2

TABLE OF CONTENTS CONDITIONAL WARRANTY

Western Shelter Systems warrants all

products against defects in materials or

workmanship for a period of one (1) year

from date of manufacture. Component

manufacturers’ warranties may exceed that

of Western Shelter.

No warranty is made or implied regarding

the intended use of the product. Warranty

does not cover damage caused by abuse,

misuse, neglect or improper care by the end

user in the application of the Western Shelter

Systems product.

Western Shelter Systems will repair or

replace any component deemed to be faulty

from manufacture in the most ecient and

timely means available to Western Shelter

Systems.

Western Shelter Systems must authorize all

claims prior to any action taken by the end

user.

For immediate attention regarding any

defective product, please phone Customer

Support at 1-800-971-7201, 7am-330pm PST.

Shipping: 815 Conger St. Eugene, OR 97402

PO Box 2729 Eugene, OR 97402 USA

Phone 1-541-344-7267

Toll Free 1-800-971-7201

Fax 1-541-284-2820

www.WesternShelter.com

A. Warnings 3

B. Shelter Specications 4

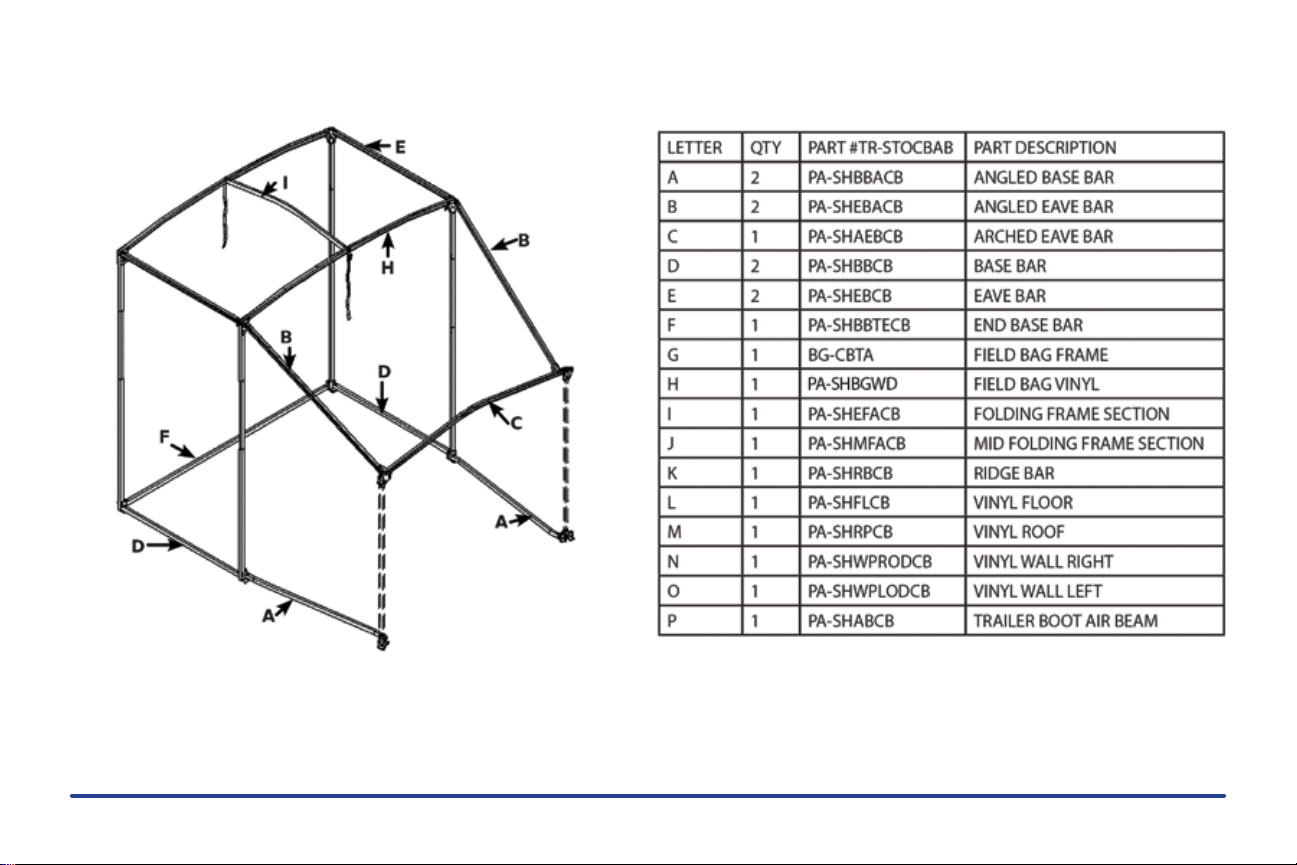

C. Component List 4

D. Erecting the Shelter 5

1. Unpacking the Shelter 6

2. End Frame Assembly 6

3. Center Frame Assembly 6

4. Roof Assembly 7

5. Raising the Frame 8

6. Floor and Basebars 8

7. Hanging the Doors 9

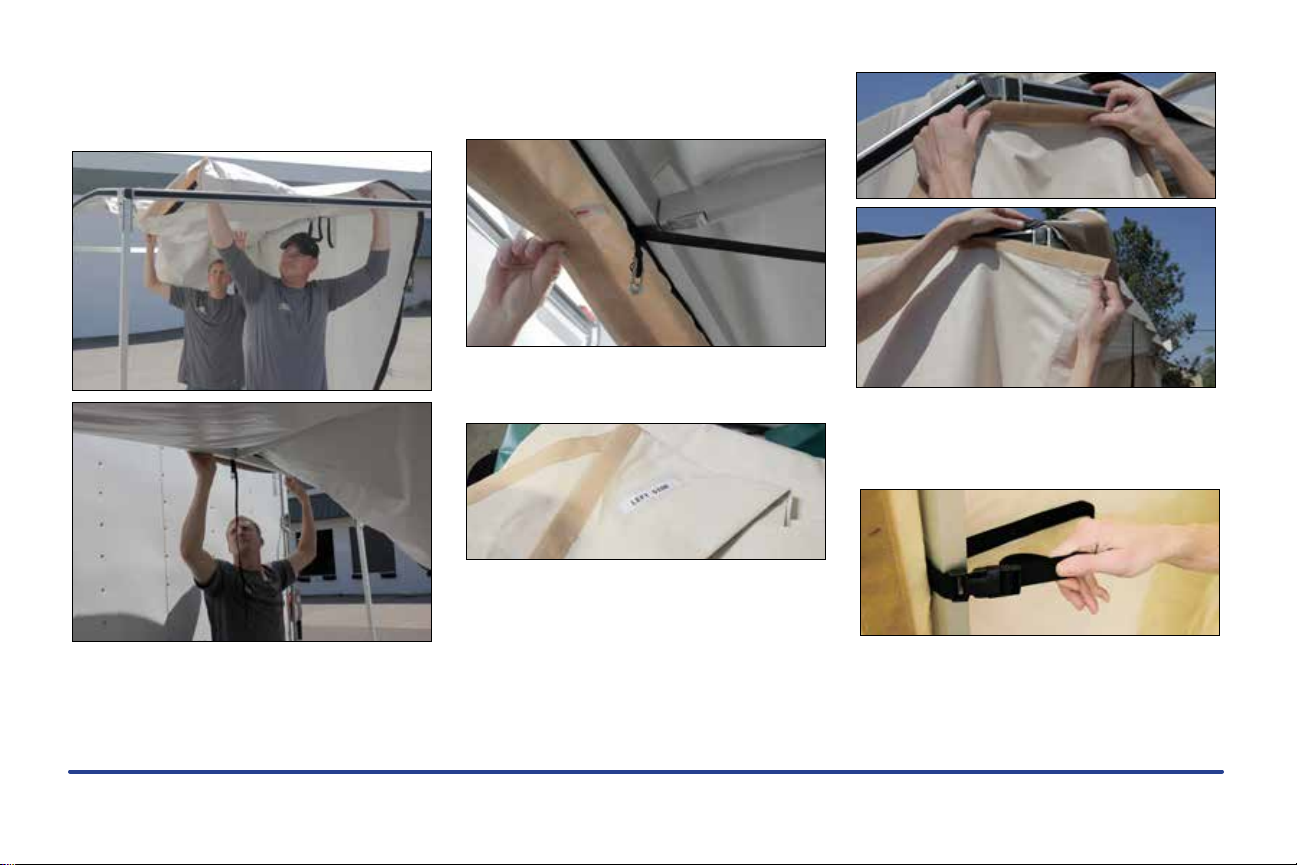

8. Hanging Shelter Walls 9

9. High Wind Tiedowns 10

10. Finishing the Shelter 11

E. Striking the Shelter 12

1. Removing Wall Panels 12

2. Folding Wall Panels 12

3. Folding Floor Panels 13

4. Lowering the Frame 14

5. Removing Vent Caps 14

6. Folding Roof Panels 14

7. Striking the Frame 16

F. Troubleshooting 17

1. Frame Connections 17

2. Wall Panels 17

3. Roof Panels 17

4. Torn or Worn Vinyl 17

5. Parts will not t in case 17

G. Tips, Care, and Repair 18

1. Vinyl Panels 18

2. Insulation Panels 18

3. Mainframe and Bars 18

4. Hinges and Pull-Pins 18

5. Cases and Lids 18

6. Vinyl Repair 19

7. Replacement Parts 19