Welbilt Manitowoc Indigo User manual

Other Welbilt Commercial Food Equipment manuals

Welbilt

Welbilt MANITOWOC RFK User manual

Welbilt

Welbilt Merrychef Eikon E3 User manual

Welbilt

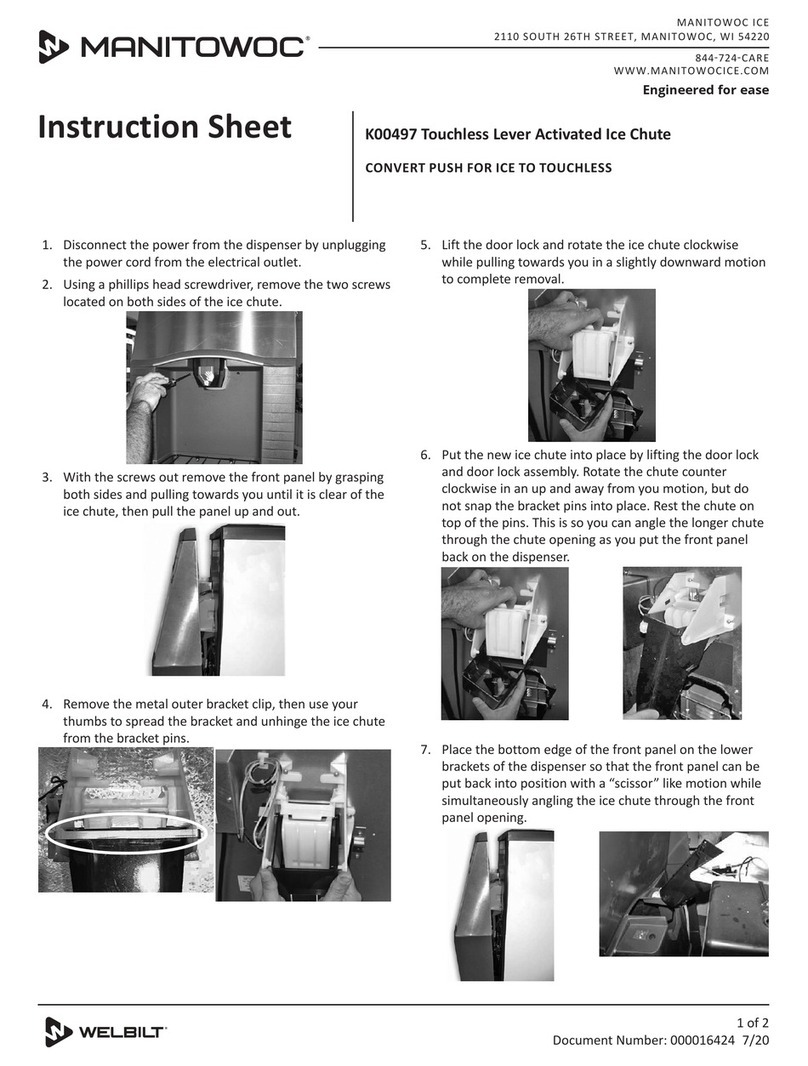

Welbilt Manitowoc K00497 User manual

Welbilt

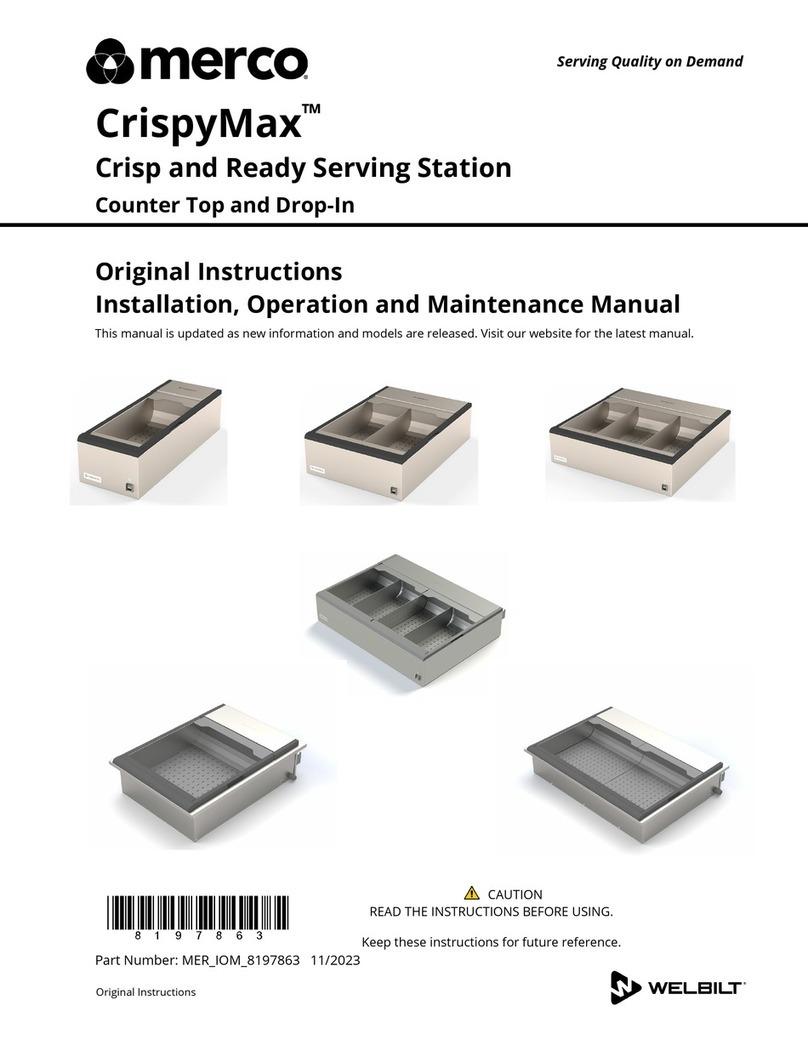

Welbilt Merco CrispyMax MCG1027NNN User manual

Welbilt

Welbilt Convotherm OES mini 6.06 User manual

Welbilt

Welbilt Frymaster Dean SDU Series User manual

Welbilt

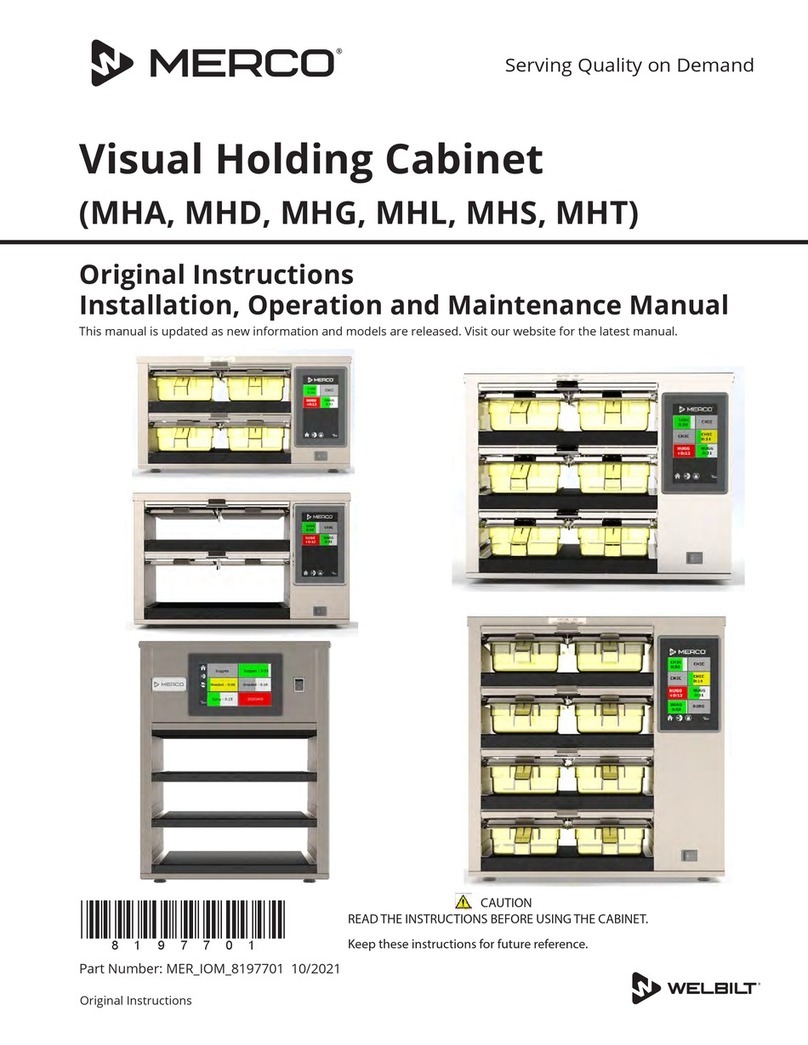

Welbilt Merco MHA Programming manual

Welbilt

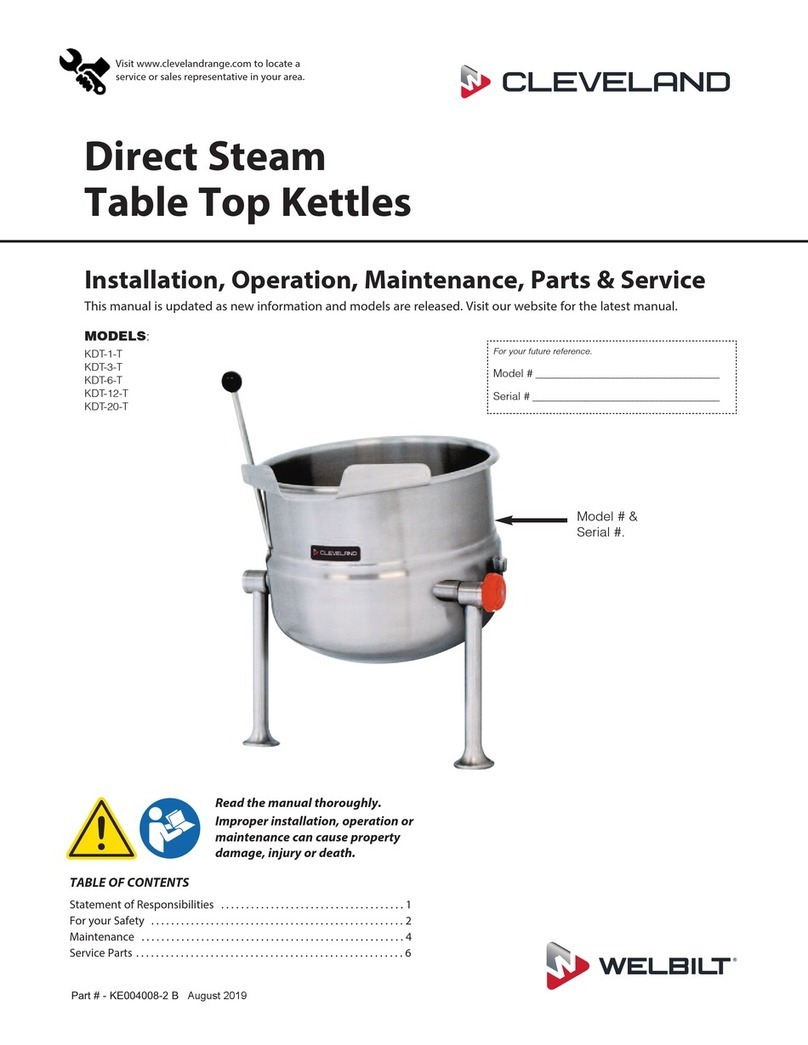

Welbilt Cleaveland KDT-1-T User manual

Welbilt

Welbilt THERMOKINETIC Series User manual

Welbilt

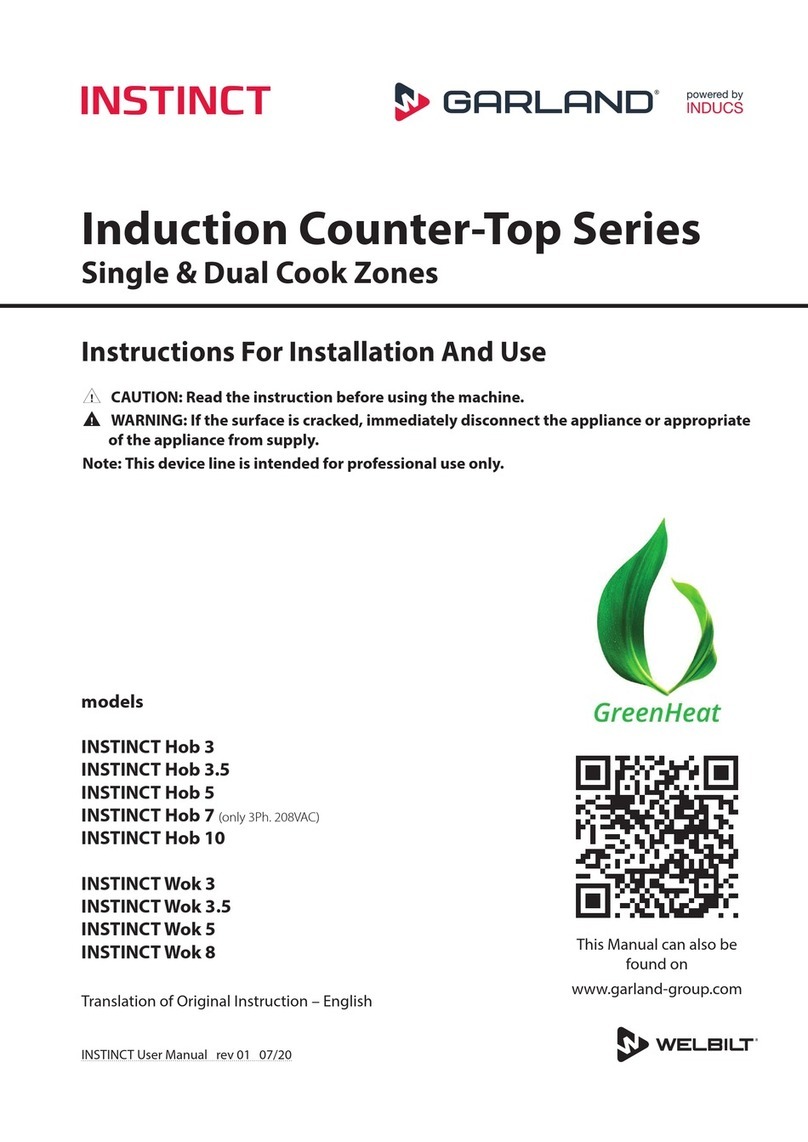

Welbilt INDUCS GARLAND INSTINCT Hob 3 User manual

Welbilt

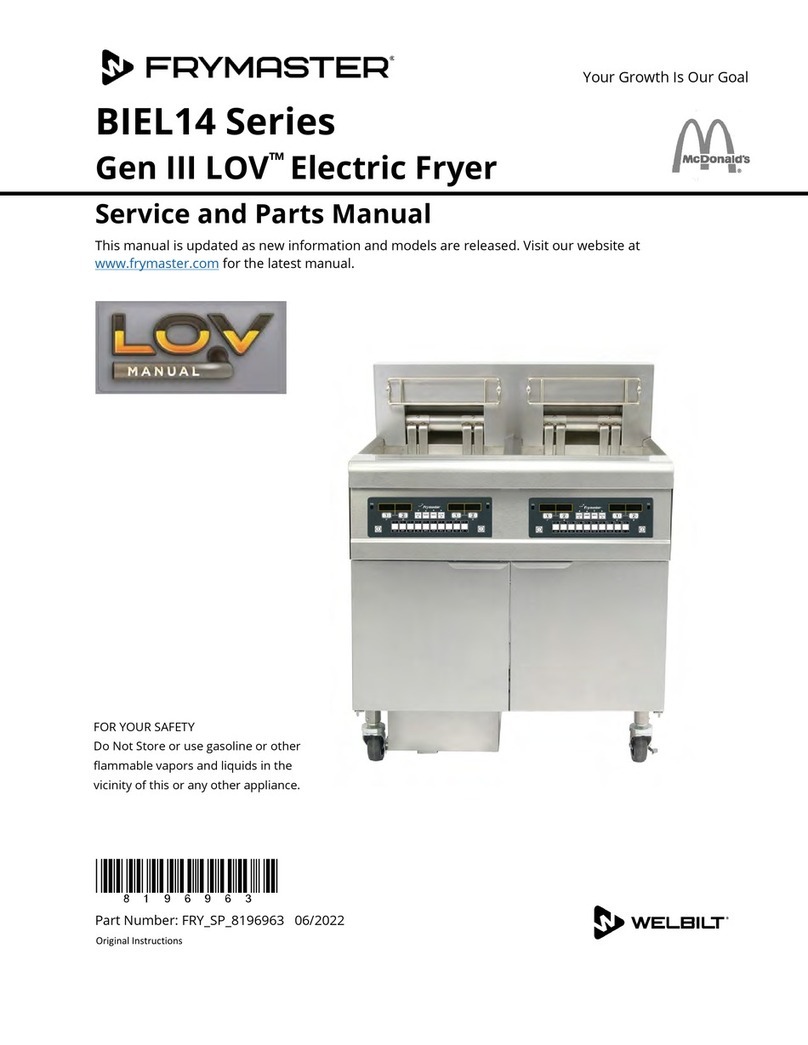

Welbilt Frymaster McDonald's Gen III LOV BIEL14... User manual

Welbilt

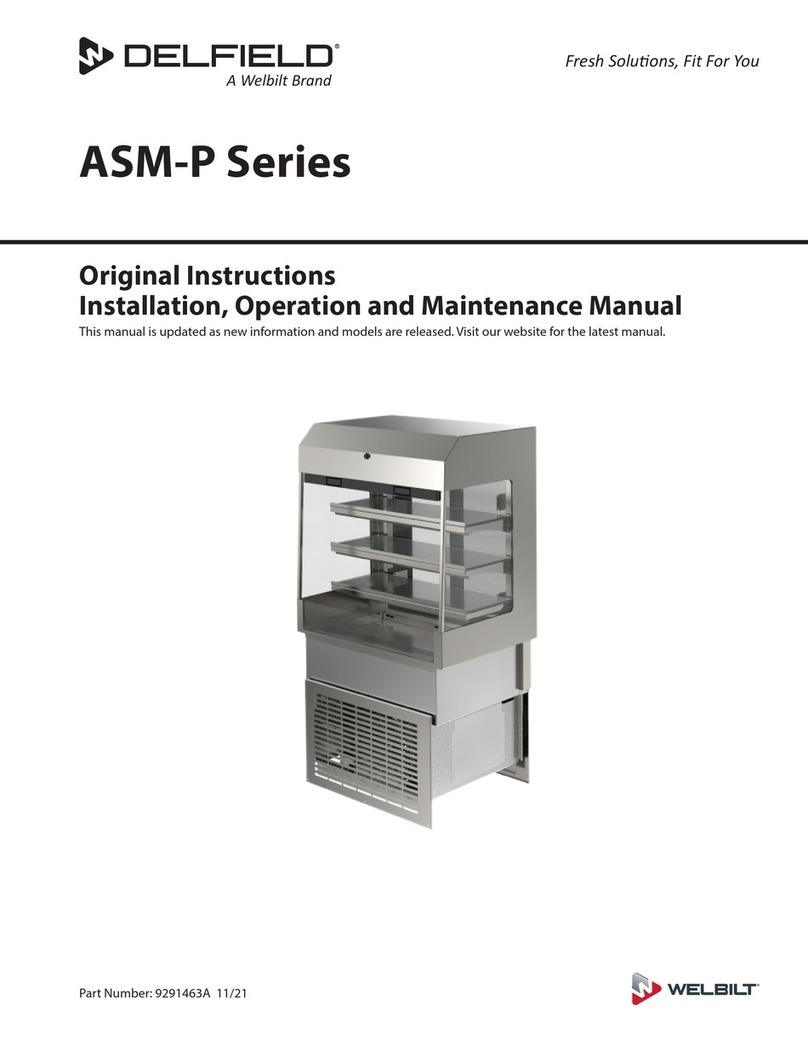

Welbilt Delfield ASM-P Series User manual

Welbilt

Welbilt Convotherm maxx pro C4 EB User manual

Welbilt

Welbilt CLEVELAND PGM Instruction manual

Welbilt

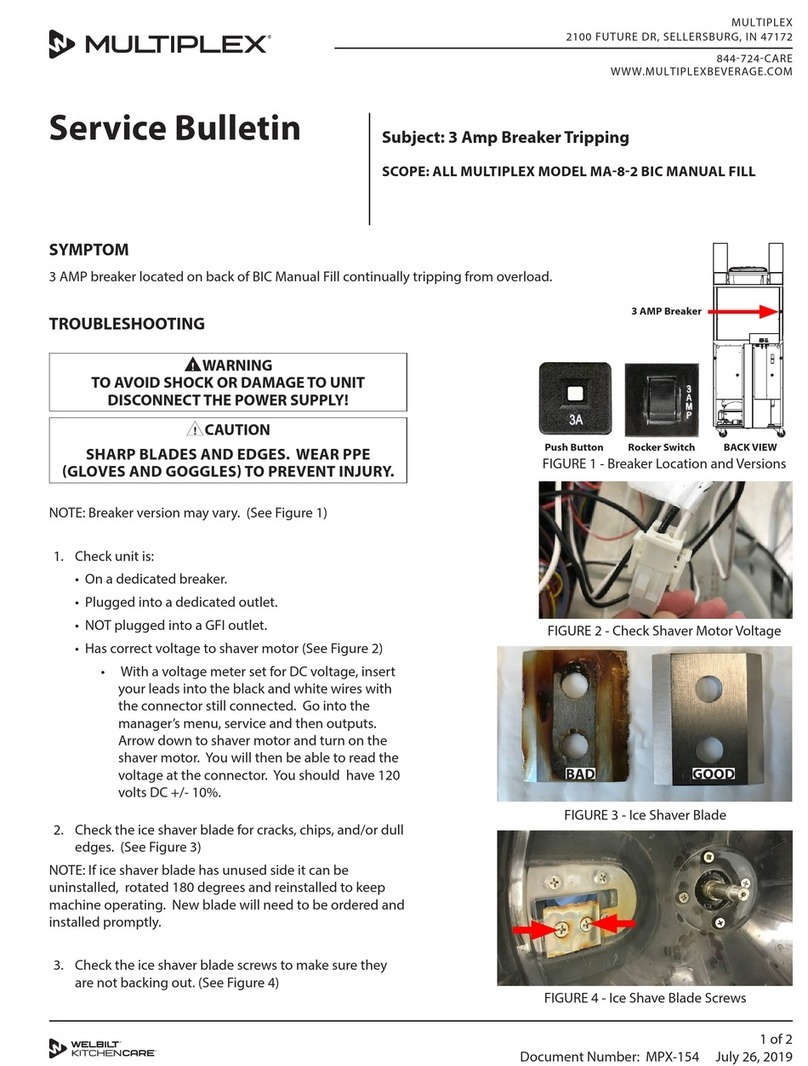

Welbilt MULTIPLEX BIC MA-8-2 Reference manual

Welbilt

Welbilt Frymaster UHCTHD Programming manual

Welbilt

Welbilt Delfield EcoMark 1043 Series User manual

Welbilt

Welbilt Frymaster SDU 50 User manual

Welbilt

Welbilt Merrychef conneX Operating instructions

Welbilt

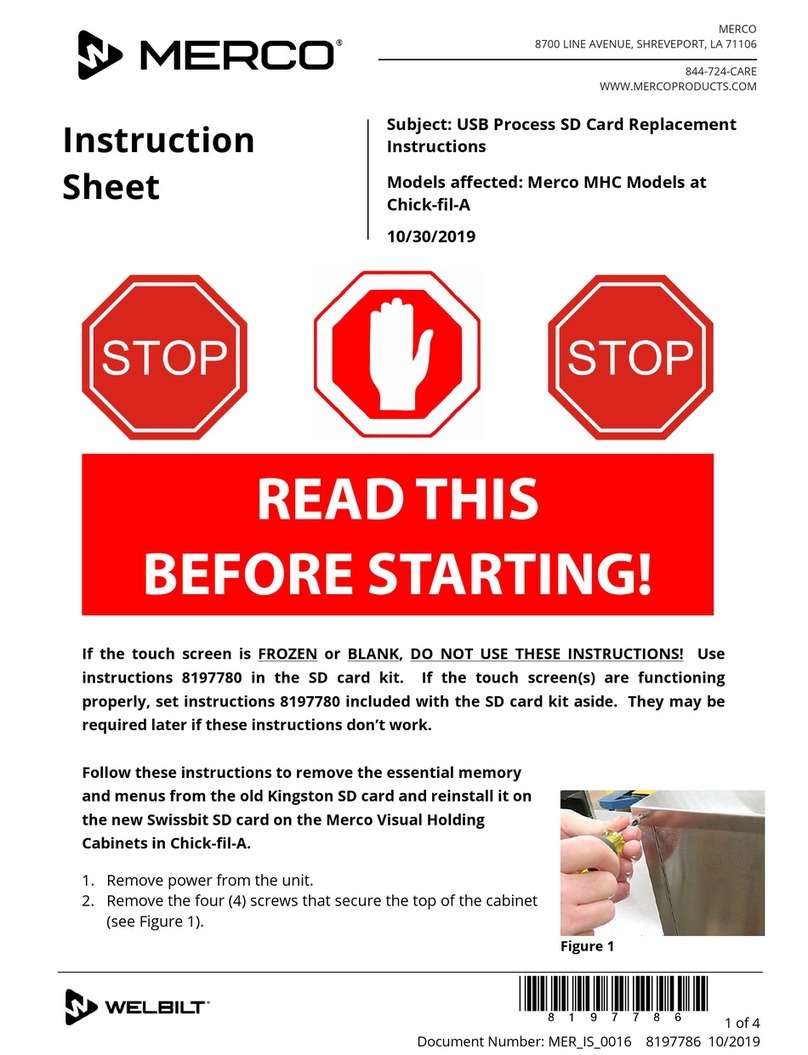

Welbilt Merco MHC Series User manual

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use