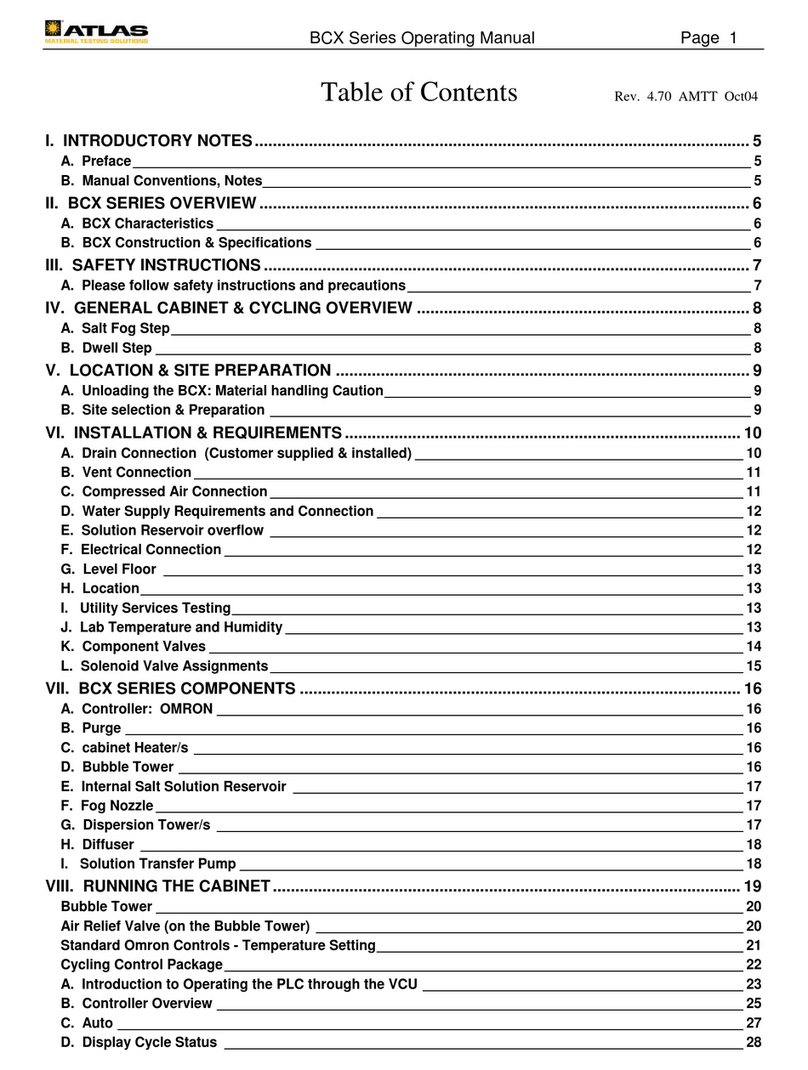

DeFelsko PosiTest AT User manual

PosiTest Pull-Off Adhesion Tester

INSTRUCTION MANUAL v. 3.0

Simple. Durable. Accurate.

PosiTest AT

(manual)

PosiTest AT-A

(automatic)

Introduction

Introduction

The portable, hand-operated PosiTest Pull-Off Adhesion Tester measures the force

required to pull a specified test diameter of coating away from its substrate using

hydraulic pressure. The pressure is displayed on a digital LCD and represents the

coating's strength of adhesion to the substrate.

In accordance with ASTM D4541, D7234, ISO 4624 and others, the PosiTest

evaluates the adhesion (pull-off strength) of a coating by determining the greatest

tensile pull-off force that it can bear before detaching. Breaking points,

demonstrated by fractured surfaces, occur along the weakest plane within the

system consisting of the dolly, adhesive, coating layers and substrate.

Basic steps for testing coating adhesion with a PosiTest Adhesion Tester:

1. Dolly & Coating Preparation

The dolly and the coating are cleaned and abraded. (see pg. 4)

2. Adhesive & Dolly Application

The adhesive is prepared and applied to the dolly. The dolly is then adhered to

the coated surface and the adhesive is allowed to cure. (see pg.4)

3. Test Area Separation - Optional step

The test area of the coating is separated from the area surrounding the dolly by

cutting or drilling. (see pg. 5)

4. Pull-off Test

a) PosiTest AT (manual) (see pg. 6)

b) PosiTest AT-A (automatic) (see pg. 8)

5. Analysis of Test Results

The dolly and the coating are examined and evaluated to determine the nature

of the coating failure. (see pg. 10)

6. Store Pull-Off Test Results - Optional step

The PosiTest’s internal memory stores maximum pull pressure, pull rate, test

duration and dolly size for up to 200 pulls. (see pg. 10)

Page 3

Throughout this manual, the symbol indicates more information about

the particular topic or feature is available on our website.

Go to: www.defelsko.com/manuals

NOTE:

Step 1: Dolly & Coating Preparation

Step 1: Dolly & Coating Preparation

Dolly Preparation

1. To remove oxidation and contaminants, place the included abrasive pad on a

flat surface and rub the base of the dolly across the pad 4-5 times.

2. As required, remove residue left from the abrading process using a dry cloth

or paper towel.

Coating Preparation

1. Lightly roughen the coating using the included abrasive pad.

As coating abrasion may introduce flaws, it should only be used when

necessary to remove surface contaminants, or when the bond strength between the

adhesive and the coating is insufficient for pull testing.

2. To promote the bond between the dolly and the coating, degrease the area of

the coating to be tested using alcohol or acetone to remove any oil, moisture or

dust.

Ensure that any alternative abrasion techniques, degreasers or adhesives

do not alter the properties of the coating. Test by applying a small amount of

degreaser or adhesive to a sample area and observing effects.

Step 2: Adhesive & Dolly Application

Step 2: Adhesive & Dolly Application

Adhesive Selection

The adhesive included in the PosiTest Adhesion Tester kit has been selected due

to its versatility. This adhesive has minimal impact on a variety of coatings and has

a tensile strength exceeding the maximum performance capabilities of the pressure

system under ideal conditions. Other adhesives may be preferred based on

requirements such as cure time, coating type, working temperature and pull-off

strength. Quick curing one-part cyanoacrylates (super glues) may be sufficient for

painted surfaces, but two-part epoxies are preferred for porous or rough coatings.

Dolly Application

1. Mix the adhesive per manufacturer’s instructions and apply a uniform film of

adhesive on the base of the dolly (approximately 2-4 mils or 50-100 microns

for best results)

2. Attach the dolly to the prepared coating test area.

If the coated surface to be tested is overhead or vertical, a means to

hold the dolly in place during the cure time may be required, i.e. removable tape.

Page 4

NOTE:

NOTE:

NOTE:

Page 5

3. Gently push down on the dolly to squeeze out excess adhesive. Do not twist or

slide the dolly back and forth on the coating as air bubbles may be generated.

4. Carefully remove excess adhesive from around the edges of the dolly with

included cotton swabs.

5. Allow to cure per the adhesive manufacturer's instructions

Many adhesives cure faster and provide a stronger bond when cured with

heat. Similarly, cold environments may cause a longer cure time and weaker bond

strength.

Step 3: Test Area Separation

Step 3: Test Area Separation

Drilling Template

Cutting Instructions

1. Cut through the coating around the edges of the dolly with the included cutting

tool, removing any excess adhesive.

2. Clear away any debris from the cutting process.

-Cutting may induce coating surface flaws such as microcracking that

may alter test results.

-For coatings with strong lateral bonding it is recommended to cut

completely through the coating down to the substrate.

The decision of when to cut around a dolly is dependent on the standard,

specification or contractual agreement to which the test is to comply. The primary

purpose for cutting through the coating is to isolate a specific diameter test area.

When the decision to cut into the coating has been made, it is recommended to cut

all the way through to the substrate. As a minimum, it is suggested to carefully cut

away excess adhesive from the dolly application process. This typically prevents a

larger area of coating from being pulled away from the substrate, resulting in a

higher pull-off pressure.

When testing very thick coatings, an optional drilling template may be preferred.

NOTE:

NOTE:

CLOSE

Page 6

Quick Guide

(1) Open the pressure relief valve completely (turn counter clockwise)

(2) Connect the actuator to the dolly

(3) Close the pressure relief valve completely (turn clockwise)

(4) Zero - Press the Zero button.

(5) Pump pressure into the system until the dolly pulls the coating away

OPEN

1. Ensure the pressure relief valve on the pump is completely open. (turn

counter clockwise)

Step 4a: Pull-Off Test

Step 4a: Pull-Off Test (PosiTest AT Manual)

Pump Handle

LCD

USB port

Actuator Handle

Quick Coupling

Actuator

Assembly

Battery

Compartment

Hose

The PosiTest AT powers-up and displays dashes when the button is

pressed. To preserve battery life, the instrument powers down after 5

minutes of no activity.

2. Push the actuator handle completely down into the actuator assembly. Place

the actuator assembly over the dolly head and attach the quick coupling to the dolly

by reaching through the holes in the actuator assembly and lifting the quick

coupling. Release the quick coupling when the dolly head is completely engaged.

Pump

Page 7

3. Close the pressure relief valve on the pump completely. (turn clockwise)

As required, verify and adjust the dolly size by pressing the

button. Select the pressure units by pressing the button. The instrument

will maintain these adjustments even after the button is pressed.

4. Zero the instrument BEFORE pumping by pressing the button. This

prepares the instrument for the test by clearing the display, and zeroing the

instrument.

5. Prime the pump slowly until the displayed reading approaches the priming

pressure. The priming pressure is the point that the instrument begins calculating

and displaying the pull rate. It is also the pressure at which the ability to store

readings is enabled. Priming pressures for the various dolly diameters are:

10 mm 400 psi 2.8 MPa

14 mm 200 psi 1.4 MPa

20 mm 100 psi 0.7 MPa

50 mm 50 psi 0.4 MPa

For optimum results, prior to exceeding the priming pressure, return the

pump handle to its full upright position and then complete a single stroke at the

desired pull rate until the actuator separates the dolly from the coating.

6. Open the pressure relief valve and remove the dolly from the actuator assembly.

7. Readings may be stored into memory by pressing the button (pg. 10).

NOTE:

Troubleshooting (PosiTest AT)

Digital display “freezes” at a low value

The Tester uses a sudden drop in actuator pressure as an indication that the dolly

has been pulled from the surface. The test stops and the highest pressure remains

on the display for easy viewing and recording. Pumping up pressure too quickly at

the beginning of a test can cause a sudden pressure pulse, fooling the Tester into

thinking the test is complete. If this happens, restart the test by opening the

pressure relief valve, closing it, then pressing the button. For more

information, see Step 5 above.

NOTE:

Page 8

Dolly Size PSI Rates MPa Rates

10 mm 125, 200, 400, 600, 725 1.00, 2.00, 3.00, 4.00, 5.00

14 mm 60, 100, 200, 300, 360 0.40, 0.70, 1.40, 2.00, 2.50

20 mm 30, 50, 100, 150, 180 0.20, 0.30, 0.70, 1.00, 1.20

50 mm 5, 8, 16, 24, 30 0.04, 0.08, 0.12, 0.16, 0.20

Quick Guide

(1) Connect the actuator to the dolly

(2) Power-up with the button

(3) Verify measurement units, dolly size and pull rate

(4) Ready the instrument with the button

(5) Test with the button

1. Place the actuator assembly over the dolly head and attach the quick coupling

to the dolly by reaching through the holes in the actuator assembly and lifting the

quick coupling. Release the quick coupling when the dolly head is completely

engaged.

2. Press the button to power-up the instrument if necessary. The instrument

will power-down after 5 minutes of no activity or by holding the button for 2

seconds.

3. Check settings:

Step 4b: Pull-Off Test

Step 4b: Pull-Off Test (PosiTest AT-A Automatic)

LCD

USB port Actuator

Handle

Quick

Coupling

Actuator

Assembly

Hose

AC Adapter Port

(Charges batteries

and powers instrument)

(a) Verify displayed measurement units. Change with the button if

necessary.

(b) Verify dolly size with the button and change if necessary.

(c) Verify pull rate with the button and change if necessary. The following

user selectable rates are available:

Page 9

6. Remove the dolly from the actuator assembly.

7. Readings may be stored into memory by pressing the button (pg. 10).

All settings and test results in memory are retained during power-down.

The red button may be pressed to stop the pull test at any time. The

maximum pressure value will remain on the display while the pump retracts the

actuator. This value can be stored into memory and will be uniquely identified by

the optional PosiSoft software. Stopping the pull test before destruction is handy

when specifications allow the test to be stopped when required adhesion strengths

have been exceeded. Uncouple the actuator from the dolly and then remove the

dolly from the surface with a sharp, sideways hammer tap.

Troubleshooting (PosiTest AT-A)

CAUTION: To avoid injury, keep fingers away from the quick coupling and

actuator assembly until the pull test has completed and the actuator has

been fully retracted. Press to stop the pull test at any time.

Instrument is unresponsive or will not power down

In the unlikely event that the PosiTest becomes unresponsive or will not power

down, press and hold the button, then press the button. The

instrument will power down.

Stage 1. Initiation - the display shows a blinking "0".

Stage 2. Priming - the pump applies initial pressure to the dolly.

Stage 3. Test - when the priming pressure has been achieved (see step 5 on

pg. 7) the instrument begins calculating and displaying the pull rate

established by the user. Pressure build-up stops when the dolly is pulled from

the surface or when the button is pressed.

Stage 4. Retraction - the maximum pull-off pressure value blinks on the

display while the pump retracts the actuator. The buttons are locked during

this stage.

4. Press the button to ready the instrument. This prepares the PosiTest

for the test by clearing the display and zeroing the instrument.

5. Press the button again to start the test that consists of 4 stages that

occur automatically:

Page 10

Step 6: Storing Pull-Off values into Memory

Step 6: Storing Pull-Off values into Memory

The PosiTest’s internal memory stores maximum pull pressure, pull rate, test

duration and dolly size for up to 200 pulls.

Press the button upon completion of a test to store pull-off test results. The

display will show the pull rate and alternate between the test number and the

maximum pull pressure for that test. The icon will appear to indicate that there

are test results in memory.

Press the button repeatedly to view previously stored test results. The

PosiTest AT-A also displays dolly size and pull rate by pressing their

respective buttons.

Complete information on all test results can be downloaded to a PC and viewed

using the optional PosiSoft software. Test results are not erased from memory after

downloading. Press (AT manual) or (AT-A automatic) to exit viewing

mode.

To remove all stored test results from memory, press and hold the or

button, then press the button. The icon will disappear from the

display.

All settings and test results in memory are retained during power-down.

Test results can be considered 100% valid when the coating is completely removed

from the substrate. When only a portion of the coating is removed, specific results

should be noted including the fracture pattern to determine the cohesive properties

of the coating and adhesion properties between the dolly and adhesive, adhesive

and coating, distinct coating layers, and coating and substrate.

Step 5: Analysis of Test Results

Step 5: Analysis of Test Results

Available Options

Available Options

A variety of accessories are available to help you get the most out of your PosiTest

Pull-Off Adhesion Tester.

Page 11

Technical Data

Technical Data

Power Supply / Low Battery Indicator

Power Supply / Low Battery Indicator

PosiTest AT (manual)

Power Source: AAA alkaline batteries

As the batteries become weak the symbol will

appear on the LCD. The batteries should be

replaced at the earliest opportunity.

USE ONLY AAA ALKALINE BATTERIES. Nickel-cadmium and nickel-metal

hydride rechargeable batteries will work but the low battery symbol may stay on.

PosiTest AT-A (automatic)

Power Source: Built-in rechargeable NiMH battery (>200 pulls with full charge)

The symbol will appear when remaining battery power is below 35%.

The built-in rechargeable NiMH batteries are charged using the included AC power

supply/charger. Ensure batteries are charged prior to use. The symbol will

blink while the instrument is recharging and disappear when fully charged. The

charging process will take 2-3 hours depending on remaining battery power.

Alternatively, the AC power supply can be used to power the instrument.

The USB port will not charge or power the PosiTest. The USB connection

will drain battery power when connected for an extended period of time.

Conforms to: ASTM D 4541, ASTM D 7234, ISO 4624 and others.

Specifications:

2AAA

alkaline batteries

NOTE:

*requires optional 50 mm accessory kit

Resolution: 1 psi (0.01 MPa)

Accuracy: ±1% Full Scale

Adhesion

Strength

Dolly Size (mm) Max Pull-Off Pressure

10 mm 10,000 psi (70 MPa)

14 mm 6,000 psi (40 MPa)

20 mm 3,000 psi (20 MPa)

50 mm* 500 psi (3.5 MPa)

Page 12

DeFelsko’s sole warranty, remedy, and liability are the express limited warranty,

remedy, and limited liability that are set forth on its website:

www.defelsko.com/terms

www.defelsko.com

© DeFelsko Corporation USA 2009. All Rights Reserved

This manual is copyrighted with all rights reserved and may not be reproduced or transmitted, in whole

or part, by any means, without written permission from DeFelsko Corporation.

DeFelsko, PosiTector, PosiTest and PosiSoft are trademarks of DeFelsko Corporation registered in the

U.S. and in other countries. Other brand or product names are trademarks or registered trademarks of

their respective holders.

Protection provided by the equipment may be impaired if the equipment is used in a manner not

specified by the manufacturer.

Every effort has been made to ensure that the information in this manual is accurate. DeFelsko is not

responsible for printing or clerical errors.

Returning for Service

Returning for Service

There are no user serviceable components. Any service must be performed by

DeFelsko Corporation.

If you need to return the Instrument for service, describe the problem fully and

include reading results, if any. Be sure to include contact information including your

company name, company contact, telephone number and fax number or email

address.

www.defelsko.com/support

Calibration

Calibration

The PosiTest is shipped with a Certificate of Calibration showing traceability to a

national standard. For organizations with re-certification requirements, the PosiTest

may be returned at regular intervals for calibration. DeFelsko recommends that our

customers establish the instrument calibration intervals based upon their own

experience and work environment. Based on our product knowledge, data and

customer feedback, a one year calibration interval from either the date of

calibration, date of purchase, or date of receipt is a typical starting point.

Limited Warranty, Sole Remedy and Limited Liability

Limited Warranty, Sole Remedy and Limited Liability

This manual suits for next models

1

Table of contents

Other DeFelsko Test Equipment manuals

DeFelsko

DeFelsko PosiTest AIR User manual

DeFelsko

DeFelsko PosiTector SPG User manual

DeFelsko

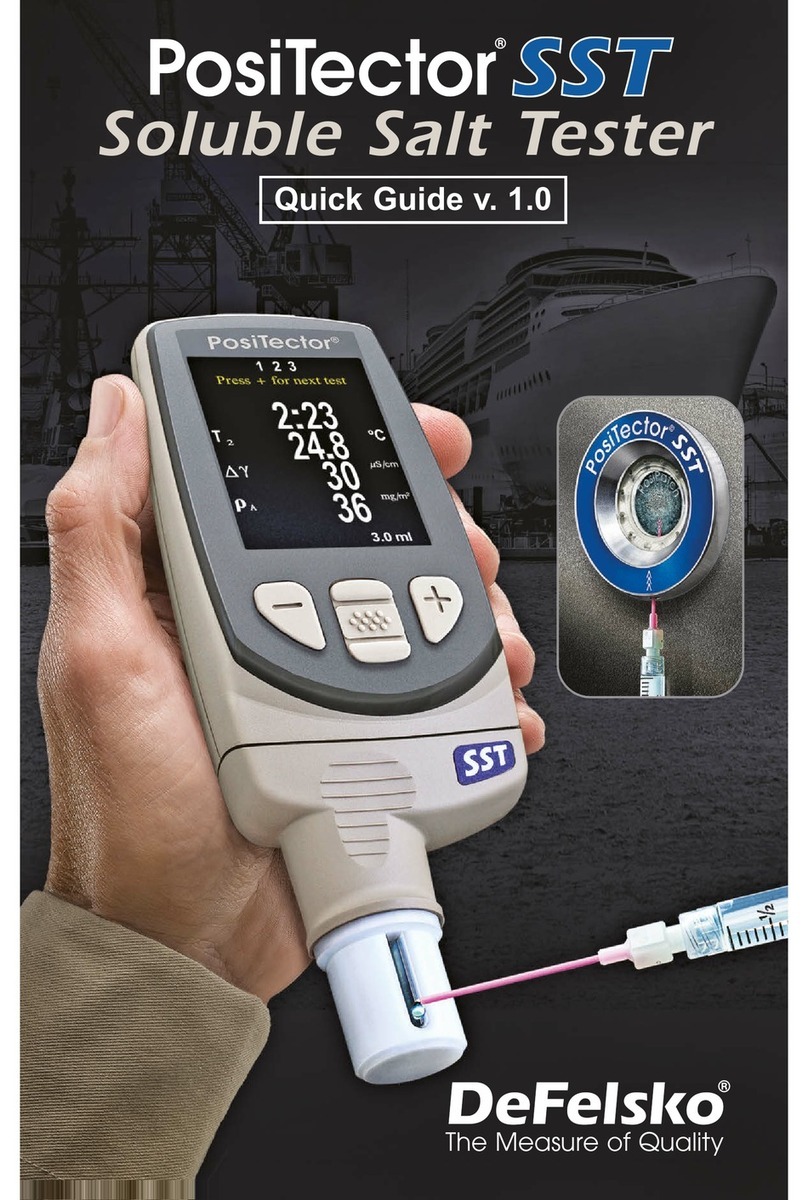

DeFelsko PosiTector SST User manual

DeFelsko

DeFelsko PosiTector SHD Verifier User manual

DeFelsko

DeFelsko PosiTest DT User manual

DeFelsko

DeFelsko PosiTest AT-A User manual

DeFelsko

DeFelsko PosiTector UTG User manual

DeFelsko

DeFelsko PosiTest AIR User manual

DeFelsko

DeFelsko PosiTest AIR User manual

DeFelsko

DeFelsko PosiTest AT-A User manual