__________________________________________________________________________________

4

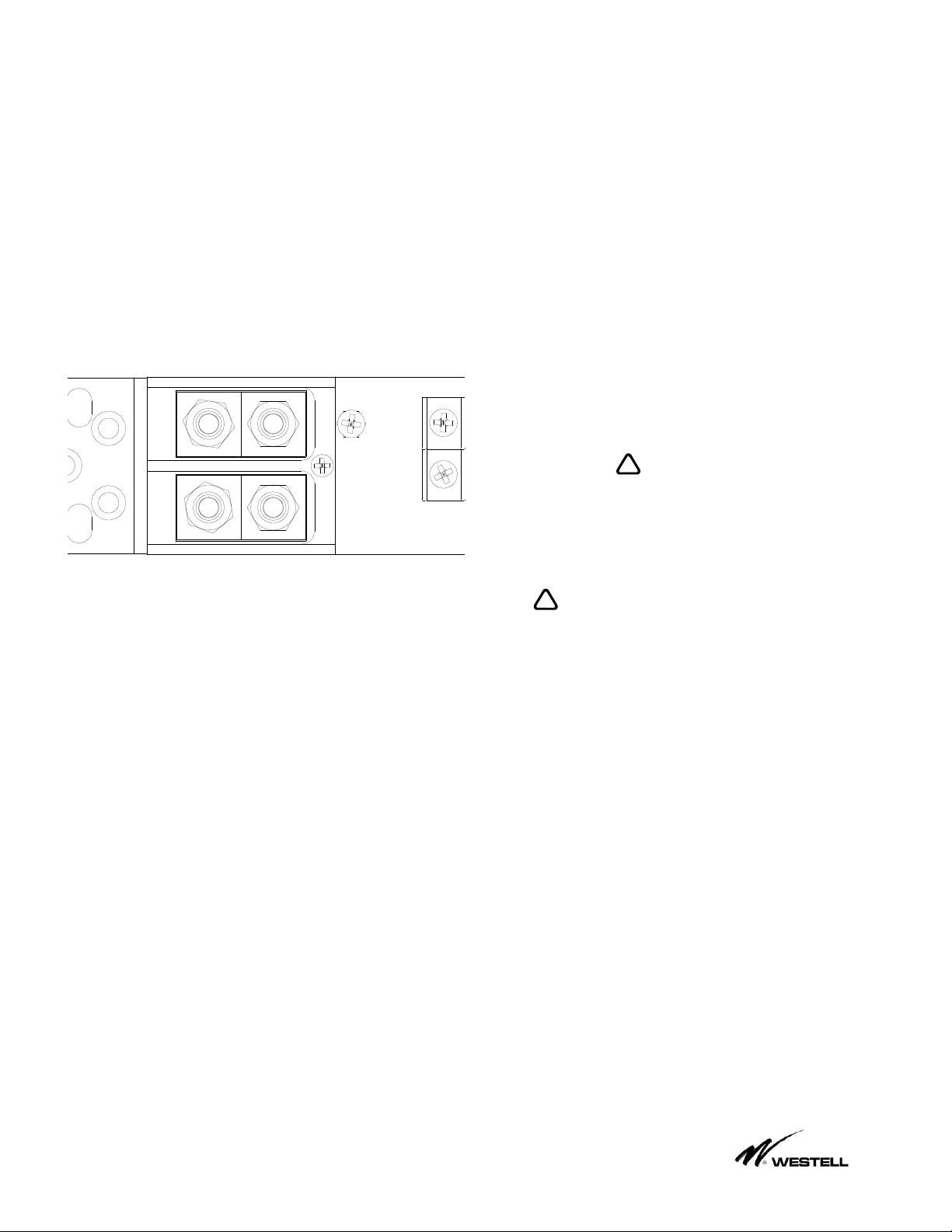

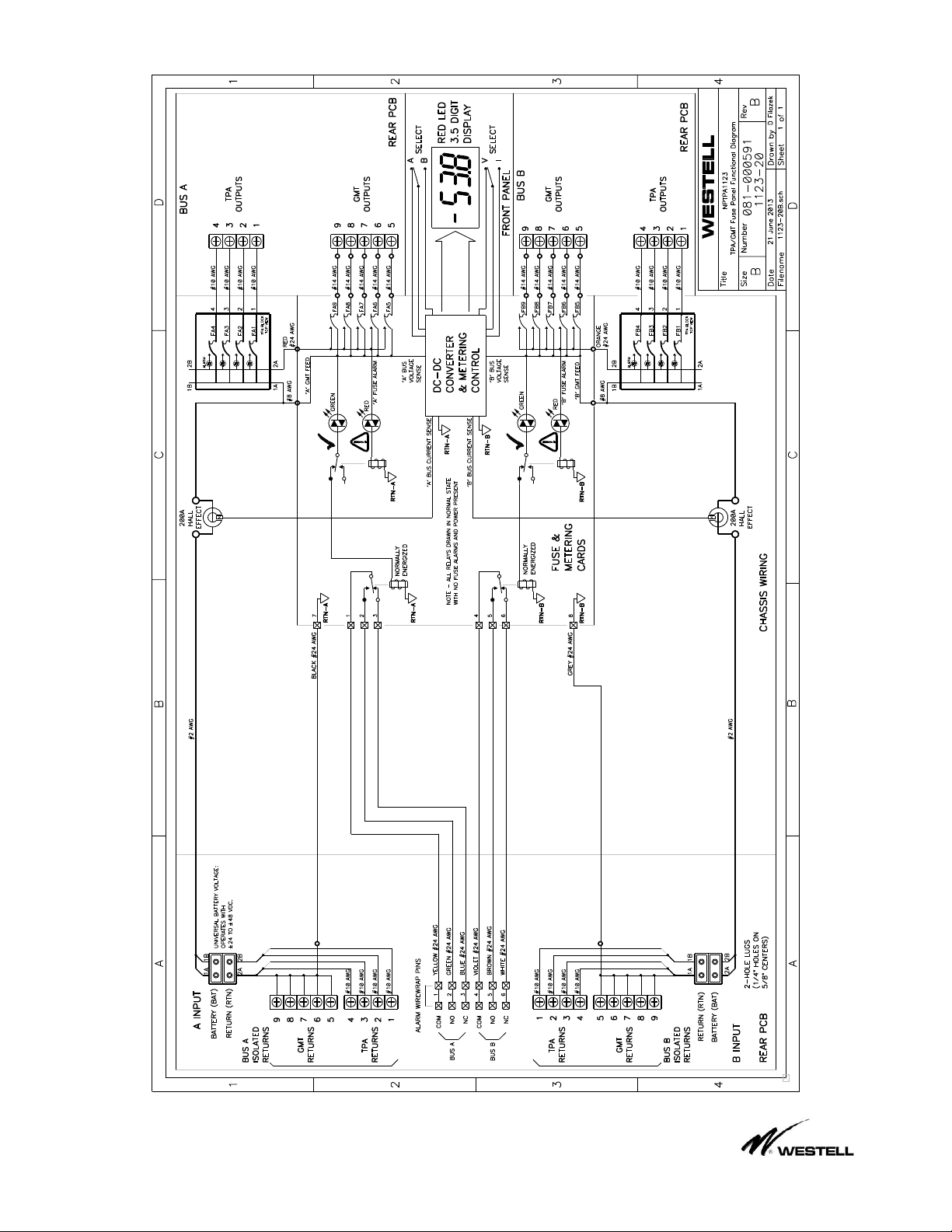

4.4. Remove the distribution fuse feeding the

input cables that are to be connected to the new

panel. Attach the input cables to the input

terminal block in accordance to the National

Electrical Code, ANSI/NFPA, and Canadian

Electrical code. Hook up the input cables to the

input terminal block on the fuse panel (“BAT” &

“RTN” for each bus). Each high current input

terminal uses a two-hole compression lug (1/4” on

5/8”, torque to 5.5 ft-lbs). A two-hole lug must be

used for proper operation (see fig 4.4.1)

Note: The supply source must be limited to an

instantaneous short-circuit current not to exceed

450 Amps.

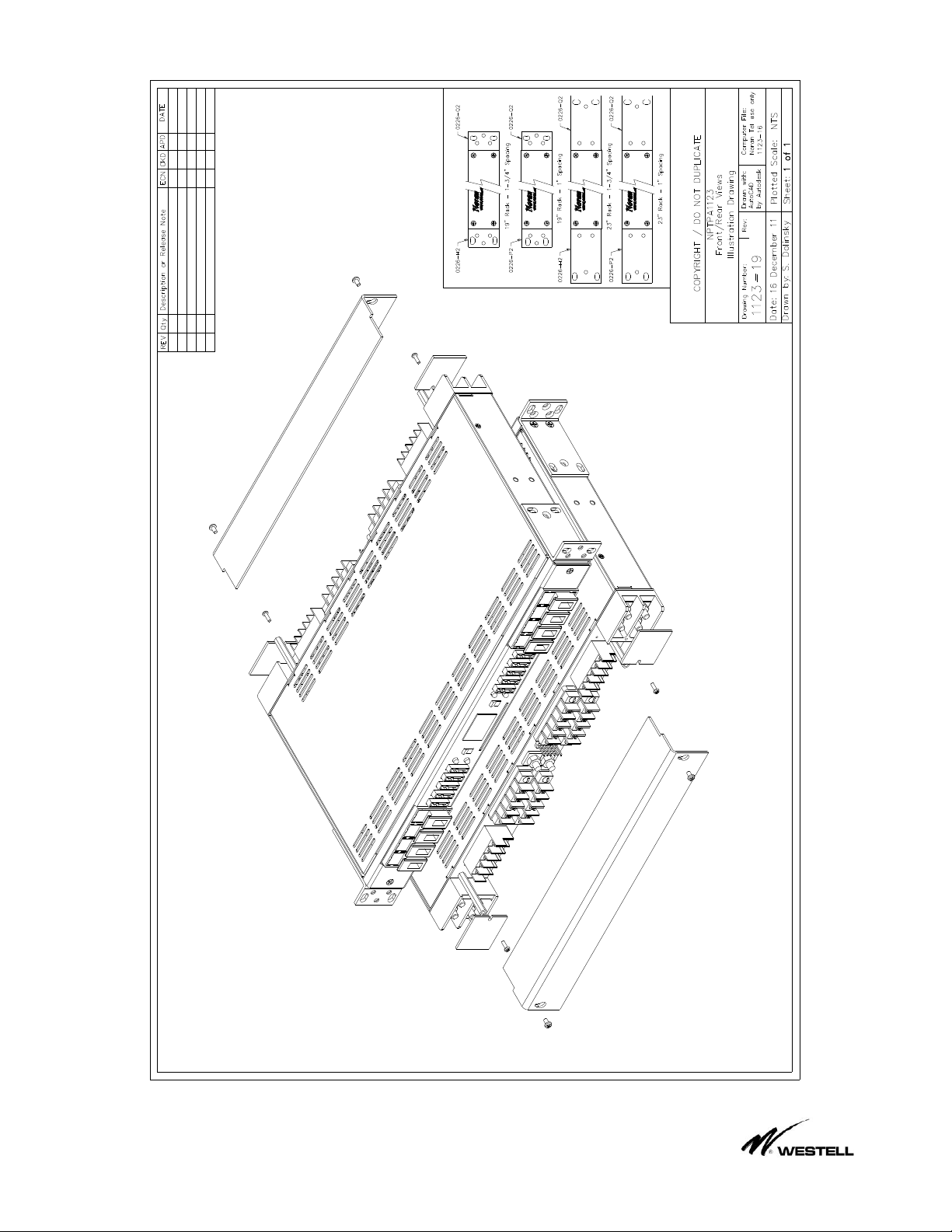

Figure 4.4.1

4.5. The fused battery outputs (BAT) and

ground returns (RTN) are also located on the

back of the panel. Each fuse holder and

terminal position is individually numbered.

Connect your load side equipment to the fuse

panel, and record which equipment is

connected to which input on the designation

card (supplied).

4.6. All battery return (“RTN”) connections are

also terminated on barrier strips (#6 screw, up to

10awg fork). Note, these returns are isolated from

the chassis frame.

4.7. This panel has Bus A, and Bus B alarm

contacts. Each alarm has a common (C),

normally open (NO) and normally closed (NC)

alarm contact. In an alarm the “C” contact will

short to the “NO” contact, and the “NC” will open.

Wire-wrap the alarm connections as per your

alarm system requirements. We recommend you

fuse the alarm battery supply (ABS) to 1A or less

to protect the alarm wiring and circuitry.

4.8. Chassis Ground; For safety reasons, and

as recommended by NEBS, the chassis should be

electrically connected to the rack ground. From

step 4.3. the panel should already be ground to

the rack via the #12-24 thread forming rack

screws and outside tooth lock washers. In

addition to grounding via the mounting brackets, it

is recommended you ground the chassis using a

ground cable and the two ¼” bolts and locks on

back of chassis (1/4” bolt torque; 5.5ft-lbs or

7.5Nm). Consult the National Electric Code,

ANSI/NFPA, and Canadian Electrical code for

AWG sizes.

4.9. The input wiring feeding this panel should

be protected by a Listed fuse/breaker rated for at

least 60Vdc, with a trip rating of 150 Amps Max.

With input wiring connected and this input fuse

installed, the panel should power up with the

Normal Operation LED illuminated and without

any red LEDs

illuminated, and the relays

should be in the “Normal” state (“C” connected to

“NC”).

4.10. If you wish to verify the fuse alarm circuit,

you can insert a blown fuse into one of the empty

fuse holders. The red Fuse Alarm

LED

should light and the Normal Operation

LED should extinguish and the appropriate

alarm extension relay should change states to

extend the alarm.

4.10. Install panel output distribution fuses as

required. Be sure to size fuses to no more than

70% of their rating (14A max for a 20A fuse).

Fuses are not included with this panel. Fuse

ratings should be selected to match the load

equipment ratings. Once the appropriate fuses

have been selected, the fuse information for F1-

F9 on BUS A and F1-F9 on BUS B is to be

recorded at the time of installation. Use the

provided designation card to keep a record of

which equipment is connected to which circuit

and what the fuse rating is. Be careful not to

overload the panel bus or BDFB fuse position

rating supplying the panel.

4.12 Install amperage marking labels as required

below each fuse for identification of circuit rating.

For fuse color codes please see table 4.12.1

below.