_____________________________________________________________________________________

2

1. GENERAL DESCRIPTION

1.1. The NPTFD1009 Fuse Panel provides

fused distribution of DC power to equipment.

The panel has 4 isolated fuse positions, each

consisting of a TFD fuse holder which can

accept both TLS and TPS style fuses. Alarm

circuits are provided to indicate and extend

alarm conditions for each fuse position.

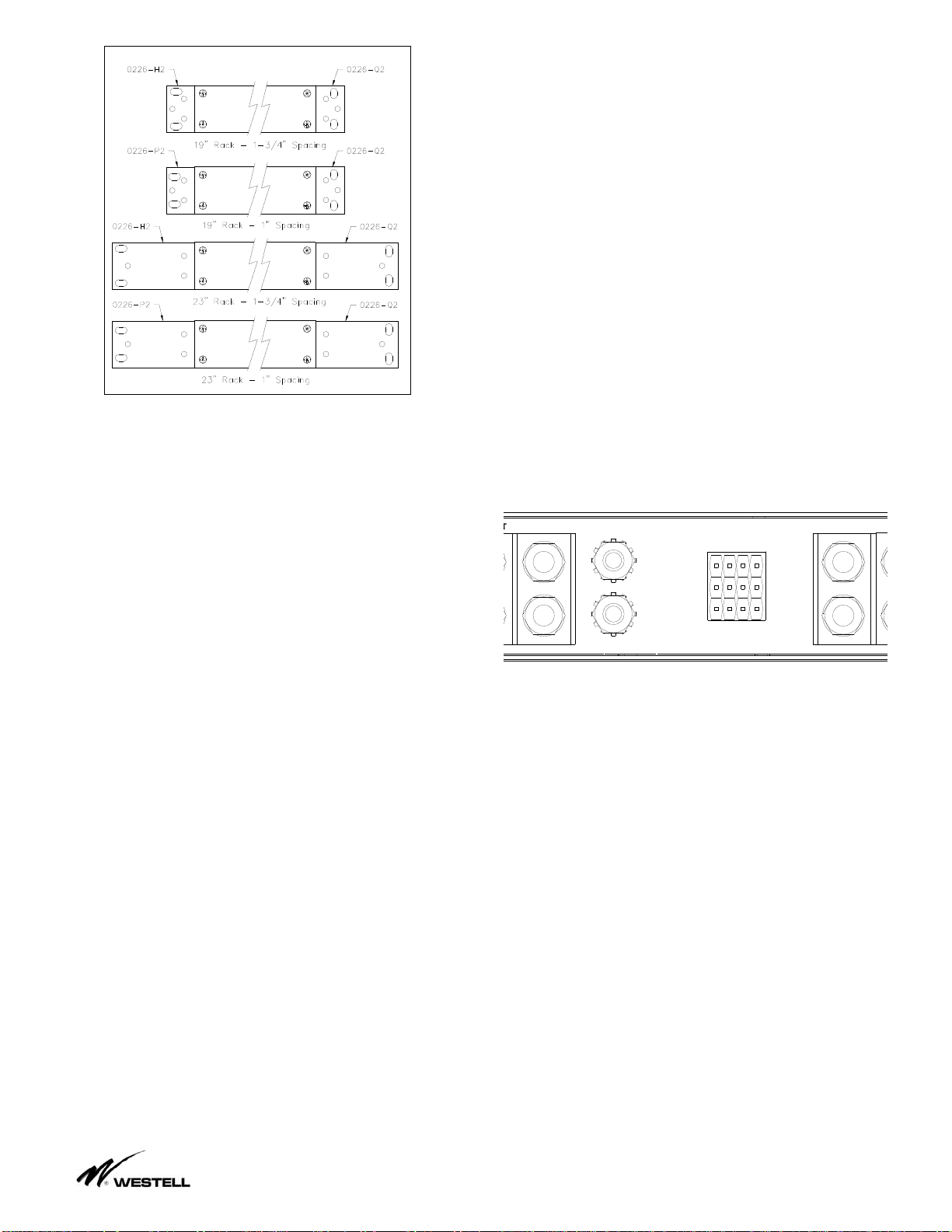

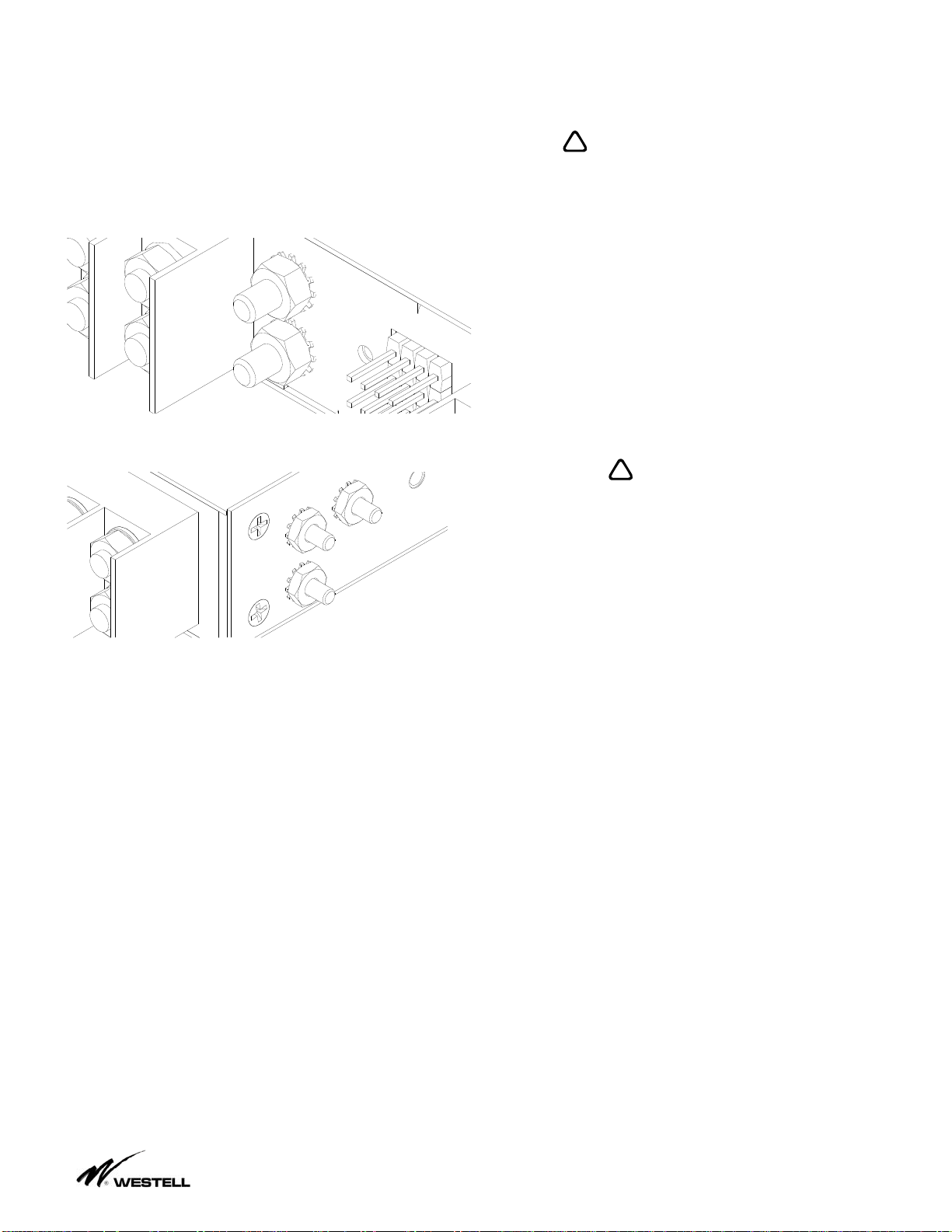

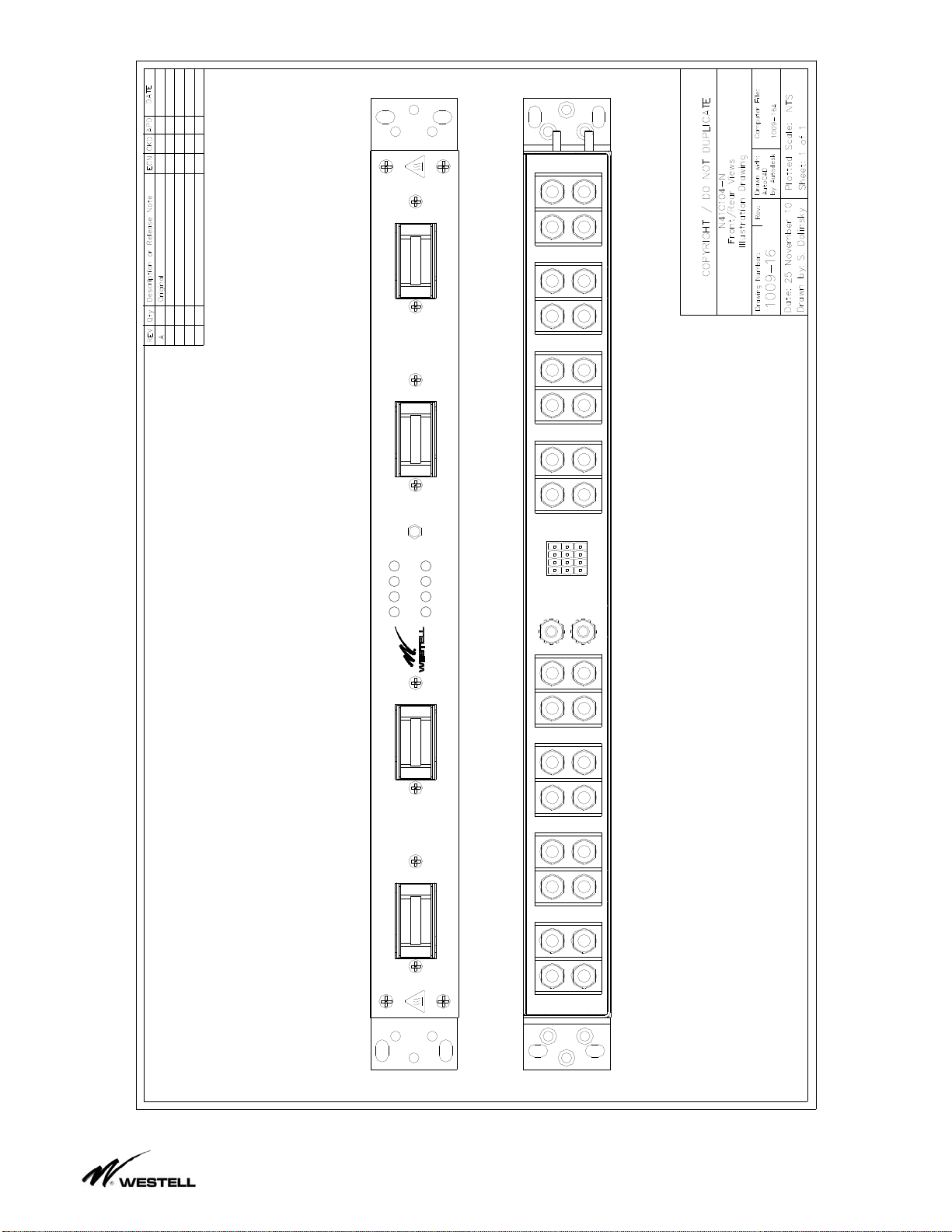

1.2. Wiring for the panel is accessible on the

rear of the panel. Power is connected via the

stud input and output blocks. Alarms are

connected via wire-wrap to the connectors on

the rear of the panel. Figure 1.2.1 shows the

connectors available on the rear of the panel.

Figure 1.2.1

1.3. Power is provided to and distributed

from the panel by using properly rated cables

equipped with standard two hole lugs (1/4”

studs on 5/8” centers). Two hole lugs must

be used for this high current fuse panel to

function properly. Power is provided to the

load side equipment through TLS or TPS

style fuses. There is one fuse position for

each input position. Each fuse position can

distribute a maximum of 125 Amps.

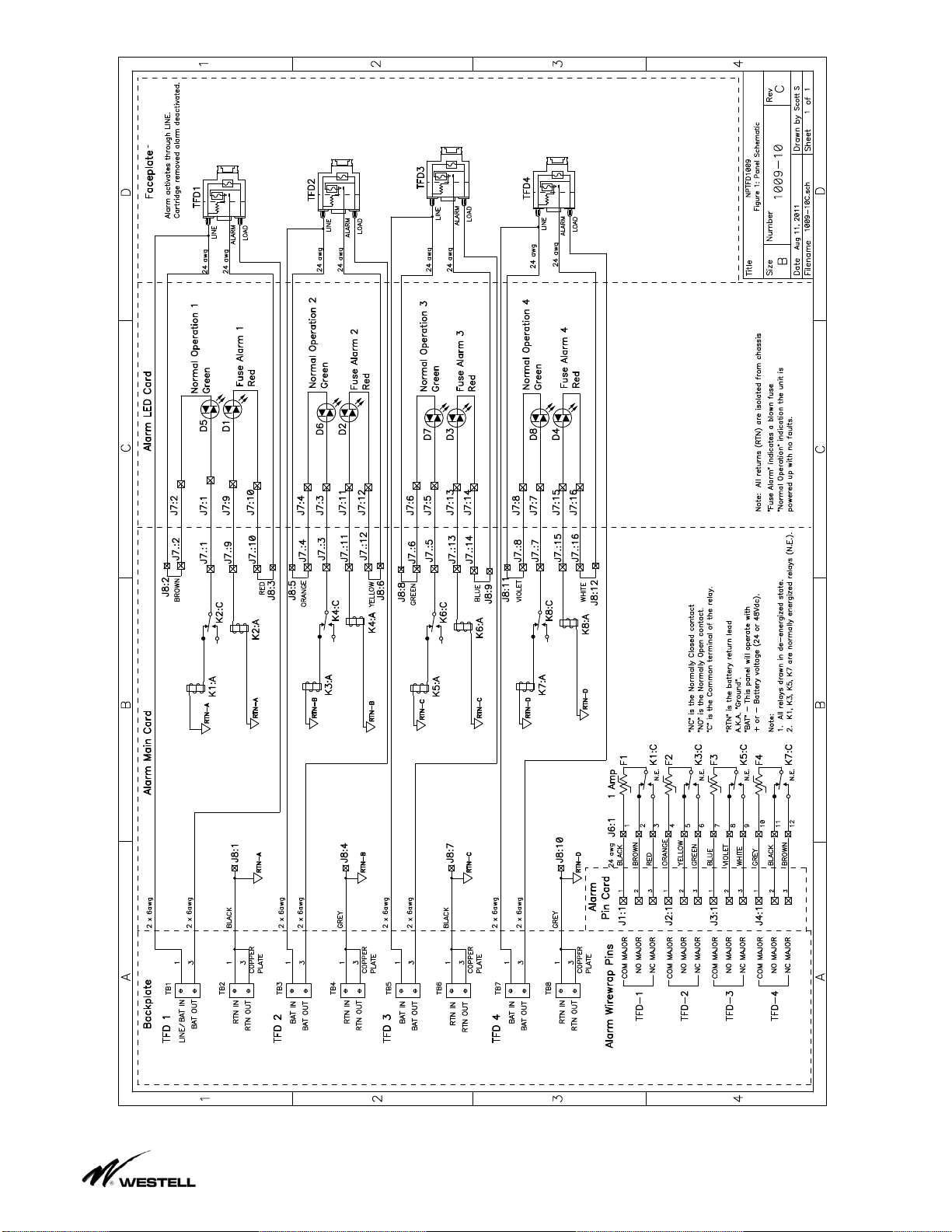

1.4. Alarm circuits are provided to indicate

and extend alarm conditions. Each TFD fuse

holder houses the main TLS fuse as well as a

GMT alarm indicating fuse. When the

cartridge is removed, the alarm is de-

activated. When an alarm condition is

present a red Fuse Alarm LED !will

illuminate. As well, the green Normal

Operation LED 9will extinguish to signal a

fuse alarm or input power failure and the

appropriate relay contacts will change states.

A set of dry “Form C” contacts is provided for

each fuse position to extend alarm conditions.

Each relay has a common (COM), normally

open (NO), and normally closed (NC) contact.

The local alarm LEDs are located on the front

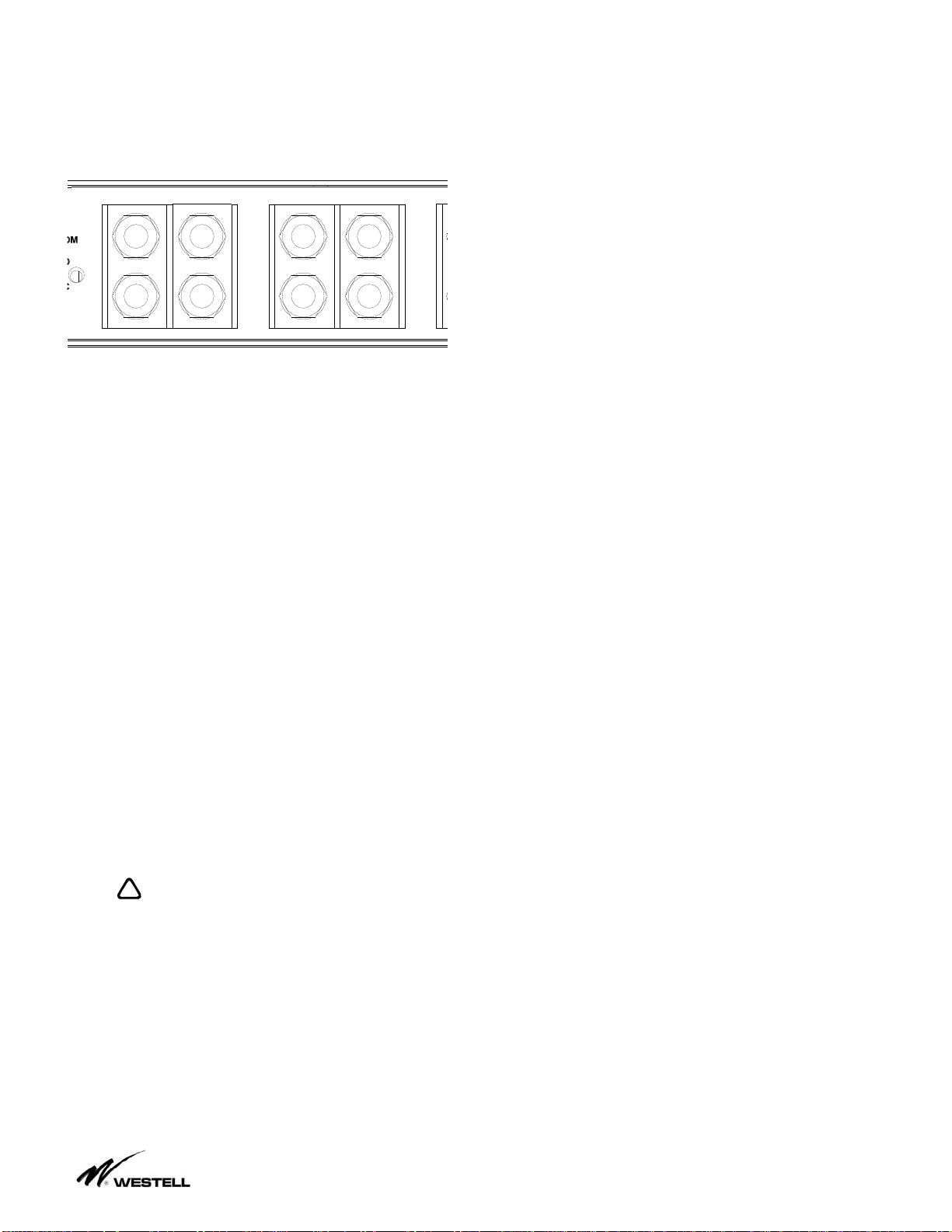

of the panel as shown in Figure 1.4.1.

LED SYMBOL SIGNIFICANCE

GREEN 9NORMAL OPERATION

RED !BLOWN FUSE

1234

Noran TelBy !

Ì

9

125A MAX FUSE

Figure 1.4.1

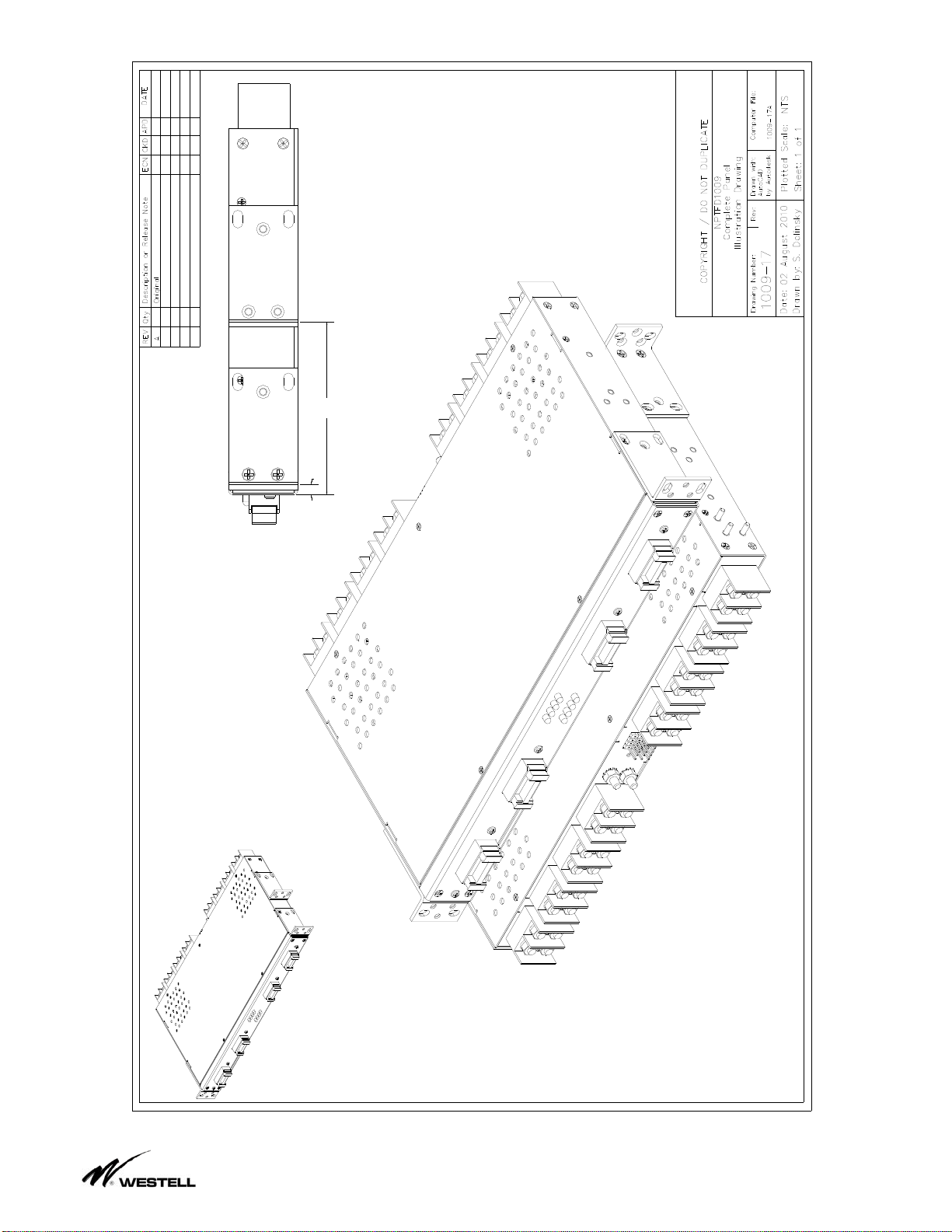

1.5. The Fuse Panel is constructed from

0.050” steel and painted off-white. The panel

is shipped with mounting brackets that allow it

to be installed in both 19” and 23” wide racks,

with either 1.75” or 1” panel hole spacing

(occupies 1 RU in a 1.75” pattern rack).

2. APPLICATION

2.1. NPTFD1009 Fuse Panel is designed to

be used in the rack level distribution of DC

power. It is a rack mount panel that provides

fused DC power for 4 isolated circuits using

TLS style fuses in a TFD style fuse holder.

2.2 The NPTFD family fuse panels are

suitable for installation as part of a Common

Bonding Network (CBN) for electrically

bonding the shelf type chassis of this fuse

panel to its equipment rack (via mounting

brackets or chassis bonding studs). Note that

all power return inputs (RTNs) are electrically

isolated from each other and from the fuse

panel chassis. As well, this family of fuse

panels is suitable for restricted access

locations in Network Telecommunications

Facilities, and OSP.