Rev 3.1/6-22 AC: #352751

BEFORE SERVICING LIFTER .....................................................................2

SERVICE SCHEDULE .......................................................................................2

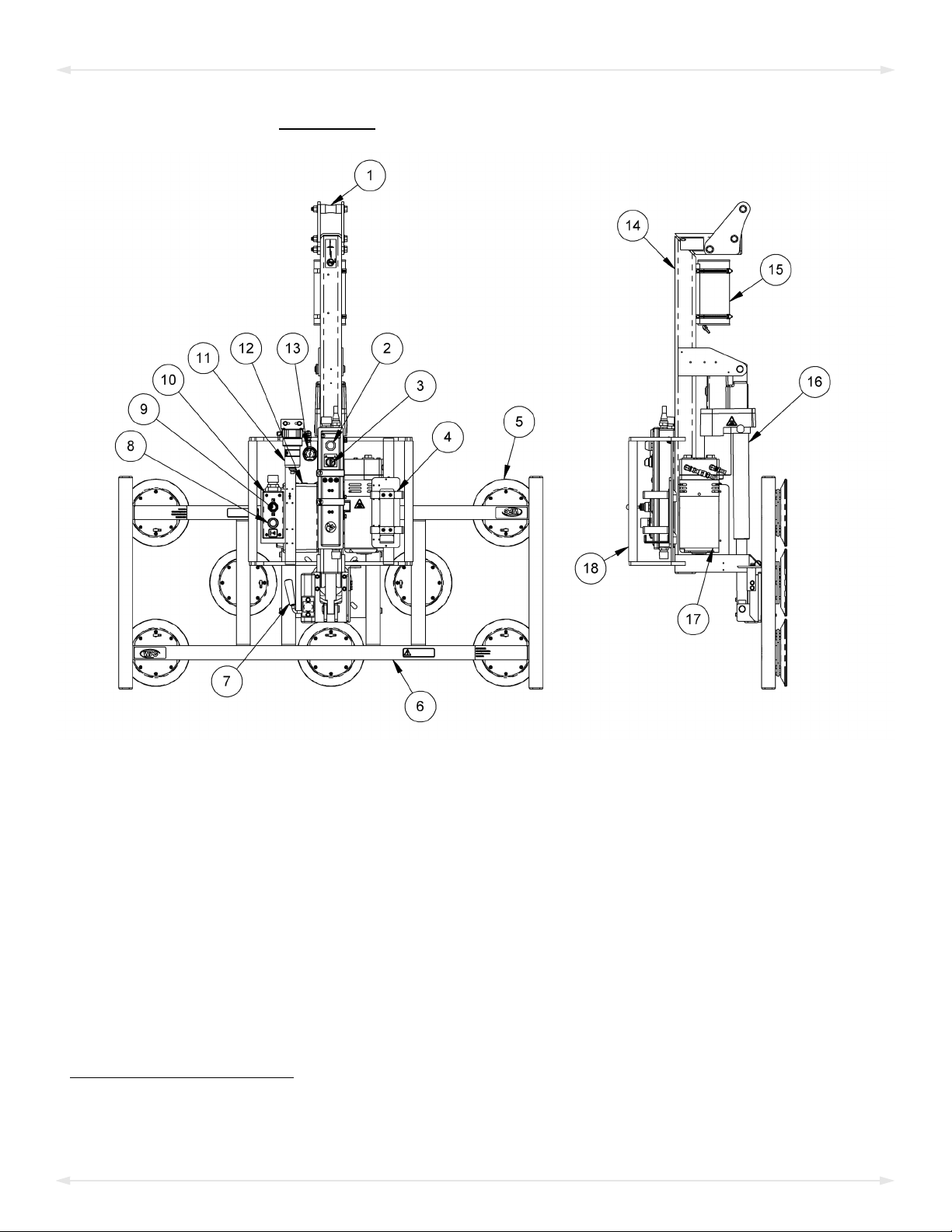

SERVICE FEATURES .................................................................................3

SERVICE PROCEDURES............................................................................4

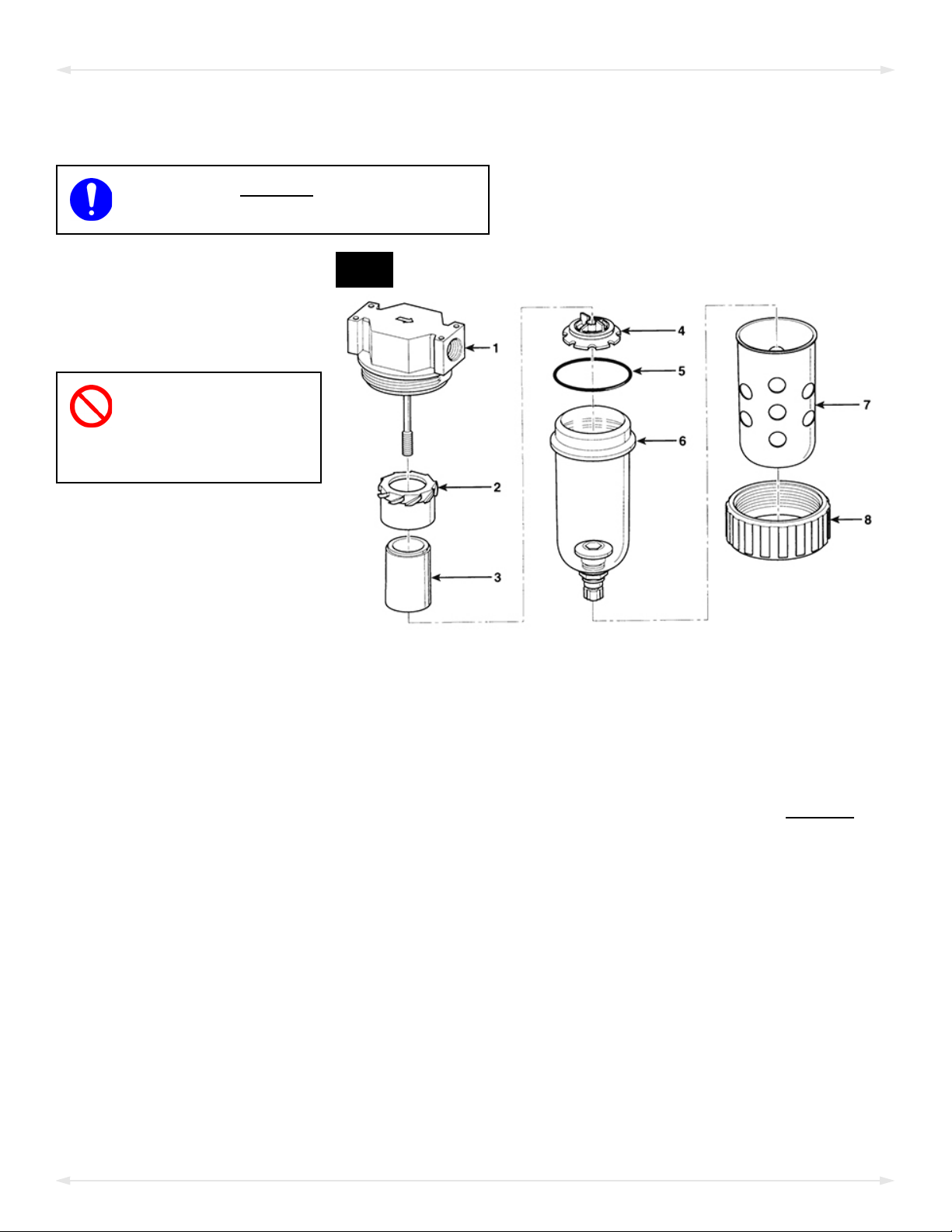

AIR FILTER MAINTENANCE – 1 OZ BOWL SIZE ...................................................4

Filter Service Procedure......................................................................................................4

AIR FILTER MAINTENANCE −4.4 OZ BOWL SIZE ................................................6

Filter Service Procedure......................................................................................................6

VACUUM PUMP MAINTENANCE −MODEL 0523...............................................8

Disassembly/Reassembly Procedure ..................................................................................8

VACUUM PUMP MAINTENANCE −MODEL 3032 OR 2032.................................9

VACUUM PUMP MAINTENANCE −MODEL MP27 ...........................................11

Removing the Head and Valve Plate .................................................................................12

Replacing the Intake Valve and Sleeve O-Ring ..................................................................12

Replacing the Exhaust Valve and Head O-Ring .................................................................12

Disassembling the Piston Assembly..................................................................................12

Replacing the Sleeve and Cup...........................................................................................13

Installing the Valve Plate and Head...................................................................................13

VACUUM SWITCH ADJUSTMENT....................................................................14

LINEAR TILT ACTUATOR ADJUSTMENT ............................................................15

REPLACEMENT PARTS...........................................................................16

TABLE OF CONTENTS