·TESTING

FOR

OVERHAUL

HOW

TO

DETERMINE

ENGINE

OVERHAUL

PERIOD

CaQse

of

Low

Compression

Generally,

the

time

at

which

an

engine should

be

overhauled

is

determined

by

various conditions such

as

lowered engine .

power

output,

decreased compression pressure,

and

increased

fuel

and

oil

consumption.

The lowered engine power output

is

not

necessarily

due

to

trouble with the engine itself, but

is

sometimes

caused by injector nozzle wear or injection pump

wear.

The

decrease

in

compression pressure is caused

by

many

factors.

It

is,

therefore,

necessary to determine a cause

or

causes

on

the

basis ofdata produced by periodic

inspection

and

maintenance.

Oil analysis on a seasonal basis

is

a

good

means

ofmonitoring engine internal

wear.

When

caused

by

worn

cylinders or pistonrings, the following.

symptoms

will

occur:

·

1 Low engine .,;ower output

2 Increased fuel consumption

·3

Iitcreased

oU

consumption

4 Hard engine

starting

5

Noisy

engine operation

These

symptoms

often appear together. Symptoms Zand 4

can

result

also

from excessive fuel injection, improper injec-

tion

timing,

and

wear of

the

injectors. They are caused also

by

defective

electrical devices such

as

the battery, alternator,

starter

and

glow

plugs. Therefore

it

is desirable

to

judge the

optimum

engine overhaul time by the

·Jowered

compressio!l

pressure

caused

by

worn

cylinders and pistons plus increased

oil

consumption.

Satisfactory combustion is obtained only

under

sufficient

compression pressure.

If

an engine lacks

compression

pressure, incomplete combustion

of

fuel

will

take

place

even

if

other

'parts

ofthe engine

are

operating

properly.

To

determine the period

of

engine overhaul, it

is

imporbplt.to

measure

the

engine compression pressure regu-

larly.

At

the

sl\!!le

time,

the engine speed at which the

mea-

.

surement

of

compression pressure is made should

be

checked

because

the

compression pressure varies with engine

rpm.

The

engine

rpm

ca:n·

be

m~ured

at

the front end ofthe

crankshaft.

NOTE:

In

case

of

severe

vibrations

and

detonation

noise,

the

cause

may

be}'u£1

ir{jector

problems,

see

FUEL

lNJECI'ORS.

Pool

fuel

quality,

contaminates

and

loss

of

positive fuel

prnssure

to

the

injection

pump

will

result

in

injector

faults.

NOTE:

Make

certain

the

engines valve clearances

are

properly

adjusted.

An

_incorrect

valve clearance

can

cause

symptons

that

might,

incorrectly,

suggest

an

engine

overhaul

(cylinder

misfire,

white

smoke,

noise,

etc).

OVERHAUL

CONDITIONS

Compression

pressure

tends

to

increase a little

in

a

new

engine

until piston rings

and

valve seats have been

broken

in.

Thereafter,

itdecreases gradually with the progress of

wear

ofthese parts.

When

decrease ofcompression pressure reaches the repair

limit,

the engine must be overhauled.

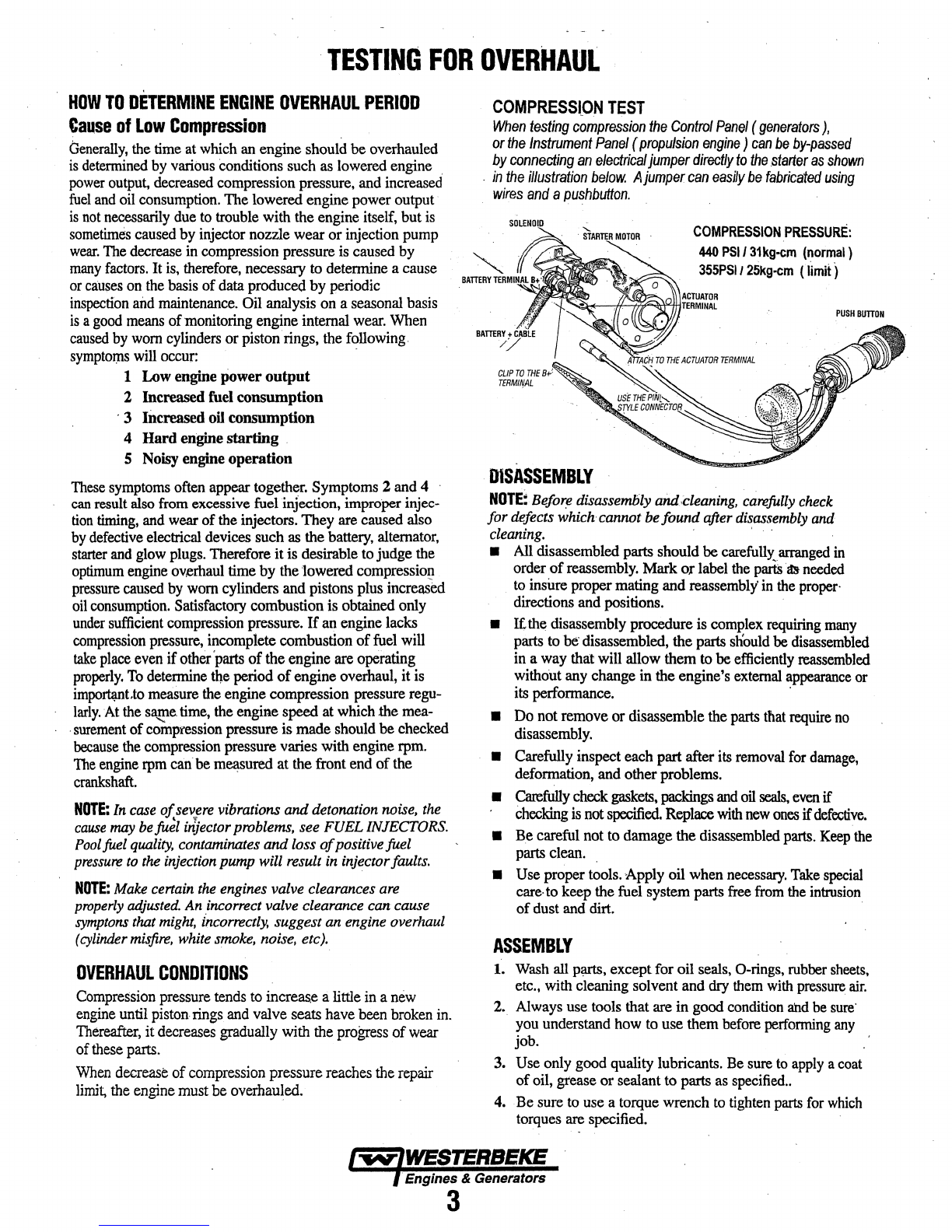

COMPRESSI_ON

TEST

When

testing

compression

the

Control

Panel

(generators),

or

the

Instrument

Panel

(propulsion

engine

)

can

be

by-passed

by

connecting

an

electrical

jumper

directly

to

the

.starter

as

shown

.

in

the

illustration

below.

A

jumper

can

easRy

be

fabricated

using

wires

and

a

pushbutton.

.

DISASSEMBLY

COMPRESSION

PRESSURE:

440

PSI/31kg-cm

(normal)

355PSI/

25kg-cm

(

limit)

NOTE:

Befo'f! disassembly

aiu:Lcleaning,

ca~lly

check

for defects

which·

cannot

be

found after

disassembly

and

cleaning.

· · ·

•

All

disassembled parts should be

carefullY._

arranged

in

order

of

reassembly. Mark orlabel

the

partS

It&

needed

to

insU.re

proper mating and

reassembly'

in

the

proper·

directions and positions.

• It:the disassembly procedure

is

complex

requiring

many

parts

to

be'

disassembled, the parts snould be

disassembled

in

a way that will allow them

to

be

efficiently

reassembled

without

any

change

in

the engine's

external

appearance

or

its

perfonnance. ·

•

Do

not remove or disassemble the parts

that

require

no

disassembly.

• Carefully inspect each part after

its

removal

for

damage,

deformation, and otherproblems.

•

Carefully

check

gaskets,

packings

and

oil

seals,

even

if

checking

is

not

specified.

Replace

with

new

ones

if

defective.

• Be careful not

to

damage the disassembled

parts.

Keep

the

parts clean.

•

Use

proper

tools.

Apply oil when

necessary.

Ta:ke

special

care·

to keep the fuel system parts

free

from

the

intrusion

ofdust

and

dirt. ·

ASSEMBLY

1.

Wash

all

p~.

exceptfor oil seals, 0-rings, rubber

sheets,

etc.,

with cleaning solvent and dry

them

with

pressure

air.

Z.

Always

use

tools that

are

in good condition ahd be

sure·

you

understand

how

to

use them

before

perfonning

any

job.

3.

Use

only good quality lubricants. Be

sure

to

apply

a

coat

ofoil, grease or sealant to parts

as

specified

..

4.

Be sure

to

use a torque wrench

to

tighten

parts

for

which

torques are specified.

·Engines&Generators

3