Cod.006.0001.1380

17/01/2020 v2.6

ENGLISH

4/22

1INTRODUCTION

This handbook must be consigned to the user prior to

installation and commissioning of the unit.

Read the "General prescriptions for use" handbook supplied

separately from this handbook before installing and

commissioning the unit.

The meaning of the symbols in this manual and the associated

precautionary information are given in the "General

prescriptions for use”.

If the "General prescriptions for use" are not present, it is

mandatory to request a replacement copy from the

manufacturer or from your dealer.

Retain these documents for future consultation.

This symbol identifies an action that occurs automatically as

a result of a previous action.

This symbol identifies additional information or a reference to

a different section of the manual containing the associated

information.

This symbol identifies a reference to a chapter of the manual.

This symbol accompanies important information concerning

the execution of the relevant operations.

Multi Power 184 is an inverter DC TIG/MMA portable welding power

source.

The solidity of the components of this unit makes it a reliable working

companion for workshop and outdoor applications.

The available DC TIG functions and digital control make this unit ideal

for maintenance, building construction, and light metalwork.

In MMA welding the Hot Start and Arc Force functions are adjustable

and they allow improved arc striking, a flatter bead and more uniform

weld.

The Anti Sticking function makes it possible to detach the electrode

rapidly from the workpiece in the event of accidental sticking.

Up to 4,00mm diameter electrode welding is possible in MMA.

The power source is designed to guarantee safety and flexibility

through the following features:

OVERCUT: in case of over-voltage in the supply line, the supply to

the power source is cut off.

The overcut protection protects electronic parts of the machine

against damage caused by voltage surges.

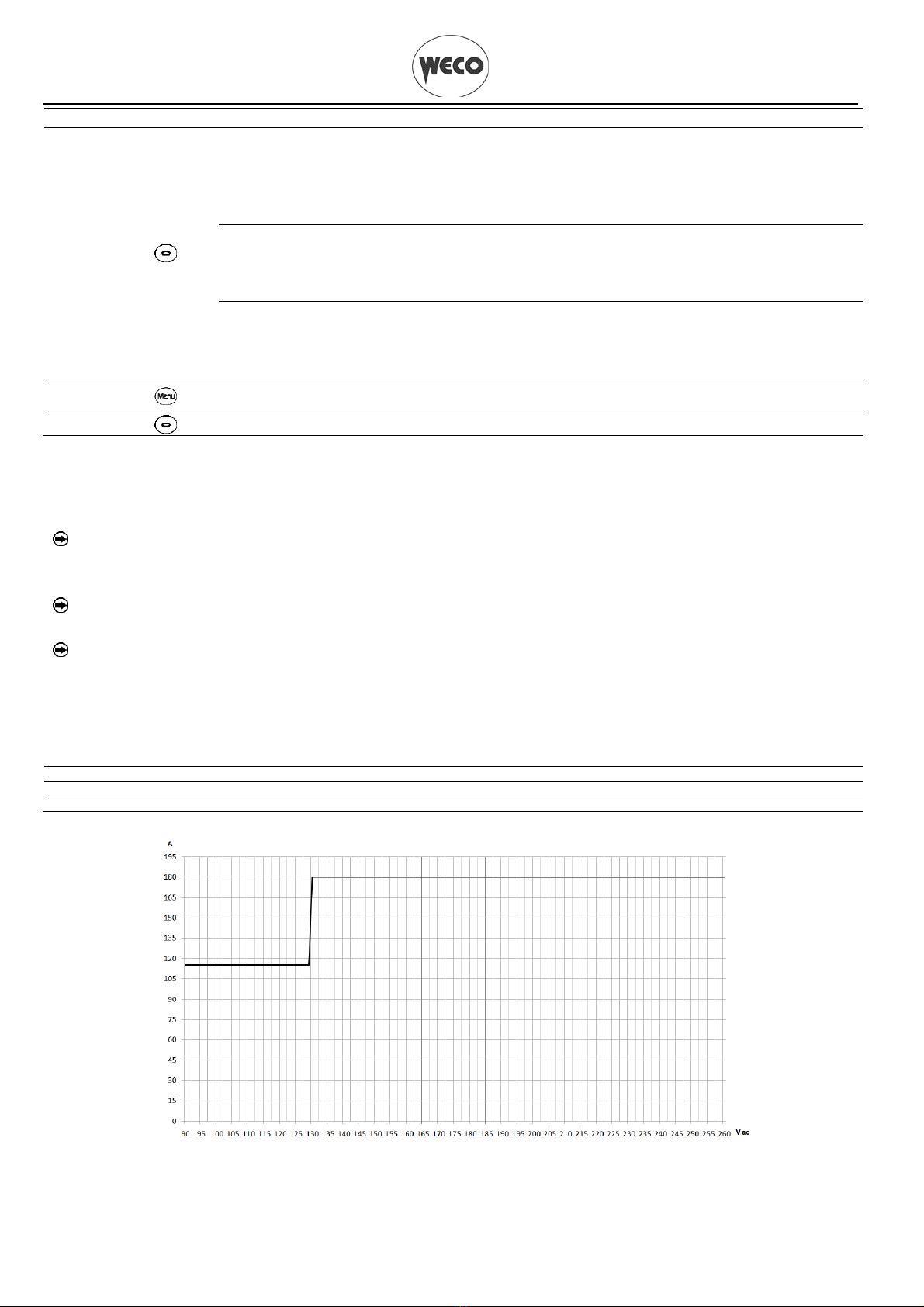

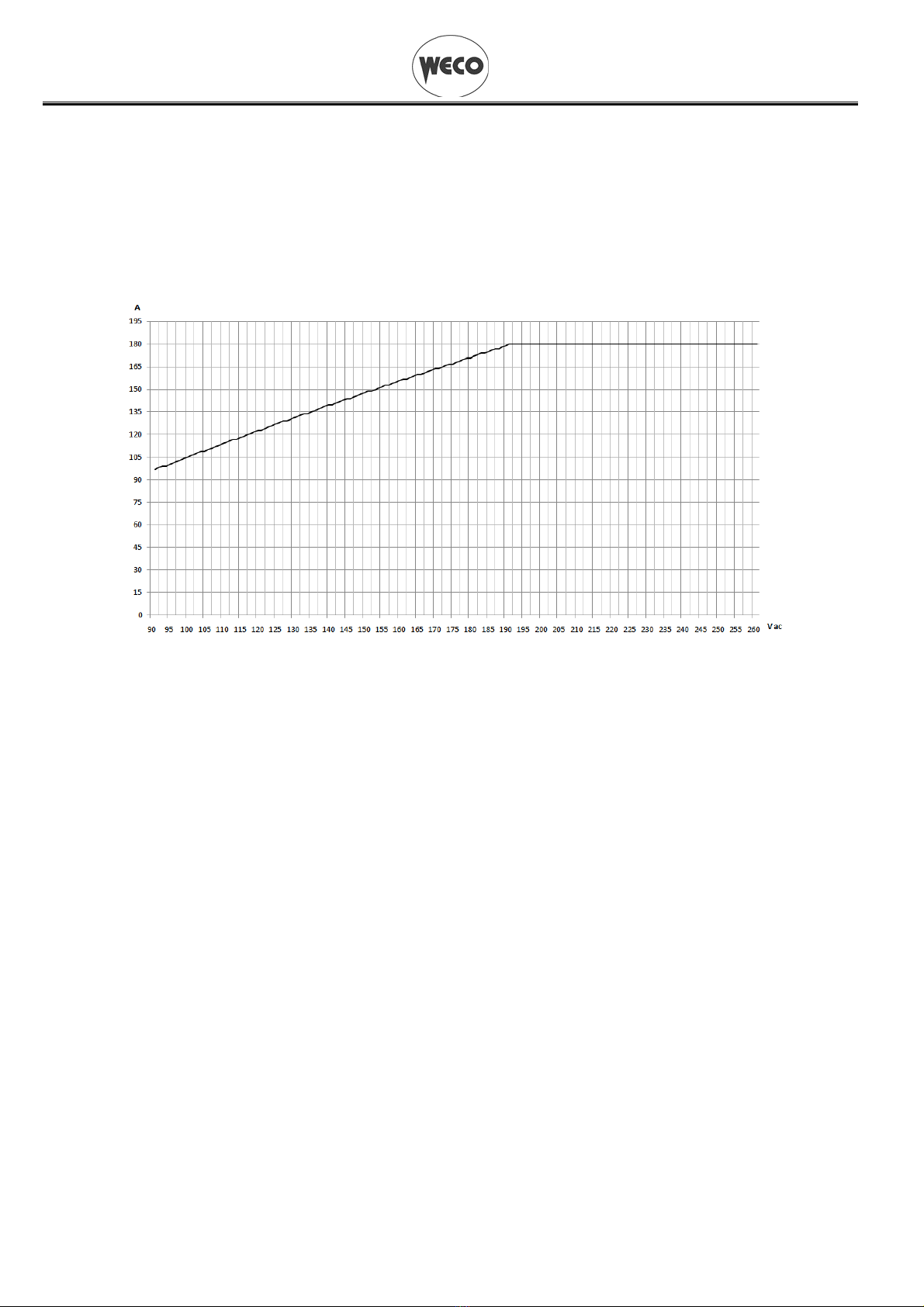

CURRENT AUTO-CALIBRATION: the power source works at a

supply voltage ranging between 115V~±15%/50-60Hz and

230V~±15%/50-60Hz.

The maximum value of the adjustable welding current is automatically

limited based on the supply voltage measured when the power source

is switched on.

DERATING: Derating limits current during welding when supply

voltage drops below the limit value of 190Vac.

This limits current input so as not to overload the inverter and keeps

the welding arc stable.

FANS: Fan speed varies based on power source internal temperature

measured by thermal sensors.

This function brings the following improvements:

reduction of noise.

reduction of dust extracted (cleaner equipment, less

maintenance).

The welding modes and procedures available are those indicated in

the table.

Accessories that can be connected to the unit:

manual remote controller for remote adjustment of the welding

current.

2FRONT PANEL

1: Positive pole welding socket.

2: Negative pole welding socket.