5

installation (continued)

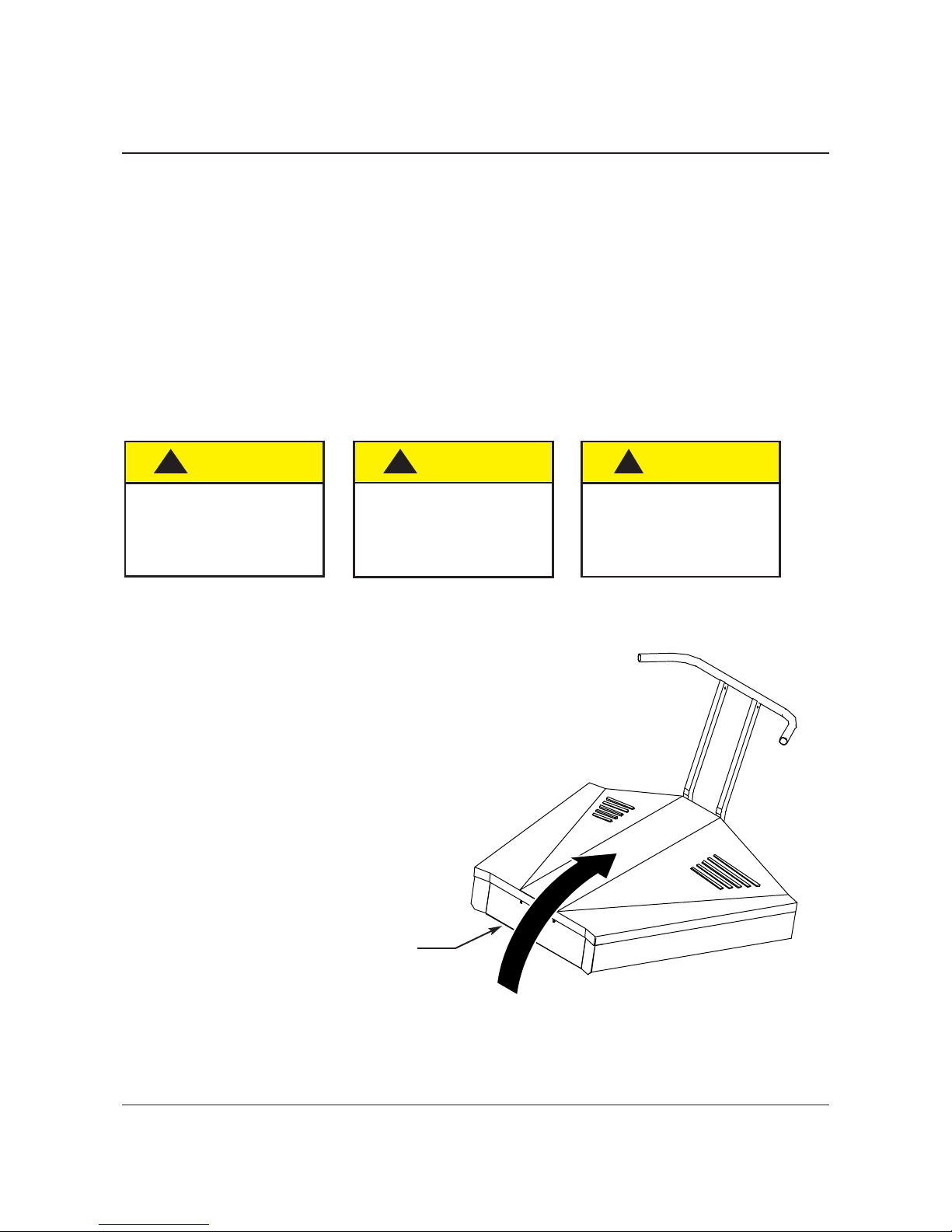

! !

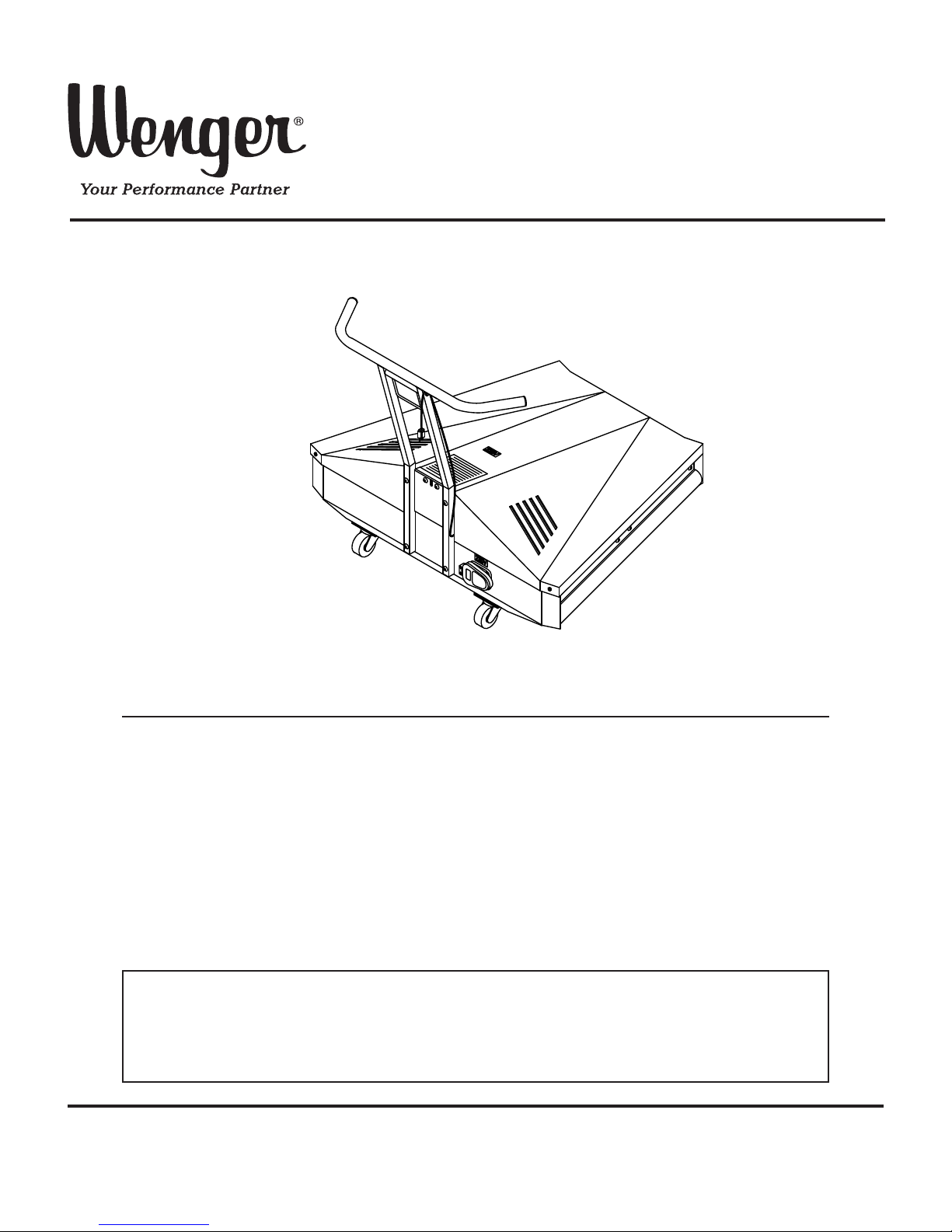

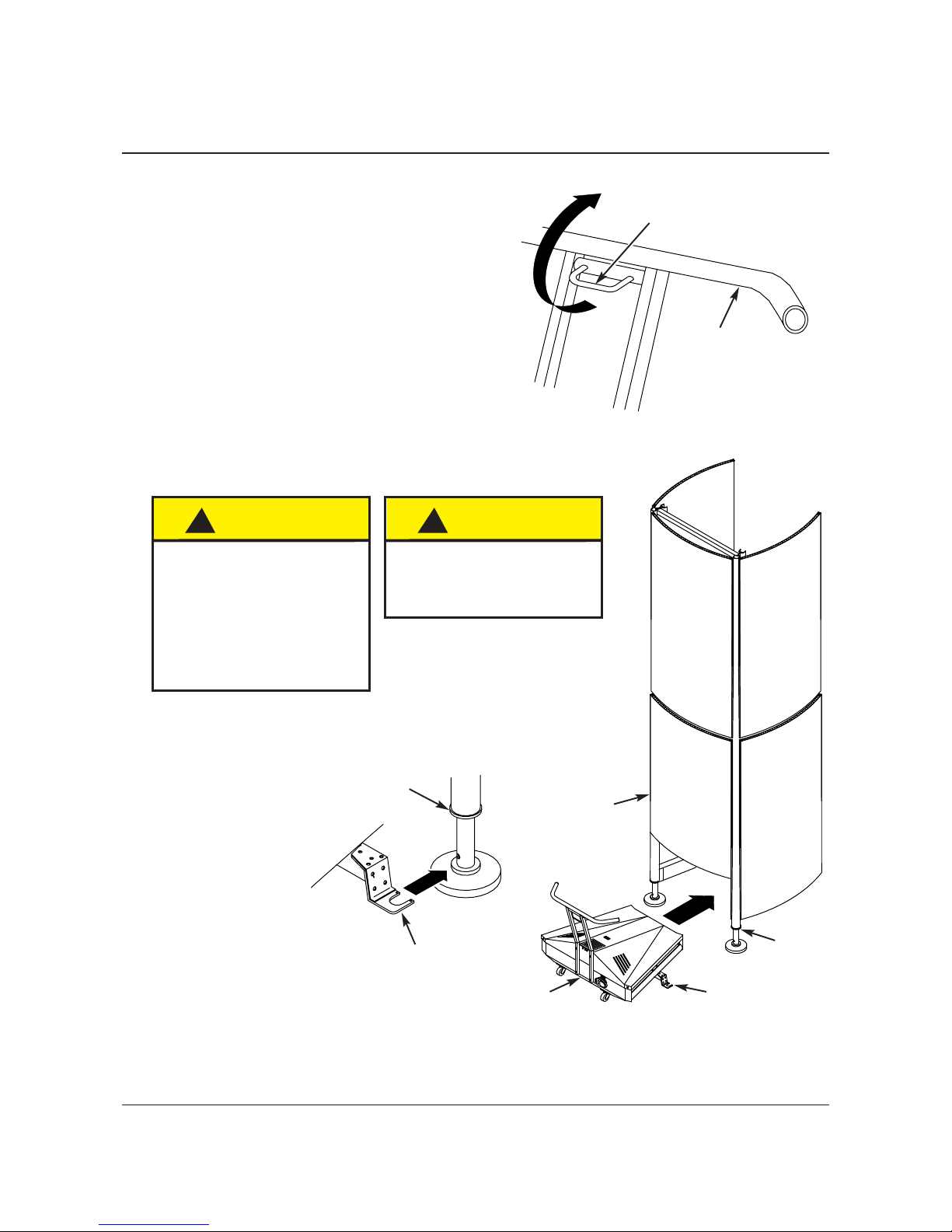

A Diva Air Transporter is designed to receive acoustic towers varying in size from 4.8 m (192 inches)

to 9.7 m (384 inches) high, 3 m (120 inches) to 3.6 m (144 inches) wide and length 1.4 m (56 inches)

deep weighing up to 885 Kg (1950 lbs). The machine is only intended to lift and transport Wenger Diva

Acoustic Towers.

# !

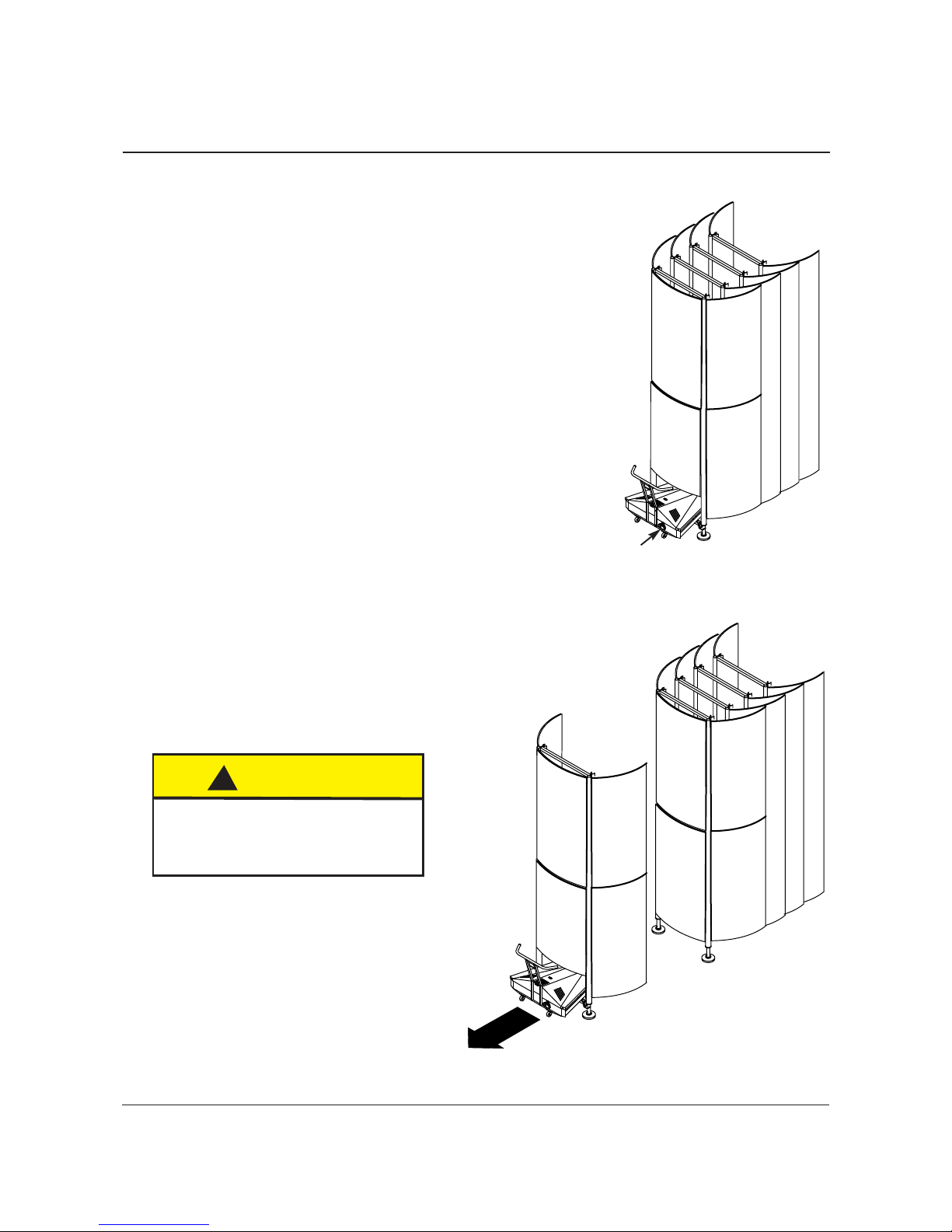

A Diva Air Transporter must only be used on level ground.

" $ #!

A Diva Air Transporter is designed for use indoors in a normal working environment.

The intended operating temperature range is 7°C (45°F) to 35°C (95°F). It must only be used

on level ground, on a smooth solid floor with no ridges, holes or obstructions.

! $ "%

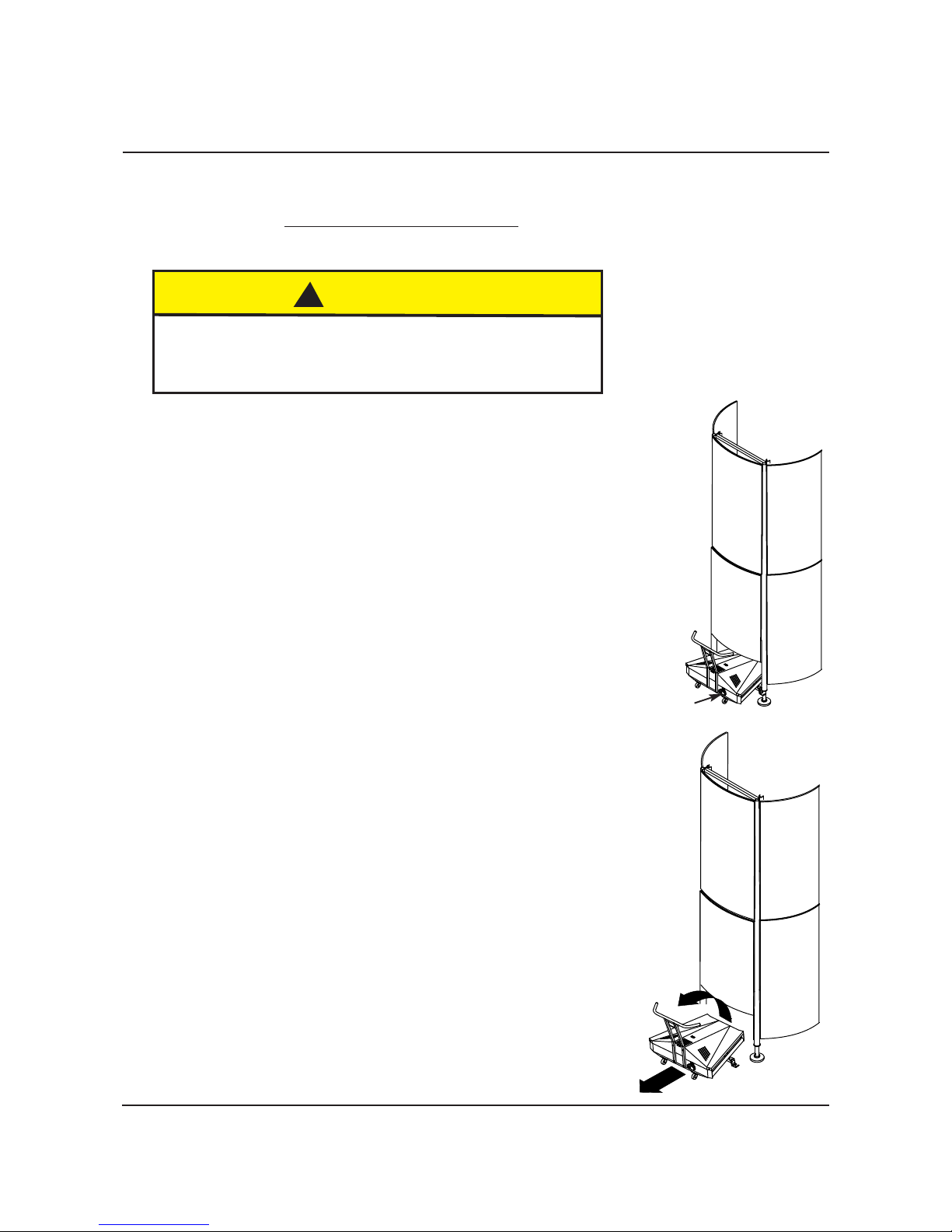

A power switch is provided to enable a Diva Air

Transporter to be disconnected from the main

electrical supply. When the power switch is

switched from the OFF position to the

ON position, the earth connection is made

before power connections are made.

When the power switch is switched from the

ON position to the OFF position, power

connections are broken before the earth

connection is broken. In the OFF position,

the electrical power supply is removed from

the entire machine. The electrical power supply

is provided by the use of a standard power cord.

The standard power cord must be routed where

there is no risk of personnel tripping and falling

because it has been routed in areas where personnel

are expected to walk. It is recommended that cables

should be routed away from such areas, run in

rubber ramps or the area cordoned off to keep people away.

" !

The blower motor, electrical control box, and metalwork of the machine are bonded to earth (ground) to

prevent a build up of static electricity. This is necessary to ensure that there is no risk of an increase in

the voltage potential of the blower motor, electrical control box and metalwork of the machine as a result

of static electricity that might be generated.

The earth conductor in the incoming main power supply is connected to a protective earth terminal and

one cable taken from this terminal to an earth distribution connector block. Functional earth connections

to the blower motor, electrical control box, and metalwork of the machine, etc. are connected to the

earth distribution connector block.

39*5

9.7(-

7&2)&5)

39*535)