SAFETY RULES

Safety is a combination of common sense, staying alert and knowing how your item works.

SAVE THESE SAFETY INSTRUCTIONS.

WARNING: To avoid mistakes and serious injury, do not use your tool until the following steps have

been read and understood

1. READ and become familiar with this entire instruction manual, no matter how boring it may be. LEARN the

tool’s applications, limitations, and possible hazards.

2. ALWAYS keep your work area clean, uncluttered, and well lit. DO NOT work on floor surfaces that are

slippery with sawdust or wax.

3. DO NOT USE THE TOOL in the presence of flammable dust, gases or fumes. The tool may produce a

spark that could ignite gases causing a fire. Driving a nail into another nail may also cause a spark.

4. KEEP BYSTANDERS AT A SAFE DISTANCE from the work area, especially when the tool is operating.

NEVER allow children or pets near the tool.

5. MAKE THE WORKSHOP CHILDPROOF. Use padlocks and master switches and ALWAYS remove

starter keys. Keep bystanders, children and visitors away while operating the power tool. Distractions can cause

you to lose control. When tool is not in use, it should be locked away in a safe place.

6. DRESS FOR SAFETY. Do not wear loose clothing, gloves, neckties, or jewelry (rings, watches, etc.) when

operating the tool. Inappropriate clothing and items can get caught in moving parts and draw you in. ALWAYS

wear non-slip footwear and tie back long hair.

7. USE PERSONAL PROTECTIVE EQUIPMENT.

• Everyone in the work area MUST wear safety glasses with side shields that conform to ANSI Z87.1

requirements (approved glasses have “Z87” printed or stamped on them). It is the employer’s responsibility to

enforce the use of eye protection equipment by both the tool operator and others in the work area.

• Wear a face mask or dust mask to fight the debris produced by operation.

• Wear ear protection such as plugs or muffs to fight hearing loss.

• Wear work gloves to protect your hands.

8. KEEP ALERT. Watch what you are doing. Use common sense. Do not operate any tool when you are tired or

under the influence of drugs, alcohol or medication that may affect your ability to properly use the tool.

9. DO NOT OVERREACH. Keep proper footing and balance at all times. Wear oil-resistant rubber-soled

footwear. Keep the floor clear of oil, scrap, and other debris.

10. DO NOT FORCE THE TOOL to do a job for which it was not designed.

11. INSPECT TOOL BEFORE USE. Do not operate if any portion of the tool, trigger, or safety bracket is dam-

aged, inoperable, disconnected, or altered. Leaking air, damaged parts, or missing parts should be repaired or

replaced before use

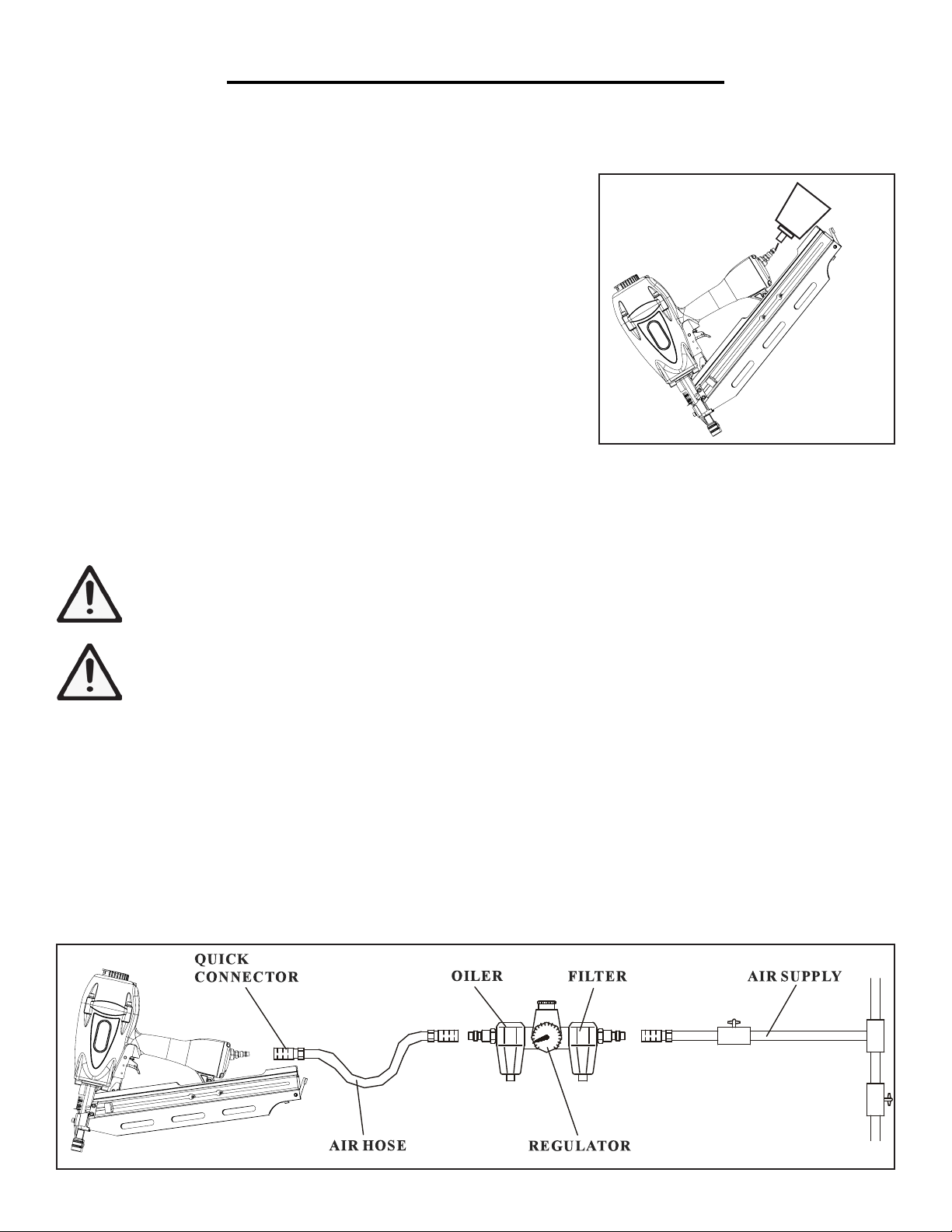

12. WHEN CONNECTING TO THE AIR SUPPLY, the tool is at risk of possibly firing fasteners. Be aware of

this and do not aim the gun at anything you do not want to shoot a nail into.

4