

BLACK

BLUE

RED Blue

Black

Red

White

24VDC

24VR

24VAC

COMMON

CONTROL

24VDC

BLACK

WHITE

Black

White

Single relay input

on panel’s main

relay switch

board

-OR-

Group channel

connection

on Group

Switching card

R = red: ON

B = black: OFF

Y = yellow: Pilot

W = white: Common

Do not hardwire multiple relay inputs

together when using a 2-wire momentary

switch for control. Use a Group Switch Card.

Visit our web site for FAQs: www.wattstopper.com

Call 888.852.2778 for Technical Support 9

Install and Wire Exterior Photocell (Optional)

The LP8 has a specific terminal block for connection to a

Watt Stopper EM-24A2 exterior photocell. This photocell

works in conjunction with the clock’s automation scenarios

to provide automatic exterior lighting control. See the

Users Guide for programming information.

1. Mount the EM-24A2 on the building roof or exterior.

Mount it so the light sensing window faces North.

2. Connect the two black wires and two red wires on the

EM-24A2 to the PCELL terminal block at the top of the

“C8” board on the low voltage side of the LP8 interior.

Using Low Voltage Sensors with LP Panels

When connected as shown in the Low Voltage Wiring section,

the sensor is powered by the panel’s auxiliary power supply. It

controls a relay when connected to a relay input. It controls a group of relays when connected to a GS input.

Control behavior depends on the input to which the sensor is connected.

• Sensor connected to a relay input: sensor controls the relay based on the scheduled state of the relay

Scheduled OPEN: sensor turns relay ON but will not turn it OFF

Scheduled CLOSED: sensor turns relay ON and OFF

• Sensor connected to a GS card input: sensor turns the group of relays ON and OFF regardless of

individual relay schedules.

To remove a sensor from the panel system after it has been commissioned, see Troubleshooting item 7.

Group Switching (GS Card) and Smartwire Procedure (Optional)

The Group Switching card provides eight channels (A-H), which

can be Smartwired to relays in the panel. GS channels are used

to group relays for common control by switches or sensors. Do

not confuse the GS channels with scheduling channels (discussed

in the Users Guide). Group channels created using the GS card

are used with switches or sensors connected to the card’s inputs

as shown in Fig. 3. These groups can be set to exactly or parially

match the scheduling channels as required.

Smartwire Setup

1. On the Group Switching card, press and hold the Group push-

button for several seconds. The red group LED and the LEDs for

relays currently controlled by that input will begin to flash.

2. On each Relay Driver card, select the relays to be controlled.

If a relay was previously Smartwired to the group input selected,

the LED flashes, otherwise the LED is off. Press the associated

Relay Control Button to add/delete that relay to/from the group.

The LED for each relay included in the group flashes.

3. On the Group Switching card, press the Group push-button

again. All LEDs stop flashing and the input switch will now

control the relays selected.

(1) Press Relay

Control Button

on each relay

to be controlled

(2) LED starts flashing

Step 2. RELAY DRIVER CARD

TO RELAY

LED

R B Y W

Step 3. GROUP SWITCHING CARD

(2) LED stops flashing

TO SWITCH

(1) Press Group

Push-button again

Step 1. GROUP SWITCHING CARD

(2) LED starts flashing

TO SWITCH

(1) Press and Hold Group

Push-button

Test Smartwired Relay Group Channels

1. Press the Group Push-button ON/OFF/ON to toggle the group ON/OFF/

ON. The input LED will track the last action.

2. With all relays in the group ON, turn OFF each relay in the group using

the individual Relay Control Buttons on the Relay Driver card. When the

last relay is turned off, the Group LED should also go off.

Group control connectors (8x)

(connect to switch or sensor

contacts, or analog photocells)

Power for

sensors

and

accessories

Gr

oup

push-

buttons

(8x)

Gr

oup

LEDs

(8x)

ABCDEFGH

R

B

Y

WR

B

Y

W

R

B

Y

W

R

B

Y

W

R

B

Y

W

24VDC

24VDC

24VDC

24VDC

YELCOM

24VR

24VAC

WHITE

R

B

Y

W

R

B

Y

W

R

B

Y

W

Install jumper

from YELCOM

to 24VR when

connecting

pilot to group

Ye

llow terminals

(4) #18 AWG

Mount Photocell on exterior or roof of building.

Light sensing window

Point toward North

1/2" thread tting

BLK

BLK

RED

RED

Sliding Window

As it is moved up,

lights turn on

earlier, and turn

off later. Locknut

PCELL

J1

C8

BLK

BLK

RED

RED

C8 Board on

LP8 Interior

Figure 10: Installing the EM-24A2 Exterior

Photocell with the LP8

Group LED Status Indicators

Red: All relays in group ON

Green: Relay group in mixed

state (some ON, some OFF)

Off: All relays in group OFF

Figure12: Smartwire Steps

Figure 11: Group Switching

#Problem Test Steps Next

1The LV switch does

not control the relay

or group.

Is it terminated correctly in the panel?

See pages 4 & 8.

No – Correct terminations

Yes – Go to next step

Is the 12VDC indicating LED on the C8

motherboard solid Green?

No – Cycle power to panel; recheck

Yes – Go to next step

Does the board mounted override

pushbutton control the relay or group?

No – Call tech support

Yes – Go to next step

Disconnect input terminals.

Does jumping the Red to White input

terminals turn the relay on and does

Black to White turn it off?

No – Call tech support

Yes - Verify the LV wiring is not

shorted and that the switch is

operating correctly

If using a Group switch, have the relays

been assigned to the particular group

using the GS card?

No – Make the necessary

assignments (refer to page 9)

Yes – Go to next step

2When I try to turn

the relay off it goes

off for a second then

comes back on.

Is this relay scheduled using the “AS

Manual ON/Auto OFF” or the “AS

Automatic ON/OFF” scenarios.

No – Go to next Step

Yes – The relay can only be

overridden OFF during unoccupied

periods

Remove any LV switching that is landed

at the relay input and attempt to turn

relay ON using the board override

buttons.

No change in status - Go to next

step

Relay functions normally - Verify

the LV wiring is not shorted

and that the switch is operating

correctly

Move LV relay connection to a different

point on the RD board and attempt to

override the relay on.

No change in status - relay needs

to be replaced - call tech support

Relay functions properly – circuit

board needs to be replaced - call

tech support

3When I try to turn

the relay on it comes

on for a second then

comes back off.

Remove any LV switching that is landed

at the relay input and attempt to turn

relay ON using the board override

buttons.

No change in status - Go to next

step

Relay functions normally – Verify

the LV wiring is not shorted

and that the switch is operating

correctly

Move LV relay connection to a different

point on the RD board and attempt to

override the relay on.

No change in status - relay needs

to be replaced - call tech support

Relay functions properly – circuit

board needs to be replaced - call

tech support

TROUBLESHOOTING

10 Visit our web site for FAQs: www.wattstopper.com

Call 888.852.2778 for Technical Support

#Problem Test Steps Next

4My EM24-A2

photocell does not

turn the relay on

or off.

Is the relay scheduled using the

“Photocell ON/OFF” or “Photocell and

Schedule ON/OFF” scenarios?

No – Make the necessary schedule

changes and test again.

Yes – Go to next step.

Remove the photocell wires or

connector and jumper from Red to Red.

Do the relays turn on/off?

Note: If using the “Photocell and

Schedule ON/OFF” remember to

adjust the clock time to be within your

occupied times before doing the jumper.

No – Call tech Support

Yes – Verify the LV wiring is not

shorted and that the photocell is

operating correctly on the roof.

5The Astronomic

schedule is turning

on the relay too

early/late.

Is the relay scheduled using the

“Astronomic ON/OFF” or “Astronomic

and Schedule ON/OFF” scenarios?

No – make the necessary changes

and test again

Yes – Go to next step

Is the panel’s location set up for the

correct city/state?

No – make the necessary changes

and test again

Yes – Go to next step

Is Daylight Savings set up correctly for

the panel’s location?

No – make the necessary changes

and test again

Yes – Call tech support

6I go to enter my

on and off times

and I get the “You

are attempting to

enter a ON/OPEN

time that happens

after the OFF/Close

time. Please correct

before moving on.”

Error message.

Are you entering ON/OFF times using

the 24-hour format?

No – Using the 24-hour format

make the necessary scheduling

corrections

Yes – Refer to the “Spanning

Midnight With A Schedule” section

of the User’s Guide and make the

necessary scheduling corrections

7I need to remove

a sensor from the

system.

Once a sensor has been connected to

a relay driver or group switch card low

voltage input, the input will remain in

the sensor mode even if the sensor is

removed.

To restore normal operation:

1. Remove the sensor wiring from the

panel input.

2. Turn the associated relay or group

off using the red override button

corresponding to the input where the

sensor had been connected.

3. Momentarily jumper the white and

red terminals.

4. Does the relay/group turn on?

No – Call tech support

Yes – Normal operation is restored.

The input is configured for

standard low voltage switches.

11

ORDERING INFORMATION – STANDARD CONFIGURATIONS

Catalog No. Description of Lighting Control Panel

LP8S-4-115 Surface-mount cover, 4 relay; 115/277VAC

LP8F-4-115 Flush-mount cover, 4 relay; 115/277VAC

LP8S-8-115 Surface-mount cover, 8 relay; 115/277VAC

LP8S-8-240 Surface-mount cover, 8 relay; 240VAC

LP8S-8-347 Surface-mount cover, 8 relay; 115/347VAC

LP8S-8G-115 Surface-mount cover, 8 relay, Group switch card; 115/277VAC

LP8S-8G-240 Surface-mount cover, 8 relay, Group switch card; 240VAC

LP8S-8G-347 Surface-mount cover, 8 relay, Group switch card; 115/347VAC

LP8F-8-115 Flush-mount cover, 8 relay; 115/277VAC

LP8F-8-240 Flush-mount cover, 8 relay; 240VAC

LP8F-8-347 Flush-mount cover, 8 relay; 115/347VAC

LP8F-8G-115 Flush-mount cover, 8 relay; 115/277VAC

LP8F-8G-240 Flush-mount cover, 8 relay, Group switch card; 240VAC

LP8F-8G-347 Flush-mount cover, 8 relay, Group switch card; 115/347VAC

Optional system equipment

EM-24A2 Low voltage exterior photocell

AS-100* Automatic control switch; 120/277VAC; 50/60Hz

LVS-1* Standard momentary toggle switch

RS2-3x* Two button low voltage momentary switch

L1S* Single button low voltage architectural design toggle switch

LxS* Multi-button low voltage architectural design toggle switch

DCC2* Low voltage momentary switch, Miro Decorator style with LED

* Multiple options available, such as color, lighted/unlighted, keyed, number of buttons, etc. Consult Watt

Stopper/Legrand Product Selection Guide for details.

WARRANTY INFORMATION

Watt Stopper/Legrand warranties its products to be free of defects in materials and workmanship for

a period of one (1) year. There are no obligations or liabilities on the part of Watt Stopper/Legrand for

consequential damages arising out of, or in connection with, the use or performance of this product or

other indirect damages with respect to loss of property, revenue or profit, or cost of removal, installation or

reinstallation.

2800 De La Cruz Boulevard, Santa Clara, CA 95050

Technical Support: 800.879.8585

www.wattstopper.com

09853r2 12/2014

Please

Recycle

This manual suits for next models

2

Table of contents

Other wattstopper Control Panel manuals

Popular Control Panel manuals by other brands

Kuhse

Kuhse KEA 3 0 Series user manual

Beninca

Beninca MATRIX manual

American Standard

American Standard ACONT602AF22MA installation instructions

Fire-Lite Alarms

Fire-Lite Alarms MS-9200E Programming, installation, maintenance and operating instruction manual

DAS

DAS DL200 installation manual

Sices

Sices GC310 Use and maintenance manual

Vallox

Vallox Exxeo manual

Honeywell

Honeywell Notifier ST.PL4+ Installation and user manual

Logicor

Logicor PSU 1001 user guide

weintek

weintek cMT3108XP Series Installation instruction

Radionics

Radionics D7212 Operation and installation manual

Beckhoff

Beckhoff CP2912 Installation and operating instructions