WC-9UW 7

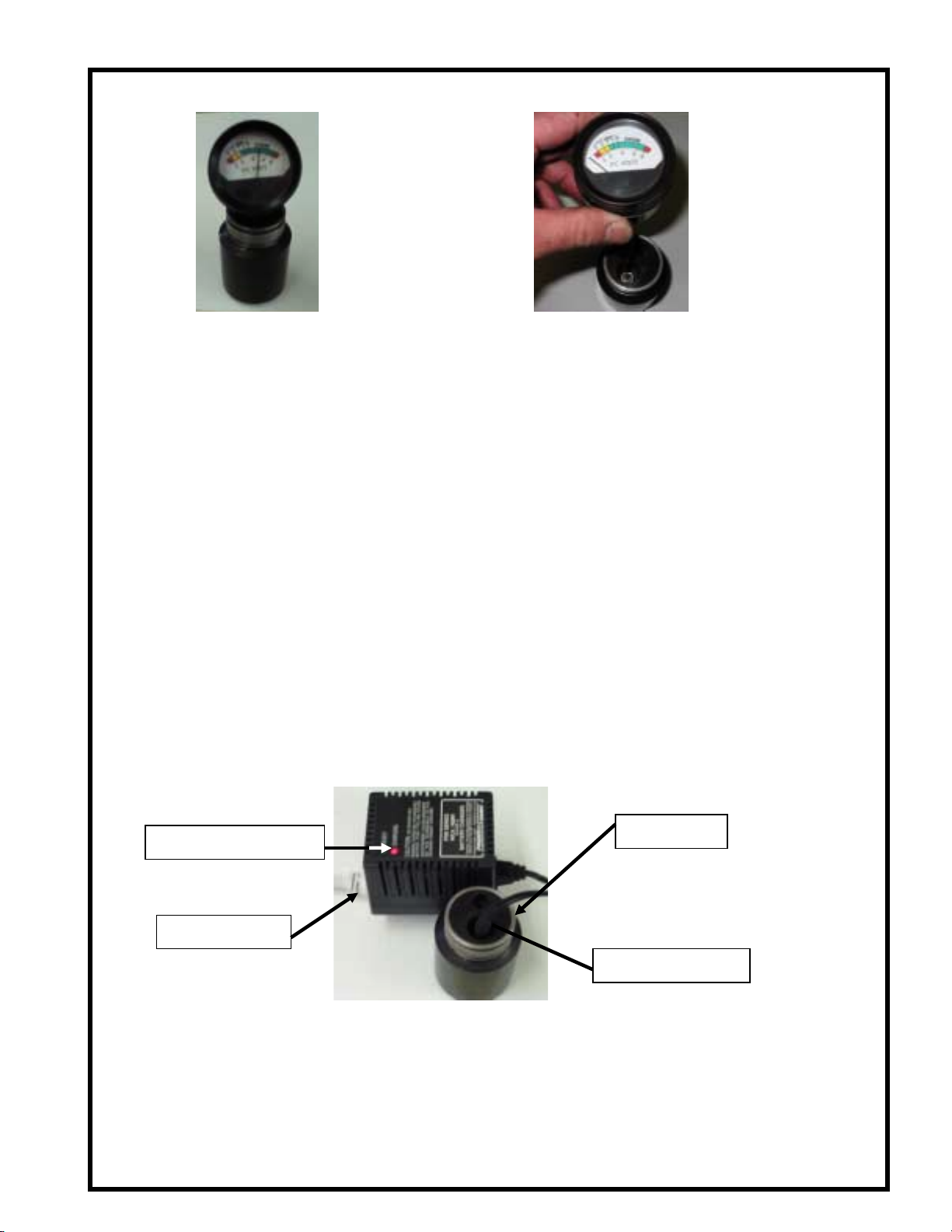

use. However, rather than applying inhibitor, cover them with the Dielectric

Grease included in the WC-9UW Kit. Any potential problems to these

assemblies must be reported to the Distributor or Western Instruments for

instructions on corrective action.

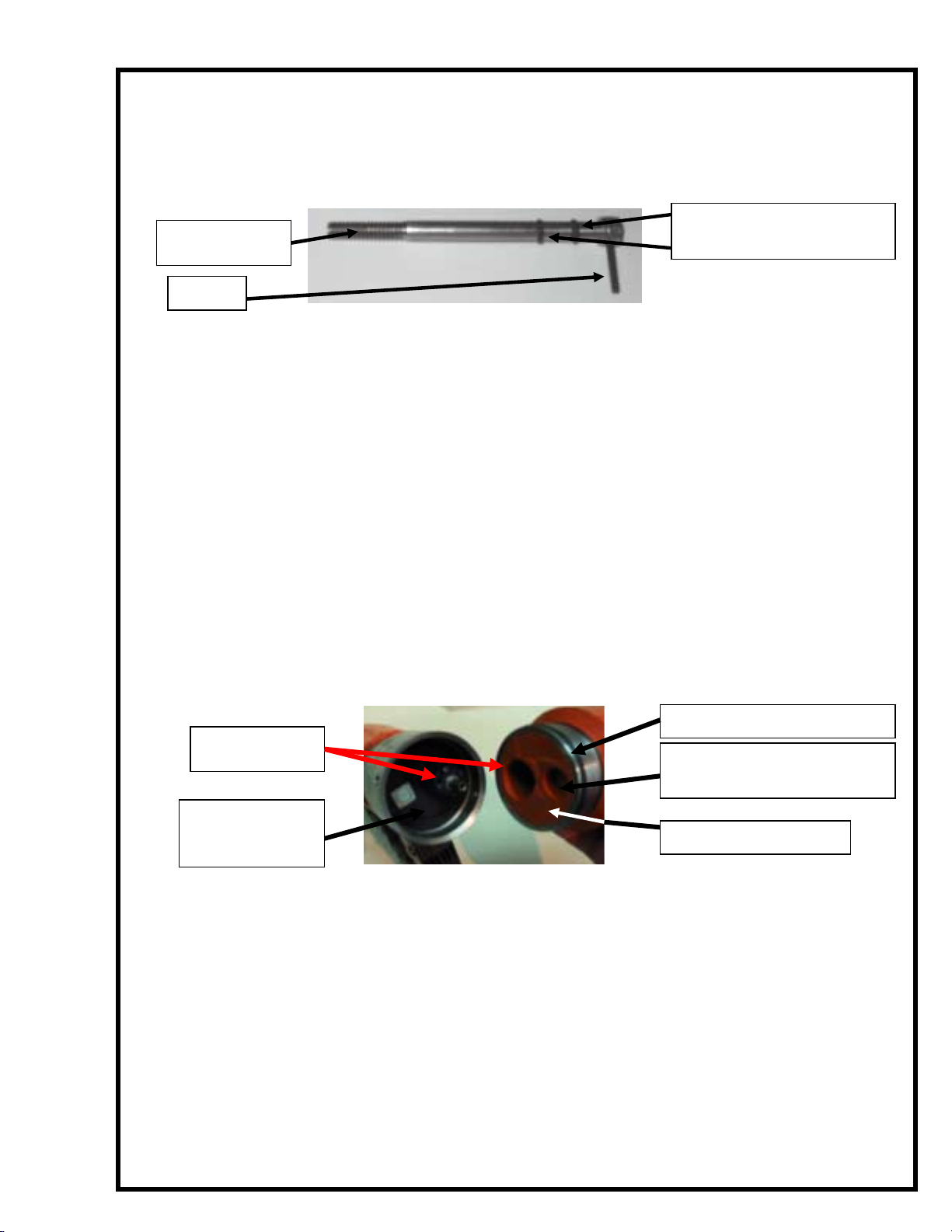

Special attention should be employed to the sealing surface on the inside of

the Yokes Junction Tube, and the O-Ring seal on the Battery Pack and

Switch Plunger. These are the primary seal of the system, and must be free

of rust, dirt, and any foreign matter. A supply of O-Rings (42mm x 48mm x

3mm –ID/OD/Dia.) are included in the WC-9UW Kit, and should be changed

frequently. The fit of the Sealing System should be reasonably tight however,

it there is a “loose fit”, report the problem to the distributor or Western

Instruments for instructions on corrective action. Do not operate the unit in

hazardous environments when the Battery Pack in not fully assembled.

Whether industrial specifications are being observed or not, the Yoke should

be tested periodically, using certified Pull Test Bar(s) such as the W-Series

W-PT, to ensure it continues to lift the specified amount of weight. If the

unit fails such a test, first inspect the Pole Pieces to ensure they fully contact

the test weight. If the unit continues to fail, contact the Distributor or Western

Instruments for instructions on corrective action.

7. Warranty – Western Instruments warrants this product, against defects in

materials and workmanship for a period of 3 months from receipt by the end

user. If Western Instruments receives notice of such defects during the

warranty period, Western Instruments will either, at it’s option, repair, replace,

or condemn products that prove to be defective. Due to the nature of the

Underwater operational environment for this product, excessive corrosion is

considered misuse. Consumable items, such as Batteries, are warranted for

30 days from the date of shipment.

Any warranty is void if the unit has been modified in any way, or if it has been

repaired by an unauthorized agency. The end user agrees that any

equipment’s disposition, when returned for warranty work, is at the full

discretion of Western Instruments as to whether a claim is under warranty or

due to misuse. Western Instruments warranty shall overlook normal wear,

however does not include operation outside the general specification outlined

in these instructions. All warranty work is FOB Western Instruments, and any

returned units shall include a written description, by the end user, of the

fault.

Western Instruments makes no other warranty, either expressed or implied,

with respect to this product. Western Instruments specifically disclaims any

liability arising from the use of this equipment. For the correct use of the

product, refer to the Operating Instructions, furthermore we recommend

instructional training to CGSB, ASNT, or other regulatory authority

qualifications.