2

Table of contents

Table of contents.... ......................................................................... 2

1 EC Deglaration of Conformity........................................................... 4

2 Legal information......................................................................... 5

3 Important basic informatation.......................................................... 6

3.1 Scope of supply.................................................................. 6

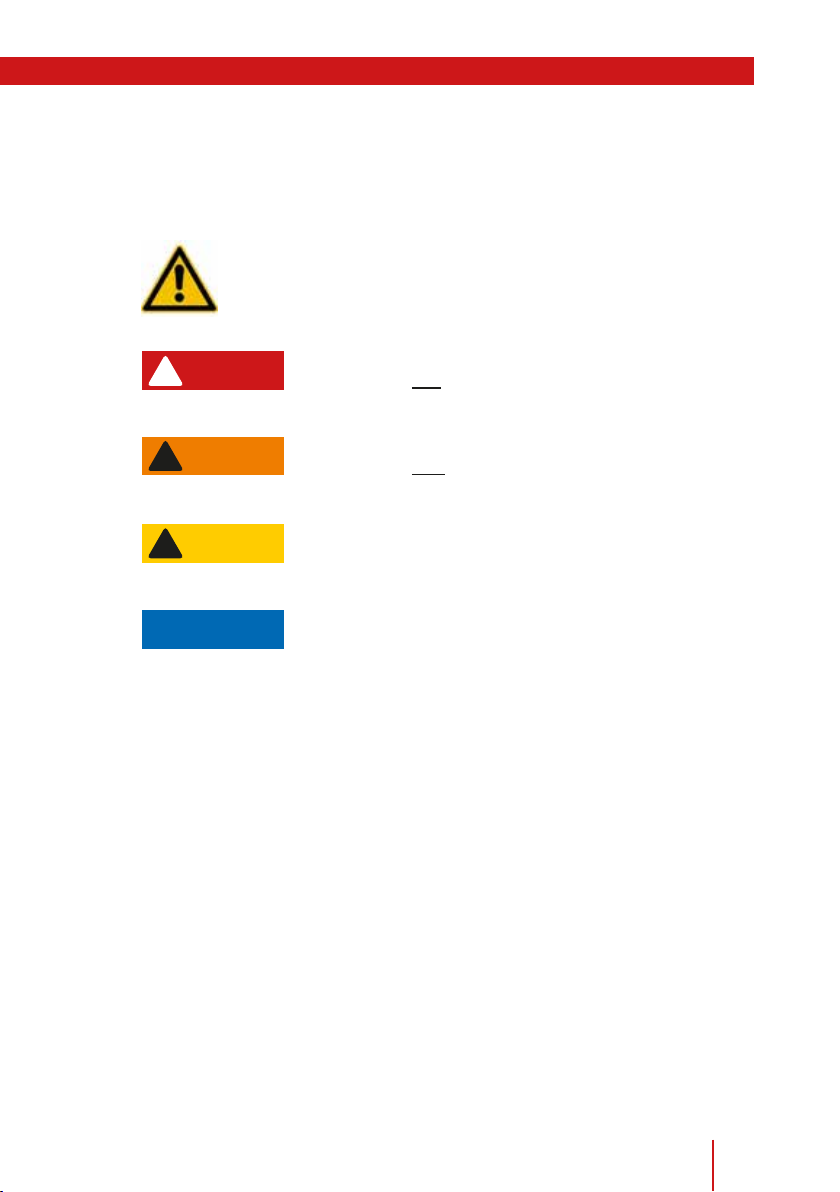

3.2 Conventions...................................................................... 7

3.2.1 Symbols and signal words ........................................... 7

3.2.2 Pictogram overview .................................................. 8

3.3 Marking on the machine ....................................................... 9

3.3.1 Warning pictogram on the machine................................ 9

3.4 Ordering spare parts.......................................................... 10

4 Safety............... ...................................................................... 11

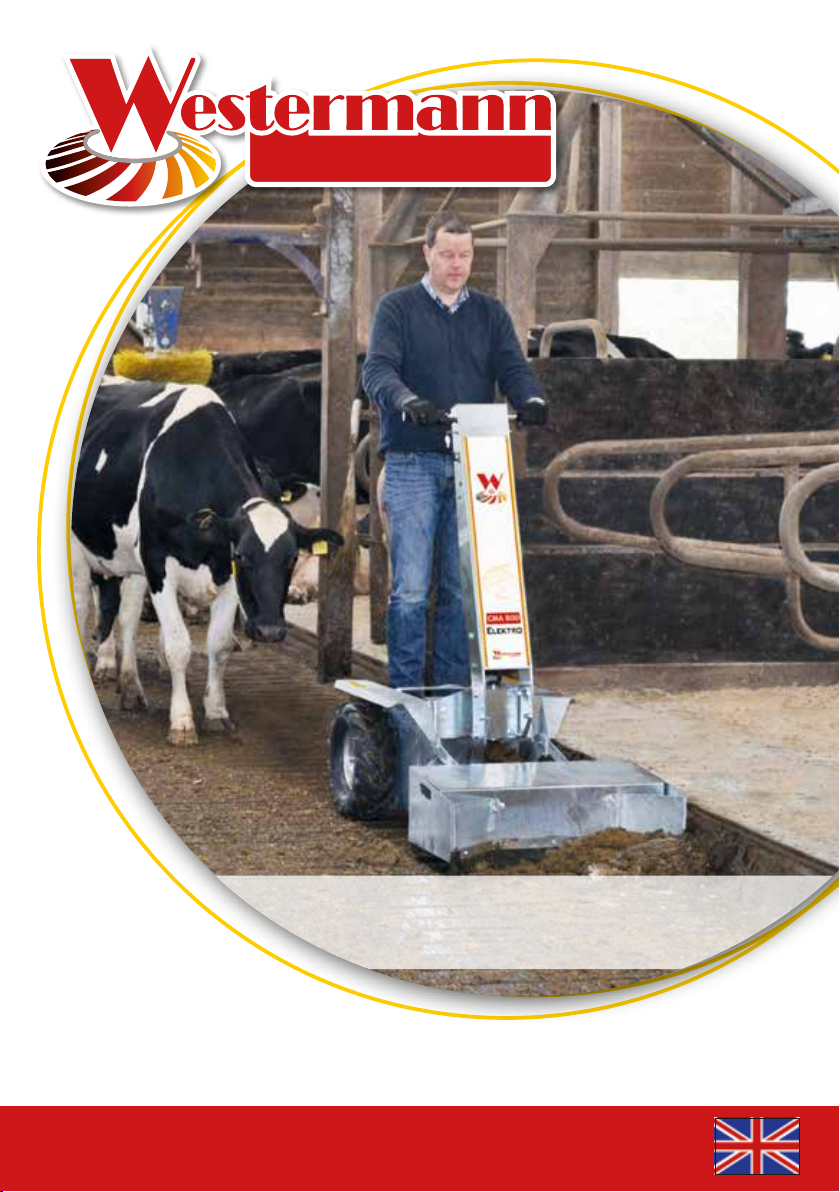

4.1 Intended use of the machine................................................ 11

4.2 Machine naming information ................................................ 11

4.3 Requirements for the operator ............................................. 12

4.4 Danger area .................................................................... 13

4.5 Foreseeable misuse |

Reasonably foreseeable misuse ............................................. 14

4.6 Behaviour in case of emergency ............................................ 14

4.6.1 Pesonal injury ....................................................... 14

4.6.2 Caseofre .......................................................... 14

4.6.3 Technical complications ........................................... 14

4.7 Application..................................................................... 15

4.7.1 Lokal requirements................................................. 15

4.7.2 Disposal .............................................................. 15

4.8 Responsibility of the operator .............................................. 16

4.8.1 Obligations of the operator ....................................... 16

4.9 Personal responsibility ....................................................... 17

4.10 Observance of the operating manual ...................................... 18

4.11 Residual hazards and protective measures ............................... 18

4.12 Safety marking on the machine............................................. 18

4.13 personal protection........................................................... 19

5 Safety instructions for the operator/user .......................................... 20

5.1 Before use...................................................................... 21

6 Technical data........................................................................... 22

7 Assembly, commissioning .............................................................. 23

7.1 Start preparation.............................................................. 23

7.2 Adjustment of the handlebar and holder for the pusher .............. 23

8 Installation............................................................................... 24

9 Installation / Adjustment of the attaching machine .............................. 25

9.1 Installation of attaching machine .......................................... 25

9.2 Adjustment of attaching machine.......................................... 25

10 Charging the CMA 800 Elektro............ ............................................ 26