WELDMAX - 7 - MIG S (3-phase) + SWF 2

The mach ne s controlled by an electronic unit wh ch prov des the

feed ng motor's DC voltage, sw tches the contactor and gas valve on/off

and controls the weld ng process.

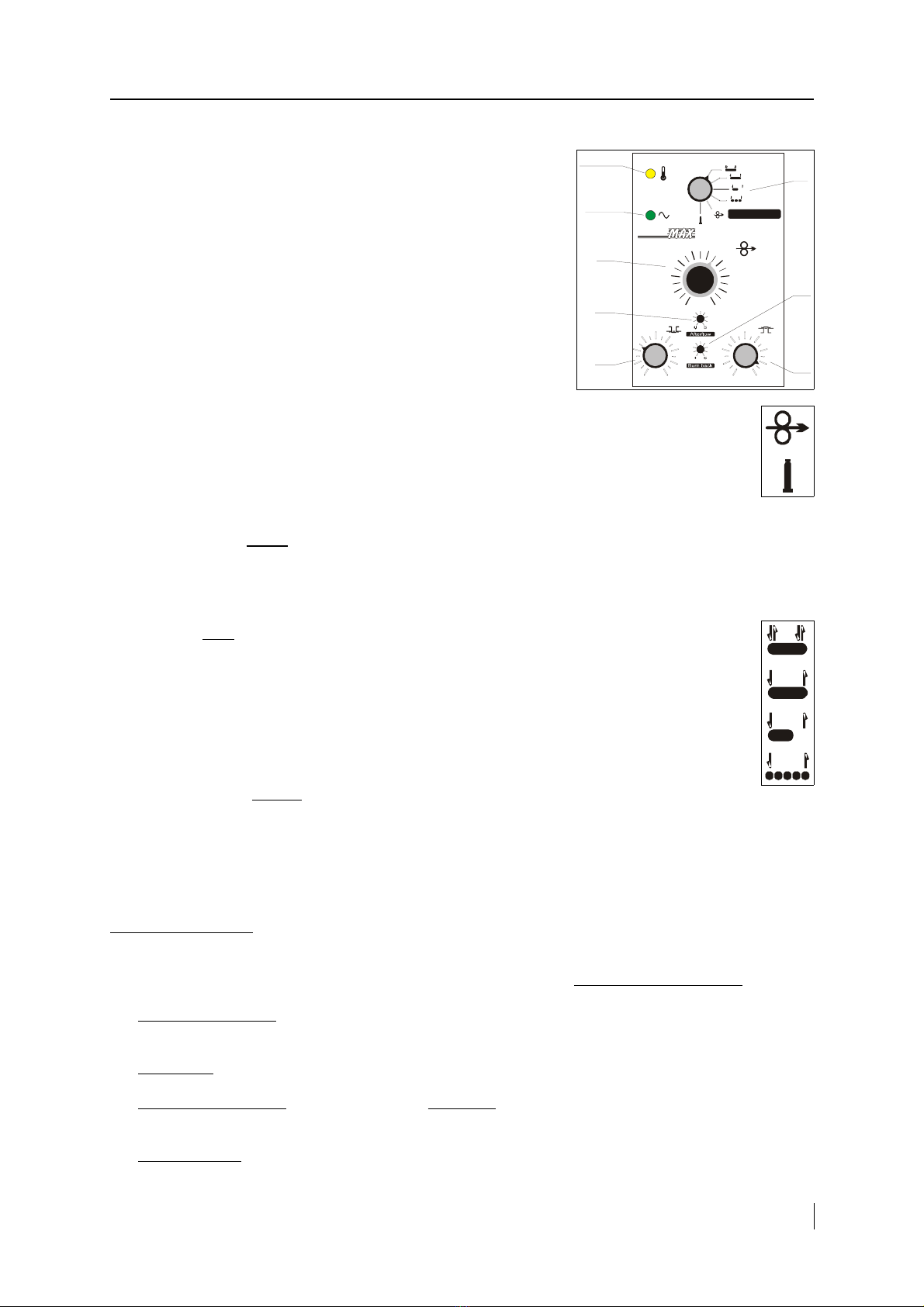

•Green LED: s gnals the mach ne's on.

•Yellow LED: s gnals the overheat ng of the power source.

•K: Funct on selector sw tch.

•P4: W re feed speed potent ometer.

•P7: Weld ng on t me potent ometer.

•P8: Weld ng off t me potent ometer.

•P1: W re burn back (m n ) potent ometer.

•P2: Gas post-flow t me (m n ) potent ometer.

Two operat on modes wh ch can be chosen by the sw tch K are:

Wire threading: Wh le pushing the torch button, the feeder s feeding

the w re w th speed approx. 10 m/m n. nto the torch cable (any other funct ons are proh b ted). For

smooth w re feed, keep torch cable as straight as poss ble dur ng th s operat on. In case of slippage

of the w re, ncrease dr ve roll pressure by the set screw.

Gas test: Wh le pushing the torch button, the gas valve s open (any other funct ons are

proh b ted). Dur ng th s t me the quant ty and the pressure of gas can be checked and set. Set gas

flow between approx. 16-20 l/m n (depending on the weld ng current).

The weld ng can be started by push ng the button on the weld ng torch:

•F rst there s only gas pre-flow ( ts durat on can be 0-0.5 sec., sett ng by P3 potent ometer on the PCB);

•Afterwards the wire feeding beg ns, w th soft start ( ts durat on s set to 0.2 sec. by P9 on PCB), and also the

welding current starts.

The weld ng work s accord ng to the operat on modes set by the funct on selector sw tch (K):

4-stroke mode: Releas ng the button the weld ng continues and t stops only f the button s pushed

aga n.

2-stroke mode: After releas ng the button, the weld ng stops.

Spot welding: After the set t me s f n shed (or releas ng the button), the weld ng stops. The

durat on of the spot weld ng can be set by P7 potent ometer (0.5-2.5 sec).

Interval welding: The weld ng stops f the button s released n the pause t me. The durat on of the

feeding can be set by P7, wh le the pause t me can be set by P8.

When the weld ng s f n shed:

•F rst the wire feeding stops ( f t works);

•Elaps ng the w re burn back t me (P1), the welding current ceases;

•Elaps ng the gas post-flow t me (P2), the gas flow stops, too.

The P6 potent ometer on the PCB sets the m n mal w re speed, wh le the P5 sets the max mal one.

6. Trouble shooting

All repa r works are needed to be carr ed out by a technician, on disconnected mach ne!

If the fault of the equ pment rema ns or s caused by an unknown reason, contact the serv ce d v s on!

•The green LED s off: Faulty sw tch (Q1), ma ns cable or transformer(s); ⇒ replace t or contact the serv ce.

Bad electr c connect ons to the power source; ⇒ check these cables.

•Blown fuse: ⇒ F nd the cause of trouble (short c rcu t may be ns de!), replace fuse and check ts rat ng.

•The yellow LED s on: The power source s overheated; ⇒ wait unt l the fan cools t down and the LED

ext ngu shes.

•No weld ng arc: Faulty torch or ts cable or button; ⇒ replace t. Loose connect on at weld ng cables; ⇒

fasten t. Faulty control un t; ⇒ contact serv ce.

M I G / M A G P o w e r S o u r c e w t h s e p a r a t e W r e F e e d e r

Green

LED

Yellow

LED K

P7

P1

P2

P8

P4

1

2

3

4

5 6

7

9

8

10

PROGRAMME

S

S

0,5

1,5

2,5 sec. 0,5

1,5

2,5 sec.

WELD