5

Donaldson Company, Inc.

The unit is suitable for either indoors or outdoors.

Reference the Rating and Specification Information.

Foundations or Support Framing

Prepare the foundation or support framing in the

selected location. Foundation or support framing must

comply with local code requirements and may require

engineering.

Foundation and support framing must be capable of

supporting dead, live, wind, seismic and other applicable

loads. Consult a qualified engineer for final selection of

foundation or support framing.

Unit Location

Donaldson Torit equipment is not

designed to support site installed

ducts, interconnecting piping, or electrical

services. All ducts, piping, or electrical

services supplied by others must be adequately

supported to prevent severe personal injury

and/or property damage.

When hazardous conditions or materials are

present, consult with local authorities for the

proper location of the collector.

If combustible materials will

be processed through this

collector, local codes may require the collector

be located either outside or adjacent to an

exterior wall to accommodate devices related

to a fire or explosion mitigation strategy.

Consult local codes prior to installation.

Locate the collector to ensure easy access to electrical

and compressed air connections, to simplify solids

collection container handling and routine maintenance,

and to ensure the straightest inlet and outlet ducts.

Site Selection

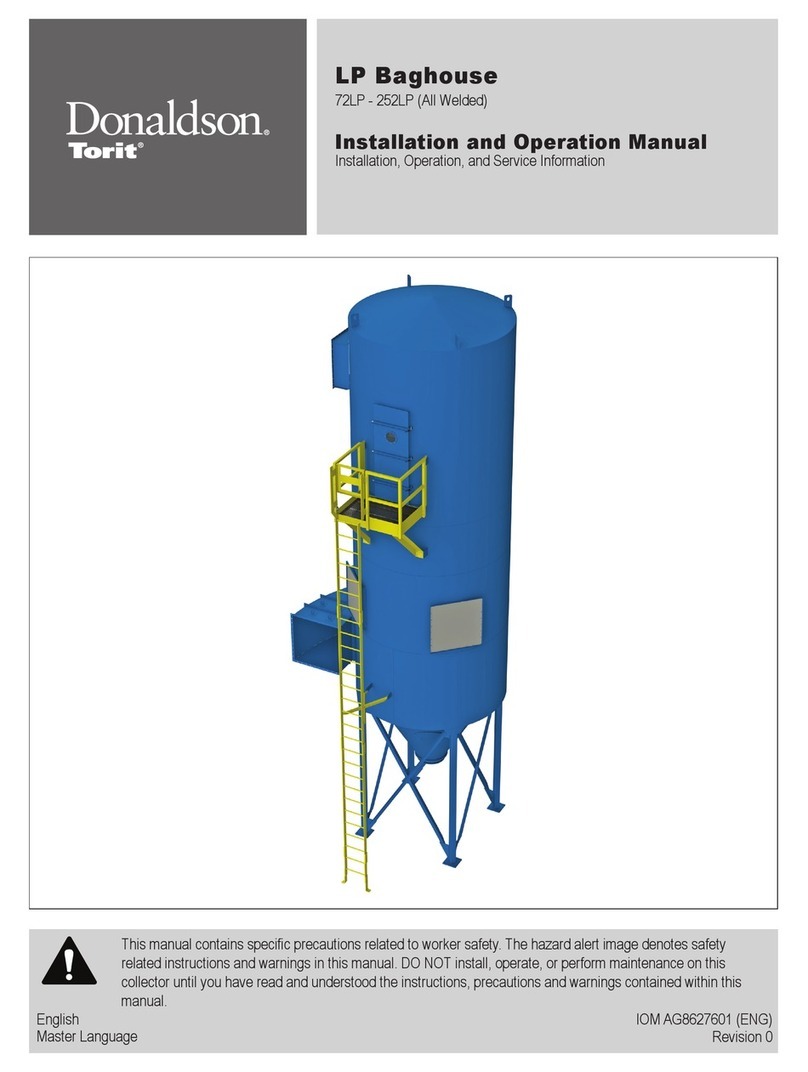

This unit can be located on a foundation or structural

framing.

Provide clearance from heat sources and avoid any

interference with utilities when selecting the location.

Portable units require special installation

accommodations.

Note: Units with explosion vents are not available

in portable configurations.

If unit is to be located outdoors, an appropriate exhaust

and remote electrical controls may be necessary.

When outdoor locations are

selected, always mount motors

with drain holes pointed down for proper

drainage of moisture.

Rigging Instructions

Suggested Tools & Equipment

Clevis Pins and Clamps Lifting Slings

Crane or Forklift Pipe Sealant

Drift Pins Pipe Wrenches

Drill and Drill Bits Screwdrivers

End Wrenches Socket Wrenches

Adjustable Wrench Spreader Bars

Torque Wrench (inch/lbs, 9/16-in Socket)

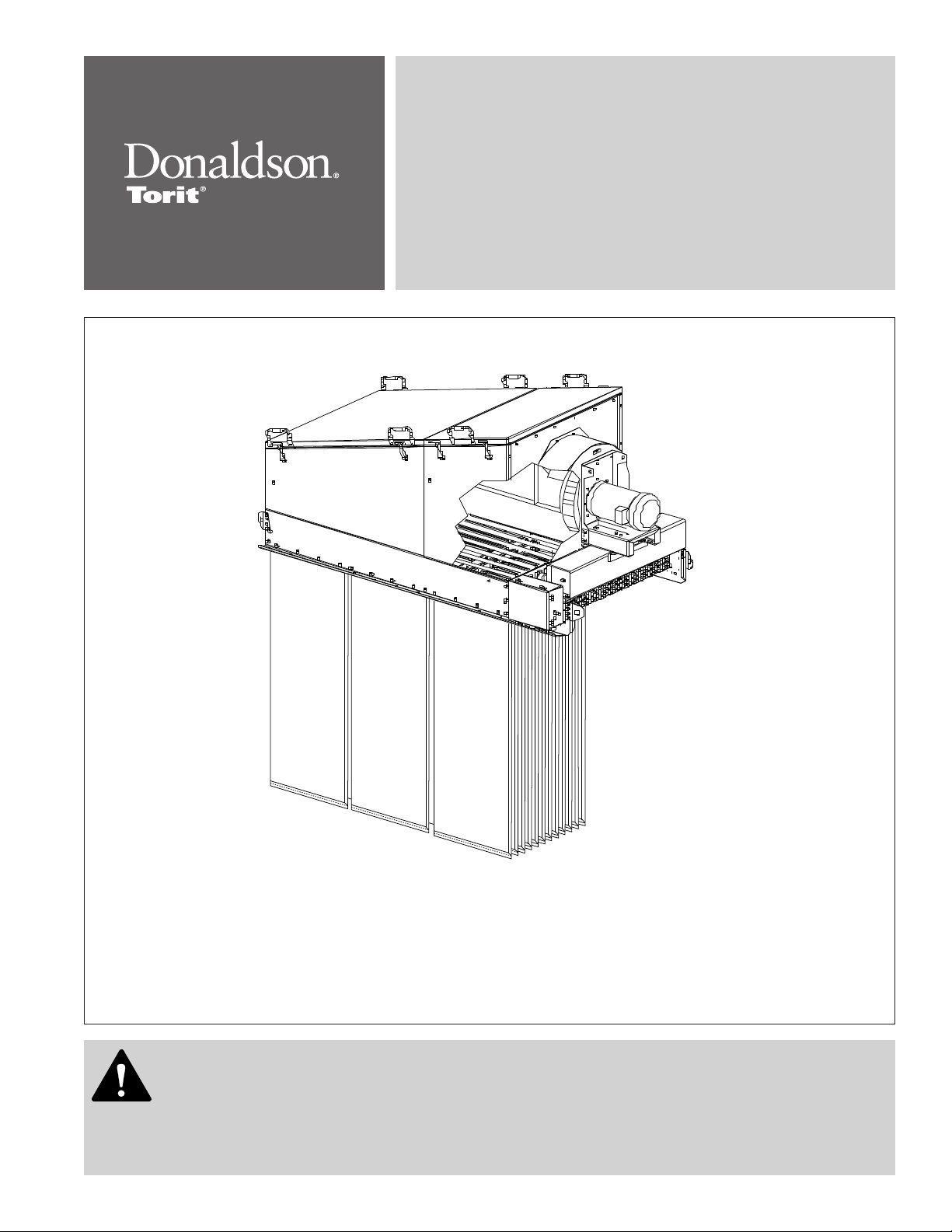

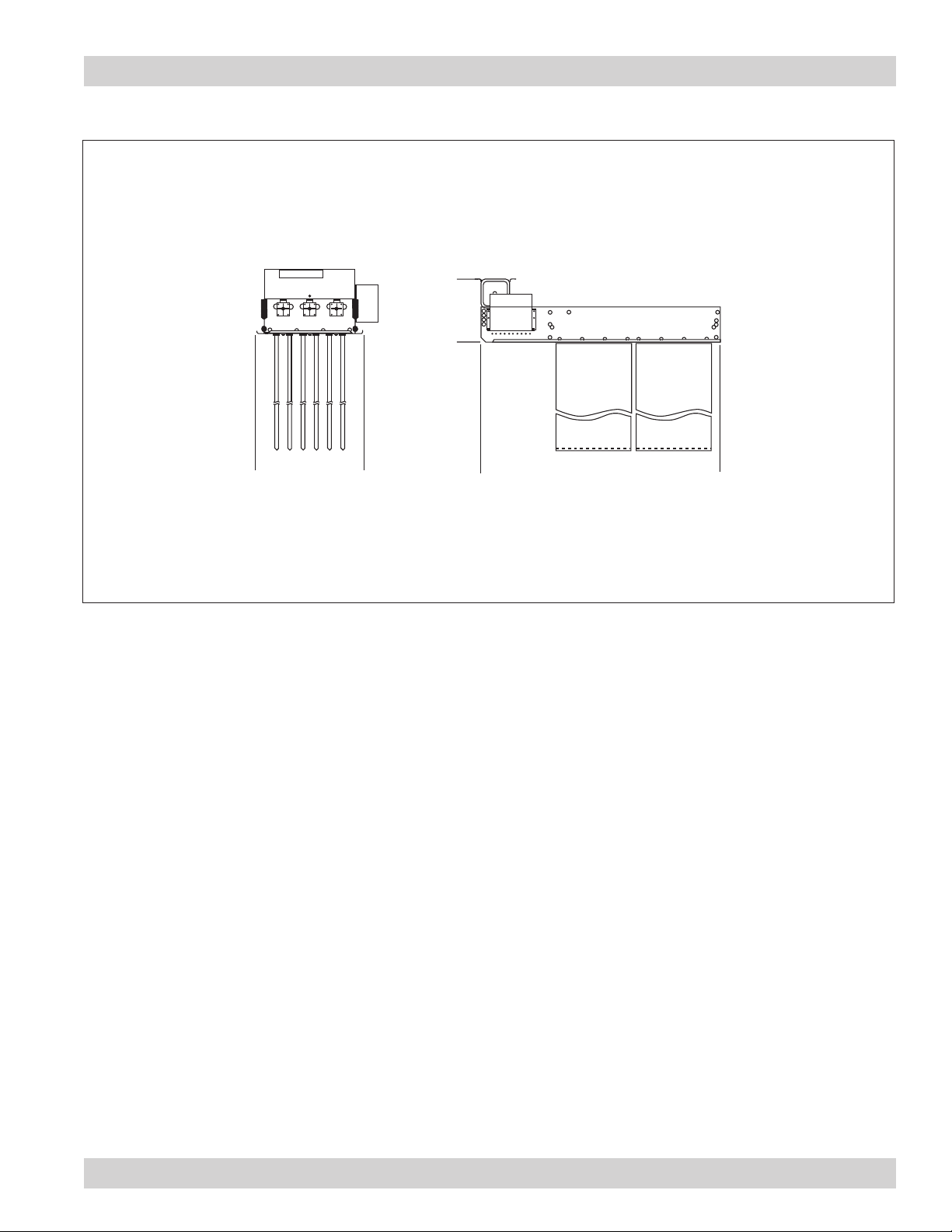

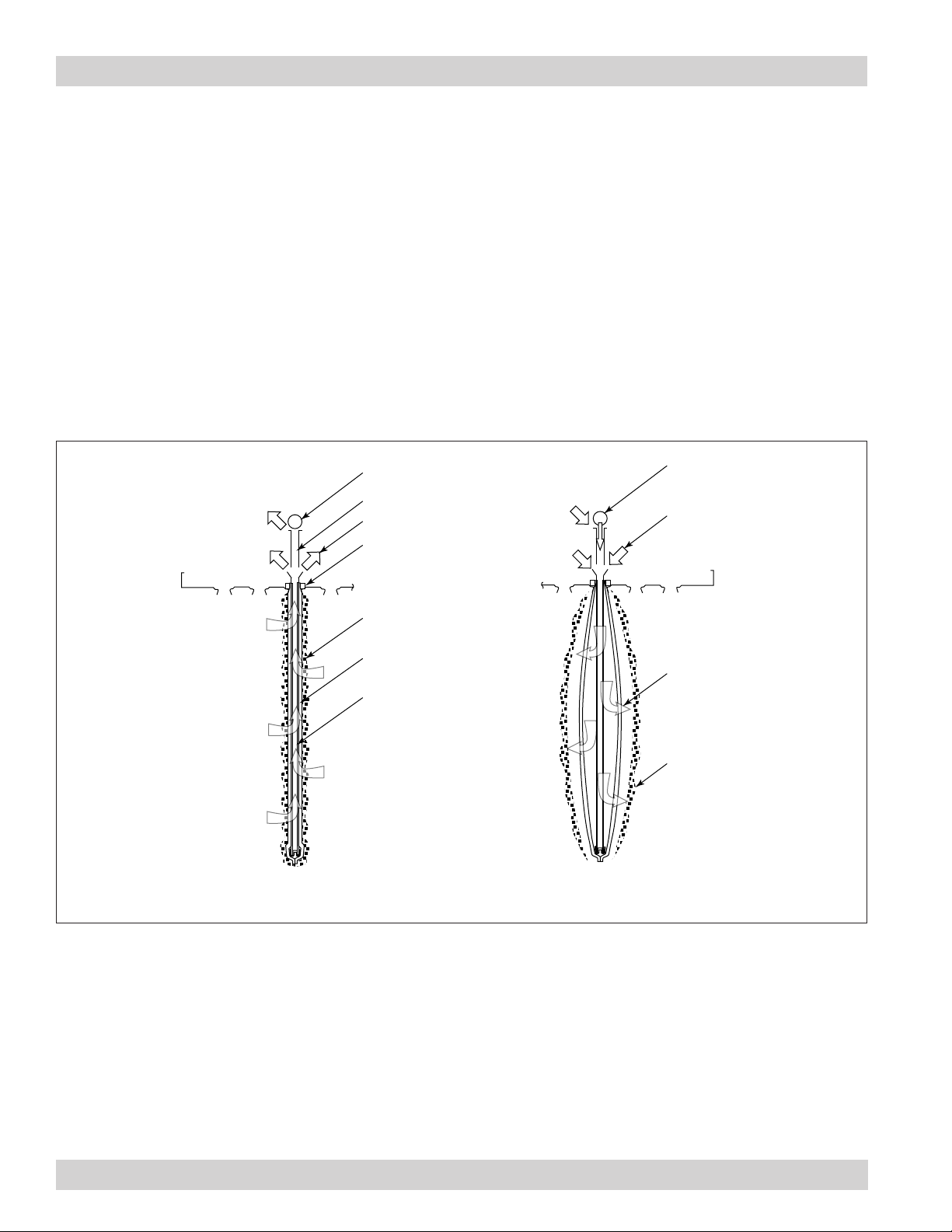

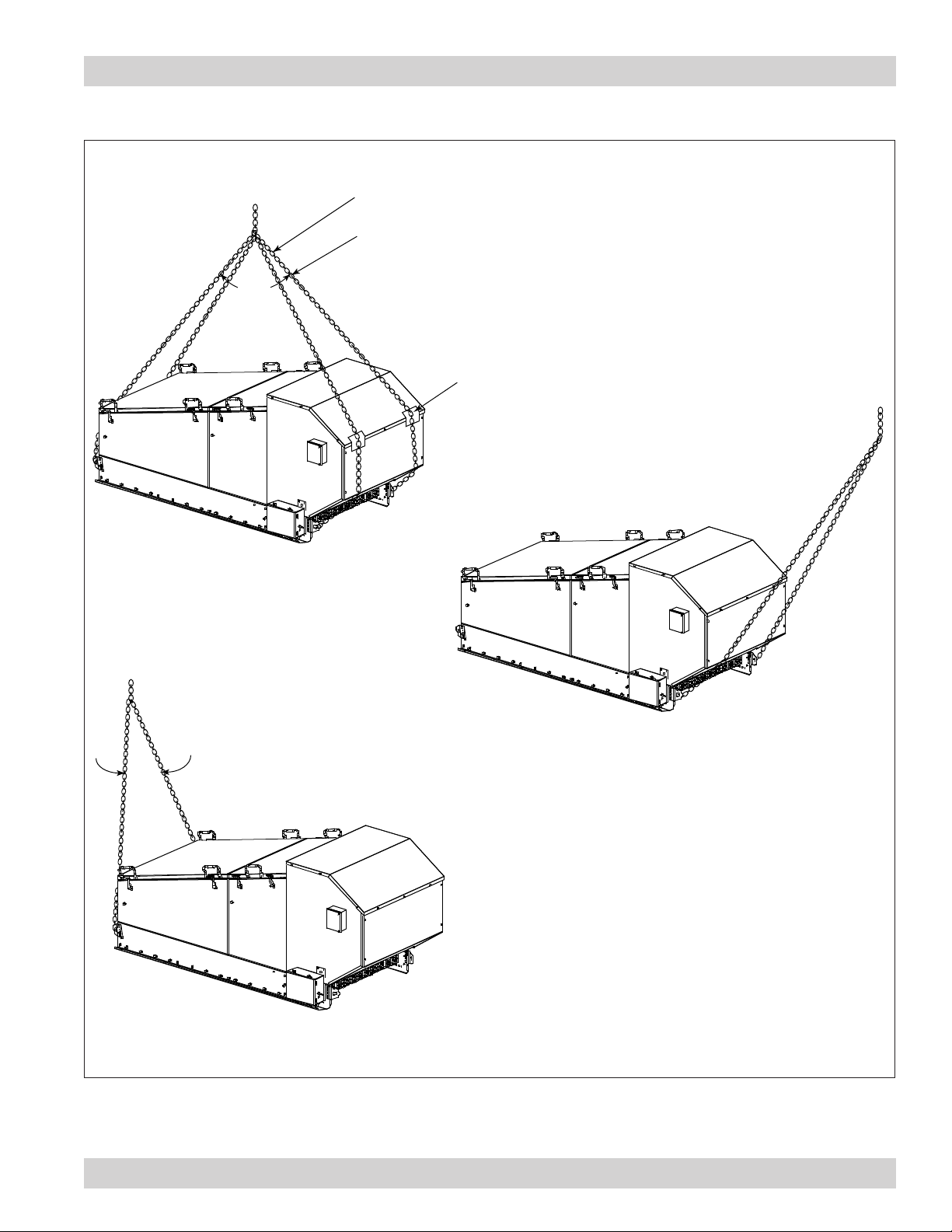

Hoisting Information

Failure to lift the collector

correctly can result in severe

personal injury or property damage.

Use appropriate lifting equipment and adopt

all safety precautions needed for moving and

handling the equipment.

A crane or forklift is recommended for

unloading, assembly, and installation of the

collector.

Location must be clear of all obstructions, such

as utility lines or roof overhang.

Use all lifting points provided.

Use clevis connectors, not hooks, on lifting slings.

Use spreader bars to prevent damage to unit’s casing.

Check the Specification Control drawing for weight

and dimensions of the unit and components to ensure

adequate crane capacity.

Allow only qualified crane operators to lift the equipment.

Refer to applicable OSHA regulations and local codes

when using cranes, forklifts, and other lifting equipment.

Lift unit and accessories separately and assemble after

unit is in place.

Use drift pins to align holes in section flanges during

assembly.