CEW SEALFORM – WIDE-CORR® GRAIN BIN

194543 R8 3

CONTENTS

1. Introduction ............................................................................................................................................ 4

2. Safety....................................................................................................................................................... 5

2.1. Safety Alert Symbol and Signal Words..................................................................................... 5

2.2. General Product Safety ............................................................................................................ 5

2.3. Personal Protective Equipment................................................................................................ 5

2.4. Safety Decals ............................................................................................................................ 6

2.5. Decal Installation/Replacement ............................................................................................... 6

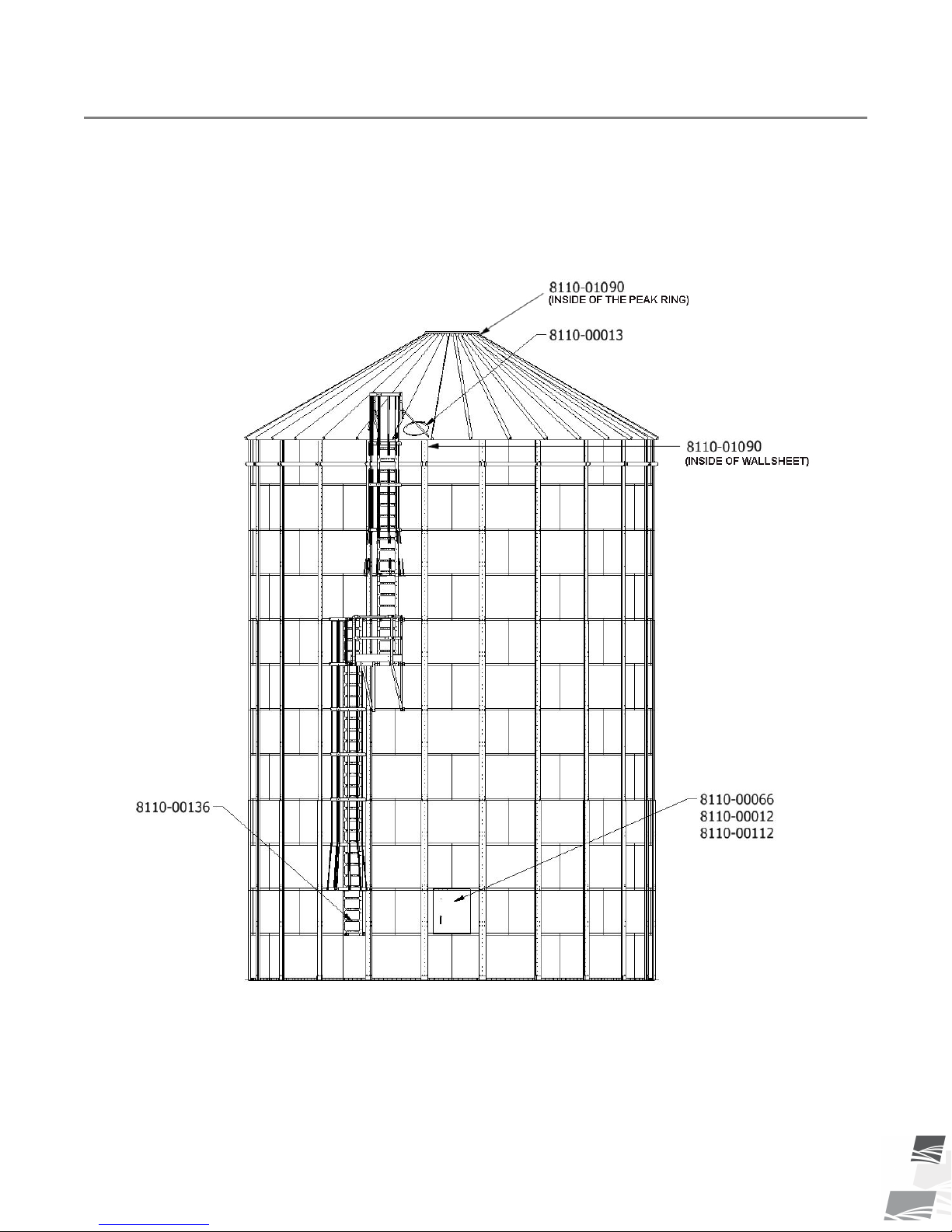

2.6. Safety Decal Locations and Details .......................................................................................... 7

3. Before You Begin .................................................................................................................................. 10

3.1. Bin Design and Capacity......................................................................................................... 10

3.2. Foundation Design and Loads ................................................................................................ 10

3.3. Site and Assembly .................................................................................................................. 10

3.4. Methods of Installation .......................................................................................................... 11

3.5. Cutting Openings in Wide-Corr® Grain Bins .......................................................................... 11

3.6. Critical Assembly Requirements ............................................................................................ 12

3.7. Product Storage...................................................................................................................... 13

3.8. Grain Bin Use.......................................................................................................................... 14

3.9. Important Notes ..................................................................................................................... 14

4. Preparation ........................................................................................................................................... 16

4.1. Check Shipment...................................................................................................................... 16

4.2. List of Tools and Equipment................................................................................................... 16

4.3. Order Optional Equipment..................................................................................................... 16

5. Assembly ............................................................................................................................................... 17

5.1. Assembly Safety ..................................................................................................................... 17

5.2. CEW Sealform Disclaimer....................................................................................................... 17

5.3. Foundation Specifications ...................................................................................................... 17

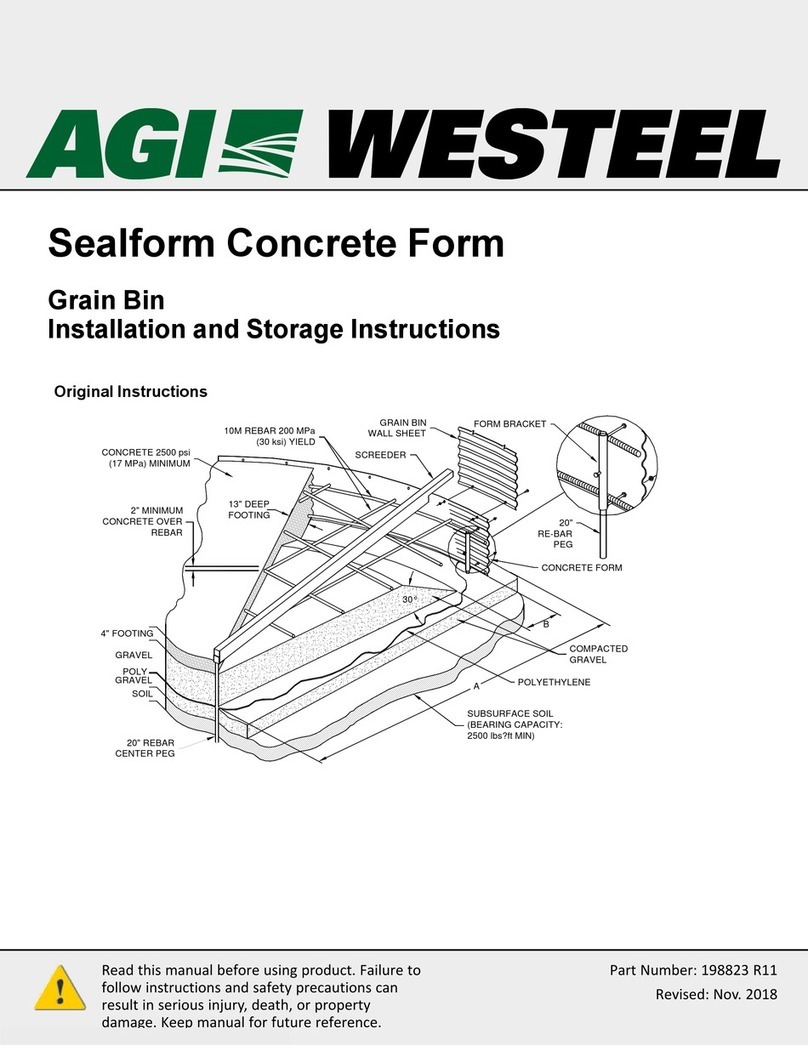

5.4. Foundation Diagrams ............................................................................................................. 19

5.5. Concrete Form Assembly ....................................................................................................... 19

6. Appendix ............................................................................................................................................... 23

6.1. CEW Sealform Kit Contents.................................................................................................... 23

6.2. CEW Sealform Hardware Pail Contents ................................................................................. 23

7. Limited Warranty: Westeel Grain Bin Products .................................................................................. 24