4

Thermoelectric Temperature Controllers

The 3500 series advanced design offers an unprecedented combination of features,

performance, and value. A variety of sensors including thermistors, IC sensors (AD590

and LM335), and RTDs are supported. A versatile I/O analog interface is provided at no

additional cost. Connect a standard 12 V fan to the 3500 series and cool your TE's

heatsink.

The fast PID control circuitry provides low noise, stable performance for even the most

stringent temperature control situations. With four proportional gains, two integral time

constants, and an optional derivative time constant, the PI/PID control loop can stabilize

virtually any load. The 3500 series utilizes Wavelength's "Smart Integrator" circuit to

reduce overshoot and improve settling time.

Extensive protection features are incorporated into the 3500 series to protect your

thermoelectric and temperature controlled device from damage. Easy to read LEDs

indicate temperature limit, open thermoelectric, and sensor open/short conditions.

Temperature and current limits are readily adjustable from front panel trimpots. For

additional safety, use the analog interface to disable an LFI-4500's laser diode driver

output if the temperature controller output is turned off for any reason.

Interlock any combination of LFI-3500 series temperature controllers or LFI-4500 series

laser diode drivers without additional hardware. Two or more modules mount into a 19"

rack with optional rack mount kits.

KEY FEATURES...

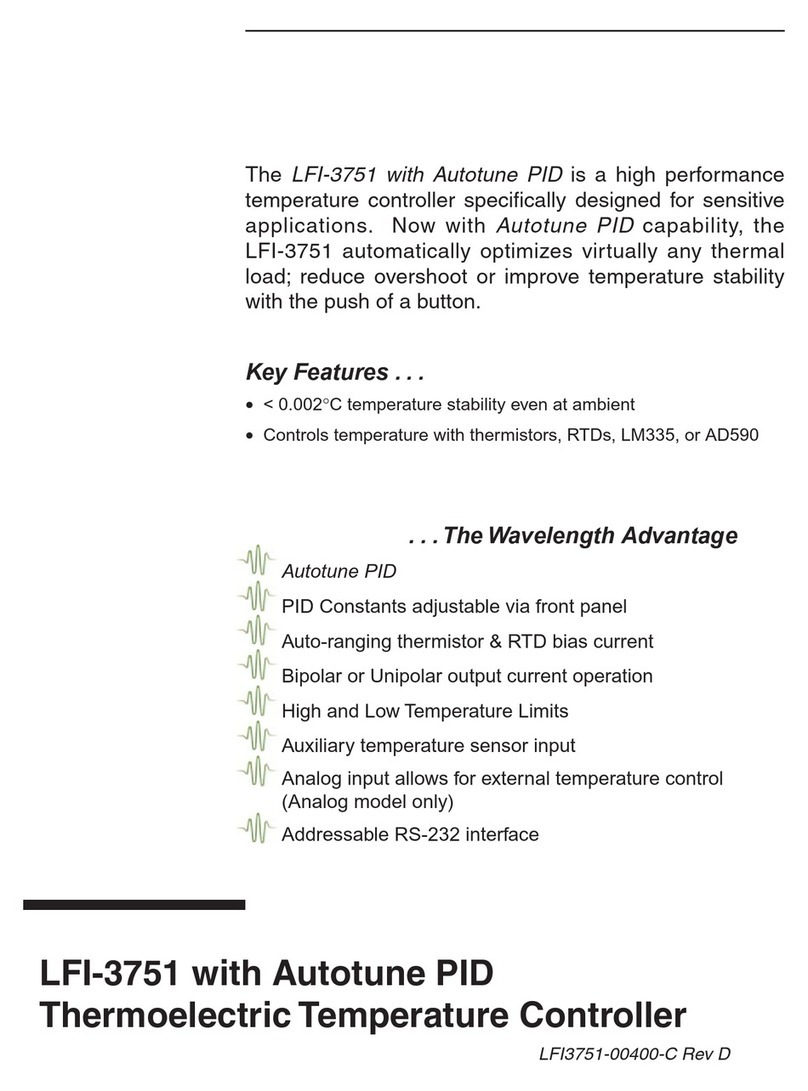

•Ultra stable temperature control (< 0.002 °C)

•Compatible with Thermistors, AD590, LM335, and RTDs

•Four models deliver 15, 22, 25, and 40 W

•Wide temperature control range from −60°C to > +150°C

•Easy to adjust operating temperature and current limit

•Linear, low noise, bipolar current source

...THE WAVELENGTH ADVANTAGE

Low cost, flexible instrument

Fast PID control with "Smart Integrator" overshoot suppression

Adjustable "LOW" or "HIGH" temperature limit protection

Auxiliary thermistor monitors heatsink or ambient temperature

Connect an external fan and cool your TE's heatsink

Display thermoelectric voltage and current

Interlocking enclosures for complete laser drive solutions

Comprehensive Analog Interface includes:

TE V, TE I, TEMP SET, and ACTUAL TEMP outputs

Remote output ON/OFF control

External control of operating temperature

"Open Drain" ON/OFF and error status outputs

Directly integrates with LFI-4500 series laser diode drivers

Booster signal can drive higher powered amplifiers