www.teamwavelength.com© 2005 PRELIMINARY

LDTC2/2

PAGE 10

LDTC2/2-00400-A Rev A

WTC OPERATION, continued

4. PROPORTIONAL GAIN AND

INTEGRATOR TIME CONSTANT -

PI TERMS

The LDTC2/2 is configured to the mid-range

positions appropriate for most laser diode loads.

To adjust these parameters to optimize the

temperature control system time to temperature or

stability, contact Wavelength.

5. POWER SUPPLY SELECTION

The VDD voltage supply input is common to both

the WLD3343 and the WTC3243. This supply

furnishes the voltage to the control electronics of

the devices as well as the compliance voltage for

the WLD3343 Laser Driver.

The supply should be capable of providing at least

3.0 Amps of current in applications that use a

separate VS supply in the temperature control

implementation. Temperature control applications

that tie VDD and VS together require a VDD

current capacity that equals the sum of the

maximum TEC or Resistive Heater current,

plus the maximum laser diode current, plus

approximately 200 mA for the control electronics

of the WTC3243 Temperature Controller and the

WLD3343 Laser Driver, plus current to an optional

fan. Using the maximum potential of the WLD and

WTC will not require more than 6.0 Amps.

VS is the voltage that is applied to the TEC

or resistive heater. This voltage should be high

enough to supply the voltage required by the TEC

or resistive heater plus the compliance required by

the WTC. The voltage available to the TEC will

be from between 0.5 to 1.8V lower than VS. To

minimize power dissipation in the WTC, keep VS

as low as possible.

Online Safe Operating Area (SOA) calculators

are available for the WTC3243. Calculate the

maximum power dissipation of your design at

http://www.teamwavelength.com/

tools/calculator/soa/defaulttc.htm before applying

power to the LDTC2/2.

7. MONITOR ACTUAL TEMP AND

SETPOINT

Pins 9 & 10 of Connector 2 are ACT T Monitor and

SET T Monitor respectively. Measure the actual

sensor voltage across Pin 9 and Pin 12 (COM).

For a 10kΩthermistor with 100µA bias current,

the resistance (in kΩ) is given by:

R = VPIN 9 / 0.1

To monitor the Setpoint Voltage used by the WTC,

use pins 10 and 12.

For other sensor calculations, contact Wavelength.

6. TEMPERATURE SETPOINT

Wavelength introduces a special setpoint circuit

with the LDTC2/2. An on-board trimpot (TSET)

will adjust the voltage from 0.3V to 2.5V.

Additionally, Pin 11 (R TC SET) & 12 (COM) of

Connector 2 will accept a DAC voltage (from 0.3

to 2.5V). The new feature - the “Failsafe Setpoint”

will default the setpoint to 1V (~25°C for a 10kΩ

thermistor) if the chosen signal (from pot or DAC)

falls below 0.3V.

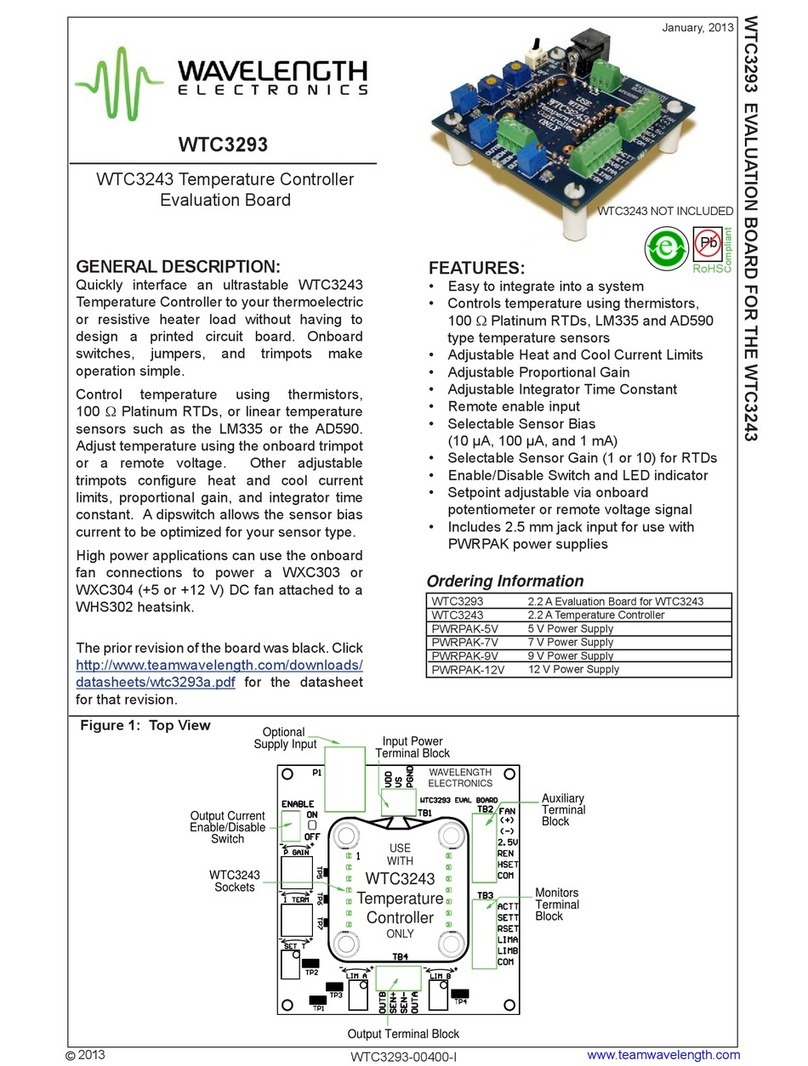

A jumper set lets you choose to use only the

on-board potentiometer or the external voltage.

JP1 configures the Remote Temperature Setpoint

choice. There is about 100mV of hysteresis built

into the default voltage. The input impedance of

the R TC SET is greater than 20kΩand is fully

buffered.

If you use a different sensor or would prefer a

different default voltage, contact Wavelength.

8. ENABLE CURRENT TO TEC

Output current is supplied to the load as soon as

power is applied to the controller. The Power LED

indicator will light GREEN when power is applied.

ExtTset Vset

PDset

ExtTset Vset PDset

Use On-board

trimpot only

Use Extermal

Voltage

Figure 1

Source of setpoint