SAFETY RULES

magazine, perform maintenance or clear jammed fasteners while connected to the air supply. If the contact

trip is adjusted when the tool is connected to the air supply with loaded nails, accidental discharge may occur.

13. LOAD FASTENERS after connecting the tool to the air supply. Otherwise, fasteners are at risk of being

fired during connection. The tool’s driving mechanism may cycle when it is connected to the air supply. Do

not load fasteners or connect the air supply when the trigger or the safety is pressed down in order to prevent

unintentional firings of a fastener.

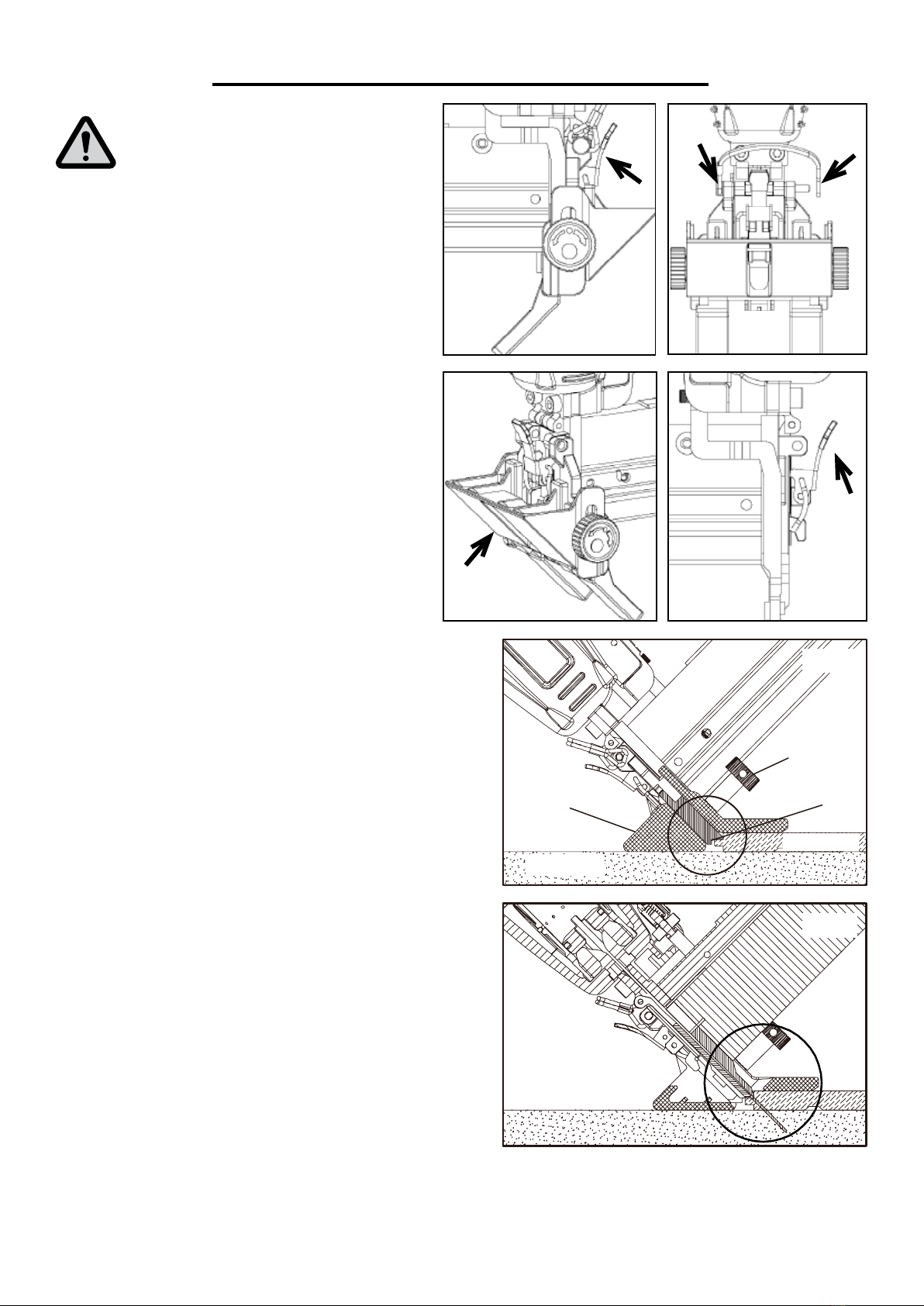

14. DO NOT REMOVE, tamper with, or otherwise cause the tool, trigger or contact trip to become

inoperable. Do not tape or tie the trigger or contact trip in the ON position. Do not remove springs from the

contact trip. Make daily inspections for free movement of the trigger and contact trip. Uncontrolled discharge

may result. Do not alter or modify the tool in any way.

15. DO NOT OVERREACH. Keep proper footing and balance at all times. Wear oil-resistant rubber-soled

footwear. Keep the floor clear of oil, scrap, and other debris.

16. MAINTAIN TOOLS PROPERLY. ALWAYS keep tools clean and in good working order. Follow

instructions for lubricating and changing accessories. Inspect tool before use. Do not operate if any portion of

the tool, trigger, or contact trip is damaged, inoperable, disconnected, or altered. Leaking air, damaged parts,

or missing parts should be repaired or replaced before use.

17. ALWAYS ASSUME that the tool contains fasteners. Do not point the tool at coworkers or yourself at any

time, even if you think it will be really funny.

18. MAKE THE WORKSHOP CHILDPROOF. Use padlocks and master switches and ALWAYS remove

starter keys. Keep bystanders, children and visitors away while operating the power tool. Distractions can cause

you to lose control. When tool is not in use, it should be locked away in a safe place.

19. DO NOT operate the tool if you are under the influence of drugs, alcohol, or medication that may affect

your ability to properly use the tool.

20. REMOVE FINGER FROM TRIGGER when not driving fasteners. Never carry the tool with your finger

on the trigger.

21. MAKE SURE HOSE is free of obstructions or snags. Entangled or snarled hoses can cause a loss of

balance.

22. DO NOT DISCHARGE fasteners into open air, concrete, stone, extremely hard woods, knots or any

material too hard for the fastener to penetrate. Do not use the body of the tool or top cap as a hammer.

Discharged fasteners may follow unexpected paths and cause bodily injury.

23. DO NOT DRIVE FASTENERS near the edge of your work material. The workpiece may split, causing

the fastener to ricochet, injuring you or a co-worker. Be aware that the nail may follow the grain of the wood,

causing it to protrude unexpectedly from the side of the work material. Drive the nail perpendicular to the

grain to reduce risk of injury.

24. DO NOT DRIVE NAILS onto the heads of other fasteners. Do not use the tool at too steep of an angle.

Personal injury from strong recoil, jammed fasteners, or ricochetted nails may result.

25. BE AWARE of material thickness when using the nailer. A protruding nail may cause injury.

5