7. Maintenance

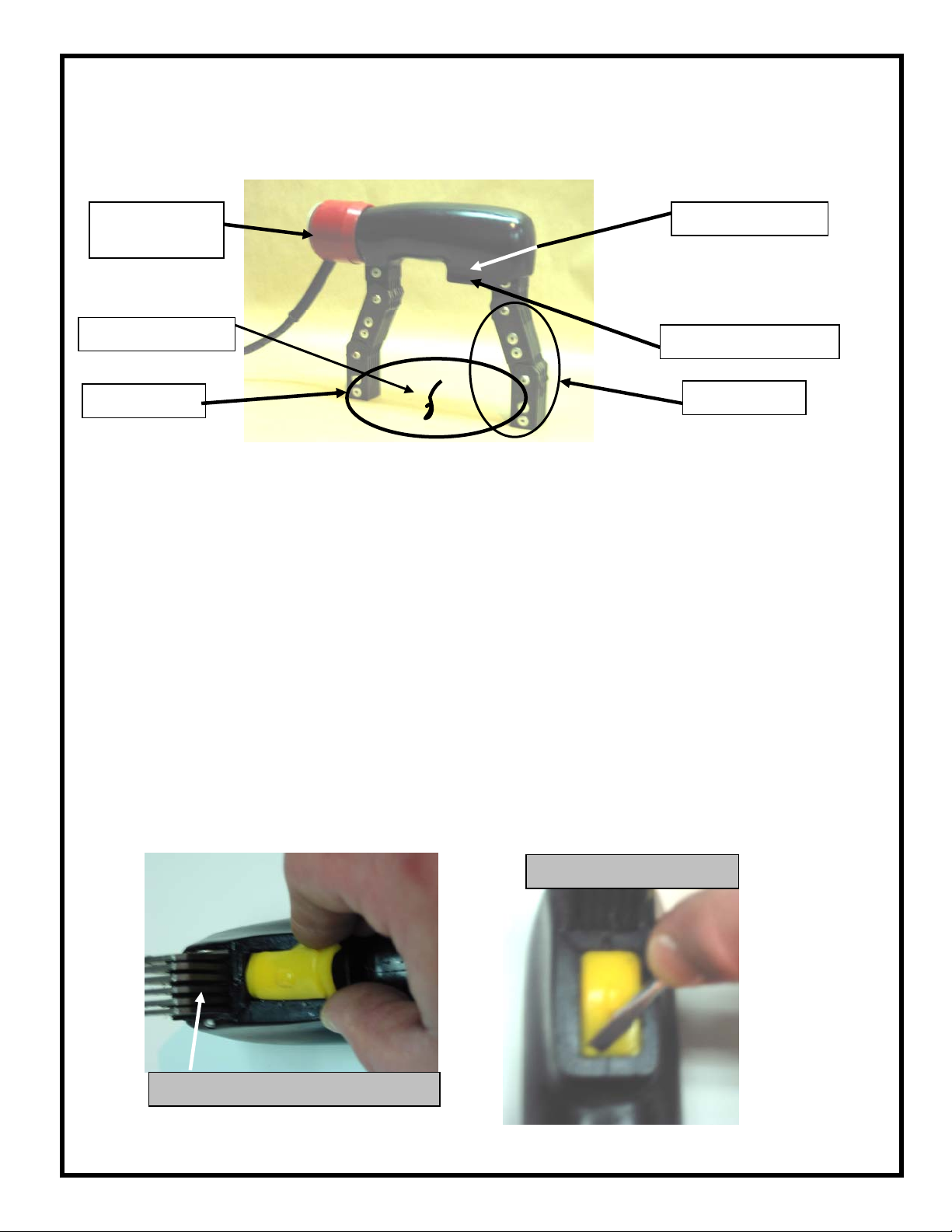

After extended use the Yoke should be cleaned with a mild soap solution and

thoroughly dried. The unit should be visually inspected for any damage that could

cause harm to the operator, or the material being inspected. Special attention should

be paid to the Push Button Switch Cover, to ensure it is fully inserted to the groove

cast in the Switch Cavity. The most frequent maintenance issue with any MPI Yoke

is the; Power Plug, Power Cord, and the End Cap/Cord Protector. Attention should

be paid when inspecting these items to ensure they appear in a good state of repair.

Before performing maintenance, cleaning, or repositioning the End Cap. The Yoke

should be disconnected from any power source, with safe industrial practices

employed. Our Web Site has write-up on many of the maintenance issues outlined

above. Any potential problems to these assemblies must be reported to the

Distributor or Western Instruments for instructions on corrective action.

Whether industrial specifications are being observed or not, the Yoke should be

tested periodically, using a certified Pull Test Bar such as the W-Series W-PT®, to

ensure it continues to lift the specified amount of weight. If the unit fails such a test,

first inspect the Pole Pieces to ensure they fully contact the test weight. If the unit

continues to fail, contact the Distributor or Western Instruments for instructions on

corrective action.

Wiring

Western Instruments publishes a Trouble Shooting Guide for WE-Series, and can be

requested by E-Mail upon request. WE-Series Yoke Frames are manufactured in 4

styles; the Standard Frame and the LT Frame, and both frames are available in 115

Volt, and 230 Volt. The Standard frames are black in color, and the LT Frames are

Orange. The only identification distinguishing 115 and 230 Volt frames, is from the

Serial Number; 230 Volt frames have a “K” at the end. As an example, a 230 Volt

frame might have a Serial Number 3490EK, while a 115 Volt unit would be 3490E.

Serial Numbers are indicated on the name plates, but also are stamped onto the

Legs, where they protrude form the casting.

W-Series 230 Volt Models, are designated by a “K” placed after the Serial Number

and the Model number (e.g. WC-6K), are shipped without an AC Power Plug as there

is no international standardization. When installing an AC Power Plug onto the AWG

18-3 Power Cord, the following is the identity of the 3 Color Coded Conductors;

•Green – Ground

•White - Neutral

•Black – Live

Care must be taken to insure the proper installation of an AC Power Plug, and if there

is any question, contact your distributor or Western Instruments. If an AC Plug in not

installed before use, any warranty is void.

8. Pull Test / Calibration

When performing a 10 Pound (4.6Kg) Pull Test, ensure the contact feet are flat as

possible to the Pull Test Bar (W-PT®), which ensures as much magnetic attraction as

possible. While not particularly important on Full Size Yokes (WE-3 & HD units), it is

very necessary on the WE-3LT due to the flexibility of the Pole Pieces. If a Yoke fails

a pull test, it should be sent to an authorized repair facility for Contact Foot Dressing.

WE-Series Operating Instructions

5