9

6651-2271

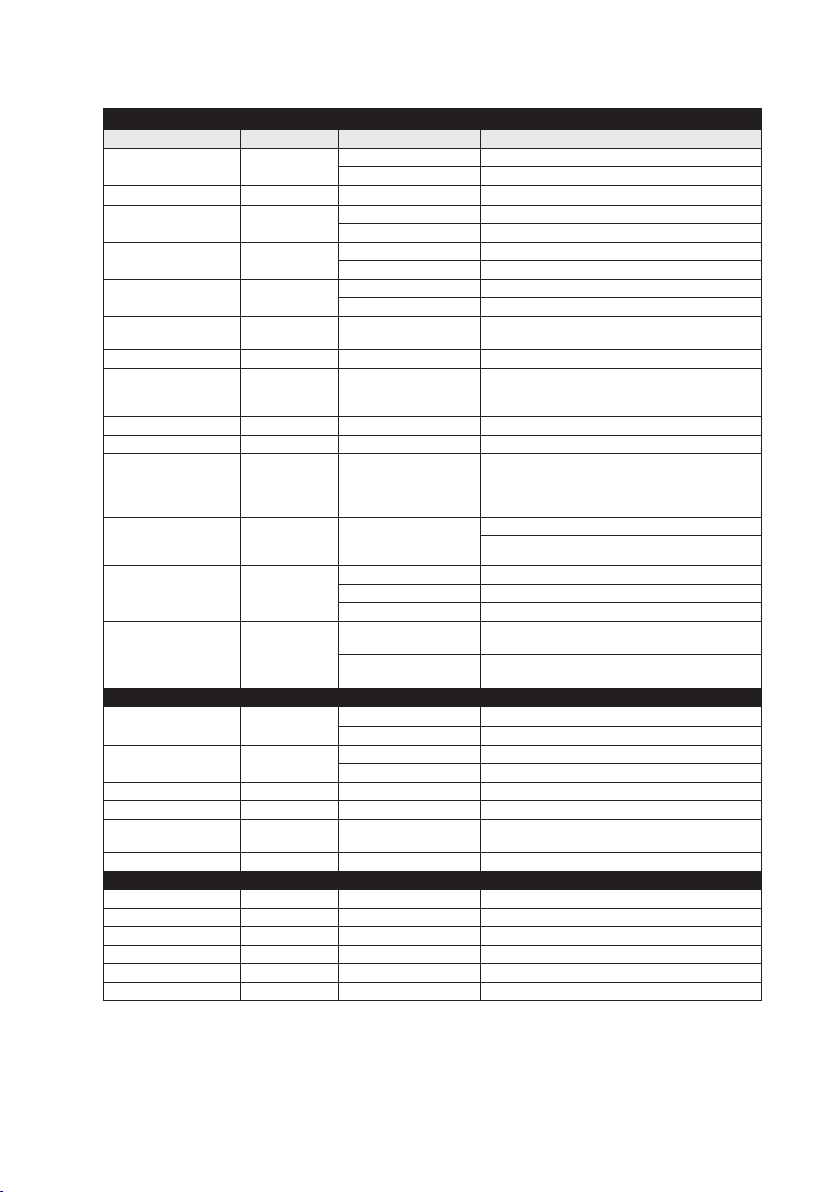

Type Tests and Environmental Conditions

Electromagnetic Compatibility

Phenomena Test Description Level

ESD EN 61000-4-2 Enclosure contact ± 4 kV

Enclosure air ± 8 kV

RF field AM modulated IEC 61000-4-3 Enclosure 10 V/m 80% AM (1 kHz)

Fast transient EN 61000-4-4 Signal ports ± 1 kV

Power ports ± 2 kV

Surge Signal ports balanced ± 1 kV line to earth, ± 1 kV line to line

Power ports ± 0.5 kV line to earth, ± 0.5 kV line to line

RF conducted EN 61000-4-6 Signal ports 10 V 80% AM (1 kHz), 0.15 – 80 MHz

Power ports 10 V 80% AM (1 kHz), 0.15 – 80 MHz

Power frequency

magnetic field

EN 61000-4-8 Enclosure 100 A/m, 50 Hz, 16.7 Hz & 0 Hz

Pulse Magnetic field EN 61000-4-9 Enclosure 300 A/m, 6.4 / 16 µs pulse

Voltage dips and

interruption

EN 61000-4-11 AC power ports 10 & 5 000 ms, interruption

10 & 500 ms, 30% reduction

100 & 1 000 ms, 60% reduction

Mains freq. 50 Hz EN 61000-4-16 Signal ports 100 V 50 Hz line to earth

Mains freq. 50 Hz SS 436 15 03 Signal ports 250 V 50 Hz line to line

Voltage dips

and interruption

EN 61000-4-29 DC power ports 10 & 100 ms, interruption

10 ms, 30% reduction

10 ms, 60% reduction

+20% above & –20% below rated voltage

Radiated emission CISPR 16-2-3

ANSI C63.4

(FCC part 15)

Enclosure Class B

Class A

Conducted emission CISPR 16-2-1

ANSI C63.4

(FCC part 15b)

AC power ports Class B

AC power ports Class B

DC power ports Class A

Dielectric strength EN 60950 Signal port to all other

isolated ports

1.5 kVrms 50 Hz 1min

Power port to other

isolated ports

2 kVrms 50 Hz 1min

Environmental

Temperature EN 60068-2-1

EN 60068-2-2

Operating –40 to +60ºC LRW-702-F2

Storage & Transport –40 to +70°C

Humidity EN 60068-2-30 Operating 5 to 95% relative humidity

Storage & Transport 5 to 95% relative humidity

Altitude Operating 2 000 m / 70 kPa

Service life Operating 10 years

Vibration IEC 60068-2-6 Operating 7.5 mm, 5 – 8 Hz

2 g, 8 – 500 Hz

Shock IEC 60068-2-27 Operating 15 g, 11 ms

Packaging

Enclosure UL 94 PC / ABS Flammability class V-1

Dimension W x H x D 35 x 121 x 119 mm

Weight 0.26 kg

Degree of protection IEC 529 Enclosure IP 21

Cooling Convection

Mounting Horizontal on 35 mm DIN-rail