VEHICLE RECOVERY ELECTRIC WINCH FITTING INSTRUCTIONS

T-MAX

UTV SERIES

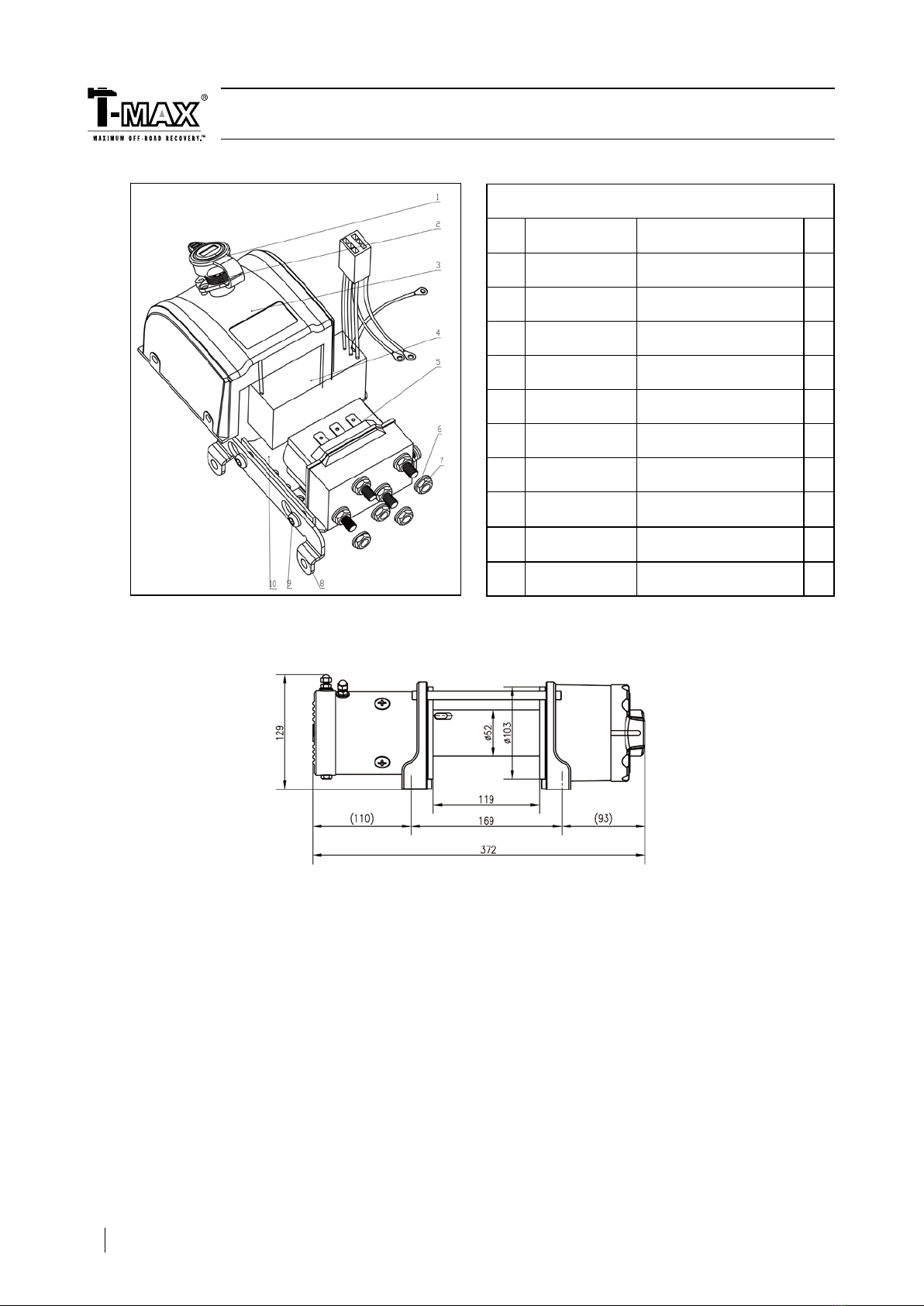

EXPLODED VIEW OF ATW4500

Item Part No. Description Qty

1 GB/T70 M6×120 Bolt M6 X 120 2

2 7241100.1.3-2 Motor End Cover 1

3 7241100.1.1.3.1 Carbon Assy 1

4 7241100.1.1 Stator 1

5 7241100.1.2 Rotor 1

6 GB/T-85 M6×18 Bolt M6X18 4

7 7241100.1-1 Motor Frame Cover 1

8 7241100.3-1 Drum Base 2

9 7241100.8 Torque Limiter 1

10 GB/T276-1994 Bearing 2

11 7241100.2 Drum 1

12 7241100.0-1 Tie Rod 2

13 7241100.3-9 Sun Gear 1

14 7241100.0-3 Spring 1

15 7241100.8-7 Washer 1

16 7241100.3-3 Inner Gear- Output 1

17 7241100.5 Braking System 1

18 7241100.3.1-4 Gear Spindle 3

19 7241100.3.1-1 Gear Carrier 2

20 GB/T276-1994 61812 Bearing 2

21 7241100.3.1-3 Planetary Gear 3

22 7241100.3-4 Anti-friction Gasket 1

23 7241100.3-5 Inner Gear 1

24 7241100.3-8 Clutch Yoke 1

25 7241100.3-7 Inner Lock washer 1

26 7241100.3-2 Gear Box Tube 1

27 GB/T3452.1 23.6×1.80 O Ring 1

28 7241100.3-6 Clutch Cover 1

29 7241100.0-2 Mounting Plate 1

30 GB/T5782-2000 M8×20 Bolt M8 X20 2

31 7241100.4 Roller Fairlead 1

32 7241100.7 Wire Rope 1

33 RU104206 Clevis Hook 1

34 7309200.7-2 Aluminum Fairlead 1

35 9163151 Synthetic Rope 1

36 7241100.6-1 Short Black Cable (10mm2 x 5cm) (wrapped by Black

Thermoplastics Pipes) 1

37 7241100.6-2 Short Black Cable (10mm2 x 10cm) (wrapped by Red

Thermoplastics Pipes) 1

38 7241100.6-3 Short Black Cable (10mm2 x 12cm) (wrapped by Yellow

Thermoplastics Pipes) 1

39 7241100.6.2 (W) Control for ATV Use (match to Wire Rope) 1

7241100.6.2 (S) Control for ATV Use (match to Synthetic Rope) 1

40 7241100.6.4 Socket Assy 1

41 7241100.6-4 Long Cable (10mm2 x 180cm) 1

42

7241100.6.3 (W) Remote Handle Control for UTV & Utility Use (match to Wire

Rope) 1

7241100.6.3 (S) Remote Handle Control for UTV & Utility Use (match to

Synthetic Rope) 1

43 7241100.6.4 (W) Control Box Assy(match to Wire Rope) 1

7241100.6.4 (S) Control Box Assy (match to Synthetic Rope) 1

44 7241100.6.1 ISM 1

3