NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS FRYMASTER EQUIPMENT OTHER THAN AN

UNMODIFIED NEW OR RECYCLED PART PURCHASED DIRECTLY FROM FRYMASTER DEAN, OR ANY OF ITS AUTHORIZED SERVICERS,

AND/OR THE PART BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS WARRANTY WILL BE VOID. FURTHER,

FRYMASTER DEAN AND ITS AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE

CUSTOMER WHICH ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF ANY MODIFIED PART

AND/OR PART RECEIVED FROM AN UNAUTHORIZED SERVICER.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified personnel only. A Frymaster Factory

Authorized Servicer (FAS) or other qualified professional should perform installation, maintenance, and repairs. Installation,

maintenance, or repairs by unqualified personnel may void the manufacturer’s warranty. See Chapter 1 of this manual for

definitions of qualified personnel.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes of the country and/or region in

which the appliance is installed. For the United States and Canada these are the National Fuel Gas Code, ANSI Z233.1/NFPA

54, or the Natural Gas and Propane Installation Code, CSA B149.1. See NATIONAL CODE REQUIREMENTS in Chapter 2 of this

manual for specifics.

The gas manifold of this appliance or of the battery of which it is a part must be connected to a gas appliance pressure

regulator adjusted for the manifold pressure marked on the rating plate.

The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure

testing of that system at test pressures in excess of ½ psi (3.5 kPa/13.84 inches W.C.).

The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test pressures equal to or less than ½ psi (3.5 kPa/13.84 inches W.C.).

NOTICE TO U.S. CUSTOMERS

This equipment is to be installed in compliance with the basic plumbing code of the Building Officials and Code

Administrators International, Inc. (BOCA) and the Food Service Sanitation Manual of the U.S. Food and Drug Administration.

DANGER

Instructions to be followed in the event the operator smells gas or otherwise detects a gas leak must be posted in a prominent

location. This information can be obtained from the local gas company or gas supplier.

WARNING

Improper installation, adjustment, maintenance or service, and unauthorized alterations or modifications can cause

property damage, injury, or death. Read the installation, operating, and service instructions thoroughly before installing

or servicing this equipment. Only qualified service personnel may convert this appliance to use a gas other than that for

which it was originally configured.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable liquids or vapors in the vicinity of this or any other appliance.

DANGER

No structural material on the fryer should be altered or removed to accommodate placement of the fryer under a hood.

Questions? Call the Frymaster Dean Service Hotline at 1-800-551-8633.

WARNING

After installation of a gas fryer and after any maintenance to the gas system of a gas fryer-manifold, valve, burners, etc. –

check for gas leaks at all connections. Apply a thick soapy solution to all connections and ensure there are no bubbles. There

should be no smell of gas.

NOTICE

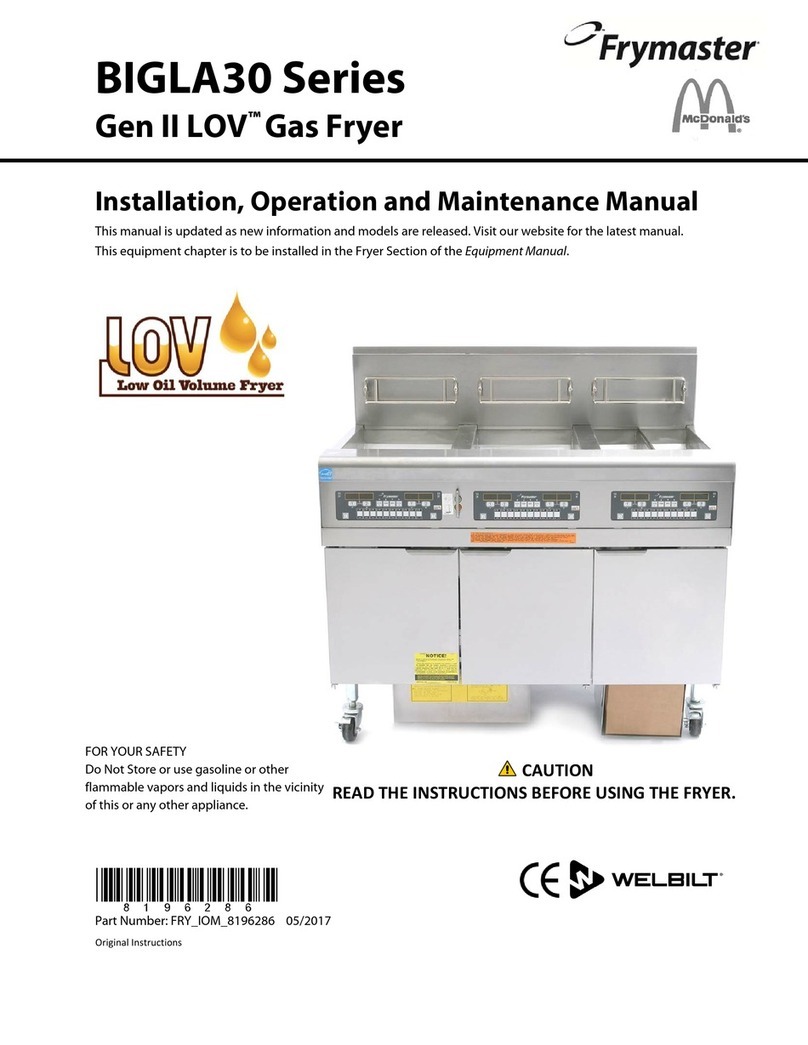

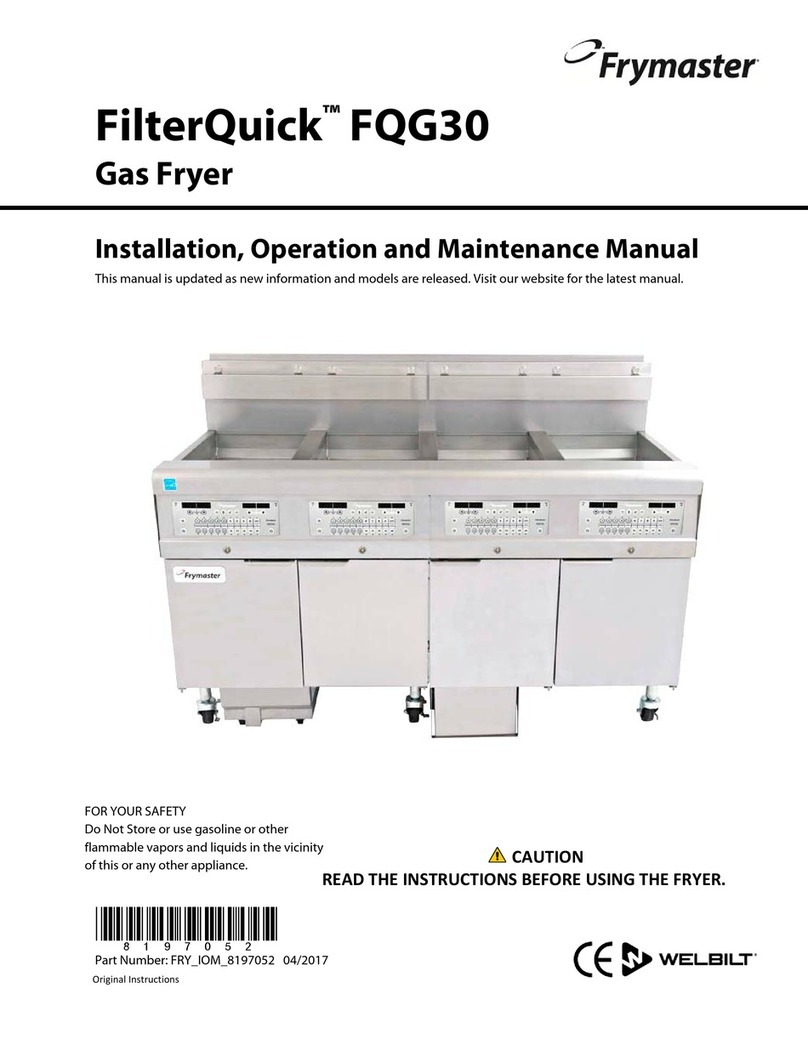

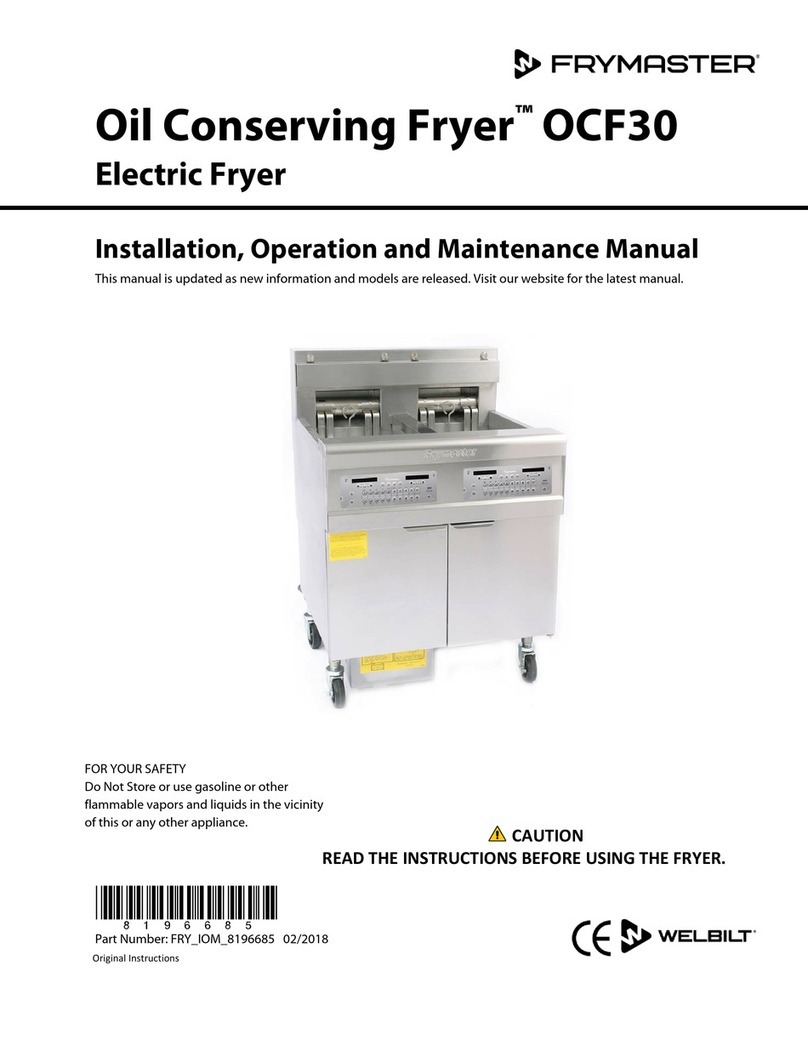

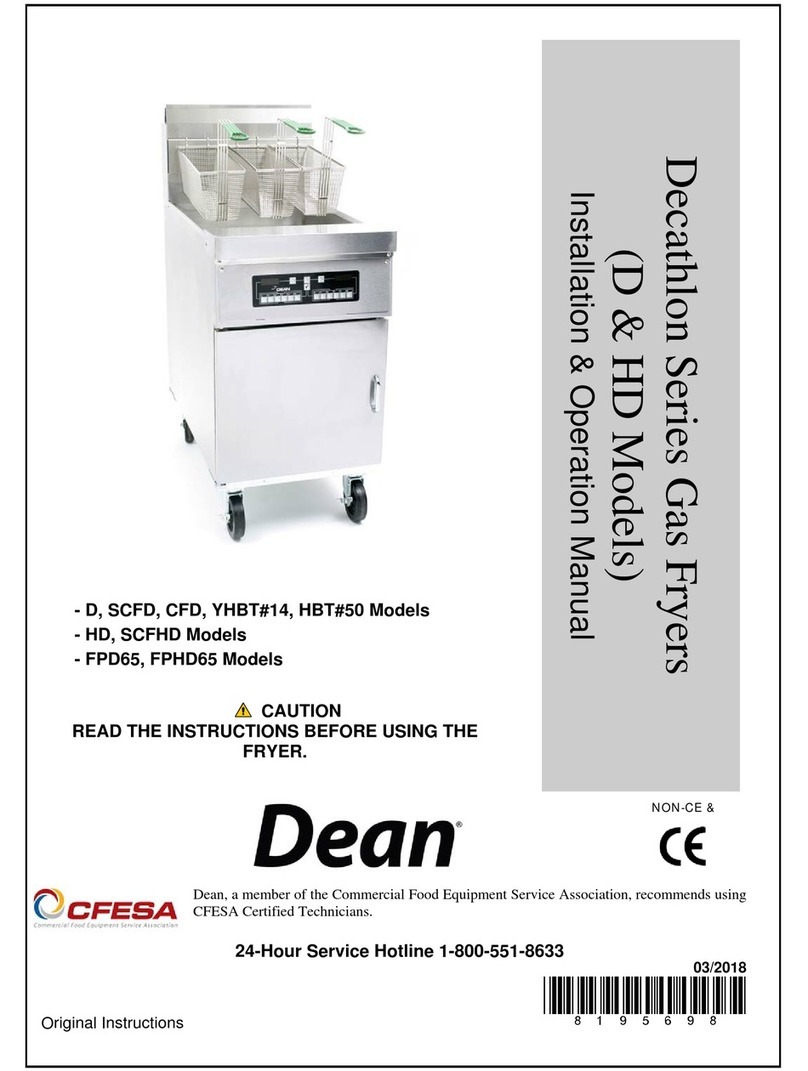

Drawings and photos used in this manual are intended to illustrate operational, cleaning and technical procedures and may

not conform to onsite management operational procedures.