NeoDen NeoDen10 User manual

1

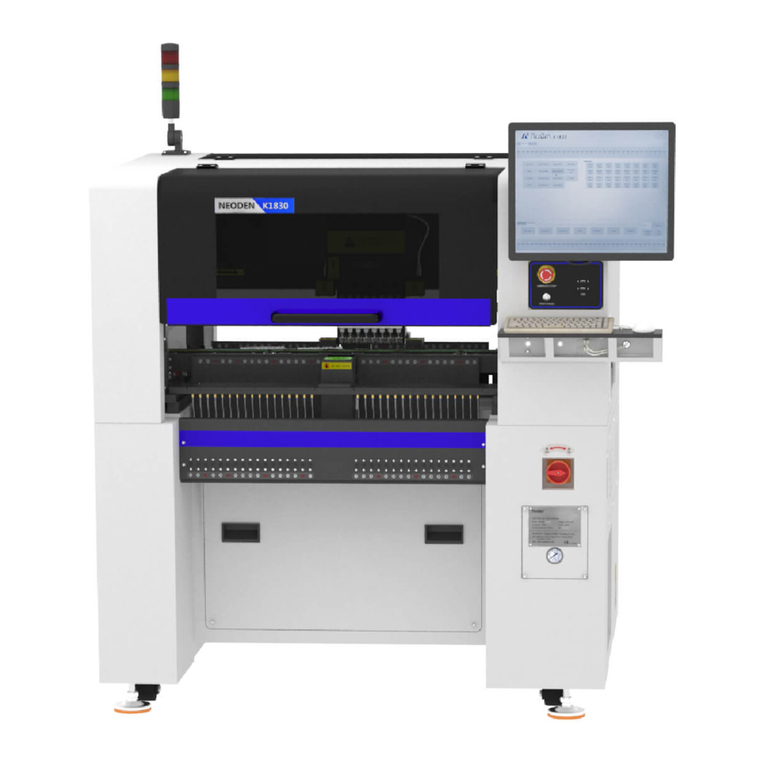

NeoDen10

High Speed Pick and Place Machine

User Manual

2

Model:NeoDen10 High Speed Pick and Place Machine

Version:V1.0

3

Catalog

1. Foreword................................................................................................................................. 5

2. Precautions before using the machine.................................................................................... 5

2.1 Important Notes...............................................................................................................7

2.2Machine Structure of NeoDen10.....................................................................................9

2.3 Machine dimension.......................................................................................................10

2.4 Working area structure..................................................................................................10

2.5 Operation flow chart..................................................................................................... 12

2.6 Flow chart of making a programming file....................................................................13

3. File List Introduction............................................................................................................ 14

4. PCB Information Editing...................................................................................................... 15

4.1 PCB Forward Setting.................................................................................................... 15

4.2 PCB Eject setting.......................................................................................................... 17

5. Panelized PCB Edit...............................................................................................................17

5.1 Panelized PCB origin (SMD1 coordinate)................................................................... 17

5.1.1 Single board:........................................................................................................ 18

5.1.2 Panelized board....................................................................................................19

5.1.3Mirror board..........................................................................................................20

5.2 Introduction of Lock interface......................................................................................21

6. Coordinate information.........................................................................................................22

6.1 PCB Mark setting..........................................................................................................22

6.2 Mark Point information................................................................................................ 23

6.3 Component list setting.................................................................................................. 24

4

6.3.1 Manual programming.......................................................................................... 25

6.3.2 Import the coordinate file.................................................................................... 26

7. Feeder setting........................................................................................................................ 34

7.1 Function of feeder setting interface..............................................................................34

7.2 Feeder Setting............................................................................................................... 35

8. Nozzle Information............................................................................................................... 39

9. Assembly Interface............................................................................................................... 40

10. System Setup.......................................................................................................................44

10.1Feeder Position Configuration.....................................................................................45

10.2 Component Positions Setup........................................................................................47

10.3 Basic Configuration.................................................................................................... 50

11. Manual Test.........................................................................................................................51

12. First trial and test.................................................................................................................52

12.1 Program first dry run...................................................................................................52

12.2 First production test.................................................................................................... 53

12.3 Component Inspection................................................................................................ 53

12.4 Continuous SMT production...................................................................................... 54

13. Structure and maintenance instruction............................................................................... 55

13.1 Feeder Brief Introduction........................................................................................... 55

13.2 Installing tape and reel components........................................................................... 56

13.3 Incorrect installation Samples:................................................................................ 57

14. Maintenance........................................................................................................................ 60

14.1 Take effective measures to reduce /avoid malfunction..............................................61

5

14.2 Maintenance................................................................................................................ 62

14.3 Related issues during solder paste printing process...................................................63

1. Foreword

Sincerely thank you for choosing NeoDen SMT machine.NeoDen10 is designed and used according to the following

purpose---pick and place electric components on PCB. Please do not use this machine for other purposes.

2. Precautions before using the machine

Remove the rust-proof protective film:

In order to prevent rust caused by environmental impact during transportation, we pasted a

protective film in the following parts of the machine as protection (as shown in the figure below).

This protective film needs to be manually removed before the machine is powered on. If there is

any omission, it may cause hidden trouble in operation and damage.

Notice to users:

Dear users, before the equipment starts working, please read the relevant information of this user

manual carefully, so as not to cause equipment failure affecting the use or equipment lifespan

reduction.

Table of contents

Other NeoDen Industrial Equipment manuals