EATON Airex DPA Caliper Brake Installation, operation and maintenance manual E-CLCL-II010-E October 2015 7

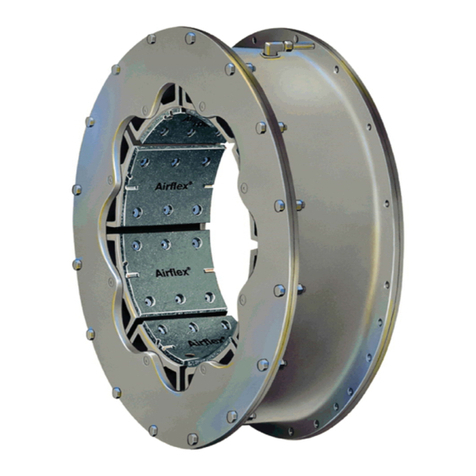

Airflex DPA Caliper Brake

3.0 Operation

Warning

Do not overheat the brake pads. Maximum

recommended temperature on the brake disc surface

is 392° F (200° C).

3.1 Pressure limits

Warning

Maximum allowable operating pressure is 2000

psi (138 bar). Exceeding the maximum allowable

pressure may result in personal injury or damage

to the brake.Due to the spring force, a minimum

pressure of 8 psi (.6 bar) is required to engage new

friction shoes. Thirteen psi (.9 bar) is required with

worn friction material.

3.2 Discs

Minimum disc diameter is 12 inches (304.8 mm).

3.3 Initial operation

Before putting the brake into operation a short wear-

in period is required before generating full rated

torque. Use the brake to slow and stop the machine

a number of times. The brake shoes are ready for

operation when the entire surface of the friction shoe

shows signs of contact and discoloration.

4.0 Maintenance

4.1 Periodic inspection

The friction discs should be checked to make sure

that they are not contaminated by oil, grease, dirt or

excessive moisture. Brake pads should be replaced if

the friction material has absorbed oil or grease.

Warning

Contamination of the friction material will signicantly

reduce the torque capacity of the brake and/or result

in erratic torque. Observe the friction shoes with

the actuation pressure at zero Psig/ bar. If the brake

shoes do not release from the disc, it may indicate

the calipers are not releasing.

Caution

Damage to the guide pin (3) and shoulder screw (4)

will result if the lining is allowed to wear beyond this

point.

4.2 Periodic maintenance

The piston (2) should be inspected when pressure

is applied and the brake shoes do not move. If

inspection of the piston shows signs of wear or

damage it should be replaced.

4.2.1 Bleeding the hydraulic system

Warning

Use appropriate gloves and eye protection equipment.

Caution

Do not work on the brake while the system is

pressurized. Pinch points exist when pressurizing the

brake and injury may occur.

Caution

Re-tighten the bleeder valve before releasing the

applied pressure to avoid drawing air back into

the system.

Find the air bleeder connection (10) on each of the

cylinder blocks (1). Apply hydraulic pressure of 8PSI

standard operating pressure, to the actuation media

connection (9); gently loosen the bleed screw,

venting the air from the system. During this operation

uid will escape, the amount depends upon the

number of times needed to thoroughly vent the air

from the system. Retighten bleed screw once the

air has been removed from the system. Repeat this

procedure on both brake cylinders, and as many

times as necessary to remove all the air bubbles from

the system.

Caution

Prevent contamination of friction material.

Caution

During the bleeding operation, make sure that an

adequate supply of uid is available to prevent air

from entering the system.

4.3 Friction material replacement

Caution

Keep replacement friction material clean and free

from oil and grease during storage. Use only genuine

Airex friction material. Use of non-original Airex

material may result in unpredictable performance.

The brake does not need to be removed in order

to replace friction material. Doing so may require

realignment of the brake.

4.3.1 Friction material wear adjustments

There are no wear adjustments necessary with

this caliper.

4.3.2 Friction material wear limits

An inspection is required to determine when the

friction shoes should be replaced. New friction lining

thickness is 0.315 inches, (8 mm), not including the

backing material. See table 2 for wear limits