Operating instructions Date: 09/2015

CLICKMATE™ TW154 - 200 bar

Page 8

D-2007/10/00252-9-3

4�1 Safety instructions for operation

4�1�1 Observe the right order when connecting and disconnecting the

WEH®Connector.

4�1�2 Disconnect the WEH®Connector only after complete pressure venting. In case

the operating loop is lifted in pressurized condition, the safety peg locks the

operating loop and prevents disconnection under pressure. If force is used to

actuate the loop with the safety peg extended, the safety peg could be damaged.

4�1�3 Do not use excessive force when connecting.

4�1�4 Do only connect the WEH®Connector to faultless cylinder valves.

4�1�5 Please note: Only use cylinders of a size suitable for the TZ100 weight and height

balancing system used. When positioning the gas cylinder onto the cylinder

holder of the TZ100, the cylinder valve has to be above the connection port of the

CLICKMATE™ TW154 200 bar. If this is not the case, the cylinder size is not

appropriate for the weight and height balancing system size.

NOTE: The CLICKMATE™ TW154 200 bar is equipped with a safety peg (figure 11,

page 12) that is actuated at a pressure between 15 and 20 bar, locking the operating loop

and preventing disconnection under pressure. After completion of the filling procedure

and complete pressure venting, the safety peg retracts allowing the operating loop to be

lifted easily into its initial position. The safety peg can be damaged if the operating loop is

forcibly actuated before the system has been completely vented and the safety peg is still

visible.

4�2 Connection

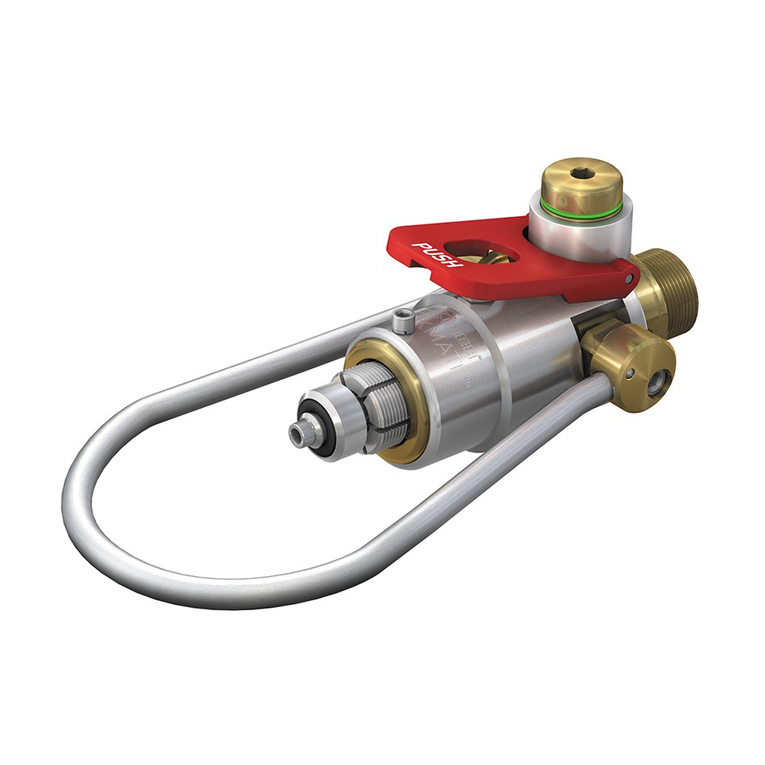

The CLICKMATE™ TW154 200 bar has a green control ring at the locking device and a red

marking at the front part of the connector (figure 3) indicating the proper connection of the

CLICKMATE™ TW154 200 bar.

4�2�1 Place the cylinder onto the cylinder holder of the weight and height balancing sys-

tem. Press the cylinder down until the cylinder valve is opposite the CLICKMATE™

TW154 200 bar (figure 4) connection port.

4�2�2 Lift the operating loop until it stops� Align the cylinder valve with the connector

thus preventing damage to the front seal by sharp edges of the valve. Place the

cylinder valve loose onto the CLICKMATE™ TW154 200 bar until it stops. Do not

use force.

4�2�3 Lower the operating loop until it stops (figure 5)� The operator must be able to

lower the operating loop easily and without using force. The loop must lock into

place with an audible ‚click‘. The clamping jaws are locked, clamp into the cylin-

der thread, the valve is sealed and the pressure-tight connection is made.

4�2�4 Check the connection. Ensure that the operating loop has travelled through its

full stroke to a point below the centre line of the CLICKMATE™ TW154 200 bar

(figure 6) to enable the safety peg to protrude when pressure is applied. The jaws

must fully clamp into the thread.

4 OPERATION

Green ring

Red marking

Figure 3

Figure 4

Figure 5

Figure 6