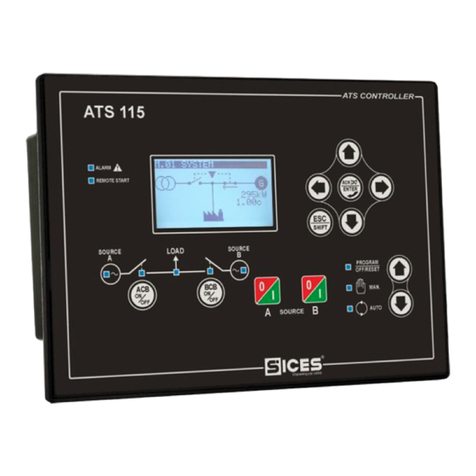

Sices GC310 User manual

Filename: Use and maintenance manual

Rev. 00 Date: 23/09/2014

Product: AUTOMATIC GENSET

CONTROL PANEL with GC310/GC350

2

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

THIS MANUAL IS TO BE CONSIDERED AN ATTACHMENT OF THE GC310/GC350

CONTROLLER MANUAL.

INDEX

1. Introduction to the manual (see also GC310/GC350 manual)....................................3

2. General conditions of use (see also GC310/GC350 manual) .....................................4

3. Instructions for the installation (see also GC310/GC350 manual).............................5

3.1 Safety distances.......................................................................................................6

3.2 Control panel protection ...........................................................................................6

3.3 Power cables connection and screw tightening: switchover.....................................7

3.4 Power cables connection and screw tightening: genset protection switch................8

4. Start-up (see also GC310/GC350 manual) ...................................................................9

4.1 General information..................................................................................................9

4.2 Additional services....................................................................................................9

4.2.1 External emergency stop..................................................................................9

4.2.2 Battery charger.................................................................................................9

4.2.3 Engine pre-heating ...........................................................................................9

4.3 Working logic (standard version)............................................................................10

4.3.1 Changeover carried out by couple of contactors.............................................10

4.3.2 Changeover carried out by motorized switch..................................................11

4.3.3 Automatic mode..............................................................................................13

4.3.4 Manual mode..................................................................................................14

4.3.5 Test mode.......................................................................................................15

5. Control panel composition .........................................................................................16

5.1 Connection terminal board interface (power and auxiliaries)..................................21

6. Check and maintenance (see also GC310/GC350 manual) ......................................25

7. Transport, storage, decommissioning.......................................................................26

8. Faults and possible causes (see also GC310/GC350 manual).................................27

9. How to ask for assistance...........................................................................................29

10. Overall dimensions....................................................................................................30

11. Slot dimensions and assembly ................................................................................31

3

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

SICES is pleased to thank you for purchasing our Automatic Genset Control Panel.

These Control Panels are the result of the design, the selection of the best components, the careful

assembly and the strict tests to which all SICES products are submitted.

We recommend to read this manual carefully and to observe the safety rules and all regulations for

the correct use andmaintenance of the Control Panel. This will guarantee better duration results and

efficiency.

In case of any doubts or questions, please do not hesitate to contact SICES technicians for

clarifications.

The information contained in this Manual are updated to the printing stage, but they may be modified

without notice in compliance with our aims of continuous development andimprovement of products.

This manual and all enclosed documents are to be intended as part of the Control Panel and are

intended to be read by all those who are involved in the life cycle of the machinery; therefore they

must be collected in a well-known place and be accessible to the operators, keeping them carefully

in order to avoid their loss or deterioration.

This manual has been drafted for the installer, the user and the maintenance technician. It is

obligatory to read it carefully and view all electrical diagrams and instructions enclosed, as they

provide indications on the Control Panel use and also show the technical characteristics, as well as

the installation and assembling features.

The customer must observe all safety instructions.

WARNING:

The transfer switch control panel must be only used by properly trained

personnel.

The installation must only be planned and carried out by skilled personnel.

Any fault in installation and use may cause serious damage to the machinery,

to the user system and to the persons involved.

Please note that it is obligatory to observe the regulations in force in the Country where

the installation is carried out; in case of more than one regulation in force around the

same topic, always the strictest one must apply.

4

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

The product has been designed and manufactured in compliance with the safety regulations in force,

for use in normal and not classified environments.

In order to prevent damages and injuries to things and persons, we strictly recommend to use all

necessary caution and observe the regulations.

The Control Panel dimensions for the calculation of the wasting heat power have been estimated

considering that no other heating sources occur nearby.

If the Control Panel is placed into a room together with other panels, a suitable distance allowing the

wasting of the heating produced must be guaranteed.

The calculation has been carried out for a use at 35°C average environmental temperature

according to CEI EN 60439-1 and IEC 439-1rules.

In case it is necessary to use the equipment at a different average ambient

temperature, please contact our Engineer Department for the necessary evaluations.

The Control Panel must only be intended for the purpose to which it has been designed. Any other

use is considered improper and therefore dangerous.

5

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

Do not carry out or try to perform actions of start-up, maintenance, reparation or

modification you have neither the specific expertise nor the precise instructions.

If any doubt persists after reading the following paragraphs and attachments, please

do not hesitate to contact SICES Technical Service. All actions must always be

performed complying with safety regulations.

We recommend to check that the Control Panel is intact after unpacking. In case of doubts, do not

use it, but refer to the manufacturer under penalty of warranty nullity.

Before proceeding to the installation, ensure you checked and observed the following indications:

- All installation operations must be performed by skilled personnel who strictly observe the

safety regulations in force in the country where the installation takes place;

- Ensure that the data on the identifying label of the control panel comply with the plant values;

in detail, check the power, the voltage, the current and the frequency;

- For the electric connection, strictlyfollow the enclosed electric diagram, which contains useful

information;

- In the connection of the power and command lines, we recommend to guarantee at least the

section value suggested;

- Ensure that the connection of the earthing protection conductor is always connected,

compatibly with the distribution system and the regulations in force in the country of issue;

- Ensure that the conductors of the auxiliary circuit are correctly connected. Also check

the correct connection of the phase and neutral conductors.

A wrong or missed neutral conductor connection may cause serious damages

to the Control Panel and to the distribution plants connected to it.

Install the control panel according to the protection degree.We recommend the use of a cable press

with the same characteristics, in order to avoid a decrease of the protection value.

The control panels must be installed properly. Any faults, modifications to the original project,

interferences from external agents such as plants, animals, dust, mould, etc. must be removed or

restored to the default values.

6

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

The panel must be placed at a safe distance from heating sources, fuel storage,

flammable material (paper, cloth, etc.) and chemical substances. The precautions

adopted must be those approved by the competent authorities. In order to avoid

potentially dangerous situations, isolate the area around the panel preventing

unauthorised personnel from approaching.

Although SICES products comply with the electromagnetic compatibility rules,

we still strongly recommend NOT to install the Panel (and Genset) next to

equipment ejecting emissions.

Pay special attention while assembling the control panel, in order to prevent external elements from

falling into the panel, i.e. metal shavings or other which could damage or impede the operation of

the electric components.

CEI EN 60439-1 rule assigns INDIVIDUAL TESTS to the installer, in particular the following points:

- 8.3.1. Equipment inspection, including cable inspection and insulation test;

- 8.3.3. Protection measures check.

Note:

It is responsibility of the installer to provide a DECLARATION OF CONFORMITY around the

Control Panel installation once the work has been completed.

WARNING!

A wrong installation or electrical connection may cause serious damage to

persons, Genset, Control Panel and/or plants connected to it.

In order to protect the panel from indirect contacts, overload and short-circuit, it is the installer

responsibility to connect a protection device on the MAINS line with the correct characteristics and

values for the installation point.

As guarantee against electrodynamics stress caused by a short circuit, for panels fixed to the floor,

it is necessary to fix the various lines to each other or to a support. It is also necessary to provide

supports for the power cables so that these don’t weigh down the transfer switch connection bars.

It is the responsibility of the installer to check that the electrical loads connected to the load and its

relative current values do not exceed the projected value of the panel.

The installer must provide the installation of all the necessary equipment apt to

guarantee a safe and correct operations of the system in which the genset control

panel is installed (i.e. coordination of the protections against direct and indirect

contacts).

Note: We recommend the use of proper devices (overvoltage arresters) in order to protect the

circuits directly supplied by the Mains from overvoltage due to atmospheric discharges or particular

events.

7

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

WARNING: Before connecting the phase and neutral conductors of MAINS,

GENSET and LOAD to the control panel, it is the installer responsibility to check

the type of distribution system of the plant.

Pay special attention to check the function of the neutral conductor. If it takes on

the combined neutral and protection function (PEN), IT MUST NOT BE SELECTED.

A wrong or missed neutral conductor connection may cause serious damages to

the Control Panel and to the distribution plants connected to it.

For powers (35÷80kVA), the power cables connection has to be carried out in the terminal board.

For the remaining powers (100÷1580kVA), the power cables connection has to be carried out in the

extension bars.

During the closing phase of the screws that tighten the cable or connection terminals on the bars,

look out not to overtighten the screws, but follow the values of the following table:

SCREW TIGHTENING TORQUE (MAX)

TERMINAL BOARD (35÷80kVA)

MOTORIZED SWITCH (100÷1580kVA)

16mm2

35mm2

CS2

CS3

CS4

CS5

CS6

M5

M6

M8

M10

M12

M16

M14

2 Nm

2.5 Nm

20 Nm

35 Nm

65 Nm

160 Nm

100 Nm

8

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

WARNING: Before connecting the phase and neutral conductors of MAINS,

GENSET and LOAD to the control panel, it is the installer responsibility to check

the type of distribution system of the plant.

Pay special attention to check the function of the neutral conductor. If it takes on

the combined neutral and protection function (PEN), IT MUST NOT BE SELECTED.

A wrong or missed neutral conductor connection may cause serious damages to

the Control Panel and to the distribution plants connected to it.

For powers (35÷80kVA), the power cables connection has to be carried out in the terminal board.

For the remaining powers (100÷1580kVA), the power cables connection has to be carried out in the

extension bars.

During the closing phase of the screws that tighten the cable or connection terminals on the bars,

look out not to overtighten the screws, but follow the values of the following table:

SCREW TIGHTENING TORQUE (MAX)

TERMINAL BOARD (35÷80kVA)

ABB AUTOMATIC SWITCH (100÷1580kVA)

16mm2

35mm2

XT2

T5 (200-250kVA)

T5 (300-400kVA)

T7

T8

M8

M10

M12

2 Nm

2.5 Nm

20 Nm

35 Nm

65 Nm

9

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

In the following pages there will be described in particular the prescriptions of the control panel and

the sequences the operator shall manage.

Before the automatic start-up of the plant, it is advisable to check the good operation of the genset.

In order to guarantee the correct operation of the plant, there are the following devices included:

In case of need of an external emergency stop button, it is possible to connect it to the terminals

n°1/2 on the terminal board XA, after removing the existing bridge.

The Genset is equipped with its own battery charger alternator for the battery recharge sufficient for

the maintenance of the batteries charge when they are working.

Otherwise, when the Genset is not in operation (with Mains presence), it is necessary to maintain

the batteries in perfect charge (to compensate for the auto-discharge, the consumption of the

auxiliary circuits, etc.) in order to guarantee always a good start-up.

Therefore, the panel is equipped with a proper automatic battery charger supplied by the Load, which

is composed by a mechanic unit made up of the electric machine (transformer) and the electronic

control, which includes a heat sink for the components that modulate the charge and internal status

LEDs.

For further details of the characteristics and the operations of control, see the proper operations

manual.

In order to reach the ideal conditions to allow a rapid genset start-up and load pick-up, the engine

water is kept at a medium temperature of 40/50°C. In the internal water circuit there are electrical

heating resistances, with a thermostat device (thermostat contact that closes with min. engine

temperature) that commands the insertion. The circuit supply is resulted from the mains line,

deactivating it automatically when the genset begins to work (in case of mains failure).

10

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

The Genset Automatic Control Panel is a device which allows to manage the load supply from two

separate and independent sources of energy that are: the Mains and the Genset.

According to the nominal current, the switch Mains/Genset is carried oud by means of:

- Up to 125A (35 ÷ 80kVA): 2 4-pole contactors mechanically and electrically interlocked

- From 160A (100 ÷ 1580kVA): 1 4-pole motorized switch TECHNOELECTRIC

MECHANIC INTERLOCK

AUXILIARY CONTACTS

35-53kVA

70-80kVA

35-80kVA

The couple of contactors is mechanically interlocked by

means of the proper device. In order to guarantee a greater

security of the plant, the contactors position is electrically

interlocked by means of auxiliary contacts on the front of the

contactor (see table above).

This system ensures the insertion of one contactor at a time,

in order to avoid to supply the load by both sources

(mains/genset).

When the contactor is excited by the mechanic part, as

shown by the arrow, it comes back.

11

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

In the front of the motorized switch (100÷1580kVA) there is a mechanic position indicator that shows

the status of contacts, so the load status in respect to MAINS and GENSET. In the figure below, the

possible status are shown:

TECHNOELECTRIC

WARNING: check the cyclic direction of the phases MAINS and GROUP before

supplying the LOAD.

The reverse cyclic direction can cause serious damages to the machinery.

WITH INDICATOR

IN POSITION “0”

THE LOAD IS NOT

SUPPLIED BY ANY OF THE

TWO SOURCES

WITH INDICATOR

IN POSITION “2”

THE LOAD IS SUPPLIED

BY THE GENSET

WITH INDICATOR

IN POSITION “1”

THE LOAD IS SUPPLIED

BY THE MAINS

12

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

In front of the switch there is a series of devices, as:

1 Lock that impedes any electric or manual operation.

2 Mechanic indicator of the contacts status.

3 Bush for the insertion of the handle for the manual operation of the switch.

The motorized switch, thanks to its exclusive device, can be managed manually by a proper lever,

even in case of no connection to the remote control logic or damaged system.

The lock is important in case you would like to impede any operation to unauthorized persons, or in

case you would like to ensure that nobody changes the supply status, causing danger to those who

manage the plant. Using the frontal lock, the insertion of the handle for the manual operation is

impeded. With inserted lock, stopping the supply, the electric operation is inhibited too.

The genset control panel must be connected to receive MAINS and GENSET voltage values,

keeping GC310/GC350 in AUTO mode, so that the switch can close automatically on one of the two

sources and supply the plant.

2

TECHNOELECTRIC

FRONTAL VIEW MODELS

CS 4-5-6

WARNING

For the manual operation of the switch, disconnect the

electric command by removing the supply connector.

Then move the operation lever.

OTHERWISE THE DEVICE CAN BE DAMAGED

13

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

All genset control logics are carried out by the GC310/GC350 controller with microprocessor:

Set the GC310/GC350 controller in AUTO mode, using the selection arrows.

The operation cycle is composed as follows:

In case of mains failure or trespassing of the thresholds values set

(calibrations and configurations set in the GC310/GC350 controller)

and with GC310/GC350 in AUTO mode, the genset start-up sequence

begins.

14

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

After the genset start-up, the controller GC310/GC350 measures the

genset voltage value.

The controller GC310/GC350 controls the

status switch, from MAINS to GENSET, in

order to supply the load.

When the mains voltage

comes back to the

threshold values set,

GC310/GC350 produces a reverse

sequence to the previous cycle and brings

the system supply back to Mains,

disconnecting the Genset.

Set the GC310/GC350 controller in MAN. mode, using the selection arrows.

Manual start-up control of the Genset

Manual stop control of the Genset

In MAN mode, by pressing this button it is possible to

change the switch position MAINS/GENSET (the

controller must have the start-up control of the genset

and measure the start-up genset voltage).

This operation cycle is managed with times and thresholds settable in the GC310/GC350 controller.

All these values are changeable by the user and can be consulted in the controller manual.

Note: Please remember that with Mains live and GC310/GC350 in OFF mode, the switch is

commanded to close always in MAINS position.

15

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

Set the GC310/GC350 controller in TEST mode, using the selection arrows.

It allows the automatic start of the genset for the periodic test, enabling the protections. The switch

Mains/Genset is excluded. Any possible mains failure, with lighting of the LED connected to it,

causes the immediate genset supply.

+

This function is enabled by selecting the AUTO/TEST button and by pressing the START and STOP

buttons together.

16

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

STEEL SHEET BOX (35÷53kVA)

Terminal

board

interface

Auxiliaries

zone

Power zone

Power cables

connection -

XR-MAINS

Power cables

connection -

XL-LOAD

Power cables

connection -

XG-GENSET

Earthing bar

Terminal

board

XA

Terminal

board

XM

17

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

STEEL SHEET BOX (80kVA)

Terminal

board

interface

Terminal

board

XM

Terminal

board

XA

Power cables

connection -

XR-MAINS

Power cables

connection -

XL-LOAD

Power cables

connection -

XG-GENSET

Earthing bar

Power zone

Auxiliaries

zone

18

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

STEEL SHEET BOX (100kVA)

Auxiliaries

zone

Bars

protection

Terminal

board

XA

Interface

cable return

duct

Earthing bar

Power zone

Power cables

connection

bars -

XL-LOAD

(front)

Power cables

connection

bars -

XR-MAINS

(back)

Power cables

connection

bars -

XG-GENSET

Terminal

board

XM

19

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

STEEL SHEET BOX (200÷400kVA)

Terminal

board

XA

Interface

cable return

duct

Auxiliaries

zone

Protection

bars

Earthing bar

Power cables

connection

bars -

XG-GENSET

(front)

Power cables

connection

bars -

XR-MAINS

(back)

Power zone

Terminal

board

XM

Power cables

connection

bars -

XL-LOAD

20

Use and maintenance Manual AUTOMATIC GENSET CONTROL PANEL with GC310/GC350

FLOOR STANDING STEEL SHEET CABINET (500÷1580kVA)

Auxiliaries

zone

Interface

cables return

duct

Earthing bar

Power zone

Terminal

board

XM

Power cables

connection

bars -

XL-LOAD

(front)

Power cables

connection

bars -

XR-MAINS

(back)

Power cables

connection

bars -

XG-GENSET

Terminal

board

XA

Interface

cable return

duct

Bars

protection

Other manuals for GC310

1

This manual suits for next models

1

Other Sices Control Panel manuals